Transform Your Shop’s Capabilities with Exhaust Pipe Bending Machines

Looking for an exhaust pipe bending machine for sale? Here’s a quick overview of what you need to know:

- Types Available: Hydraulic compression, CNC-controlled, mandrel benders

- Price Range: $5,000-$20,000+ depending on features and capabilities

- Top Considerations: Tube diameter capacity, bending angle range, manual vs. automated control

- Key Benefits: Reduces outsourcing costs, improves quality control, increases profitability

An exhaust pipe bending machine for sale represents a significant opportunity for automotive repair shops, fabrication facilities, and manufacturing operations to bring exhaust work in-house rather than outsourcing these jobs. These specialized machines allow you to bend metal tubing with precision, creating custom exhaust systems that perfectly fit vehicles while maintaining pipe integrity.

As Jerry Huth finded when he created the first portable pipe bender in 1958, having the right equipment transforms what your shop can accomplish. Today’s bending machines range from manual models that give complete hands-on control to fully automatic CNC systems that deliver consistent, repeatable results at higher volumes.

Hines Bending Systems stands as the #1 worldwide manufacturer of tube and pipe benders, supplying industry giants including NASA. With best expertise and experience in the bending machine industry, Hines offers custom solutions that can add profitability back to your automotive repair or fabrication business.

“Our benders are powerful, but at Hines Bending, we’re in the business of empowering you.”

The right exhaust pipe bending machine eliminates the need to outsource exhaust jobs, allowing you to complete more work in-house while maintaining complete quality control. For busy shops handling multiple exhaust system repairs or custom fabrication projects daily, this capability translates directly to improved efficiency and increased profit margins.

Simple exhaust pipe bending machine for sale word guide:

– 3 inch exhaust pipe bender

– 3 inch exhaust pipe bends

– 5 inch exhaust pipe bender

For more information about the history and evolution of pipe bending technology, you can visit the Wikipedia page on tube bending.

Why an Exhaust Pipe Bending Machine is Essential for Your Shop

Picture this: It’s Friday afternoon, and a customer needs their custom exhaust system fixed before a weekend car show. You have the skills to do it, but without an in-house bending machine, you’re forced to say those dreaded words: “We’ll need to send this out.” There goes your profit margin – and possibly your customer.

Sound familiar? You’re not alone. Many shop owners watch potential profits drive away with every outsourced exhaust job.

An exhaust pipe bending machine isn’t just another tool in your shop – it’s a game-changer that transforms what you can offer customers. Here’s why it’s become essential equipment for forward-thinking automotive shops:

Increased Productivity

When you bring exhaust work in-house, you eliminate the waiting game. No more delays while parts get shipped or another shop fits your job into their schedule. Your technicians can complete repairs and custom fabrication on the spot, dramatically speeding up turnaround times. One Hines Bending Systems customer told us they now complete exhaust jobs in hours instead of days – allowing them to handle 30% more work with the same staff.

Reduced Outsourcing Costs

Every time you send exhaust work to another shop, you’re watching your profits disappear. These outsourcing costs add up quickly, especially for shops in competitive markets. By investing in a quality exhaust pipe bending machine for sale from Hines Bending Systems, you eliminate these recurring expenses permanently. Many of our customers report saving thousands of dollars monthly after bringing this capability in-house.

Improved Profitability

The business case is straightforward: when you cut outsourcing costs while increasing your job capacity, your bottom line grows. Most shops find their Hines bending machine pays for itself within 6-12 months through cost savings alone – everything after that is pure profit improvement. Plus, the ability to offer custom exhaust work often commands premium pricing, further boosting your margins.

Complete Control Over Quality

When you outsource, you’re putting your reputation in someone else’s hands. With your own bending machine, you maintain complete control over every bend, ensuring the finished product meets your exacting standards. This quality control extends to materials too – you choose exactly what goes into each job rather than accepting whatever the outsource shop decides to use.

Meeting Client Demands Efficiently

Today’s customers expect speed without sacrificing quality. Having an in-house exhaust pipe bending machine allows you to offer same-day or next-day service for both repairs and custom work. This capability creates a significant competitive advantage in your local market – and in the age of online reviews, fast turnaround times lead directly to five-star ratings.

Improved Customization Capabilities

The custom exhaust market continues to grow year after year. Performance enthusiasts, restoration specialists, and even everyday drivers increasingly want personalized solutions. With your own bending machine, you can offer truly custom exhaust systems custom to each client’s specific needs, opening up entirely new revenue streams for your business.

As one shop owner who invested in a Hines Bending Systems machine shared with us: “Before we had our own exhaust bender, we were either turning away custom work or making pennies after outsourcing costs. Now we’re known as the go-to shop for custom exhaust systems in our area. It’s completely transformed our business.”

The bottom line? In today’s competitive automotive market, an exhaust pipe bending machine for sale represents more than just equipment – it’s an investment in your shop’s independence, capability, and future profitability.

Top Exhaust Pipe Bending Machines for Sale

When you’re in the market for an exhaust pipe bending machine for sale, the choices can feel overwhelming. But here’s the truth: not all benders are created equal. The difference between a quality machine and a subpar one isn’t just about initial cost—it’s about reliability, precision, and ultimately, your shop’s reputation.

Hines Bending Systems: The Best Exhaust Pipe Bending Machines for Sale

If you’re serious about exhaust work, Hines Bending Systems should be at the top of your list. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, Hines has earned their reputation through decades of innovation and thousands of successful installations.

What makes a Hines machine special isn’t just the metal and hydraulics—it’s the expertise behind every design. With more bender installations worldwide than any other manufacturer, the Hines team understands the real-world challenges that shops face every day.

Unlike off-the-shelf solutions that force you to adapt your workflow, Hines specializes in creating custom bending solutions custom to your specific needs. Their team works alongside you, listening to your requirements and designing a machine that fits seamlessly into your operation.

When NASA needs precision bending equipment, they call Hines. That’s not just an impressive client name to drop—it speaks volumes about the quality standards these machines meet. After all, if a bender is reliable enough for rocket scientists, it’s probably going to handle your exhaust work just fine.

As the folks at Hines often say: “Nobody in the bending machine industry has more expertise and experience than Hines.” Having spent time with their team, I can tell you this isn’t marketing fluff—it’s the genuine confidence that comes from being the best at what you do.

Key Features of Hines Exhaust Pipe Benders

A Hines exhaust pipe bender isn’t just another piece of equipment—it’s a game-changer for your shop. Here’s what sets these machines apart:

The hydraulic compression technology in Hines benders delivers powerful, precise bending while minimizing wall thinning and distortion. This means smoother, more consistent bends that maintain the pipe’s structural integrity—crucial for performance exhaust systems where flow characteristics matter.

For shops that handle repeat work, the precision CNC control options are invaluable. You can program complex bending sequences once and reproduce them perfectly every time, ensuring consistent quality whether you’re making your first bend of the day or your fiftieth.

Preventing wrinkles and maintaining the pipe’s cross-sectional shape is essential for quality exhaust work. That’s why Hines machines offer mandrel bending capability, supporting the inside of the pipe during bending to ensure professional results every time.

In a busy shop environment, equipment takes a beating. Hines machines are built with exceptional durability in mind, featuring heavy-duty components that stand up to daily use. Many shop owners report their Hines benders performing flawlessly after decades of service—that’s value you can’t calculate on a price tag alone.

Whether you’re a small custom shop or a high-volume production facility, Hines offers scalable automation options to match your needs. Start with a more hands-on approach and upgrade as your business grows, or jump straight into fully automated production—the choice is yours.

When you buy a Hines bender, you’re not just getting a machine; you’re gaining a partner. Their comprehensive training and support ensures your team knows how to get the most from your investment, with experts available when you need them.

Want to learn more about your options? Check out the Automotive Exhaust Pipe Bender page for detailed specifications.

How Hines Machines Improve Productivity and Profitability

An exhaust pipe bending machine for sale represents more than just a purchase—it’s an investment in your shop’s future. Here’s how a Hines machine transforms your business operations:

Say goodbye to outsourcing delays. With a Hines bender in your shop, you gain increased efficiency through intuitive controls, quick setup times, and rapid tool changes. This minimizes downtime between jobs and lets you process more work in less time—turning what used to be a bottleneck into a smooth-flowing part of your operation.

Every time you send exhaust work to another shop, you’re watching profit margins walk out the door. By bringing this capability in-house with a Hines machine, you completely eliminate outsourcing costs while gaining control over quality and turnaround time. Many shops find this benefit alone justifies the investment.

Customers notice quality. The precision and consistency of Hines bending machines result in superior quality results that build your reputation. This means fewer comebacks, happier customers, and the word-of-mouth advertising that helps your business grow.

With a Hines bender in your shop, you can maximize production capacity by taking on work you previously had to turn away. Many shop owners find they can enter entirely new markets after bringing this capability in-house—from custom performance exhausts to restoration work that requires precision bending.

The accuracy of Hines machines means reduced waste and higher profit margins on each job. When material costs are on the rise, the precision of your bends becomes even more important to your bottom line.

Exhaust Pipe Bending Machines for Sale: Key Features to Consider

Shopping for an exhaust pipe bending machine for sale can feel overwhelming with all the options available. As someone who’s been helping shop owners make this important decision for years, I want to walk you through the features that really matter when you’re making this investment.

Think of your bending machine as the backbone of your exhaust fabrication capabilities – getting the right one can transform your business, while choosing poorly might leave you frustrated and still outsourcing work.

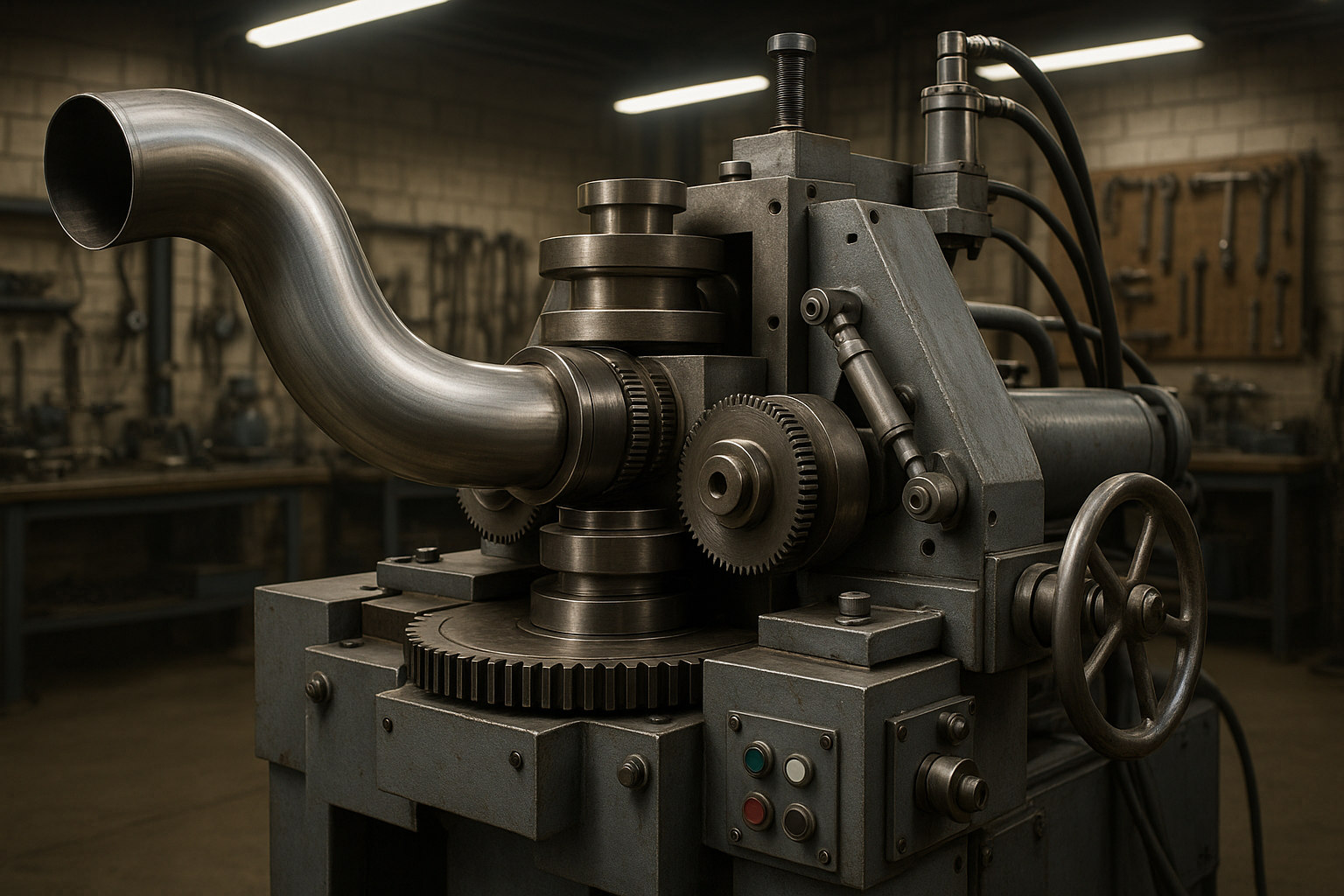

Understanding Hydraulic Compression Exhaust Pipe Bending Machines for Sale

When you’re looking at an exhaust pipe bending machine for sale, hydraulic compression technology is likely to be at the top of your list. This popular bending method has become the gold standard in the industry for good reason.

The beauty of hydraulic compression bending lies in its simplicity and effectiveness. Your pipe sits securely between a clamp die and pressure die, while a powerful hydraulic ram applies consistent force to bend the pipe around a bend die. This creates that perfect curve you’re looking for without compromising the pipe’s integrity.

What makes hydraulic compression benders from Hines stand out is how they maintain wall thickness during the bending process. Unlike cheaper machines that stretch and thin the outer wall, a quality hydraulic system preserves material consistency throughout the bend. This is crucial for exhaust performance – those thinned areas become weak points that can crack under heat and vibration.

The smooth, wrinkle-free bends you’ll achieve with a Hines hydraulic bender not only look professional but also maintain optimal exhaust flow. When you’re working with pipes ranging from 1.5″ to 3″ diameter (common in most exhaust work), having this capability in-house means you can handle virtually any exhaust job that comes through your door.

When evaluating specifications, focus on finding a machine that can handle your largest anticipated pipe diameter with room to grow. Most shops need at least 3″ capacity to avoid limitations. Wall thickness capacity is equally important – especially if you work with heavier-gauge mandrel-bent tubing. And don’t overlook power requirements – make sure your shop’s electrical system can support the machine before you buy.

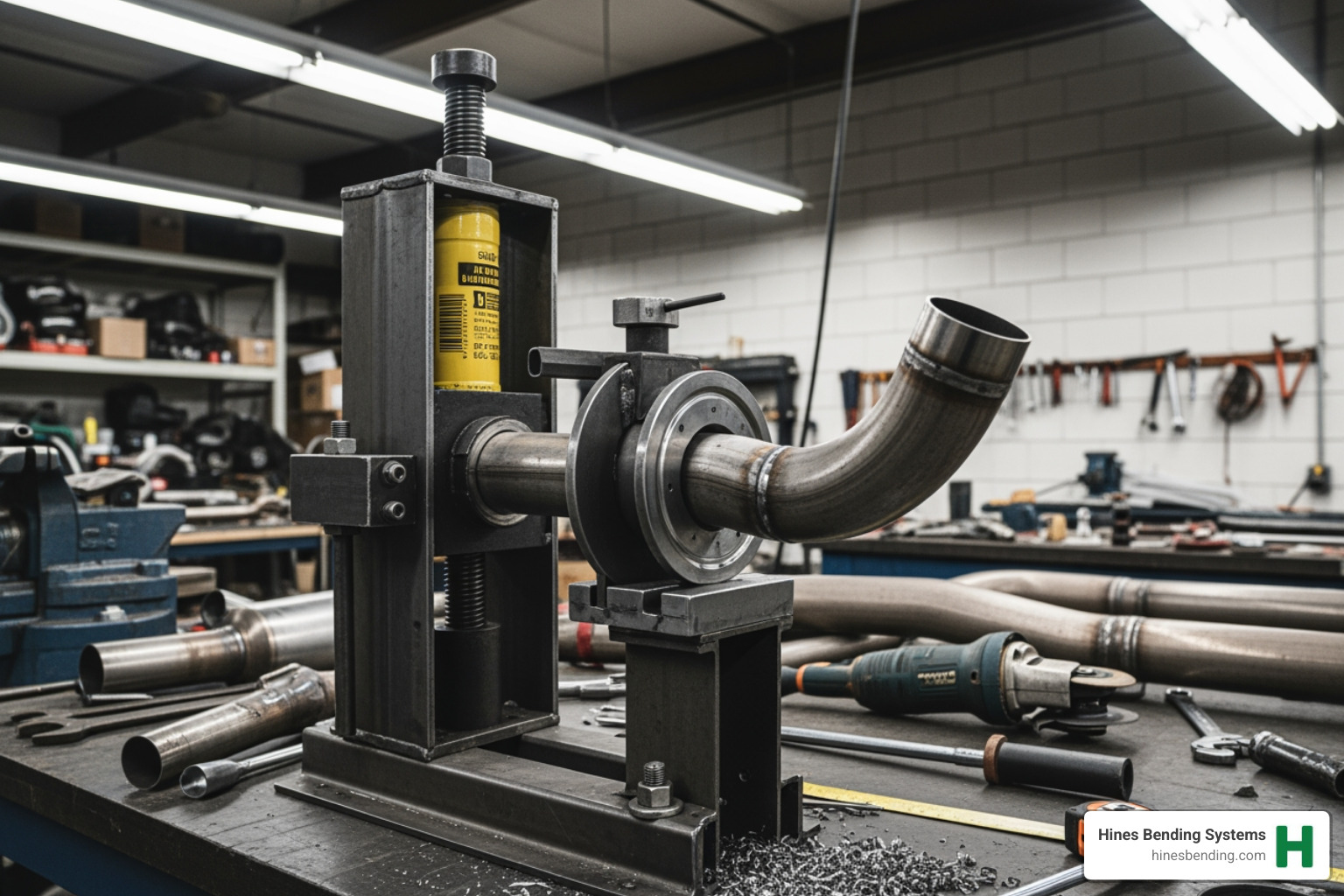

Benefits of Using Mandrel Benders for Exhaust Pipes

If you’re serious about exhaust work, particularly custom systems, mandrel bending technology will take your capabilities to the next level. This method represents the difference between amateur and professional results.

Mandrel bending uses a solid or segmented steel rod inserted inside the pipe during bending. This internal support prevents the pipe from collapsing or developing those unsightly wrinkles on the inside radius of the bend. The result? Exhaust pipes that maintain their perfect circular cross-section throughout even the tightest bends.

This preservation of pipe shape isn’t just about looks – it directly impacts performance. When an exhaust pipe collapses or wrinkles during bending, it creates restriction points that disrupt flow, increase back pressure, and ultimately rob engines of power. Mandrel bending eliminates these issues, ensuring your custom exhaust systems deliver the performance your customers expect.

Tight-radius bends are particularly challenging without mandrel support. That stylish, tucked-up exhaust system hugging the undercarriage of a lowered vehicle? It’s only possible with quality mandrel bending. Without it, those tight turns would flatten and collapse.

Hines Bending Systems’ mandrel machines are designed with user-friendliness in mind. Even technicians with limited bending experience can achieve professional results after proper training. The mandrel system is engineered to work smoothly with minimal setup time, helping you move efficiently from one job to the next.

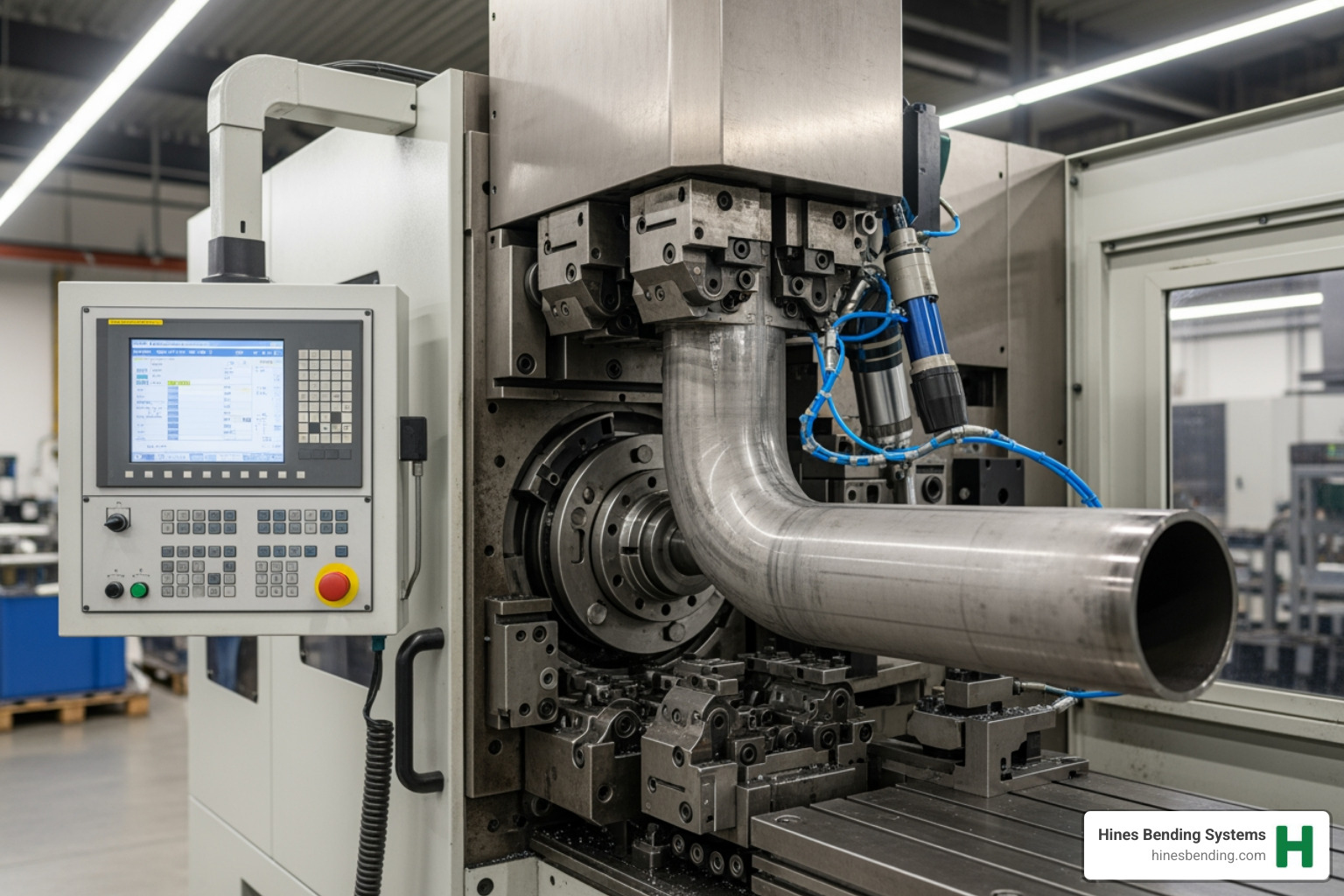

Advantages of CNC Tube Bending Machines

For shops looking to scale up production or guarantee absolute precision across multiple jobs, CNC (Computer Numerical Control) technology is a game-changer. These sophisticated machines represent the cutting edge of bending technology.

The precision of a Hines CNC bender is measured in thousandths of an inch, ensuring each bend matches your specifications exactly. Once you’ve programmed a bending sequence, you can reproduce it perfectly a hundred times over. This level of consistency is impossible to achieve with manual machines, no matter how skilled the operator.

One shop owner told me, “Our Hines CNC bender paid for itself within a year just from the increased efficiency. What used to take hours of trial and error now happens at the push of a button.”

The automation benefits extend beyond precision. Complex exhaust systems requiring multiple bends in different planes can be programmed as a single operation. Your technician initiates the program and is free to work on other tasks while the machine executes the bending sequence flawlessly. This multitasking capability dramatically increases your shop’s throughput.

Perhaps the most valuable aspect of CNC technology is the ability to store programs for future use. When that customer returns six months later needing the same custom exhaust system, you simply recall the program and produce an identical replacement – no measuring, no guesswork, no variation.

Many Hines CNC benders can also integrate with your existing design software, creating a seamless workflow from digital design to finished product. This integration is particularly valuable for shops working with performance vehicles where precise specifications are critical.

| Bender Type | Control Method | Best For | Typical Price Range |

|---|---|---|---|

| Manual | Hand/foot operation | Small shops, occasional use | $5,000-$10,000 |

| Semi-Automatic | Partial automation with manual input | Medium-volume shops | $10,000-$15,000 |

| Fully Automatic (CNC) | Computer-controlled operation | High-volume production | $15,000-$25,000+ |

While the initial investment for a CNC system is higher, the long-term return often justifies the cost through increased productivity, reduced material waste, and the ability to take on more complex, higher-margin jobs. As with all their machines, Hines provides comprehensive training to ensure you maximize the potential of your CNC bender from day one.

How to Choose the Best Exhaust Pipe Bending Machine for Sale

Selecting the right exhaust pipe bending machine for sale isn’t just about finding equipment—it’s about making a strategic investment in your shop’s future. With the right machine, you’ll transform your capabilities and boost your bottom line for years to come.

Assess Your Shop’s Needs

Before you start comparing machines, take a good look at what your shop actually needs—both now and in the future.

Start with your current workload. Are you turning away five exhaust jobs weekly because you can’t handle them in-house? Or are you outsourcing dozens of bends that could be profitable if done under your own roof? The volume of work will directly impact what level of machine makes sense for your operation.

Think about the materials you typically work with too. Most automotive shops need to handle aluminized steel and stainless steel pipes ranging from 1.5″ to 3″ in diameter. If you’re doing performance work or diesel applications, you might need even larger capacity.

The complexity of your typical jobs matters tremendously. If you’re primarily doing simple replacement bends for stock exhaust systems, your needs will differ from a shop specializing in custom performance systems with multiple tight-radius bends and precise mandrel work.

Don’t forget about space considerations! I’ve visited shops where they purchased a machine that technically fit their space—but left no room for the operator to work comfortably. Measure twice, buy once.

Finally, be honest about your team’s skill level. Even the most advanced machine won’t perform well if your staff isn’t comfortable operating it. Sometimes a simpler machine with excellent training support (like those from Hines Bending Systems) will outperform a more complex unit that intimidates your technicians.

Consider Key Machine Features

Once you understand what your shop needs, it’s time to evaluate specific machine features.

Bending capacity should top your list of considerations. Make sure the machine can handle your largest diameter pipes with the thickest walls you typically encounter. There’s nothing more frustrating than turning away profitable work because your machine falls just short of the required capacity.

Bending method matters tremendously for exhaust work. Hydraulic compression delivers excellent results for exhaust systems, providing the smooth, consistent bends that prevent flow restrictions and maintain back pressure specifications. Rotary draw methods can also work well for certain applications.

The control system you choose will impact both ease of use and precision. Manual controls offer simplicity and are often sufficient for basic repair work. However, if you’re doing custom fabrication or high-volume production, CNC controls provide the repeatability and precision that can set your work apart.

Tooling options deserve careful consideration too. The best machine becomes useless without the right dies and tooling for your specific applications. Check what comes standard and what’s available as add-ons. Hines Bending Systems offers comprehensive tooling packages custom to the typical needs of automotive exhaust shops.

Don’t overlook power requirements. I’ve seen shops purchase machines only to find they need electrical upgrades to operate them properly. Verify your shop’s electrical capacity against the machine’s specifications before making a decision.

Finally, consider whether you need a stationary or mobile solution. Some shops benefit from machines that can be moved around as needed, while others prefer permanent installations that become part of their workflow infrastructure.

Evaluate Training and Support

Even the finest bending machine is only as good as the support behind it—and this is where Hines Bending Systems truly shines.

Comprehensive training programs ensure your team can maximize the machine’s potential from day one. Ask detailed questions about what training is included, whether it happens on-site or at the manufacturer’s facility, and what ongoing education is available as your needs evolve.

Technical support availability can make or break your experience with a bending machine. When you have a shop full of waiting customers and a technical issue arises, immediate access to knowledgeable support becomes priceless. Hines offers responsive support from technicians who truly understand their machines inside and out.

Warranty coverage varies widely between manufacturers. Look beyond the duration to understand exactly what’s covered and what isn’t. The best warranties, like those from Hines, reflect the manufacturer’s confidence in their product’s reliability.

Spare parts availability might seem like a minor consideration—until you need a part. Choose a manufacturer with a robust parts inventory and efficient shipping processes to minimize any potential downtime.

Consider Manufacturer Reputation and Experience

This is where doing your homework really pays off. Not all manufacturers have the depth of expertise needed to create truly exceptional bending equipment.

Industry experience translates directly to machine quality. With more bender installations worldwide than any other manufacturer, Hines Bending Systems brings best expertise to every machine they build. This translates to equipment that anticipates and addresses the real-world challenges you’ll face.

Don’t hesitate to ask for customer references, particularly from shops similar to yours. Speaking with current users provides insights no brochure or sales presentation can match. Ask about reliability, support experiences, and whether they’d make the same purchase decision again.

Company stability matters for long-term support. A manufacturer that’s been in business for decades, like Hines, is more likely to be there when you need parts or support years down the road.

The ability to provide custom solutions sets premium manufacturers apart. Rather than forcing you to adapt to their standard offerings, companies like Hines Bending Systems will work with you to understand your specific needs and customize a solution accordingly.

Make a Long-Term Decision

An exhaust pipe bending machine represents a significant investment that should serve your business for many years.

Consider your shop’s growth potential when selecting a machine. The right equipment should accommodate your needs not just today, but for the next 5-10 years as your business evolves and expands.

Calculate the return on investment carefully. A quality machine from Hines Bending Systems typically pays for itself through eliminated outsourcing costs and new service offerings within 12-24 months, depending on your volume.

Look beyond the sticker price to understand the total cost of ownership. A less expensive machine that requires frequent repairs or produces inconsistent results can ultimately cost far more than a premium machine that delivers reliable performance year after year.

By carefully weighing these factors, you’ll select an exhaust pipe bending machine for sale that becomes a cornerstone of your shop’s capabilities and profitability. And remember, when it comes to quality, reliability, and expertise in bending machines, Hines Bending Systems stands alone as the industry leader, ready to partner with you in taking your shop to the next level.

Learn more about Exhaust Bender for Sale options from Hines Bending Systems.

Frequently Asked Questions about Exhaust Pipe Bending Machines

What Maintenance is Required for an Exhaust Pipe Bending Machine?

Keeping your exhaust pipe bending machine in top condition isn’t complicated, but it does require attention to detail. Think of it like maintaining a high-performance car – regular care means better performance and a longer lifespan.

The heart of most bending machines is the hydraulic system. Checking hydraulic fluid levels should be part of your weekly routine – it takes just seconds but prevents costly damage. Hines Bending Systems designs their machines with convenient sight glasses so you can see fluid levels at a glance. Plan to change this fluid every 1,000 operating hours or annually, whichever comes first.

Lubrication is another simple but crucial maintenance task. Your bending machine has moving parts that need regular lubrication to prevent wear and tear. Hines machines feature easily accessible lubrication points that make this job quick and painless. Just follow the schedule in your manual – your future self will thank you!

Those dies and tooling that contact the pipe? They need love too. Keep them clean and free of debris, and inspect them regularly for signs of wear. When they do eventually wear out, Hines offers high-quality replacements that maintain the precision of your original equipment.

For machines with electrical components, a quarterly visual inspection of wiring and connections can catch small issues before they become big problems. Look for wear, loose connections, or any damage that might cause trouble down the road.

To get the most life from your investment, follow these simple best practices:

– Always operate within the machine’s specifications

– Ensure all operators receive proper training

– Keep the machine clean and free of debris

– Address unusual noises or performance changes immediately

– Schedule annual professional service from Hines technicians

“We see machines that are 20+ years old still running strong when they’ve been properly maintained,” notes one Hines service technician. “And we see others that needed major repairs after just a few years of neglect.”

How Does an Exhaust Pipe Bending Machine Improve Profitability?

Let’s talk dollars and sense. An exhaust pipe bending machine for sale represents more than just a piece of equipment – it’s a profit center that can transform your business.

First, consider the outsourcing costs you’re currently paying. Every exhaust job you send to another shop means you’re paying their overhead plus their profit margin. When you bring an exhaust pipe bending machine in-house, you immediately eliminate those costs. A typical custom exhaust job might cost you $300-500 when outsourced, but with your own machine, your material costs might only be $100-150. That difference goes straight to your bottom line.

Beyond cost savings, there’s the revenue opportunity. With a quality bender from Hines, you can expand into high-margin custom exhaust work. Many shops charge premium rates for these services, with profit margins of 50% or more. One shop owner told us, “Custom exhaust went from being a hassle we avoided to our highest-margin service after we got our Hines bender.”

Being known as a one-stop shop attracts new customers too. Instead of sending clients elsewhere for exhaust work, you keep them in your shop – where they might also need other services. This customer retention has a multiplier effect on your overall business.

Speed matters in this business. With in-house bending capability, you can complete exhaust jobs the same day, allowing you to handle more work each week. Many Hines customers report increasing their weekly job count by 15-20% simply through improved workflow efficiency.

Take the real-world example of a Florida automotive repair shop that invested in a Hines bending machine. They paid off their investment in just nine months through eliminated outsourcing costs and new custom exhaust business. Within two years, they had expanded to three technicians dedicated to custom exhaust work, which became one of their most profitable service areas.

“We went from dreading exhaust jobs to actively seeking them out,” the owner explained. “It completely changed our business model for the better.”

What Are the Differences Between Manual, Semi-Automatic, and Fully Automatic Pipe Benders?

When shopping for an exhaust pipe bending machine for sale, you’ll encounter three main types, each with distinct advantages depending on your shop’s needs.

Manual pipe benders put you in the driver’s seat. These machines require the operator to physically control the bending process using hand or foot controls. They’re perfect for smaller shops that handle occasional exhaust work and prefer complete control over each bend. The benefits include a lower initial investment, simpler operation, and less dependence on electrical systems. However, they’re slower than automated options and results depend heavily on operator skill. As one shop owner put it, “Our manual Hines bender is perfect for us – we only do a few custom exhausts each week, but we never have to turn that work away.”

Semi-automatic pipe benders strike a balance between hands-on control and efficiency. These machines automate certain aspects of the bending process while still requiring operator input for others. They’re ideal for medium-volume shops that need increased productivity but don’t require full automation. You’ll get higher production capacity than manual benders and more consistent results with less dependence on operator skill. While they cost more upfront than manual systems, they offer significant time savings. A shop manager in Texas told us, “Our semi-automatic Hines bender gave us the perfect middle ground – faster than manual but without the learning curve of a full CNC system.”

Fully automatic (CNC) pipe benders represent the pinnacle of bending technology. These sophisticated machines use computer numerical control to automate the entire process. The operator simply programs the desired bends, and the machine executes them with precision. They shine in high-volume environments and shops that regularly produce complex exhaust systems requiring multiple precise bends. While they require the highest initial investment, they deliver best production capacity, consistent results regardless of operator skill, and the ability to store programs for repeatable production. “Our CNC bender from Hines revolutionized our custom exhaust department,” reported one performance shop owner. “We can program a complex system once and reproduce it perfectly every time.”

When choosing between these options, consider your shop’s volume:

– For 1-5 exhaust jobs weekly, a manual bender may be sufficient

– For 5-15 jobs weekly, consider a semi-automatic system

– For 15+ jobs weekly or specialty custom work, a CNC bender will likely provide the best return

Whatever your needs, Hines Bending Systems offers high-quality options in all three categories, with the expertise to help you select the machine that best matches your specific requirements. Their team can assess your operation and recommend the perfect solution – whether that’s a straightforward manual bender or a sophisticated CNC system.

Conclusion

Looking for the perfect exhaust pipe bending machine for sale? Your search ends with Hines Bending Systems. As the industry’s undisputed leader, Hines stands head and shoulders above the competition when it comes to quality, reliability, and deep technical know-how. It’s not just marketing talk when we say they’re the #1 worldwide manufacturer of tube and pipe benders – it’s backed by thousands of successful installations across the globe.

Think about what bringing exhaust bending in-house with a Hines machine will do for your shop. No more waiting on outsourced parts or watching your profits disappear to another business. You’ll gain complete control over quality and turnaround times, delighting your customers with faster service. Many shop owners tell us their Hines machine pays for itself within the first year through cost savings alone – not counting the new business opportunities that come with expanded capabilities.

Whether your shop needs a straightforward manual bender for occasional jobs or a sophisticated CNC system that can handle high-volume production, Hines has you covered. Their comprehensive range includes everything from hydraulic compression benders to mandrel systems and advanced CNC setups – all built to last for decades, not just years.

What truly makes the Hines difference, though, is their people. From your first conversation to installation day and beyond, the Hines team partners with you to ensure your success. They don’t just sell you a machine and disappear – they provide thorough training, ongoing support, and practical guidance whenever you need it. When challenges arise (as they inevitably do in any shop), Hines experts are just a phone call away.

Why settle for less when it comes to equipment that will transform your business? The shops that thrive in today’s competitive market are the ones that invest in quality tools that expand their capabilities while improving efficiency. A Hines bending machine isn’t just a purchase – it’s a strategic investment in your shop’s future.

Ready to take your exhaust fabrication capabilities to the next level? Learn more about Exhaust Pipe Benders from Hines Bending Systems and reach out to their team today. Tell them about your specific requirements, and they’ll help you find the perfect solution to transform your business. With their best expertise and genuine commitment to your satisfaction, you’ll wonder why you waited so long to make the switch.