Finding Value in the Secondary Market

Looking for a used mandrel tube bender for sale? Let me guide you through what matters most:

| Quick Guide: Used Mandrel Tube Benders |

|---|

| Price Range: $10,000-$50,000 for industrial CNC models; $30-$100 for manual lever-type |

| Top Brands: Addison McKee, Pines, Eaton Leonard, BLM, Soco, Horn, Crippa |

| Capacity Range: 1/8″ to 6″ OD tubing |

| Where to Buy: AM Industrial Group, Machineseeker, industrial auctions, Hines Bending Systems |

| What to Check: Machine hours, mandrel condition, hydraulic systems, control firmware |

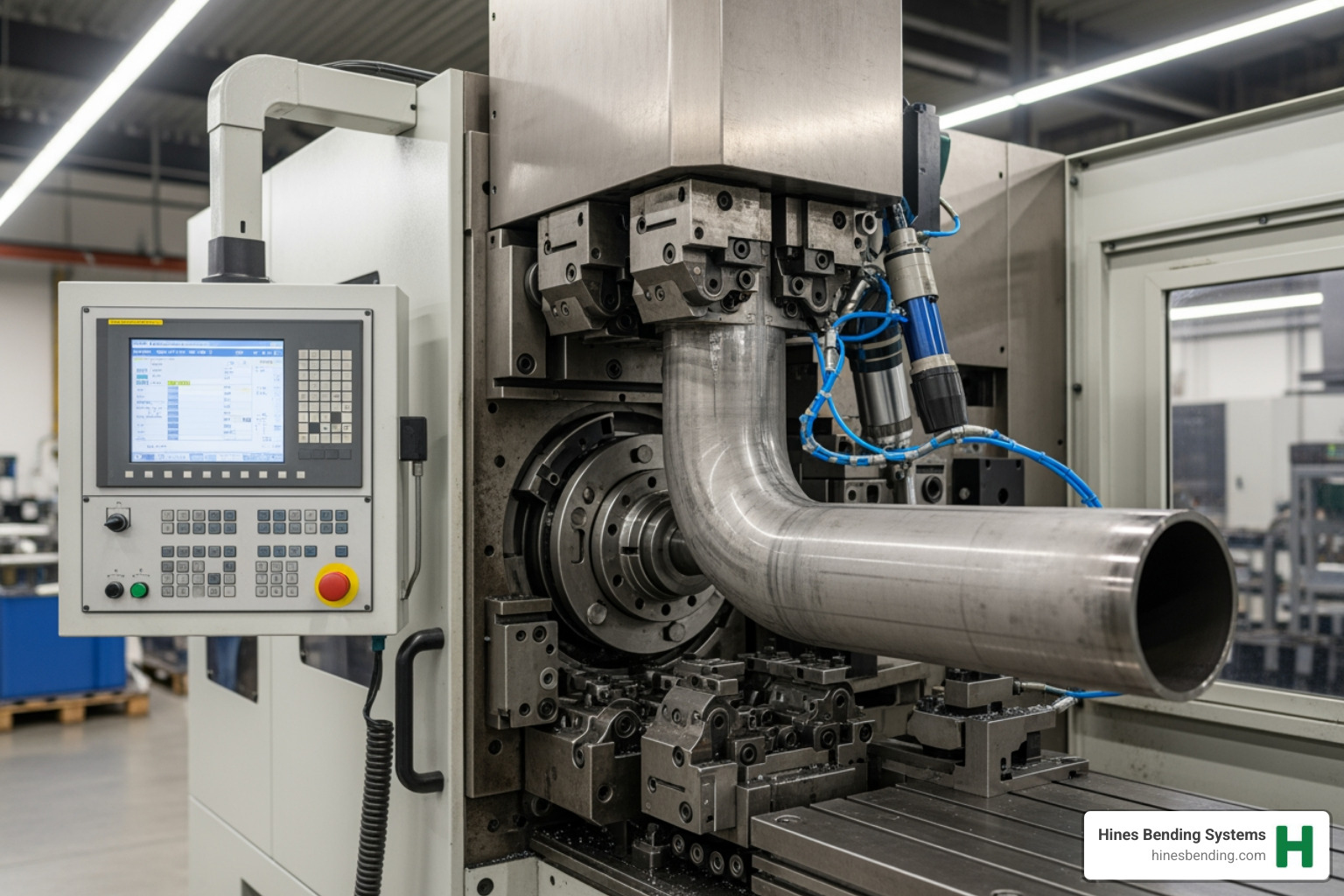

A used mandrel tube bender for sale might just be the smartest investment you’ll make this year. When you need precision tube forming but your budget is feeling the squeeze, these specialized machines deliver the gold standard in bending without the platinum price tag. The secret lies in that internal support (the mandrel) that keeps tubes from collapsing when you bend them.

Here at Hines Bending Systems, we’ve watched the demand for quality pre-owned mandrel benders skyrocket. Why? Because smart manufacturers recognize value when they see it. Many of these machines have barely broken a sweat – we’ve seen some with just 326 hours on the clock! That’s like buying a car that’s only been driven to church on Sundays.

“We get it – capital equipment isn’t something you buy on a whim,” our technical director often says. “A well-maintained used mandrel bender delivers virtually identical precision and reliability as a new machine, but at 30-60% of the cost. That’s real money back in your operation.”

The market offers everything from simple manual lever-type units for small diameters to sophisticated CNC models that perform complex multi-axis bends with tight radii. Most commonly, you’ll find used mandrel benders handling tube diameters of 1/2″, 3/8″, 5/8″, and 1-1/2″ OD, with corresponding bend radii ranging from 9/16″ to 2-1/4″.

When shopping for a used mandrel tube bender, focus on what really matters: machine hours, tooling condition, and control systems – not just the manufacturing date. These industrial workhorses are built to last decades with proper care, making the secondary market a treasure trove of high-quality equipment.

Why This Round-Up Matters

The hunt for a quality used mandrel tube bender has never been more competitive. With global supply chains still untangling themselves and budget constraints tightening across manufacturing, finding that perfect pre-owned bender has become something of a strategic chess move for forward-thinking operations.

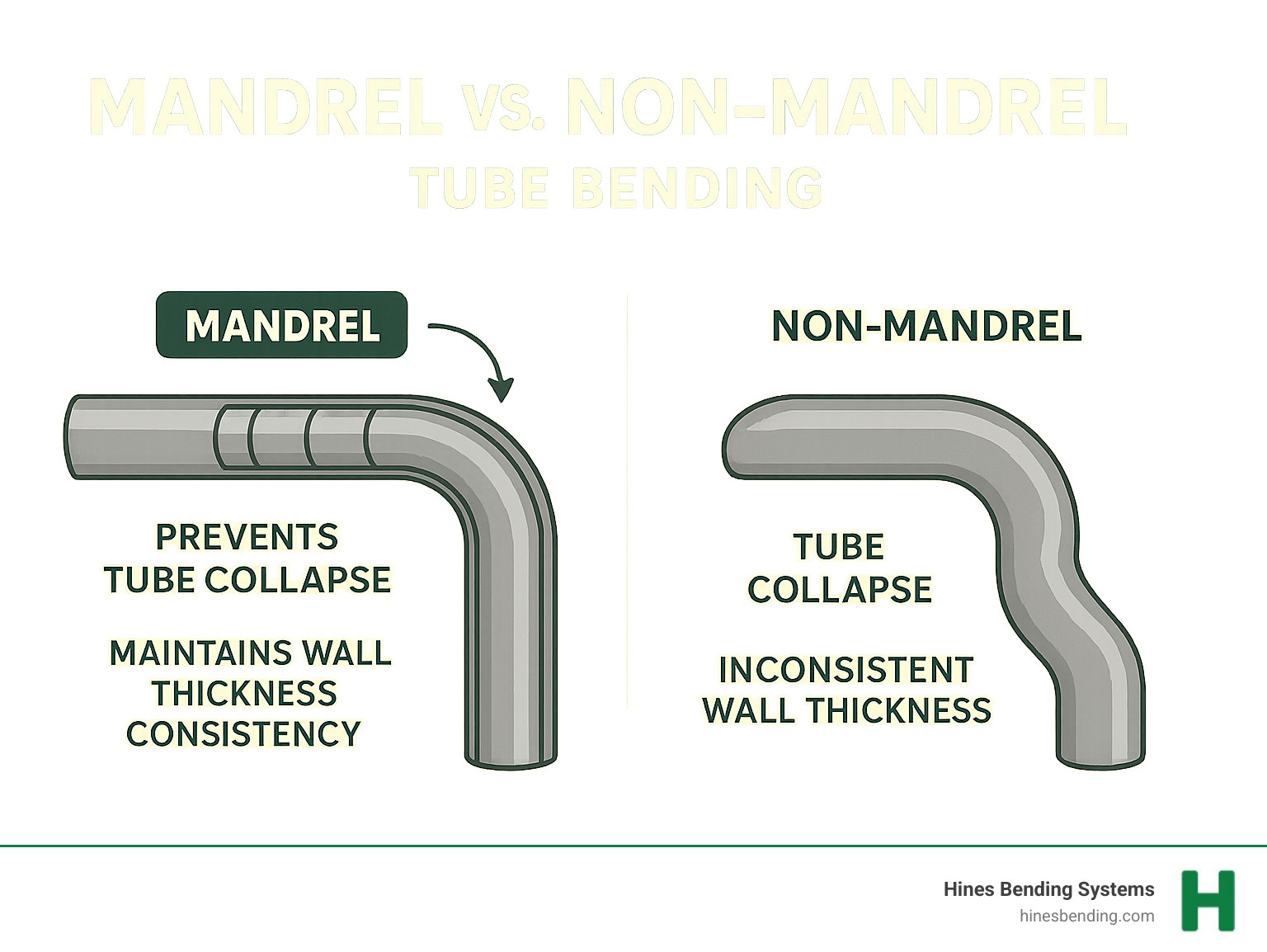

What makes this particular round-up so valuable? It’s all about those tight-radius bends. When you’re bending tubes at radii less than 3x the tube diameter (what the pros call “tight-radius bends”), a mandrel isn’t just nice to have – it’s essential. Without one, you’re looking at wrinkled inner radii, tubes that suddenly decide they’d rather be ovals, and wall thickness that varies more than the weather in April. None of that flies in precision applications.

Let’s talk dollars and sense. A brand-new industrial CNC mandrel tube bender might set you back anywhere from $75,000 to north of $200,000 depending on features and capacity. Now compare that to a well-maintained used machine at $25,000 to $50,000 – that’s savings that go straight to your bottom line while delivering identical production capabilities. For smaller operations, that difference could mean adding other essential equipment or even bringing on additional talent.

At Hines Bending Systems, we’ve spent decades perfecting the art and science of tube bending. Our expertise extends beyond simply selling equipment – we understand the unique challenges manufacturers face and how the right bending solution can transform an operation’s efficiency and capabilities.

Why Choose a Mandrel Tube Bender?

When it comes to precision tube bending, nothing beats a mandrel tube bender. The magic happens thanks to that internal support system that slides right inside the tube during bending. This prevents your tubes from looking like they’ve been through a car crusher – no collapsing or unsightly wrinkles on the inside radius.

At Hines Bending Systems, we’ve installed more mandrel benders worldwide than any other manufacturer. This hands-on experience has shown us exactly why these machines are worth their weight in gold for serious fabricators.

Superior bend quality is the most immediate benefit you’ll notice. Those smooth, wrinkle-free bends with consistent wall thickness don’t just look professional – they perform better too. For critical applications where flow rates matter or structural integrity is essential, this quality difference is night and day.

Tight radius capability is another game-changer. Need to bend tubing with a centerline radius equal to the tube diameter itself (what we call a 1D bend)? A mandrel bender handles this with ease, while other methods would leave you with crushed, distorted tubes.

The high repeatability factor makes mandrel benders ideal for production environments. Once you’ve dialed in your settings, you’ll get identical bends part after part – crucial for aerospace components, automotive exhaust systems, or any application where consistency equals quality.

We’ve seen customers switch to mandrel bending because of its material versatility. Thin-wall tubing, exotic alloys like titanium and Inconel, and high-strength materials that would buckle under other bending methods form beautifully with proper mandrel support.

NASA, one of our most demanding clients, relies on our mandrel bending technology for critical fluid and propellant lines where failure simply isn’t an option. When rocket scientists trust your bending technology, you know you’re doing something right.

Mandrel Mechanics 101

To understand why a used mandrel tube bender for sale represents such tremendous value, let’s peek under the hood at how these precision machines actually work.

Think of the mandrel assembly as a sophisticated team of components working in perfect harmony:

The mandrel rod serves as the backbone – a precision-machined shaft that extends into the tube to provide internal support. Connected to this rod are the ball segments – articulated sections that flex during bending but maintain support at the critical bend point. These segments are engineering marvels that allow for smooth extraction after bending is complete.

Working alongside the mandrel, the wiper die sits precisely at the inside radius of the bend. Its job? Preventing material from wrinkling as the tube is drawn around the bend die. The pressure die holds everything firmly against the bend die during operation, while the clamp die grips the tube securely and rotates to create the actual bend.

During operation, these components perform a carefully choreographed dance. The mandrel positions exactly at the bend point, the clamp engages, and as the bend begins, the mandrel supports the tube from within while the wiper ensures a smooth inner radius. This coordinated action is what enables those smooth, consistent bends even at tight radii that would be impossible with simpler bending methods.

Key Advantages Over Non-Mandrel Methods

The difference between mandrel and non-mandrel bending becomes crystal clear when you place the finished products side by side:

| Feature | Mandrel Bending | Non-Mandrel Bending |

|---|---|---|

| Minimum bend radius | As low as 1D (CLR = tube OD) | Typically 3D or greater |

| Wall thinning | Minimal and controlled | Significant and variable |

| Ovality | Less than 5% typically | Can exceed 15% |

| Wrinkling | Virtually eliminated | Common on inside radius |

| Material compatibility | Works with thin-wall and exotic materials | Limited to thicker walls and standard materials |

| Precision | High repeatability, tight tolerances | Variable results, wider tolerances |

| Cost | Higher initial investment | Lower initial cost |

“The difference is immediately visible in the finished product,” as our lead engineer likes to say. “A mandrel-bent tube maintains its circular cross-section throughout the bend, while non-mandrel methods often result in flattened or distorted profiles.”

This isn’t just about appearance – these differences impact performance. In high-pressure hydraulic systems, exhaust manifolds, or aerospace fluid lines, the consistent wall thickness and minimal ovality from mandrel bending translate directly to better flow characteristics, stronger joints, and longer service life.

While the initial investment in a mandrel bender is higher, the capability to produce complex, tight-radius bends with minimal distortion quickly pays for itself in reduced material waste, fewer rejected parts, and the ability to take on high-precision projects that competitors with lesser equipment simply can’t handle.

Used Mandrel Tube Bender for Sale: Today’s Best Deals

After helping countless customers find their perfect bending solution, we’ve developed a keen eye for spotting diamonds in the rough when it comes to used mandrel tube benders for sale. The secondary market can be a treasure trove of value if you know what to look for.

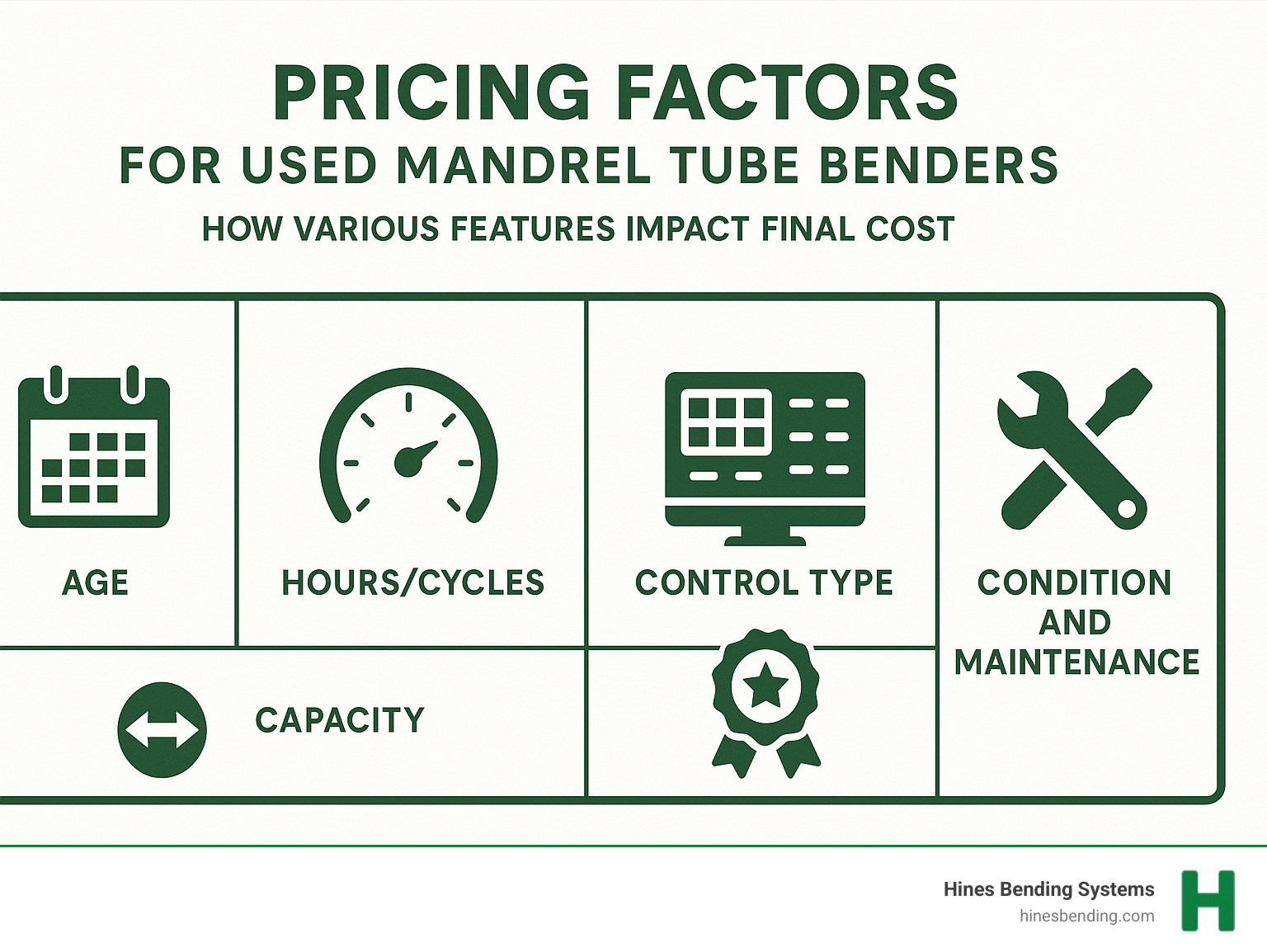

When hunting for a pre-owned bender, machine hours matter more than calendar age. I’ve personally seen 15-year-old machines with just 2,000 hours that outperform much younger models with 15,000 hours of wear and tear. And don’t assume all used machines are heavily used—we regularly encounter benders with barely 326 hours on them, practically fresh from the factory floor! These gems often come from companies that purchased them for specific projects then moved on.

Capacity consideration is crucial when shopping the used market. You’ll find everything from nimble 1/8″ units to industrial 6″ OD powerhouses. Buy too small, and you’ll limit your potential projects; too large, and you’re paying for capacity that gathers dust. Whether you need manual control for straightforward jobs or CNC precision for complex work, the secondary market has options at every price point.

Deal #1: Semi-Auto 3″ Capacity Workhorse

One of the best values we consistently see is the semi-automatic 3″ capacity mandrel bender with hydraulic draw capabilities. These reliable machines deliver the perfect balance of power and precision with hydraulic consistency, quick-change tooling for minimal downtime, and hands-free operation via foot pedal control. With the ability to handle tubes up to 3″ OD and create bends up to 180 degrees, they’re versatile enough for most shop applications.

Just last month, we helped a marine industry customer source one of these semi-auto workhorses. For about $20,000—less than half the price of a new unit—they immediately began producing premium stainless exhaust components. The smile on the owner’s face when that first perfect bend came out told the whole story.

Deal #2: Compact CNC 1.5″ OD Bender

For shops needing more automation, compact CNC mandrel benders handling up to 1.5″ OD tubing offer tremendous value. These space-saving machines pack serious technology into a small footprint, featuring multi-axis controllers that handle complex bend sequences, intuitive touchscreen interfaces that reduce training time, and memory for 200+ programs to support diverse production needs.

“The used CNC mandrel bender we got through Hines paid for itself in under 8 months,” an aerospace components customer recently told me. “We’re programming complex parts in minutes instead of hours now.” At $20,000-$35,000 depending on condition and included tooling, these machines deliver $60,000-$90,000 worth of capability at a fraction of new prices.

For more details on available CNC options, check out our CNC mandrel tube bender for sale page.

Deal #3: Heavy-Duty 6″ OD Powerhouse

When it comes to serious bending muscle, nothing beats a heavy-duty mandrel bender capable of handling 6″ OD materials. These industrial titans are built like tanks, featuring induction-ready capabilities for tackling thick-wall pipes, dual-stack tooling that lets you switch between bend radii without complete changeovers, and the brute strength to handle schedule-80 pipe without breaking a sweat.

“Large-diameter mandrel bending is specialized territory,” I often tell customers considering these machines. The good news? These beasts are engineered for decades of service, making a well-maintained used unit nearly indistinguishable from new in performance—but at $30,000-$50,000 rather than $150,000+, your accountant will definitely notice the difference.

Deal #4: Job-Shop Friendly Manual Lever Unit

Not every bending need requires industrial-scale equipment. Manual lever-type benders represent the entry point to quality mandrel bending, with used units often available for just $30-$100. These budget-friendly machines handle tubes up to 1″ OD, require minimal training, and can be moved around the shop as needed since they operate without power.

I’ve watched skilled fabricators create remarkably consistent, professional-quality bends on these simple machines. They’re perfect for automotive shops, HVAC contractors, and maintenance departments that need occasional quality bends without major investment. As our training specialist likes to say, “Don’t underestimate these simple machines—in the right hands, they’re small but mighty.”

Deal #5: All-Electric Precision Package

For those looking toward the future of bending technology, all-electric mandrel benders represent the cutting edge. These advanced machines replace traditional hydraulics with precision servo drives, eliminating fluid leaks while delivering exquisite motion control. They’re also energy-efficient, only consuming power during actual bending operations, and run significantly quieter than their hydraulic cousins.

Though newer to the market, used all-electric models have started appearing in the $30,000-$45,000 range—a substantial savings over new units that typically exceed $100,000. “All-electric technology is where the industry is heading,” I tell customers interested in long-term investments. The precision is remarkable, and the maintenance headaches associated with hydraulic systems become a thing of the past.

For a complete look at our current selection of quality pre-owned equipment, visit our Used Tube Benders for Sale page. With decades of experience matching customers to their perfect bending solution, we’re here to help you steer the used market with confidence.

How to Inspect and Evaluate a Used Mandrel Tube Bender

Finding a quality used mandrel tube bender for sale is only half the battle – knowing how to properly evaluate it before purchase can save you thousands in unexpected repairs and downtime. At Hines Bending Systems, we’ve helped countless customers steer the pre-owned equipment market, and we’ve developed a keen eye for what separates a diamond in the rough from a money pit.

“I always tell customers that a thorough inspection is non-negotiable,” shares our service manager. “The good news is that most issues we find on used benders are fixable – but you want to know about them before you write the check, not after.”

When examining a potential purchase, focus first on the mandrel rod and ball segments – these components experience the most wear and are critical to bend quality. A straight, smooth mandrel rod without scoring or bending is essential. The ball segments should move freely without excessive play and show even wear patterns rather than gouges or flat spots.

Next, turn your attention to the control system. For CNC machines, verify that all screens function properly, programs can be stored and retrieved, and the firmware is current. With manual machines, check that all levers, dials, and gauges operate smoothly and provide accurate readings.

The hydraulic system is another critical area – and often the source of costly repairs. Look beyond obvious leaks to inspect hose conditions, check pressure readings, and verify that the pump runs quietly without excessive heat. A hydraulic system that’s been well-maintained will operate at proper pressures and temperatures without unusual noises.

Safety features should never be overlooked. Test all emergency stops, guard interlocks, and pressure relief systems. A machine with bypassed safety features is not only dangerous but may indicate a seller who’s cut other corners in maintenance.

Step-By-Step Evaluation

When you’ve found a promising used mandrel tube bender for sale, approach the evaluation methodically. Start by asking for the machine’s cycle count – this gives you a much better picture of actual usage than age alone. A five-year-old machine with 20,000 cycles has seen much more use than a ten-year-old unit with 5,000 cycles.

Check for mechanical backlash by gently moving the bend arm (with the machine powered off and hydraulics depressurized). Excessive play indicates worn bearings or mechanical components that may affect bend precision.

“One of the most telling signs of a well-maintained bender is its lubrication points,” notes our senior technician. “Clean, properly greased fittings and appropriate oil levels in reservoirs suggest an owner who took maintenance seriously.” Conversely, dry or dirty lubrication points often indicate neglect in other areas.

Whenever possible, run a sample part using material similar to your intended application. Measure the finished bend for wall thinning, ovality, and angle accuracy. This real-world test can reveal issues that might not be apparent during static inspection.

For CNC machines, run through the home and calibration routines to ensure proper positioning. Watch for smooth, consistent movement without jerking or hesitation. Verify that the machine returns to the same position repeatedly – a sign that the control system is functioning properly.

Don’t hesitate to ask for maintenance records. A detailed service history suggests a machine that received proper care throughout its life. At Hines Bending Systems, we always recommend having one of our experienced technicians evaluate a potential purchase – their trained eyes can spot subtle issues that might escape notice by those less familiar with these specialized machines.

Tooling & Spare Parts Availability

One advantage of purchasing a used mandrel tube bender for sale through Hines Bending Systems is our extensive inventory of compatible tooling and spare parts. Many buyers focus solely on the machine’s price without considering the availability and cost of necessary tooling – a mistake that can lead to unexpected expenses.

Mandrel shanks and balls must match your specific tube diameters, while clamp dies need to be compatible with both your tube size and material. Wiper dies, which prevent wrinkling on the inside radius of bends, are consumable items that require regular replacement. Pressure dies must be matched to your tube diameter and wall thickness to provide proper support during bending.

“I’ve seen buyers get great deals on used benders only to find that the tooling they need costs almost as much as the machine,” our parts specialist explains. “Always check if the sale includes tooling for your applications, and if not, factor those costs into your budget.”

At Hines, we can help you identify exactly what tooling you’ll need for your specific applications and provide competitive pricing on both new and reconditioned options. For a comprehensive overview of available accessories, visit our Tube and Pipe Bender Accessories page.

Common Refurbishment Needs

Even a well-maintained mandrel tube bender may benefit from some refurbishment before being put into production. Hydraulic seal kits are typically the first components to need replacement, as seals naturally deteriorate over time regardless of usage. A complete seal kit replacement can restore proper pressure and eliminate leaks that might otherwise worsen over time.

CNC machines often require servo calibration to ensure accurate positioning. This relatively straightforward procedure can dramatically improve bend consistency and precision. Similarly, software updates for older CNC controllers can improve functionality and address known issues from earlier versions.

The mandrel assembly – including the rod, balls, and nose piece – experiences the most wear during normal operation and frequently benefits from reconditioning. Our factory-trained technicians can restore these critical components to like-new condition at a fraction of the cost of replacement.

“We recently helped a customer refurbish a 15-year-old mandrel bender that now outperforms much newer machines in their shop,” our service coordinator proudly shares. “With strategic reconditioning of key components, an older machine can deliver exceptional performance while still representing an excellent value compared to buying new.”

At Hines Bending Systems, we offer comprehensive refurbishment services for used mandrel benders of all major brands. Our deep experience with bending equipment ensures that we can identify and address the most critical needs first, helping you maximize your return on investment while bringing your used bender up to peak performance standards.

Pricing, Negotiation & Where to Buy

Shopping for a used mandrel tube bender for sale can feel like navigating a complex marketplace, but with the right knowledge, you can find exceptional value. At Hines Bending Systems, we’ve helped countless customers find their perfect match, and we’ve noticed that prices typically range from $10,000 to $50,000 for industrial-grade machines.

What drives these price differences? It’s not just about age. While newer machines often cost more, we’ve seen 15-year-old low-hour machines in better condition than some 5-year-old workhorses. The true value factors include operational hours (fewer is better), capacity (larger diameter capability commands higher prices), and control type (CNC systems add significant value over manual controls).

Brand reputation plays a crucial role too—established names with reliable parts availability maintain stronger resale values. And don’t overlook the tooling package! A machine sold with comprehensive tooling can be worth thousands more than a bare unit, often representing better overall value despite the higher price tag.

When considering where to buy, you’ll typically choose between private sellers and established dealers. Private sellers might offer lower upfront prices, but you’ll usually get what you pay for—limited guarantees and support. Reputable dealers like Hines Bending Systems typically include some warranty coverage and technical support, well worth the modest premium.

Remember to factor in freight and rigging costs—these can add $2,000-$5,000 depending on the machine size and shipping distance. These “hidden” expenses should be part of your total budget from the beginning to avoid surprises.

Negotiation Tactics That Work

The art of negotiation can save you thousands when purchasing used equipment. Our sales team has facilitated hundreds of transactions, and we’ve found several approaches consistently yield positive results.

First, try to bundle tooling with the machine. Those clamp dies, wiper dies and mandrel assemblies can add up quickly when purchased separately. Next, always request a video demonstration of the bender in action, ideally processing material similar to what you’ll be using. This simple step can reveal issues that might not be apparent in still photos.

For private transactions, consider using an escrow payment service to protect both parties. This gives you verification time while providing the seller with payment security. We’ve also seen great success with conditional acceptance terms, where final payment happens only after successful installation and testing at your facility.

Perhaps most importantly, consider the total package value, not just the price tag. As our sales director likes to say, “The machine that costs $5,000 less upfront might end up costing $15,000 more once you add missing tooling, documentation, and necessary repairs. The best negotiations create win-win scenarios, not just lower prices.”

Trusted Marketplaces & Listings

Finding reliable sources for used mandrel tube benders for sale is crucial to making a sound investment. While many online platforms offer used machinery, the level of buyer protection varies dramatically.

Industrial auctions through companies like Ritchie Bros. offer legitimacy and structure, though you’ll typically purchase “as-is.” Established machinery dealers often refurbish equipment before resale and may include limited warranties that provide peace of mind.

At Hines Bending Systems, we occasionally accept trade-ins when customers upgrade their equipment. These machines undergo thorough reconditioning in our facility and come with our full technical support—an advantage over anonymous marketplace purchases.

Industry-specific manufacturing forums often include classified sections where companies sell surplus equipment. These can be treasure troves for finding specialized benders, though always verify the seller’s reputation before proceeding.

“I’ve seen customers save thousands by buying from reputable sources,” notes our customer service manager. “The documentation, verified history, and available support are invaluable when you’re making such a significant investment.”

For more information on marketplace trust factors in industrial equipment purchases, you can review this research from MIT Sloan Management Review that explores how digital platforms are reshaping capital equipment sales.

For our current selection of professionally reconditioned machines, visit our Used CNC Bending Machines for Sale page. Our team is always available to help you evaluate options and find the perfect match for your production needs.

Frequently Asked Questions About Used Mandrel Tube Benders

How much capacity do I really need?

One question we hear almost daily at Hines Bending Systems is about proper sizing for mandrel benders. Choosing the right capacity is crucial—too small and you’ll limit your capabilities; too large and you’re paying for capacity you don’t need.

For most automotive shops, HVAC contractors, and general fabrication work, machines that handle up to 2″ OD tubing will cover the vast majority of applications. If you’re in aerospace or performance racing, you might primarily work with smaller diameters (often under 1″ OD), but the precision requirements are typically much higher. On the industrial side, applications for oil and gas or power generation might require capacities of 3″ and above.

“I always tell customers to think about where their business will be in three years, not just today,” says our applications engineer. “Adding at least 25% more capacity than your current largest application provides room to grow without needing to replace your equipment prematurely.”

Capacity isn’t just about diameter—wall thickness plays a crucial role too. A machine rated for 2″ OD with thin-wall tubing might struggle with 2″ OD heavy-wall material. Always verify that the machine’s specifications match your material requirements before purchasing.

Can I retrofit CNC controls later?

We often meet customers who want to start with a manual or semi-automatic mandrel bender with plans to upgrade to CNC controls as their business grows. While this sounds logical, the practical reality is more complex.

“Complete CNC retrofits often end up costing nearly as much as a used CNC machine would have in the first place,” our controls specialist explains. “The better approach is usually to sell your manual machine and upgrade to a used CNC model when the time comes.”

That said, partial automation upgrades can make good financial sense. Adding digital readouts or programmable bend angle controls to a manual machine can boost productivity without breaking the bank. If CNC capability might be in your future, we recommend:

Consider a used CNC machine now, even if it’s older, rather than planning a complex retrofit later.

Look at semi-automatic machines with digital controls as a middle ground that offers some programming capabilities.

Choose a manual machine with good bones if budget is extremely tight—ensure the frame and hydraulic system are robust enough to support potential upgrades down the road.

At Hines Bending Systems, we’ve guided countless customers through the upgrade path, helping them find the sweet spot between current budget constraints and future production needs.

What ongoing maintenance costs should I expect?

Understanding the true cost of ownership for a used mandrel tube bender helps avoid budget surprises down the road. Based on decades of service experience at Hines Bending Systems, here’s what you can realistically expect:

For standard hydraulic machines, plan for annual hydraulic oil changes ($200-$500 depending on reservoir size), seal replacements every 2-3 years ($500-$1,500), and mandrel component refurbishment every 2-5 years ($1,000-$3,000 depending on usage intensity).

CNC machines add some complexity with control system maintenance (about $500-$1,000 annually), servo motor maintenance ($300-$800 annually), and occasional software updates ($0-$1,500 depending on controller type).

“The customers who save the most on maintenance are those who follow preventive schedules based on cycle counts, not calendar time,” our service manager points out. “A machine running 50 hours per week needs much more frequent attention than one running 10 hours per week, regardless of how many months have passed.”

One significant advantage of purchasing through Hines Bending Systems is our comprehensive service contracts for used machines. These contracts help stabilize maintenance costs and prevent unexpected downtime—just one more reason why partnering with an established manufacturer with nationwide service capabilities makes good business sense.

Our technicians have serviced virtually every model of mandrel bender on the market, giving us best insight into common wear points and maintenance needs. This expertise translates directly into more productive uptime for your operation and lower total cost of ownership.

Conclusion

Finding the right used mandrel tube bender for sale represents an opportunity to acquire precision bending capabilities at a fraction of the cost of new equipment. Throughout this guide, we’ve explored everything from simple manual units to sophisticated CNC systems capable of complex multi-axis bending – all available on the secondary market for savvy buyers.

At Hines Bending Systems, we’ve built our reputation on industry leadership, with more bender installations worldwide than any other manufacturer. This isn’t just a statistic we’re proud of – it’s experience you can leverage when selecting, evaluating, and maintaining your used mandrel bending equipment.

“The right bender is about more than just capacity and features,” our CEO often reminds clients. “It’s about matching the technology to your specific applications and production environment. That’s where our decades of experience make the difference.”

We don’t just sell equipment – we create partnerships. Our team takes the time to understand your applications, production volumes, and quality requirements before recommending solutions. This consultative approach ensures the machine you purchase will be the perfect fit for your operation, saving you time and money in the long run.

The mandrel bending landscape continues to evolve, but our commitment to custom solutions remains constant. Whether you need tight-radius bends for aerospace applications or high-volume production for automotive components, we’ll help you find the ideal used mandrel bender to meet your needs and budget.

As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we offer a single source for all your bending needs. From initial consultation to equipment selection, installation, training, and ongoing support – the Hines team stands ready to support your success.

When you work with Hines, you’re working with the same experts who supply bending solutions to NASA and other demanding clients who simply can’t compromise on quality or precision. We bring that same level of expertise to every client relationship, regardless of size.

Whether you’re looking for your first mandrel bender or expanding your existing capabilities, we invite you to explore our current inventory of Mandrel Bending Machines for Sale and experience the Hines difference for yourself.