The Art and Science of Exhaust Pipe Bending

Exhaust pipe bending is the process of reshaping straight metal tubing into curved sections that form a complete exhaust system, from headers to tailpipes. When done correctly, proper bending maintains consistent internal diameter for optimal exhaust flow while creating a visually appealing and functional system.

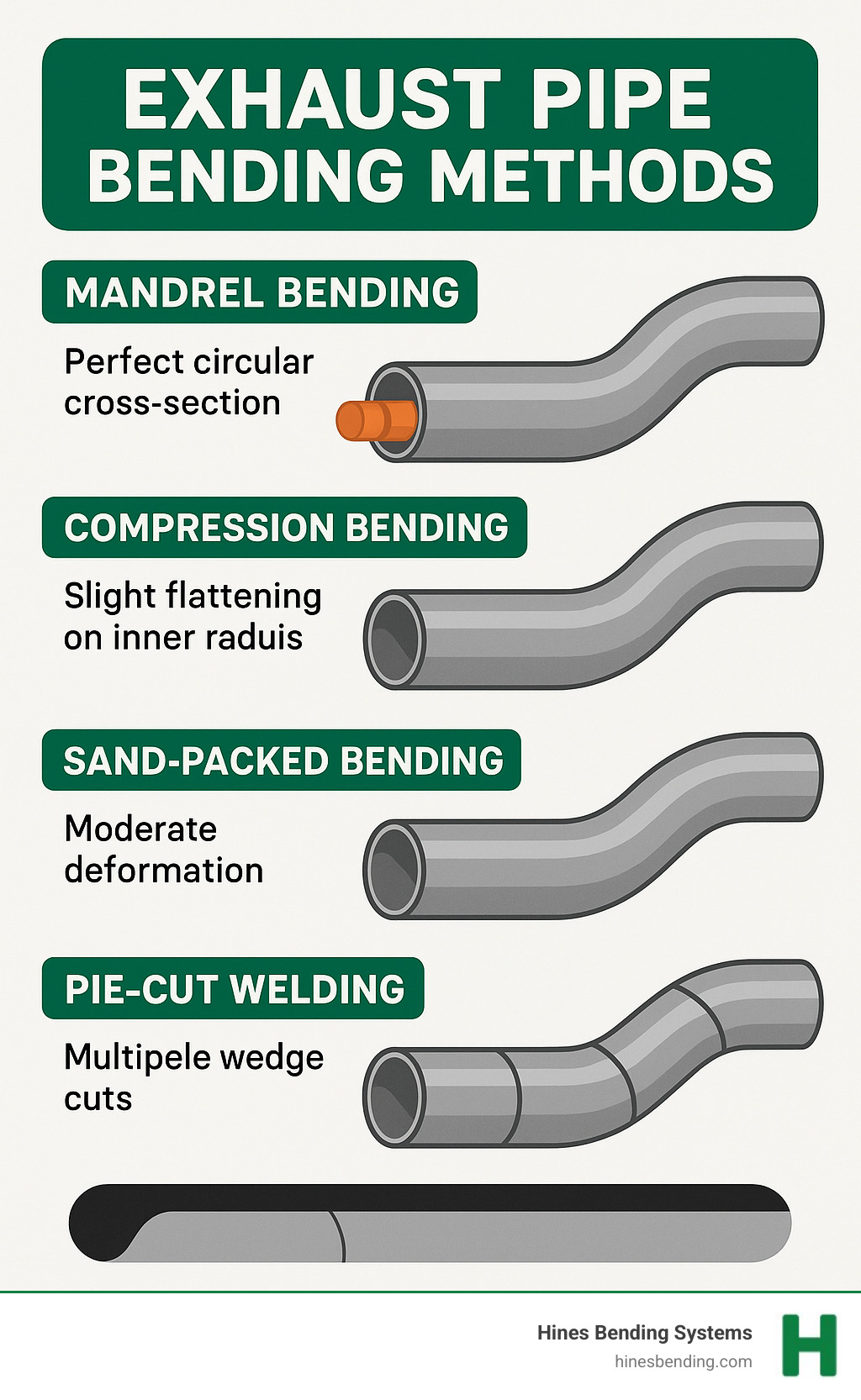

Quick Guide to Exhaust Pipe Bending Methods:

| Method | Best For | Advantages | Limitations |

|---|---|---|---|

| Mandrel Bending | Performance systems | Maintains round cross-section, best flow | Requires specialized equipment |

| Compression Bending | General repairs | Quick, economical | May cause wrinkling, requires 12-gauge+ |

| Sand Bending | DIY thin-wall tubing | Affordable, minimal equipment | Labor intensive, limited to simple bends |

| Pie-Cut Welding | Custom angles | Works with basic tools | Multiple welds, potential leak points |

At Hines Bending Systems, we’ve seen how the right bending technique can transform both the performance and aesthetics of an exhaust system. Whether you’re managing a high-volume production facility or overseeing a custom fabrication shop, the method you choose impacts flow characteristics, sound quality, and durability.

“Mandrel bending is one of the most successful methods for custom exhaust pipes,” notes an industry expert, and at Hines Bending, we’ve perfected this technique with our advanced CNC mandrel bending systems that maintain perfect tube geometry through even the tightest bends.

While DIY enthusiasts might resort to sand-packing or pie-cutting methods, professional operations typically rely on hydraulic compression benders or sophisticated mandrel bending machines like those manufactured by Hines Bending Systems. Our machines are trusted by NASA and other demanding clients who require absolute precision in their exhaust fabrication.

The right bend not only looks professional but also improves engine performance by maintaining consistent exhaust gas velocity. Poor bending techniques that cause crimping or collapse can restrict flow, creating backpressure that robs your engine of power.

Key terms for exhaust pipe bending:

– 3 inch exhaust pipe bender

– 5 inch exhaust pipe bender

– exhaust pipe bending machine for sale

Exhaust Pipe Bending Basics

When it comes to exhaust pipe bending, understanding the fundamentals can make all the difference between a system that looks great and performs beautifully versus one that restricts flow and robs your engine of power. At Hines Bending Systems, we’ve spent decades perfecting these techniques, and we’re happy to share some insights.

The golden rule of exhaust bending is maintaining consistent internal diameter throughout every curve. Think of your exhaust system like a river – any narrowing creates a bottleneck that restricts flow. This is precisely why professional-grade equipment like our mandrel benders is the gold standard for high-performance applications. Our customers consistently tell us that the investment pays dividends in both performance and longevity.

Ever wonder what that “CLR” specification means? The centerline radius (CLR) is the distance from the center of the bend to the centerline of the tube. A tighter radius creates those compact, space-saving bends you see in professional systems, but they’re also the most challenging to execute without specialized equipment. This is where Hines Bending Systems truly shines – our machines can produce tight, consistent bends without the wrinkling or collapse that plagues lesser equipment.

“The standard CAUTION from all the books is to make sure the sand is dry,” notes Pete Young, an experienced fabricator who uses the sand-filling method. This practical wisdom applies to many DIY bending approaches, highlighting why proper technique and equipment matter so much.

Material selection is another critical factor that can’t be overlooked. Modern exhaust systems typically use stainless steel (either 304 or 409 grade) or aluminized steel. Wall thicknesses generally range from 1.2mm to 1.6mm (0.047″ to 0.062″), which presents unique challenges. These thin-walled materials demand precision equipment to bend properly – exactly the kind of solutions we specialize in at Hines Bending.

Have you ever bent something only to find it “springs back” slightly? This natural phenomenon, known as springback, occurs when metal tries to return to its original shape after bending. Our professional bending machines automatically compensate for this effect, ensuring your final angles are spot-on every time. It’s this kind of precision that separates professional results from amateur attempts.

When comparing different bending methods, it’s important to recognize how each affects the tube’s cross-section. Mandrel bending (our specialty at Hines) maintains a perfect circular cross-section, while compression bending can cause flattening on the inner radius. Sand-packed bending offers a middle ground for DIY enthusiasts, while pie-cut welding creates multiple seams that require skilled TIG welding.

The wall thickness of your exhaust tubing also plays a crucial role in determining which bending method will work best. Thinner walls (common in high-performance systems) are more prone to collapse and require more sophisticated bending equipment – precisely the kind of advanced solutions we provide at Hines Bending Systems.

The quality of your bends directly impacts both the performance and sound of your exhaust system. When properly executed with professional equipment, good bends maintain consistent gas velocity and create that perfect exhaust note that enthusiasts crave. This is why leading performance shops and OEMs worldwide trust Hines Bending Systems for their exhaust fabrication needs.

Main Methods and When to Use Them

When it comes to exhaust pipe bending, there’s no one-size-fits-all approach. At Hines Bending Systems, we’ve spent decades perfecting various bending techniques and developing machinery that delivers superior results for each method. Let’s explore the main approaches and when you might want to use them for your exhaust fabrication needs.

Mandrel exhaust pipe bending

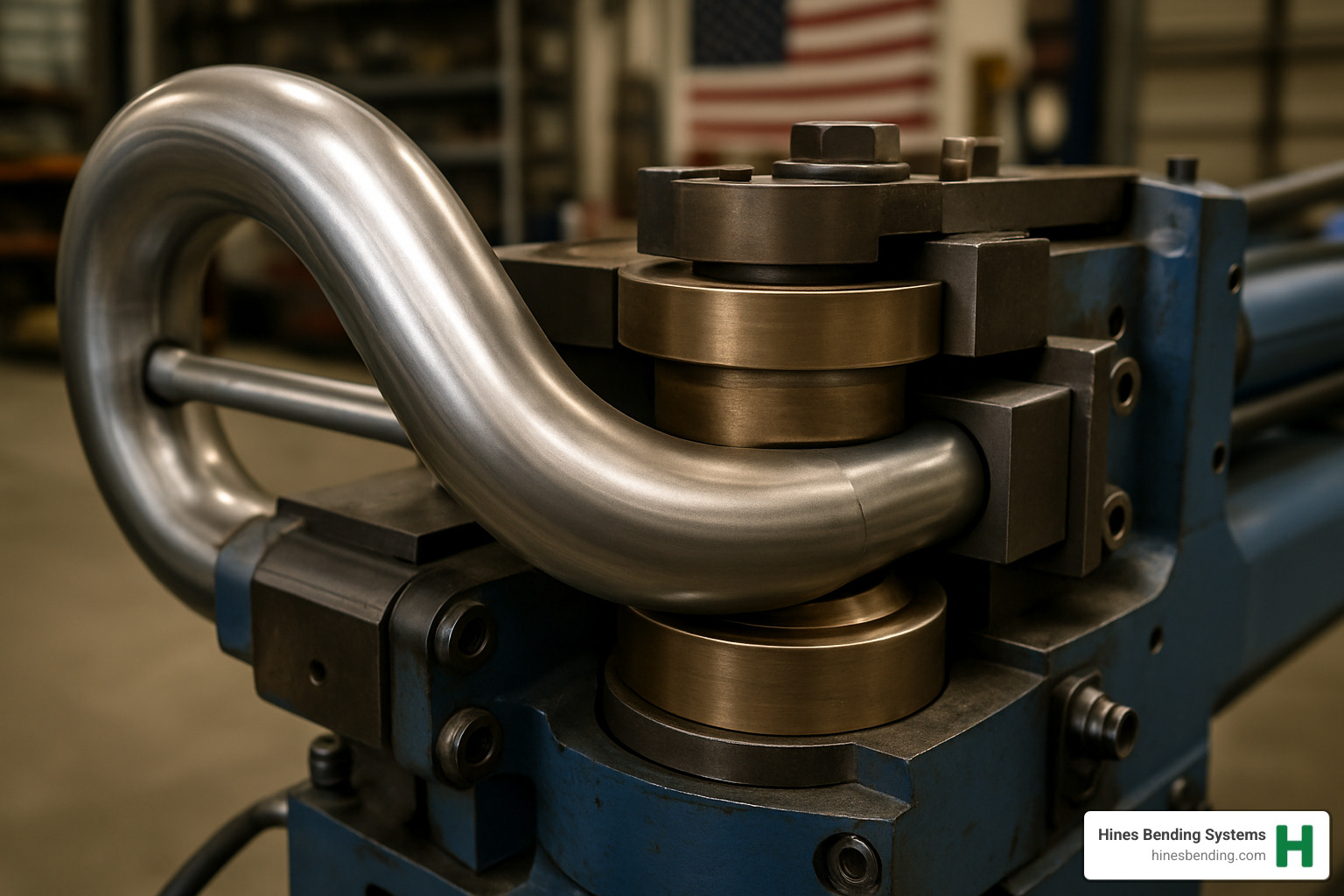

If you’re serious about performance, mandrel bending is simply the gold standard. This premium method uses an internal support (the mandrel) that slides inside the tube during bending, preventing collapse and maintaining that crucial round cross-section throughout the bend.

“When you cut through non-mandrel bent els, you’ll find an egg-shaped hole. With mandrel bends, you get a virtually round cross-section through the entire bend,” explains one of our technical specialists. This difference isn’t just cosmetic – it directly impacts exhaust flow and engine performance.

Our Hines mandrel bending machines can create smooth, wrinkle-free bends up to 180 degrees, even in thin-wall tubing that would collapse with lesser methods. For high-performance vehicles where every bit of airflow matters, there’s simply no substitute. It’s why NASA trusts our equipment when absolute precision is non-negotiable.

Compression bending for shop repairs

For everyday exhaust shop repairs where speed and economy matter, compression bending (also called ram-style bending) gets the job done. This method uses a forming die that the tube is forced against to create the bend.

Many of our repair shop clients appreciate our hydraulic compression benders for their efficiency – the knee controls keep both hands free for material handling, allowing for quicker turnaround on standard repairs. While compression bending typically causes some flattening on the inside radius, it’s perfectly adequate for most repair work using tubing with a minimum 12-gauge wall thickness.

When absolute flow optimization isn’t the primary concern but getting vehicles back on the road quickly is, our compression bending solutions deliver reliable results day in and day out.

DIY exhaust pipe bending with sand

We understand not everyone has access to professional bending equipment right away. For DIY enthusiasts or small shops just starting out, the sand-filling method offers a budget-friendly alternative for bending thin-wall exhaust tubing.

This old-school technique involves filling the tube with dry, tightly packed sand to provide internal support. The tube is then typically heated to a dull red color and gradually bent to shape. As one fabricator put it, “Sand bending is ideal for thin-walled, unstressed exhaust systems where mandrel bending is cost-prohibitive.”

While we at Hines Bending Systems always recommend professional equipment for consistent results, we’ve seen many talented fabricators get their start with sand bending. Just remember that safety comes first – wet sand can create dangerous steam pressure when heated, so always ensure your sand is completely dry.

Pie-cut welding for tight angles

Sometimes you need an angle that’s difficult to achieve with conventional bending. Enter the pie-cut and weld method – cutting wedges out of straight pipe and welding the edges together to create a bend. This technique requires minimal specialized equipment but demands strong welding skills, particularly with TIG for stainless systems.

Pie-cutting allows for incredibly precise angles and custom shapes that might be challenging with other methods. The trade-off? Multiple weld seams that introduce potential leak points and affect the visual flow of your finished system.

For shops looking to eliminate the need for pie-cutting, Hines Bending Systems offers advanced bending solutions that can achieve even the most challenging angles with clean, seamless results – giving you the best of both worlds.

Roll and section bending

Need those beautiful, sweeping curves for truck stacks or decorative exhaust tips? Roll bending creates large-radius sweeps by passing the tube between rollers that gradually form the desired curve. The result is a gentle, flowing bend that adds both function and aesthetic appeal to your exhaust system.

Section bending takes a different approach, using pre-bent sections (U-bends, J-bends, etc.) and welding them together to create a complete system. “Most DIY exhaust builders often use pre-bent mandrel sections and weld them together, as most local muffler shops don’t have mandrel bending machines,” notes one industry observer.

At Hines Bending Systems, we provide the equipment that eliminates these limitations, allowing fabricators to create custom bends on demand with perfect consistency. Why settle for piecing together pre-made parts when you could be crafting exactly what you need in-house?

For more scientific information about tube bending principles and techniques, you can refer to the Wikipedia article on tube bending, though nothing compares to the practical expertise and advanced technology that Hines Bending Systems brings to the industry.

Planning Your Bend & Choosing Materials

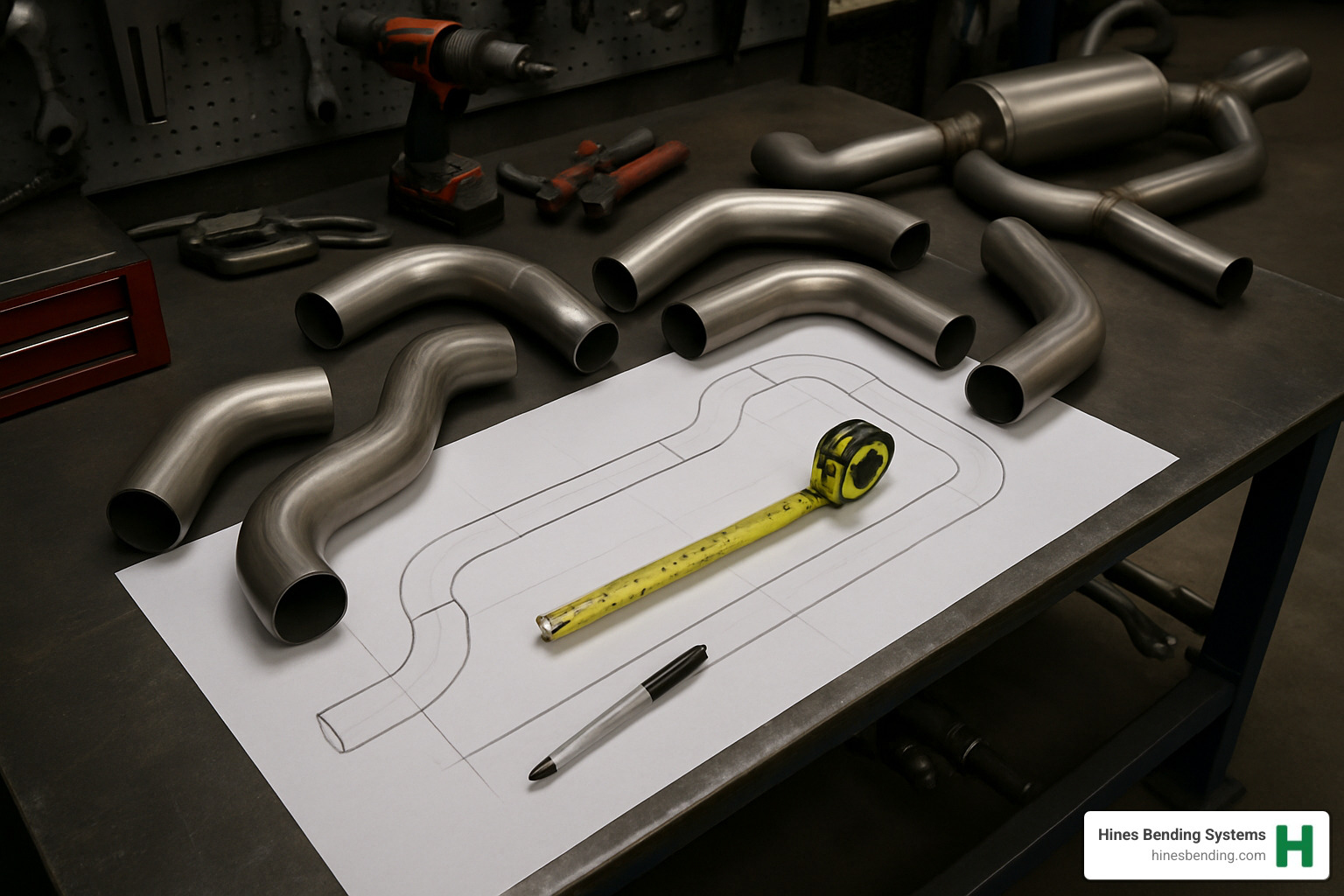

The secret to perfect exhaust pipe bending starts long before the first piece of metal meets a bending machine. At Hines Bending Systems, we’ve learned through decades of experience that proper planning and material selection make all the difference between a system that looks professional and performs beautifully versus one that disappoints.

Creating a detailed layout is your first step toward success. Many of our clients swear by 1:1 scale drawings or templates that let them visualize the entire system before making a single bend. This approach is incredibly practical – it helps you spot potential clearance issues with frame rails or suspension components and ensures your routing will be optimal for both performance and aesthetics.

“Make a good drawing with accurate dimensions of what you want,” is advice we share with fabricators at every skill level. This simple step prevents costly mistakes and frustrating rework. When you’re ready to step up to our CNC bending machines, these dimensions can be directly programmed, giving you perfect repeatability for production runs.

Always mark your starting and stopping points for each bend directly on the tubing. This becomes especially important when creating complex systems with multiple bends in close proximity. Our advanced Hines bending systems feature precise measurement capabilities that eliminate guesswork, ensuring your 45-degree turn starts and ends exactly where you need it.

Material selection is equally crucial to your project’s success. For exhaust applications, you’ll typically choose between:

Stainless Steel 304 offers exceptional corrosion resistance and durability – perfect for show-quality systems that need to look beautiful for years. The tradeoff is higher cost and more challenging bending properties.

Stainless Steel 409 provides a more budget-friendly option with excellent heat resistance, making it the go-to choice for many performance applications. It’s easier to work with than 304 while still offering good longevity.

Aluminized Steel delivers decent corrosion protection at a more accessible price point, making it suitable for many street applications where absolute perfection isn’t the primary goal.

Wall thickness demands careful consideration too. While thin-wall tubing (typically 1.2mm-1.6mm) reduces weight – desirable for performance applications – it’s also significantly more challenging to bend without high-quality equipment. That’s why many shops turn to Hines Bending Systems when working with premium thin-wall materials.

“Mandrel bending is absolutely essential for stainless steel exhaust pipes thinner than 14 gauge,” our engineers often explain to clients. Without proper support, these premium materials collapse or wrinkle during bending, ruining both appearance and performance. Our mandrel bending systems are specifically designed to handle these delicate materials with precision.

When measuring for your bends, remember to use centerline measurements rather than inside or outside edges. This approach ensures accuracy regardless of tube diameter and wall thickness. All Hines bending machines are calibrated to work with centerline measurements, providing consistent results across different tubing specifications.

The right planning tools make all the difference. Many professional fabricators use dedicated bend layout templates or software to calculate precisely where each bend should start and end. For those seeking to upgrade their capabilities, our 3 inch exhaust pipe bender solutions offer precision that eliminates the need for guesswork, delivering perfect results every time.

Tools, Equipment & Safety Essentials

The quality of your exhaust pipe bending equipment directly impacts the final product you’ll create. At Hines Bending Systems, we’ve seen how the right tools can make all the difference between a professional exhaust system and one that falls short of expectations.

Professional Bending Equipment

For serious fabrication shops, we offer several tiers of bending equipment to match your needs and budget:

Our Hydraulic Shop Benders have become the reliable workhorses in countless exhaust shops across the country. I love how the knee controls keep both your hands free to handle the material – it’s those thoughtful design elements that make daily work so much more efficient. The hydraulic compression systems with counter-dies prevent that frustrating material folding that can ruin a good bend.

The crown jewels in our lineup are our CNC Mandrel Machines. These precision instruments maintain perfect tube geometry even through the tightest bends, which is absolutely critical for high-performance applications. When you’re building an exhaust system where every bit of flow matters, there’s simply no substitute for a quality mandrel bender. Our multi-stack tooling and partial changeover capabilities make these machines versatile enough for both high-volume production runs and one-off custom projects.

For those special applications that push the boundaries, our Specialty Benders like our induction bending systems use electromagnetic induction to heat and bend heavy-wall or large-diameter tubing with minimal deformation. It’s fascinating technology that delivers remarkable results.

As one seasoned fabricator told me, “Nothing beats a guy that has been doing it for years behind a professional hydraulic bending machine.” That’s why at Hines Bending Systems, we don’t just sell you equipment – we provide comprehensive training to ensure you get the most from your investment.

DIY and Budget Options

While professional equipment delivers best results, we understand that some shops start with more modest budgets. Many fabricators begin with hand tubing benders for small-diameter, thick-wall tubing, though these generally struggle with thin-wall exhaust applications.

Some creative fabricators use torch and jig setups combined with sand filling to achieve acceptable results for simple bends. It works in a pinch, but the consistency and quality rarely match what you can achieve with proper equipment.

Many starting shops purchase pre-bent mandrel sections and weld them together. This approach can produce decent results, but limits your creativity and customization options.

What we’ve consistently found is that serious fabricators quickly outgrow these methods. The time saved and quality gained by investing in professional Hines equipment delivers returns that make the initial investment worthwhile. When you’re ready to take that step up, we’re here to help you find the perfect bending solution.

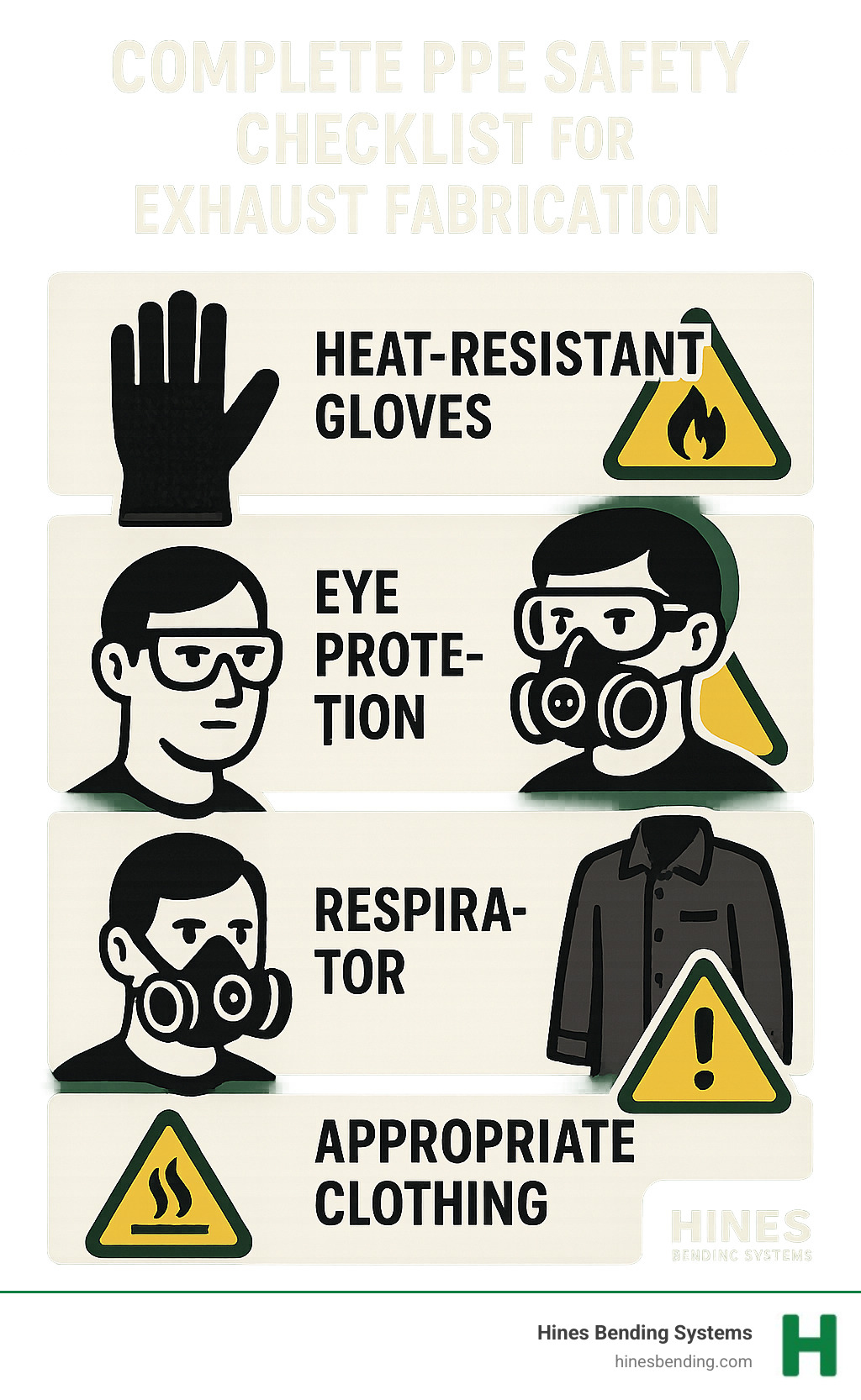

Safety Considerations

Safety should always come first when bending exhaust tubing. The proper personal protective equipment is non-negotiable:

Heat-resistant gloves protect your hands from hot metal and tools. Eye protection or a face shield guards against flying debris or sparks. When working with galvanized or coated materials, a proper respirator prevents inhalation of potentially harmful fumes. And always wear appropriate clothing that covers exposed skin – those metal burrs and hot surfaces don’t play nice with bare arms.

When using heating methods, proper fire safety measures become essential. Always keep a fire extinguisher within reach and ensure adequate ventilation to prevent the buildup of harmful fumes. A moment of preparation can prevent a disaster.

The risks of improper bending extend beyond safety concerns to quality issues as well. Wrinkling, collapse, and inconsistent bends will compromise both performance and appearance of your finished system. Our professional bending equipment at Hines minimizes these risks through precise control and proper support during the bending process.

I smiled when one customer told me, “Beating your brains out on poor equipment is a real character-building experience.” We’d rather help you skip that particular character-building opportunity! At Hines Bending Systems, we provide reliable, precision-engineered bending solutions that deliver consistent results from day one, saving you the frustration and wasted materials that come with inferior equipment.

Joining, Welding & Finishing a Custom System

After you’ve mastered the art of exhaust pipe bending, it’s time to bring those beautifully bent tubes together into a complete, leak-free exhaust system. This final stage is where craftsmanship truly shines – or where it all falls apart (sometimes literally!).

Welding Techniques for Exhaust Systems

When it comes to joining exhaust components, you have two main welding methods to choose from:

TIG Welding is the gold standard for high-end exhaust work, especially with stainless steel. It produces those gorgeous, stack-of-dimes welds that look as good as they perform. At Hines Bending Systems, we’ve seen how TIG welding’s precise heat control prevents warping in thin-wall tubing and creates joints that are both strong and beautiful.

MIG Welding offers speed and efficiency that many production shops depend on. While perhaps not as pretty as TIG, a well-executed MIG weld is perfectly suitable for most exhaust applications. For aluminized steel systems, MIG welding with the right wire and gas mix provides excellent results.

“I spent years learning to make the perfect TIG weld on stainless,” shared one of our customers who fabricates custom motorcycle exhausts. “The secret is cleanliness – you simply can’t overstate how important proper cleaning is before welding.”

For stainless steel, we recommend using ER309 or ER310 filler rod with TIG. If you’re MIG welding, ER70S-3 wire with 75% Argon/25% CO2 shielding gas works well for most applications.

Here’s a pro tip from our fabrication experts: when welding stainless steel components, purge the inside of the tube with argon gas. This prevents oxidation on the backside of the weld, resulting in stronger connections and better corrosion resistance – especially important for performance and marine applications.

Joint Preparation and Fit-Up

The difference between an amateur and professional exhaust system often comes down to joint preparation. Cuts should be square and clean, with edges carefully deburred for tight fit-up. Many of our clients invest in specialized tube notchers that create perfect joints with minimal gaps.

For the best results, we recommend tack-welding components in position and checking alignment before completing the full welds. This approach allows for fine-tuning before everything is permanently joined. A simple jig can help maintain perfect alignment during this process.

“Measure twice, tack once, then measure again before final welding,” is advice we frequently share with fabricators new to exhaust work. This methodical approach prevents the disappointment of a beautiful system that doesn’t quite fit.

Testing and Finishing

Once your system is welded together, don’t skip the crucial leak test. A common method is pressurizing the system with compressed air and using soapy water to detect any escaping bubbles. Finding and fixing leaks at this stage is infinitely easier than dealing with them after installation.

Proper mounting is another critical factor in system longevity. High-quality hangers and clamps that accommodate thermal expansion will prevent stress cracks and premature failures. Exhaust systems can expand significantly when hot – sometimes up to half an inch or more in longer systems.

Many custom systems receive additional finishing treatments:

Polishing transforms stainless steel exhausts into mirror-finish showpieces. It’s labor-intensive but delivers best visual impact.

Ceramic coating provides superior heat management and corrosion resistance. These specialized coatings can reduce underhood temperatures and protect surrounding components from heat damage.

Aluminized or high-temperature paint offers a more budget-friendly protection option that still looks professional and prevents rust.

Cost Considerations

Building a custom exhaust system represents a significant investment, with costs varying widely based on materials, complexity, and finishing. While DIY approaches might seem economical at first glance, professional equipment like Hines Bending machines often delivers better value through:

- Significantly reduced material waste

- Dramatically faster production time

- Superior results that command premium pricing

- Elimination of outsourcing costs for complex bends

The initial investment in quality equipment pays dividends through improved efficiency and capability. As one shop owner told us after purchasing a Hines bender: “We went from turning away custom exhaust jobs to actively seeking them out. The machine paid for itself within the first year.”

At Hines Bending Systems, we understand that joining and finishing are just as critical as the bending process itself. That’s why we work closely with our clients to ensure they have the right equipment and knowledge to create complete exhaust systems that perform flawlessly and look exceptional.

Used exhaust pipe bender for sale

Frequently Asked Questions about Exhaust Pipe Bending

What bend radius is best for performance street cars?

Finding that sweet spot for bend radius can make all the difference in your exhaust system’s performance. For most performance street applications, you’ll want a centerline radius (CLR) that’s about 2-3 times the tube diameter. This gives you that perfect balance between smooth flow and practical packaging.

Let me put that in real terms – if you’re working with a 2.5″ exhaust pipe, aim for a 5-7.5″ CLR for your bends. It’s that simple formula that delivers results.

Too tight of a radius (anything approaching 1:1 where the CLR equals the tube diameter) can create unwanted backpressure as those exhaust gases struggle to steer the sharp turn. On the flip side, going too large with your radius might leave you playing an automotive version of Tetris, trying to fit everything in your vehicle’s limited undercarriage space.

At Hines Bending Systems, our precision mandrel benders excel at creating those ideal bends while maintaining perfect flow characteristics – even at tighter radii where lesser equipment would cause restriction. Our engineering team works hand-in-hand with clients to determine the perfect bend radius for each unique application, taking into account everything from available space to desired performance characteristics and even aesthetic preferences.

Can I bend thin-wall stainless at home without collapsing it?

The short answer? Yes, it’s possible – but it’s a bit like trying to fold an origami crane while wearing oven mitts.

Thin-wall stainless steel tubing (we’re talking 1.2mm-1.6mm/.047″-.062″) is notoriously finicky to bend without professional equipment. The sand-filling method is your best DIY approach, but it demands significant patience and skill to achieve anything close to professional results.

The secret to sand bending success lies in using absolutely bone-dry sand packed extremely tightly inside the tube. You’ll need to heat the tube to a dull red color – not bright red, which is a one-way ticket to ruined material. The bending needs to happen gradually, working small sections at a time with careful attention to heat distribution.

“Sequentially heating and bending 1-2″ sections yields smoother curves than heating a long stretch at once,” as one experienced fabricator puts it. And don’t forget to re-pack that sand between bends to maintain consistent internal support throughout the process.

That said, I’ve got to be honest with you – for consistent, professional-quality results that won’t have you pulling your hair out, there’s simply no substitute for proper mandrel bending equipment like the systems we manufacture at Hines Bending Systems. Our machines take all the guesswork out of the equation and deliver perfect, repeatable bends every single time.

How does exhaust pipe bending change the sound of my vehicle?

The bends in your exhaust system are like the curves in a musical instrument – they fundamentally shape the sound that comes out. The geometry of your exhaust bends has a remarkable impact on both the tone quality and performance of your vehicle.

Bend radius plays a major role in sound production. Sharper bends with smaller radii tend to create more backpressure and produce a deeper, sometimes throatier tone. Smoother, larger-radius bends promote better flow and often deliver a higher, crisper note that many performance enthusiasts prefer.

Even more important is the consistency of the pipe’s internal diameter through those bends. This is where mandrel bending truly shines. A properly mandrel-bent system maintains that crucial consistent cross-section, allowing for more predictable and often more pleasing sound characteristics. In contrast, crushed or wrinkled bends from inferior bending methods create turbulence that can produce unwanted raspy or droning sounds – the automotive equivalent of a sore throat.

At Hines Bending Systems, our precision bending equipment gives fabricators complete control over these geometric factors. This allows them to effectively “tune” the exhaust note to achieve exactly what the customer wants. Whether you’re after an aggressive, race-inspired growl or a refined, subtle purr, the quality of those bends plays the starring role in hitting that perfect note.

Conclusion

Throughout this guide to exhaust pipe bending, we’ve explored the essential techniques, equipment, and considerations that transform ordinary metal tubing into exceptional exhaust systems. From the precision of mandrel bending to the artistry of custom fabrication, creating quality exhaust systems requires both technical knowledge and hands-on skill.

At Hines Bending Systems, we take pride in our position as the industry leader in bending technology. Our solutions meet the exacting standards of clients ranging from small custom shops to NASA itself. This isn’t just marketing talk – our commitment to innovation and quality has established us as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders.

The difference between an average exhaust system and one that truly performs comes down to the quality of its bends. When executed properly, these bends maintain optimal flow characteristics, ensure long-term durability, and contribute significantly to both performance and sound quality. With our state-of-the-art equipment, fabricators consistently achieve these results without the frustration of trial and error.

“The right equipment makes all the difference,” as one of our long-time customers puts it. “What used to take us hours now takes minutes, and the quality is night and day.”

Whether you’re running a high-volume production facility or a specialized custom shop, we have the expertise and equipment to lift your exhaust fabrication capabilities. Our team works closely with each client to provide bending solutions custom to their specific needs – we don’t believe in one-size-fits-all approaches when precision matters.

As automotive technology evolves with increasingly stringent performance and emissions requirements, the importance of precision exhaust fabrication only grows. By partnering with Hines Bending Systems, you gain access not just to superior equipment but to best expertise and support that keeps you ahead of industry developments.

The right bend isn’t just about aesthetics – it’s about optimizing performance, ensuring reliability, and delivering the perfect sound. Our technology makes these goals achievable, repeatable, and profitable for fabricators at every level of the industry.

For more information about our comprehensive range of exhaust pipe benders and custom solutions, visit our website or contact our team directly. We’re here to help you achieve the highest standards in your exhaust fabrication operations.