The Evolution of Tube Bending Technology

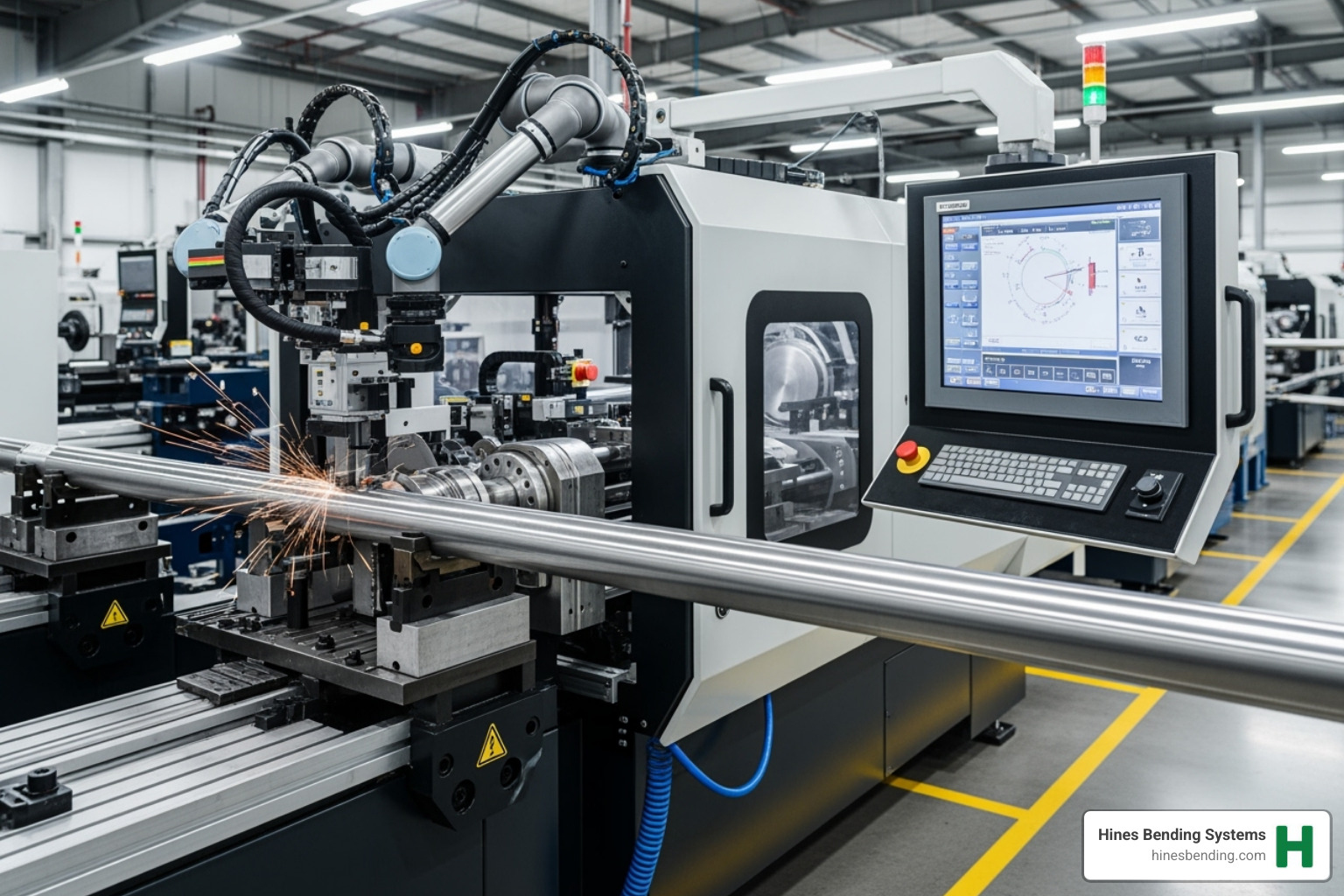

A CNC electric tube bender is a computer-controlled machine that uses all-electric servo motors to bend tubes and pipes with exceptional precision. These advanced systems have revolutionized manufacturing by combining automated programming with powerful electric drives to create complex bent parts consistently and efficiently. (For a concise historical overview of earlier bending techniques, see the Tube bending article on Wikipedia.)

Key features of CNC electric tube benders:

- Computer Numerical Control (CNC) for automated, programmable operation

- All-electric servo motors replacing traditional hydraulic systems

- Multi-axis control for complex bending sequences

- Energy savings up to 70% compared to hydraulic systems

- Bend arm repeatability of +/- 0.05 degrees

- Clean, quiet operation with no oil leaks or hydraulic maintenance

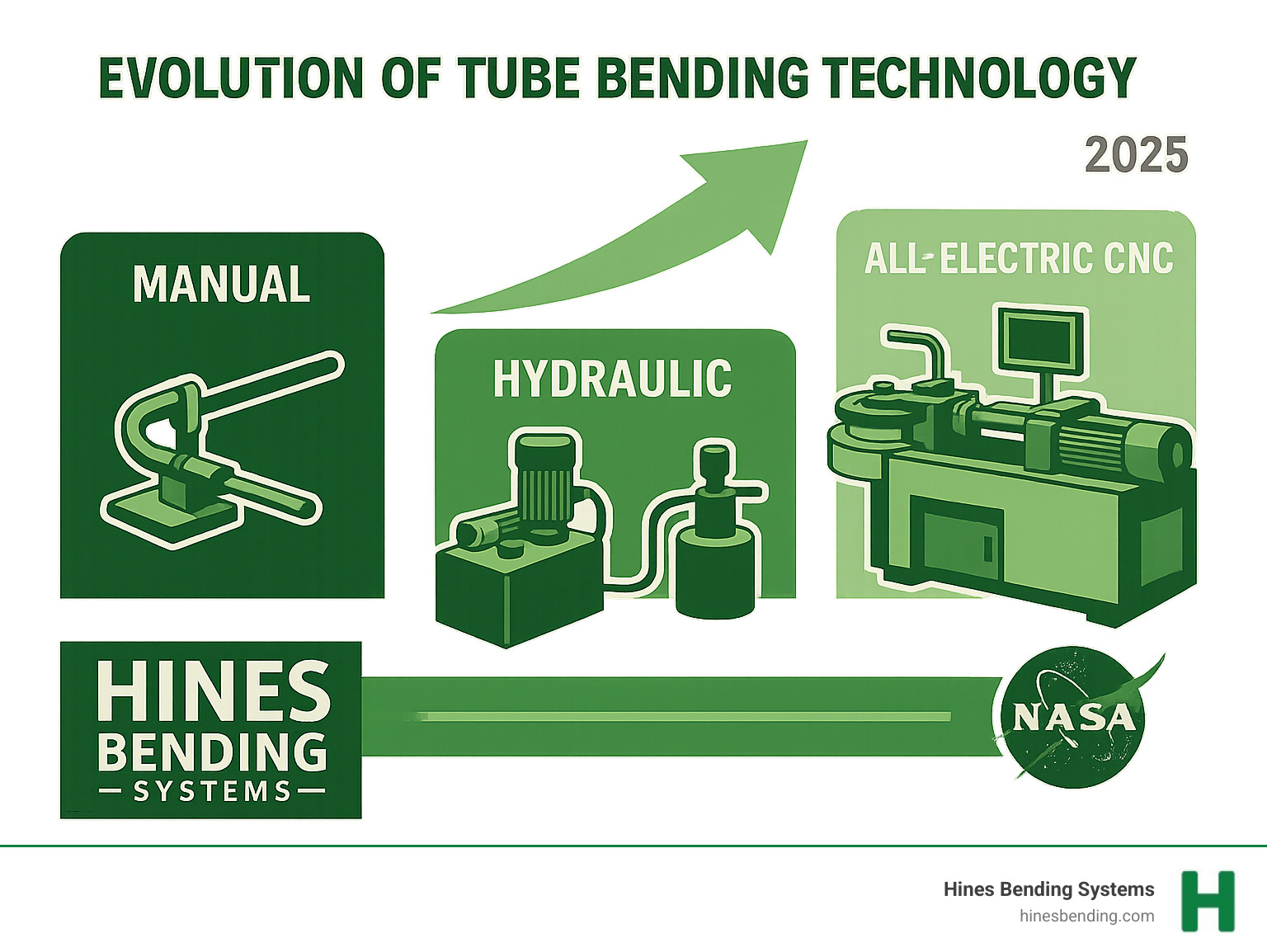

The tube bending industry has evolved dramatically over the past decades. What started as manual bending processes moved to hydraulic systems, and now the cutting-edge technology is all-electric CNC bending. This evolution reflects manufacturing’s constant push for greater precision, efficiency, and reliability.

Modern production demands have made precision bending more critical than ever. Industries like aerospace, automotive, and energy require complex bent parts that meet tight tolerances while maintaining consistent quality across thousands of pieces. Traditional methods simply can’t deliver the speed and accuracy today’s manufacturers need.

Hines Bending Systems stands as the global leader in this technological revolution. As the world’s #1 manufacturer of tube benders, pipe benders, and induction benders, Hines has pioneered many of the innovations that define modern electric bending technology. Their machines serve the most demanding applications – from NASA’s aerospace projects to high-volume automotive production lines.

The company’s expertise spans decades of continuous innovation, with thousands of installations worldwide proving their commitment to delivering the highest quality bending solutions. When manufacturers need custom solutions that can handle complex requirements while maintaining exceptional precision, they turn to Hines’ best experience and engineering capabilities.

Must-know cnc electric tube bender terms:

Understanding the Modern CNC Electric Tube Bender

A modern CNC electric tube bender represents the pinnacle of precision manufacturing technology. Think of it as the marriage between computer intelligence and raw electric power, creating something far more capable than either could achieve alone. Where older machines relied on manual adjustments and messy hydraulic systems, today’s electric benders use sophisticated servo motors that respond instantly and precisely to digital commands.

The “CNC” stands for Computer Numerical Control, which means every movement is programmed and executed by a computer. This digital control works seamlessly with an all-electric power system that uses advanced servo motors to manage each axis of motion. These motors can handle up to 16 moving axes simultaneously in Hines’ most advanced models, orchestrating complex three-dimensional bends that would be nearly impossible with traditional methods.

What sets Hines apart is our integration of cutting-edge digital design capabilities. Our CNC electric tube bender systems include CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) integration, meaning you can design your part digitally and import it directly into our machines. The result? Perfectly bent parts that match your exact specifications, every single time. No guesswork, no costly trial-and-error runs.

When you’re dealing with complex, high-stakes applications where precision isn’t negotiable, partnering with Hines becomes essential. Our decades of experience and thousands of installations worldwide have taught us the nuances that make the difference between good and exceptional results. We’ve earned the trust of organizations like NASA, providing them with the precision bending solutions their critical projects demand. When you choose Hines, you’re not just buying a machine—you’re gaining a partner with an best track record in the most challenging environments.

How a Hines CNC Electric Tube Bender Delivers Best Precision

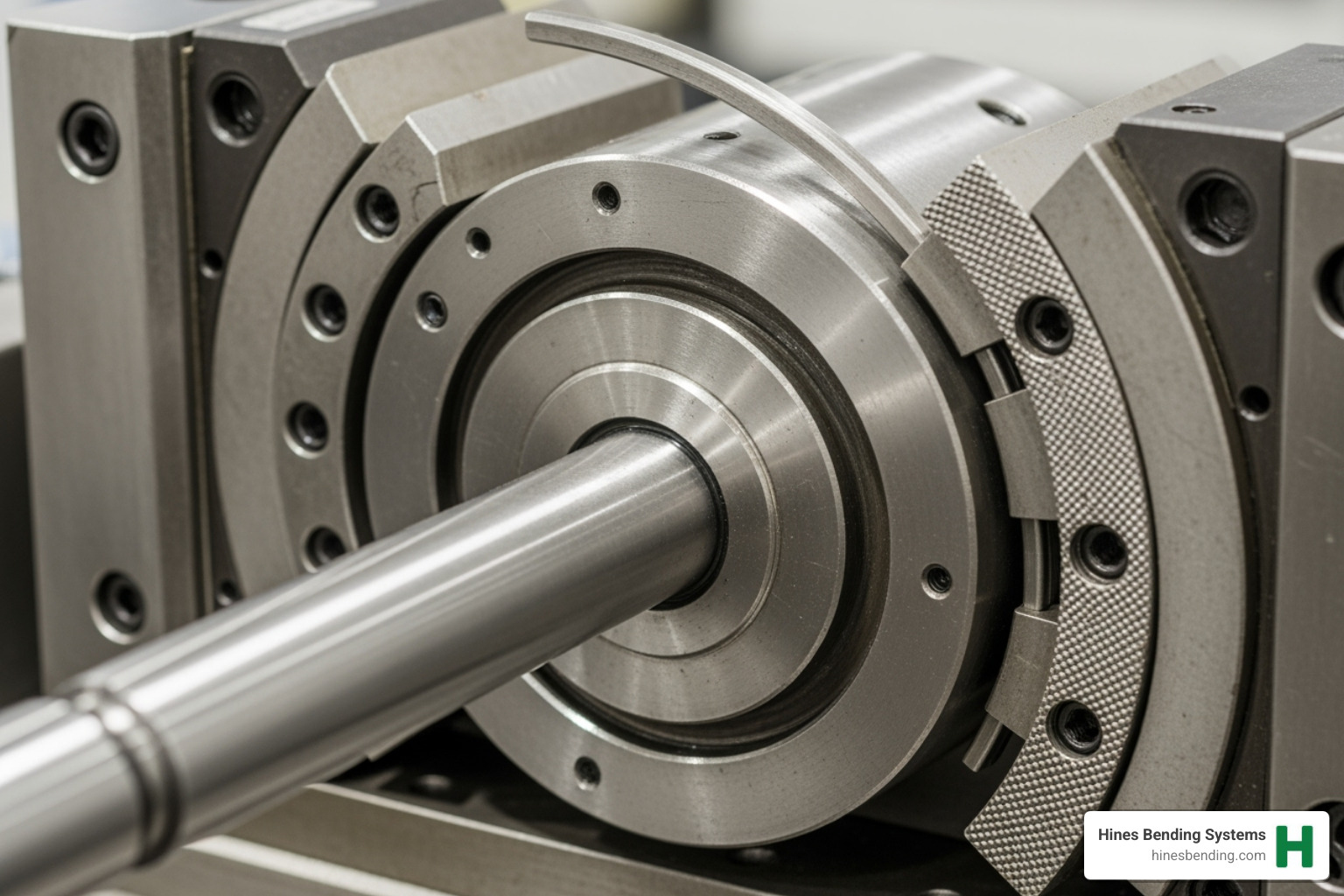

The secret behind Hines’ superior precision lies in our mastery of the rotary draw bending process, improved by advanced servo-electric technology. In this method, the tube gets clamped and drawn around a rotating bend die, with supporting tooling ensuring the tube maintains its perfect shape throughout the entire bend.

Here’s where our advanced servo-electric axes make all the difference. Unlike hydraulic systems that can suffer from pressure fluctuations and response delays, electric servo motors provide immediate, consistent, and highly controllable motion. Each axis—whether it’s feeding the tube, rotating it, or executing the bend—has its own dedicated servo motor, allowing for incredibly fine-tuned adjustments and unparalleled accuracy.

This precise control eliminates the variables that plague traditional bending methods. The result? Consistent results from the first part to the thousandth, with industry-leading tight tolerances that other manufacturers simply can’t match. Our CNC electric tube bender systems achieve bend arm repeatability of an astonishing +/- 0.05 degrees. To put that in perspective, that’s precision so fine it’s barely measurable with standard tools.

This level of repeatability is crucial for high-volume production and for creating complex, multi-bend parts that require exact alignment. Our machines can efficiently create these intricate parts in a single, continuous cycle, minimizing handling time and maximizing your throughput. When every bend must be perfect and every part must be identical, Hines delivers the consistency you need.

For more details on how our precision translates into real manufacturing advantages, explore the Advantages of CNC Tube Bending Machine.

Key Components and Terminology

Understanding the anatomy of a CNC electric tube bender helps you appreciate the intricate coordination of components that creates a perfect bend. Each element plays a crucial role in the precision process:

The mandrel serves as internal support, sliding inside the tube before bending to prevent collapse, wrinkling, or deformation—especially critical for tight radii or thin-walled materials. Working alongside it, the wiper die positions itself on the inside radius of the bend, supporting the tube as it’s drawn around the bend die and preventing wrinkles while maintaining a smooth internal surface.

The clamp die holds the tube firmly against the bend die, preventing any slippage during the bending operation. A secure clamp is vital for maintaining the control and accuracy that Hines machines are known for. On the opposite side, the pressure die applies controlled pressure to the tube, pushing it into the bend die and helping control material flow during the bend to prevent excessive thinning or distortion.

At the heart of the system, the bend die serves as the primary forming tool around which the tube is bent. Its radius determines the final bend radius, and our machines can accommodate various bend dies for different applications and requirements.

The YBC axes represent the three fundamental motions in a CNC electric tube bender: the Y-axis (Feed) controls linear feeding of the tube along its length, determining distances between bends; the B-axis (Rotate) controls tube rotation around its longitudinal axis, dictating the plane of the bend; and the C-axis (Bend) controls the bend arm rotation, determining the angle of each bend.

Perhaps most impressive is our multi-stack tooling capability, which allows a single machine to hold multiple sets of bending tools simultaneously. This means you can produce parts with different bend radii or even different tube diameters without requiring tooling changes, significantly boosting efficiency and versatility in your production runs.

To explore the full range of tube bender configurations that leverage these components, visit Types of CNC Tube Benders.

The Best Advantages of Hines All-Electric Bending Technology

When you’re looking for a CNC electric tube bender that delivers real results, the advantages of Hines all-electric technology become crystal clear. After decades of perfecting our craft and installing more bending systems worldwide than anyone else, we’ve seen how our electric technology transforms manufacturing operations.

Productivity and Speed are where our all-electric systems truly shine. Picture this: you walk up to your machine in the morning, and it’s ready to work instantly. No waiting for hydraulic systems to warm up, no pressure adjustments, just immediate, precise motion. This translates into faster setup and cycle times that keep your production line humming.

But here’s what really sets our CNC electric tube bender apart – our “first part right” capability. Thanks to our precise CNC control and servo-electric drives, you eliminate those costly trial runs that waste material and time. When NASA trusts us with their critical aerospace components, they know every part will meet specifications from the very first piece. That’s the kind of reliability that reduces material waste and keeps your operation profitable.

Energy Efficiency is another game-changer. Our all-electric systems deliver up to 70% energy savings compared to older hydraulic systems. Think about it – hydraulic pumps run constantly, burning energy even when the machine sits idle. Our electric benders only draw power when they’re actually working, resulting in lower power consumption and dramatically reduced operating costs.

The benefits extend beyond your energy bill. You’ll notice the difference immediately – quieter, cleaner operation with no oil leaks. No more messy hydraulic fluid cleanups, no more dealing with the constant noise of hydraulic pumps. Your team will appreciate the cleaner, more pleasant work environment.

Reduced Maintenance and Durability make our all-electric technology a smart long-term investment. With fewer mechanical parts and no hydraulic system upkeep, our machines spend more time producing and less time in maintenance. No hydraulic hoses to leak, no filters to change, no fluid levels to monitor.

We’re proud that many of our all-electric machines have proven machine lifespans of over 30 years. That’s three decades of reliable service, which speaks volumes about the quality and durability that comes from choosing Hines. When you invest in our technology, you’re investing in equipment that will serve your operation for generations.

For a deeper understanding of how our advanced control systems compare to older technologies, explore NC vs CNC Bending Machines.

| Metric | Hines All-Electric Benders | Traditional Hydraulic Approaches |

|---|---|---|

| Precision | Exceptional (+/- 0.05º) | Good, but can vary |

| Speed | Fast (Quick setup, cycle) | Slower (Warm-up, less reactive) |

| Energy Use | Very Low (Up to 70% savings) | High (Constant pump draw) |

| Maintenance | Low (No hydraulics) | High (Fluid, seals, filters) |

| Noise | Quiet | Loud (Pump noise) |

| Cleanliness | Very Clean (No oil leaks) | Potential for leaks, mess |

Essential Features to Look for in a High-Performance Machine

When you’re in the market for a CNC electric tube bender, you’re making a significant investment in your manufacturing future. The difference between a good machine and a great one often comes down to the features that enable versatility, precision, and adaptability to your evolving needs.

Multi-Axis and Multi-Stack Capability:

The heart of any high-performance CNC electric tube bender lies in its ability to handle complex geometries with ease. Multi-axis control is what separates basic bending from true precision manufacturing. This sophisticated capability allows your machine to create intricate, three-dimensional bends that would be impossible with simpler equipment.

What makes this particularly powerful is the ability to bend in both left and right-hand directions within the same part, often without ever having to reorient the tube. Imagine the time savings when your machine can complete complex multi-directional bends in a single setup! This is where our Stack Push Benders truly shine, offering the kind of flexibility that keeps your production moving smoothly.

Variable radius bending takes this capability even further. Instead of being limited to fixed radii, your machine can create flowing, organic curves that might otherwise require multiple operations or even welding. This opens up design possibilities that can set your products apart in the marketplace.

Automation and Industry 4.0 Integration:

The manufacturing landscape is rapidly evolving, and your CNC electric tube bender needs to be ready for tomorrow’s factory floor. Robotic loading and unloading capabilities transform your bending operation into a lights-out manufacturing cell, dramatically boosting productivity while reducing labor costs.

But true Industry 4.0 integration goes beyond just automation. Your machine should seamlessly connect with Manufacturing Execution System (MES) software, enabling factory-wide management and real-time data exchange. This connectivity allows your bending operation to communicate with other systems, optimizing production flows and providing the kind of real-time insights that drive continuous improvement.

At Hines, we design our machines to be intelligent partners in your manufacturing process. They don’t just bend tubes; they anticipate maintenance needs, monitor quality in real-time, and manage multiple part references with remarkable ease.

Customization and Tooling:

Here’s where Hines’ decades of experience really make a difference. Every application is unique, and cookie-cutter solutions rarely deliver optimal results. That’s why we specialize in custom machine designs custom specifically to your applications. Whether you’re working with exotic materials, unusual profiles, or have specific footprint requirements, our engineering team can create a solution that fits your needs perfectly.

The right tooling is absolutely critical for achieving perfect bends, and this extends far beyond standard components. Our comprehensive range of Tube and Pipe Bender Accessories includes custom-engineered tools designed for the most challenging projects. When you partner with Hines, you’re not just getting a machine – you’re getting a complete solution backed by the industry’s deepest expertise.

How Advanced Software Improves a Hines CNC Electric Tube Bender

The true magic of a modern CNC electric tube bender happens where sophisticated hardware meets intelligent software. This is where complex operations transform into streamlined, intuitive processes that even new operators can master quickly.

Our machines feature highly user-friendly interfaces that make programming and operation accessible without extensive training. A perfect example is our industry-leading BendPro G2V2 software, which has earned recognition throughout the industry for its intuitive design and powerful capabilities.

3D part simulation and collision detection represent perhaps the most valuable software features for any serious production environment. Before your machine makes a single bend, our software creates a complete 3D simulation of the entire bending process. You can visualize the final part, identify potential collisions with the machine or tooling, and optimize the bending sequence virtually. This capability alone saves tremendous amounts of material and time by eliminating costly trial-and-error runs.

Direct CAD file import eliminates the tedious and error-prone process of manual data entry. Your design team can create parts digitally, and our software seamlessly translates those files into precise bending instructions. This direct connection between design and production ensures that your digital blueprint becomes a physical part with remarkable accuracy.

Real-time production monitoring and diagnostics provide the kind of insight that transforms reactive maintenance into proactive optimization. Our software continuously tracks production rates, monitors machine performance, and provides diagnostic information that helps you identify and address issues before they become problems. This level of intelligence allows for continuous improvement and ensures your CNC electric tube bender operates at peak efficiency.

This powerful software suite is what truly lifts a Hines CNC electric tube bender from a simple machine into an intelligent, highly productive manufacturing asset that grows with your business.

Industries and Applications Benefiting from Hines Electric Bending

When you look at the incredible range of products that rely on precision-bent tubes and pipes, it becomes clear just how essential a CNC electric tube bender has become to modern manufacturing. From the rockets that reach for the stars to the cars we drive every day, Hines electric bending technology is quietly working behind the scenes, creating the components that make our world function.

Aerospace and Defense represents perhaps the most demanding application for our technology. When NASA needs precision bending for their spacecraft, they turn to Hines because there’s simply no room for error in space exploration. Our CNC electric tube bender machines excel at forming hydraulic lines, ducting, and structural components from exotic alloys like titanium and Inconel. The ability to achieve incredibly tight tolerances while maintaining the integrity of these specialized materials is what sets Hines apart in this critical industry.

The Automotive and Transportation sector showcases the versatility of our electric bending technology in high-volume production environments. Whether it’s exhaust systems that need to fit perfectly under a car’s chassis, roll cages that protect race car drivers, or structural components for heavy-duty trucks, our machines deliver the speed and consistency that automotive manufacturers demand. The “first part right” capability of our electric systems means less waste and faster production lines, which directly translates to cost savings for manufacturers.

In the rapidly evolving HVAC and Energy industry, precision is everything. Our machines create the intricate coils for heat pumps, boiler tubes for power generation, and the complex piping systems that keep buildings comfortable and energy-efficient. The growing demand for renewable energy solutions has made our precision bending machines increasingly important, as manufacturers need equipment that can handle the specialized requirements of modern energy systems.

But the applications for a CNC electric tube bender extend far beyond these major industries. In medical equipment, our machines form the frames for hospital beds and diagnostic equipment where patient safety depends on structural integrity. Fitness machine manufacturers rely on our precision to create the sturdy frames that support intense workouts. The shipbuilding industry uses our technology for everything from fluid transfer systems to safety railings that must withstand harsh marine environments.

Agriculture has accepted our bending technology for creating robust frames and components for tractors and harvesters that work in demanding field conditions. Even the furniture industry has found that our machines can create neat, flowing designs that combine style with structural strength. Construction equipment manufacturers depend on our ability to form the heavy-duty frames and hydraulic lines that power excavators and cranes on job sites worldwide.

The beauty of working with Hines is that our decades of experience across all these industries means we understand the unique challenges each sector faces. Whether you’re bending thin-walled tubing for medical devices or heavy-wall pipe for industrial applications, our team has the expertise to configure the perfect CNC electric tube bender solution for your specific needs.

Partnering for Success: Hines Service, Support, and Customization

When you’re investing in a CNC electric tube bender, you’re not just buying a machine—you’re choosing a partnership that will impact your manufacturing success for decades to come. At Hines, we understand that the difference between a good investment and a truly transformative one lies in the expertise and support behind the equipment.

The Importance of True Expertise:

What sets Hines apart isn’t just our machines; it’s our best knowledge and experience. As the world’s #1 manufacturer of tube benders, pipe benders, and induction benders, we’ve accumulated decades of real-world expertise across thousands of installations worldwide. This means when you consult with us, you’re getting advice from the industry’s most knowledgeable experts who have literally seen it all.

We don’t just sell CNC electric tube bender machines—we solve bending challenges. Whether you’re a high-tech startup with a unique prototype or a massive organization like NASA with mission-critical requirements, we have the experience to guide you to the perfect solution. Our track record speaks for itself: from aerospace applications requiring exotic materials to high-volume automotive production, we’ve successfully equipped manufacturers across every industry imaginable.

Curious about what makes our partnership approach different? Explore Why Buy a Hines Bender? to find the full scope of advantages that come with choosing the industry leader.

Custom Solutions That Fit Your Exact Needs:

One size never fits all in precision manufacturing. That’s why customization is at the heart of everything we do. We work closely with each client to tailor machines to their specific requirements—whether that means adjusting capacity for larger tube diameters, optimizing for unique materials like titanium, or designing a CNC electric tube bender to fit within challenging facility constraints.

Our engineering team thrives on solving complex problems. Need to bend exotic alloys? We’ll design the perfect tooling. Working with limited floor space? We’ll create a compact solution that doesn’t compromise performance. This commitment to custom solutions ensures your bending system integrates seamlessly with your operation, maximizing both efficiency and output from day one.

Comprehensive Training and Ongoing Support:

Even the most sophisticated CNC electric tube bender is only as effective as the team operating it. That’s why we emphasize comprehensive training as a cornerstone of our service. Our expert technicians provide thorough on-site operator training, ensuring your team is fully proficient and confident with their new equipment. This hands-on approach helps you maximize efficiency immediately, not months down the road.

For detailed information about our training programs and how they can boost your team’s capabilities, visit Tube and Pipe Bender Training.

But our commitment extends far beyond initial installation. We understand that downtime is costly, which is why our rapid service response and comprehensive parts availability are designed to keep your production running smoothly. Our service personnel are strategically located to provide quick assistance, often arriving on-site within 24-48 hours when needed.

Your Strategic Manufacturing Partner:

Hines Bending Systems isn’t just another equipment manufacturer—we’re your strategic partner in achieving manufacturing excellence. Our position as the world’s #1 manufacturer, with the most installations globally, represents decades of proven expertise in creating custom solutions for clients ranging from innovative startups to government agencies like NASA.

When you choose Hines, you’re not just getting a CNC electric tube bender; you’re gaining access to the industry’s deepest knowledge base, most experienced engineering team, and most comprehensive support network. This partnership approach ensures your investment delivers maximum value for years to come.

Conclusion: Investing in the Future of Fabrication

The CNC electric tube bender represents more than just technological advancement—it’s a fundamental shift in how we approach precision manufacturing. Throughout this exploration, we’ve witnessed how these remarkable machines deliver three game-changing benefits: best precision with bend arm repeatability of +/- 0.05 degrees, dramatically improved productivity through faster setup times and “first part right” capability, and exceptional efficiency with up to 70% energy savings compared to traditional systems.

The strategic advantage of all-electric technology extends far beyond these immediate benefits. The clean, quiet operation eliminates hydraulic fluid mess and reduces workplace noise. The minimal maintenance requirements mean more uptime and lower operational costs. Most importantly, the proven machine lifespans of over 30 years ensure your investment pays dividends for decades to come.

Looking ahead, the future of bending is unmistakably automated, integrated, and electric. Industry 4.0 integration, robotic loading systems, and seamless MES software connectivity are no longer optional features—they’re essential capabilities for staying competitive. The manufacturers who accept this electric revolution today will be the ones leading their industries tomorrow.

However, the most sophisticated CNC electric tube bender is only as valuable as the partner behind it. This is where the critical role of a trusted manufacturing partner becomes paramount. At Hines Bending Systems, our decades of expertise and position as the world’s #1 manufacturer with the most installations globally means we don’t just sell machines—we engineer solutions. From high-tech startups to government agencies like NASA, our clients trust us because we understand that achieving production goals requires more than just equipment; it requires partnership.

Our commitment to custom solutions, comprehensive training, and rapid support ensures that your investment in electric bending technology delivers maximum returns. When you choose Hines, you’re not just buying a machine—you’re gaining access to unparalleled expertise and a support network dedicated to your success.

To find the perfect bending solution for your needs, explore our range of CNC Bending Machines.