Understanding Round Tube Bender Technology

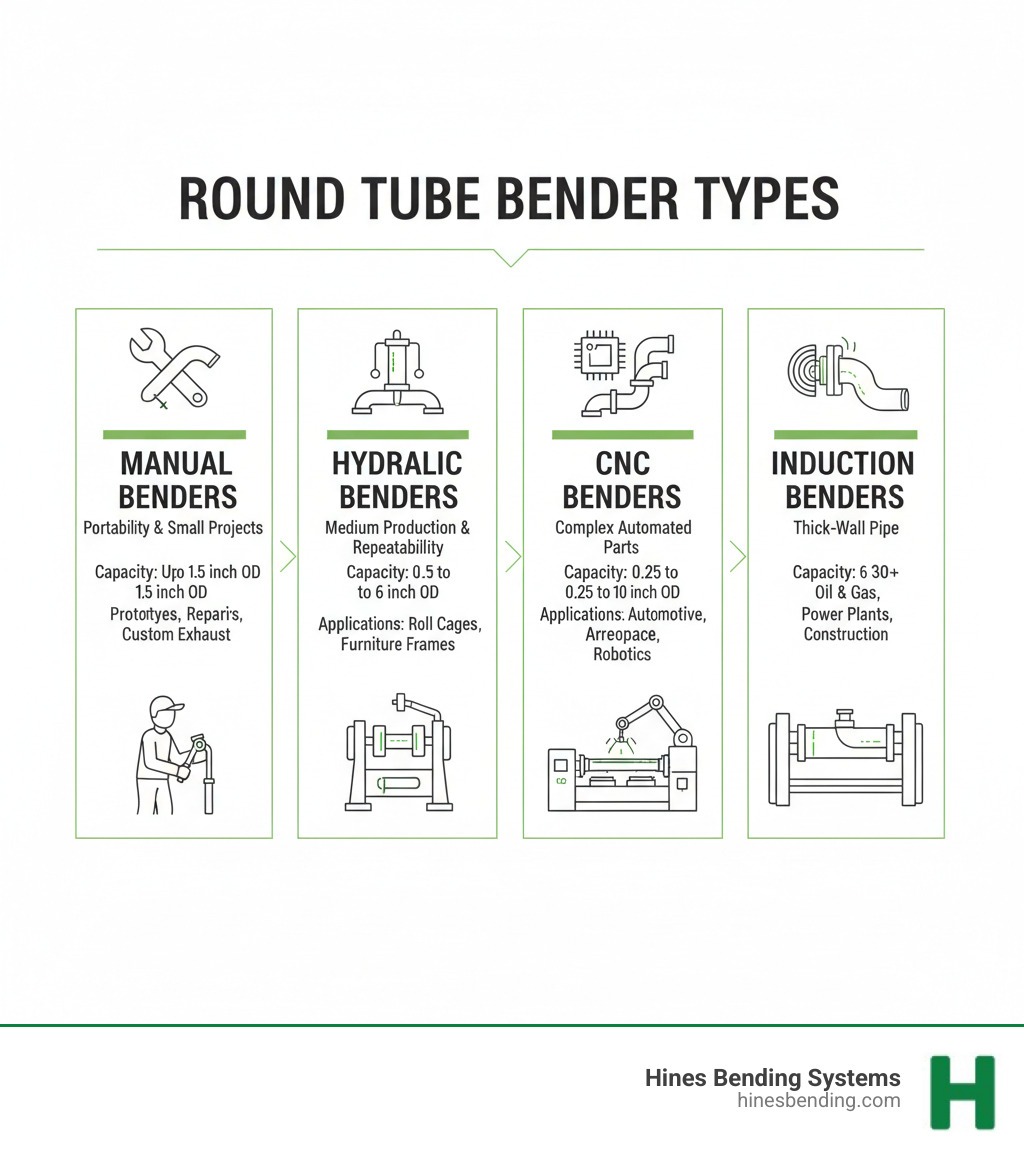

A round tube bender is a specialized machine that forms metal tubing into precise curves and angles without causing defects like wrinkling or collapse. From fabricating exhaust systems to building roll cages, selecting the right bending technology is critical. The main types include manual benders for small projects, hydraulic benders for production runs, CNC benders for complex automated parts, and induction benders for large, thick-walled pipe.

As industries from automotive to aerospace demand more complex components, the quality of your bending equipment directly impacts production efficiency and part integrity. A cheaper machine might save money upfront, but it often leads to rejected parts, wasted material, and costly delays. The right bending partner helps you steer these challenges, reducing costs while maintaining exacting quality standards.

This guide explains the different types of round tube benders and the features that separate industrial-grade equipment from consumer tools. More importantly, it shows why partnering with an experienced manufacturer like Hines Bending Systems—the #1 worldwide manufacturer of tube, pipe, and induction benders—is the key to success. With global installations and clients like NASA, Hines Bending Systems provides custom solutions backed by decades of unparalleled expertise. We don’t just sell a machine; we become a partner dedicated to your exact requirements.

Why Precision Matters: The Science Behind a Perfect Bend

At Hines Bending Systems, we know that bending is a precise science where the strength and integrity of your final product depend on the accuracy of each bend. That’s why we build decades of expertise into every machine to deliver the consistent, high-quality results your operation demands.

Understanding Bending Challenges

Successfully bending tube requires mastering several key factors:

- Material Properties: Every metal behaves differently. Our team has deep expertise in bending a wide range of materials, from versatile steel and lightweight aluminum to high-strength titanium and chromoly (4130N, DOM tubing) for performance applications. We ensure the right power and technique are used to maintain material integrity.

- Springback and Wrinkling: Materials naturally try to spring back to their original shape, which can throw off bend angles and cause wrinkling, especially in thin-walled tubing. Our advanced benders are engineered to predict and compensate for springback, while our expert guidance helps you select the right tooling and process to prevent wrinkles.

- Wall Thickness and CLR: The tube’s wall thickness dictates the force and tooling required, while the Center Line Radius (CLR) defines the bend’s geometry. Our round tube bender machines provide precise control over these variables, ensuring your parts fit and function perfectly, whether you’re working with delicate thin-wall tubes or heavy-duty materials.

Accuracy, Quality, and Expert Consultation

Accuracy is everything. Our CNC benders offer repeatability down to an incredible ± 0.05 mm, a level of precision trusted by clients like NASA for their most critical applications. This commitment to quality is built into our design philosophy, resulting in less scrap and higher productivity for you.

Choosing the right round tube bender is a major investment. With decades of experience and the most installations worldwide, Hines Bending Systems offers unparalleled expertise. We work closely with you to understand your unique needs and recommend the perfect custom solution. Nobody in the industry has more experience, making us your ultimate partner for optimal bending solutions.

More info about industry terms

Learn about our customer-first promise

Key Features to Consider When Choosing a Round Tube Bender

Choosing the right round tube bender is an investment in your productivity and part quality. At Hines Bending Systems, we build machines that stand the test of time, focusing on precision, quality, and efficiency. Here are the key features to consider.

Bending Capacity, Power, and Control

- Bending Capacity: A machine’s capacity defines the range of tube diameters and wall thicknesses it can handle. Hines benders are versatile, managing everything from 4 mm tubing for aerospace parts to 220 mm pipe for industrial applications, with wall thicknesses from 0.4 mm to 10 mm.

- Power Source: The power source affects strength and speed. Manual benders offer hands-on control for small projects. Hydraulic power provides more force for medium production runs. For ultimate precision and speed, electric servo-motors in our advanced CNC benders deliver superior accuracy and energy efficiency.

- Control Systems: The control system determines automation and precision. We offer everything from straightforward manual controls to programmable NC controls for repeatability. Our advanced CNC controls, like the BendPro G2, provide the highest level of automation for creating complex parts with extreme accuracy, making them ideal for high-volume manufacturing. Discover our CNC benders.

Tooling, Dies, and Manufacturer Expertise

- Tooling and Dies: The tooling is the heart of the bender. Hines uses premium, US-made materials like aircraft-grade 6061-T6 aluminum and P&O steel for our dies and tools. Unlike cheaper alternatives, our durable tooling withstands tough materials like chromoly and ensures a perfect bend every time. Our superior follow bars also prevent tube collapse, maintaining its shape. Explore bender accessories

- Manufacturer Expertise: The manufacturer’s reputation is critical. Hines Bending Systems is the #1 worldwide manufacturer of tube, pipe, and induction benders, with the most installations across the globe. Our work with demanding clients like NASA proves our commitment to quality and precision. When you choose Hines, you gain an industry leader who provides optimal, custom bending solutions custom to your needs, whether your workshop is in Fort Myers or Jacksonville. Why choose an expert manufacturer

An Overview of Hines Round Tube Bender Technologies

At Hines Bending Systems, we offer a wide range of top-tier bending solutions, each crafted to meet unique industry needs. As the #1 worldwide manufacturer, our commitment to quality and innovation ensures you get the best, whether you need a simple manual tool or an advanced CNC machine.

- Manual Benders: Ideal for smaller projects, prototypes, and portable field use, our manual benders like the popular bench top bender offer precise, hands-on control and are a cost-effective choice for low-volume work.

- Hydraulic & NC Benders: For medium production runs requiring more power and repeatability, our hydraulic and NC benders are the perfect step up. They deliver consistent, accurate bends and feature programmable controls for improved efficiency.

- CNC Benders: For the highest precision and automation, our CNC benders are in a class of their own. They create complex, multi-bend parts with incredible accuracy (± 0.05 mm), reducing labor costs and maximizing output for high-volume manufacturing.

- Induction Benders: Representing the pinnacle of bending technology, our induction benders are the best solution for large-diameter pipe and thick-walled materials. This advanced process preserves material integrity and is ideal for demanding projects in shipbuilding and power generation.

Choosing the Right Solution

Deciding between a manual and a hydraulic round tube bender depends on your application. Manual benders are great for custom work and small shops, relying on operator strength. Hydraulic benders use powered rams for less effort, greater speed, and superior consistency, making them ideal for production settings. While manual benders have a lower upfront cost, hydraulic machines offer a faster return on investment through increased capacity and efficiency.

At Hines Bending Systems, we don’t just sell machines; we provide perfect custom solutions. Our experts work with you to understand your needs, materials, and budget. With our unparalleled worldwide experience, we guide you to the round tube bender that will optimize your operations, from a small shop in Cape Coral to a large facility in West Palm Beach.

Common Applications and Industry-Specific Solutions

A round tube bender is an essential tool across countless industries. At Hines Bending Systems, we offer custom bending solutions for everyone, from local Florida workshops to global leaders like NASA.

Automotive & Racing

In the automotive world, a round tube bender is critical for creating high-performance exhaust systems, strong roll cages, and custom chassis. Our benders are designed to handle tough materials like chromoly and DOM tubing, ensuring top-notch safety and performance for everything from street rods to race cars.

Aerospace & Defense

In aerospace and defense, precision is non-negotiable. There is no room for error when bending fuel lines, hydraulic systems, or structural components. We are incredibly proud that Hines Bending Systems supplies machines to NASA, a testament to our expertise and credibility. Our round tube benders meet the strictest industry standards for mission-critical applications. How we work with NASA.

General Fabrication & Construction

A round tube bender is a game-changer for creating strong, durable, and aesthetically pleasing structures. Our machines are used to produce custom-bent handrails, unique tubular furniture, and other architectural details that bring visions to life in cities like Miami and Orlando.

Shipbuilding & Heavy Industry

Hines Bending provides powerful solutions for shipbuilding and other heavy industries. Our machines, including heavy-duty models like the 200 CNC bender, bend boiler tubes and hydraulic lines for harsh marine environments. Our specialized induction benders are perfect for the massive pipes found in heavy manufacturing. For materials, you can Find the right steel for your project.

Achieving Flawless Bends: Best Practices and Maintenance

A top-quality round tube bender is the first step to perfect bends, but best practices and maintenance are what guarantee consistency. At Hines Bending Systems, we provide the knowledge and support to help you get the most from your investment.

Proper Machine Setup and Software

Proper setup is the foundation of a flawless bend. This includes correct die installation, setting the right clamping pressure to prevent slippage or deformation, and precise mandrel positioning to support the tube and prevent wrinkles. Our team provides comprehensive guidance on all setup elements.

Modern bending is improved by powerful software. Our CNC benders integrate with tools like our BendPro G2 CNC Control, which offers intuitive programming and 3D simulation. This allows you to test bend sequences virtually, optimizing the process and eliminating errors before any material is wasted.

Maintenance and Training

Even the best round tube bender needs regular care. Simple but critical tasks include checking hydraulic fluid, lubricating moving parts to reduce friction, and performing periodic die inspections to catch wear before it affects part quality. For a cost-effective way to expand, consider our inspected used equipment.

The most advanced machine is only as good as its operator. That’s why we are passionate about professional training. A well-trained operator works faster, reduces scrap, improves safety, and produces higher-quality parts. Our tube and pipe bender training programs share the expertise we’ve gained as the #1 worldwide manufacturer, giving your team access to the best industry knowledge and support.

Partnering with Hines Bending Systems for Your Bending Needs

As we’ve explored, selecting a round tube bender is a critical investment. Precision is everything, the right technology prevents costly errors, and the expertise behind the equipment matters just as much as the machine itself. This is about choosing a partner who understands your challenges and is committed to your success.

This is where Hines Bending Systems stands apart. As the #1 worldwide manufacturer of tube, pipe, and induction benders, we offer more expertise and proven solutions than anyone in the industry. Our machines define industry standards, which is why demanding clients like NASA and Fortune 500 companies turn to us for their most critical applications.

We don’t believe in one-size-fits-all solutions. We work closely with you to understand your unique materials, production volume, and quality requirements. Our goal is to deliver an optimal, custom-designed solution that is precisely right for your operation. Our commitment extends beyond the sale with comprehensive training, ongoing support, and continuous innovation to keep you ahead of industry demands.

Whether you run a small fabrication shop or a major industrial facility, our team brings the best expertise to every project. With Hines, you get more than a machine—you get a complete bending solution that drives your success.

Ready to transform your bending operations? For the highest quality bending solutions customized to your exact needs, explore our complete line of tube and pipe benders.