Quick Answer: Methods for Bending Exhaust Pipes

Learning how to bend pipes for exhaust correctly requires precision equipment and expertise to prevent kinks that restrict airflow and hurt performance. While DIY methods exist, they cannot match the quality of professional-grade bending machines.

Professional Method (Recommended):

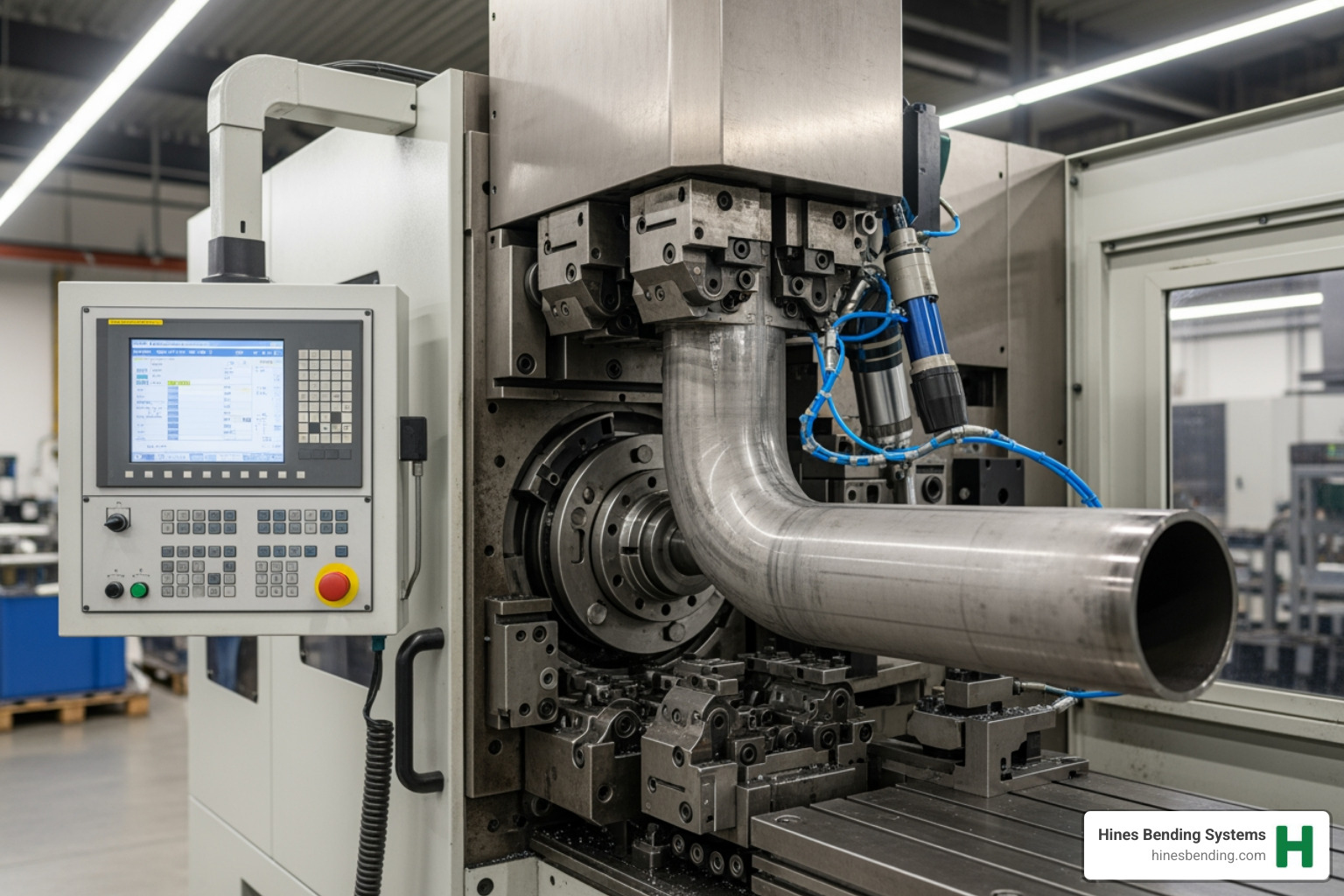

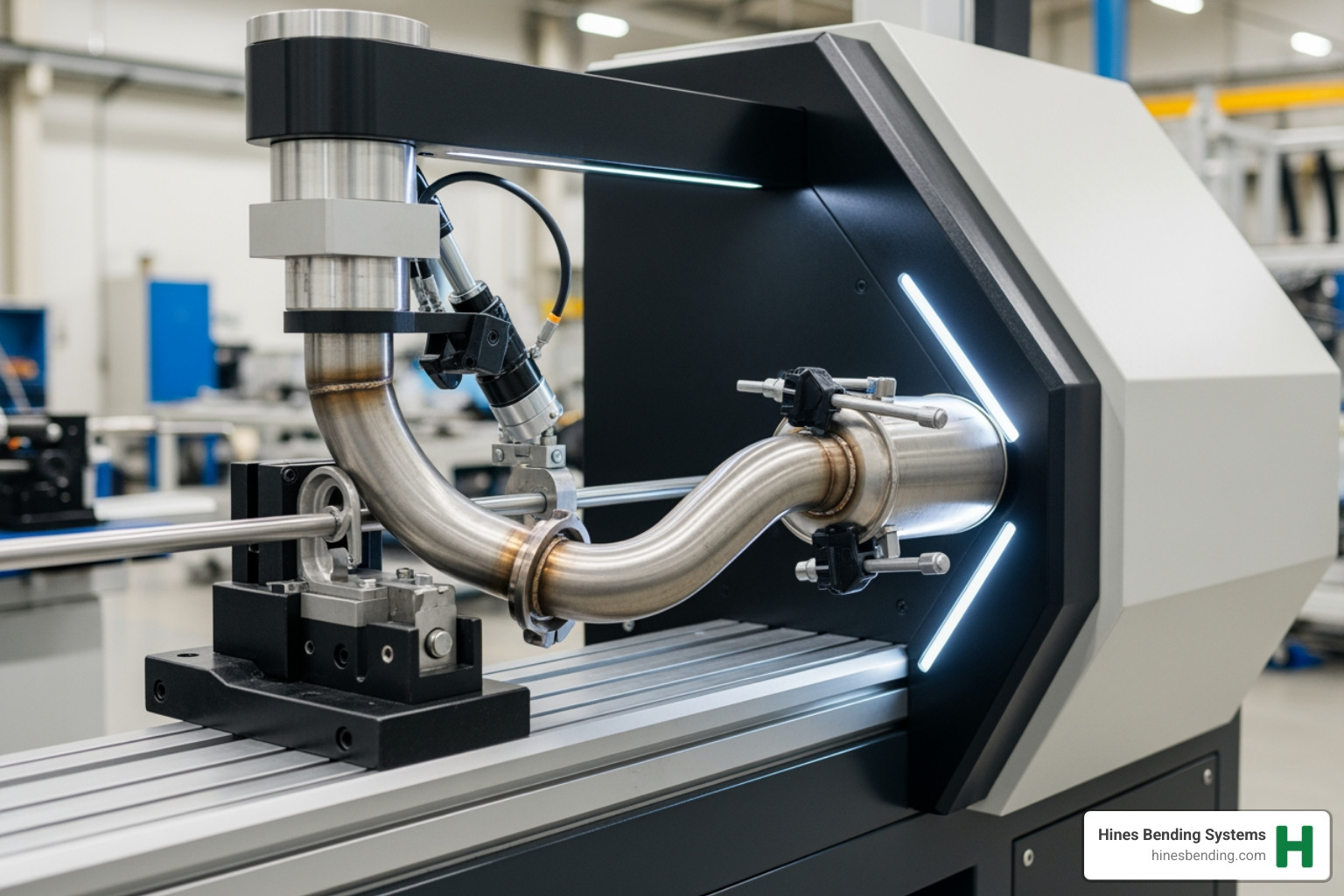

- Mandrel Bending: This technique uses internal support (a mandrel) to maintain the pipe’s full diameter through the bend. It requires specialized CNC equipment and delivers smooth, restriction-free bends for optimal exhaust flow and repeatable precision.

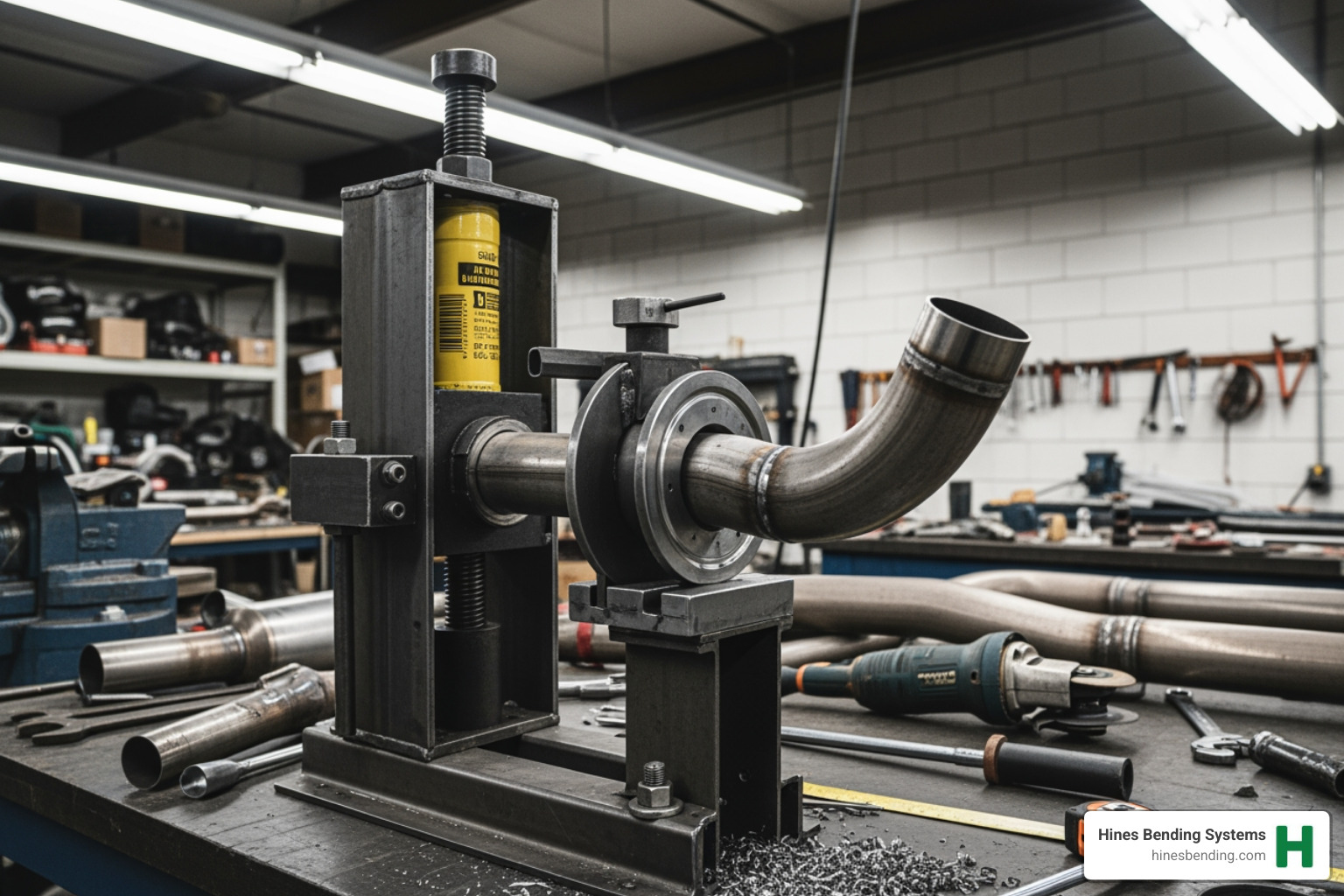

DIY Methods (Not Recommended):

- Sand Filling/Torch Bending: These methods involve heating the pipe and bending it manually. They frequently result in collapsed walls, kinks, and irregular bends that restrict exhaust flow and reduce engine performance.

A well-bent exhaust pipe is critical for vehicle performance, efficiency, and sound. It allows for smooth airflow, reducing backpressure and maximizing horsepower. In contrast, a poorly bent pipe with kinks forces your engine to work harder, decreasing performance and risking damage. As one experienced fabricator noted, “Nothing beats a guy that has been doing it for years behind a professional hydraulic bending machine.”

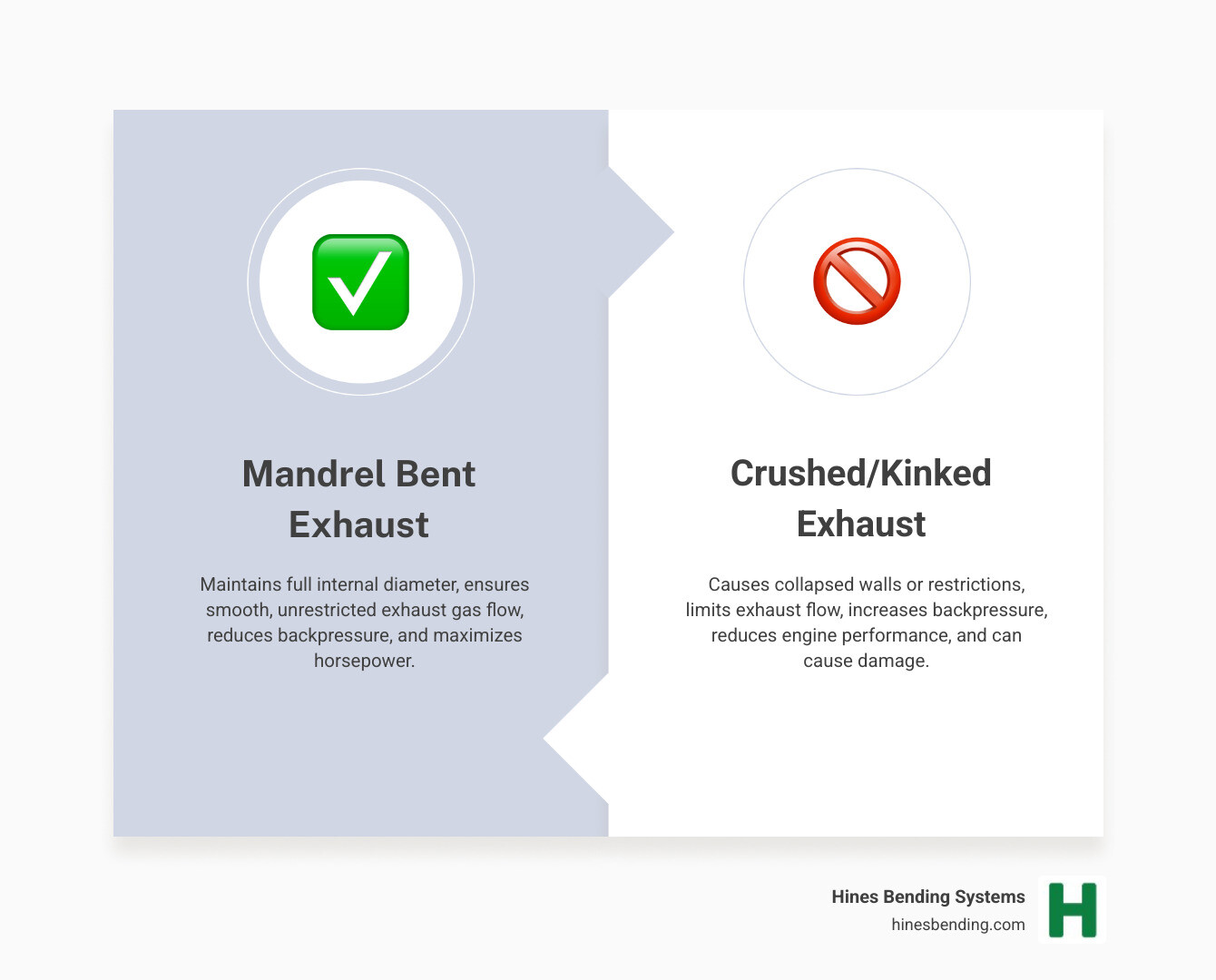

The difference between an amateur attempt and a professional result is significant. A mandrel bend maintains the pipe’s full internal diameter, while crush bends or collapsed sections create power-robbing restrictions. For manufacturers and serious fabricators, achieving flawless results comes down to superior equipment and expertise. This guide explores why professional-grade equipment is essential and how industry leaders achieve perfect bends every time.

Related content about how to bend pipes for exhaust:

- manual exhaust pipe bender

- s bend exhaust pipe

- exhaust pipe bending machine for sale

Why Proper Exhaust Bending is Crucial for Performance

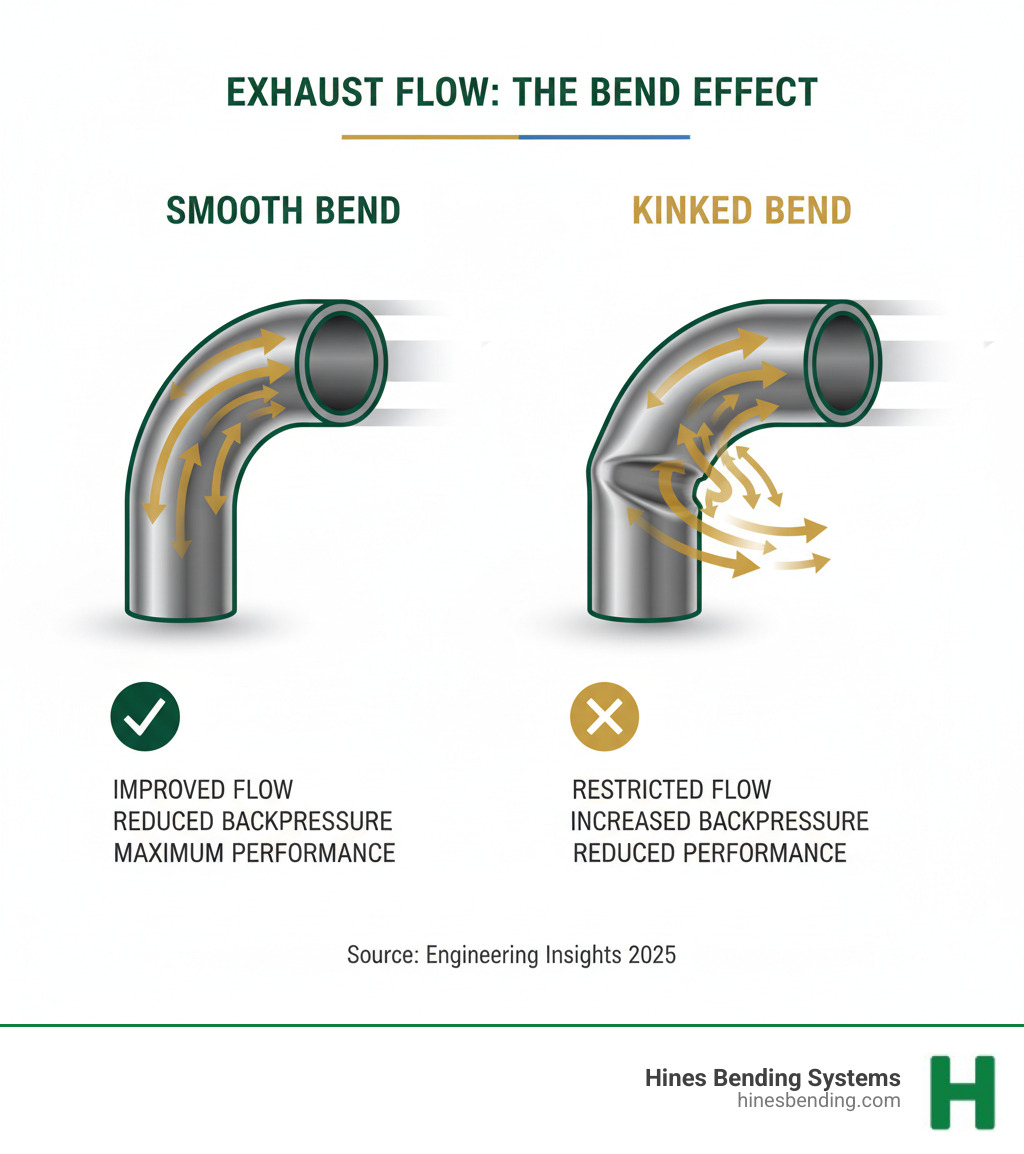

Think of your engine as an athlete needing clear airways to perform at its best. Similarly, your engine needs an unobstructed path for exhaust gases to escape. This is why knowing how to bend pipes for exhaust systems correctly is critical to vehicle performance.

When exhaust pipes are bent with precision—maintaining their full internal diameter—exhaust gases flow smoothly. This reduces backpressure, allowing your engine to breathe easier. The result is improved horsepower, better fuel efficiency, and a deep, satisfying exhaust note.

Conversely, a poorly bent pipe with kinks or collapsed sections creates significant backpressure. Your engine must work harder to push gases out, which robs power, wastes fuel, and can even cause long-term damage. It’s like trying to run a marathon while breathing through a pinched straw—your engine simply can’t perform at its peak.

The difference between a professional bend and an amateur attempt is measurable. Industry testing shows that even minor restrictions in exhaust flow can cause a noticeable loss in horsepower. Poorly bent pipes can also develop stress cracks and fail prematurely. Beyond performance, a custom exhaust system with perfectly contoured pipes signals a commitment to quality and craftsmanship.

This is why organizations like NASA and leading automotive manufacturers trust Hines Bending Systems. The precision and expertise required to create flawless exhaust bends demand advanced technology and decades of industry knowledge—exactly what Hines brings to every project.

The Hines Bending Systems Advantage in Exhaust Pipe Bending

When it comes to excellence in how to bend pipes for exhaust systems, one name stands above the rest: Hines Bending Systems. We are the #1 worldwide manufacturer of tube, pipe, and induction benders, a reputation built on decades of expertise, relentless innovation, and an unwavering commitment to delivering custom solutions.

Our machines are trusted by major organizations and government agencies, including NASA. When precision and absolute quality are non-negotiable, the world’s most demanding clients turn to Hines. From our headquarters in Fort Myers, Florida, we serve clients across the state—from Sarasota to Miami and Orlando—and around the globe. Every bending system we deliver is a custom solution designed for your specific requirements.

Why Professional Bending with Hines Matters

The key to a successful exhaust pipe bend is maintaining the pipe’s internal diameter throughout the curve. This is where mandrel bending is essential. A mandrel is an internal support that slides inside the pipe during bending, preventing the walls from collapsing. With Hines bending machines, every bend is a true mandrel bend, ensuring the pipe’s cross-section remains perfectly round. No collapsed sections. No egg-shaped distortions. No restrictions.

The result is superior airflow and genuine performance benefits. Exhaust gases flow smoothly, reducing backpressure and allowing your engine to breathe freely. This translates directly into increased horsepower and torque.

In contrast, DIY methods like sand filling or torch bending are a gamble. Without proper internal support, pipes collapse and kink, strangling exhaust flow. Even less sophisticated “crush bend” machines deform the pipe and create hidden bottlenecks. These compromised bends don’t just reduce performance; they can lead to engine damage and costly do-overs.

Hines ensures flawless results every time through advanced technology and best expertise. Our machines are engineered to deliver precise, consistent bends that maintain full pipe integrity. With more benders installed worldwide than anyone else, our experience shows in every finished piece. When you’re serious about performance, professional-grade equipment from Hines delivers results that DIY methods and inferior machines simply cannot match.

Key Factors for a Perfect Bend

When you’re learning how to bend pipes for exhaust, success depends on a careful balance of material properties, geometry, and machine precision. Getting one element wrong can result in a kinked mess instead of a smooth, performance-enhancing curve.

Key factors include the pipe material, wall thickness, and bend radius (centerline radius, or CLR). Thicker walls handle more stress, while thin-walled pipes require precise support to prevent collapse. Tighter bends save space but demand advanced techniques. Another consideration is the springback effect, where metal tries to return to its original shape. Professional equipment accounts for this automatically, while DIY methods are pure guesswork. The goal is preventing kinks, which are performance killers that restrict airflow.

How Pipe Material Affects the Bending Process

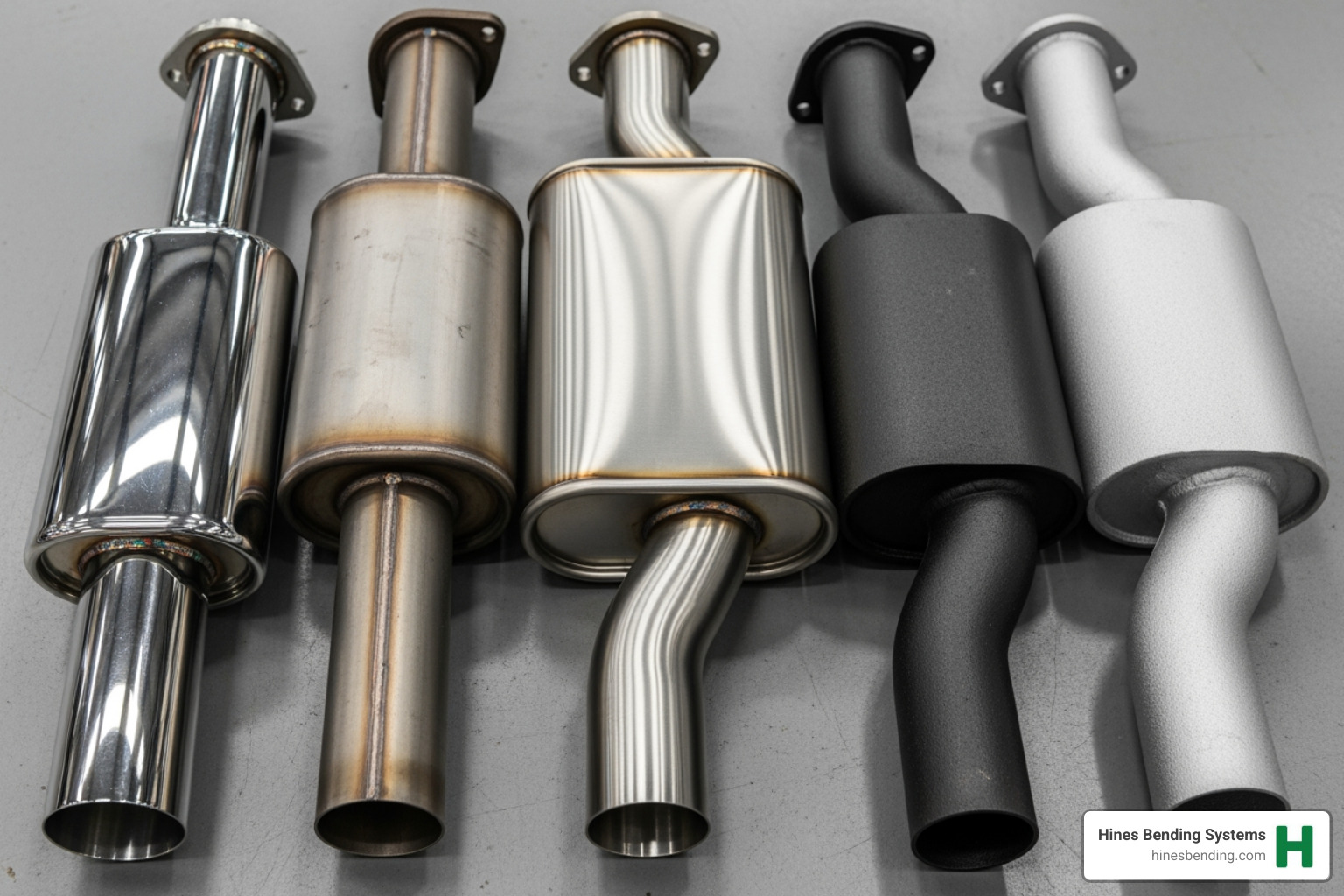

The material you choose dramatically changes the bending process. Mild steel is budget-friendly and easier to bend, but it corrodes quickly, especially in humid climates like Florida’s.

Stainless steel, particularly 304 grade, is the choice for serious fabricators. It offers exceptional corrosion resistance and strength at high temperatures. However, stainless steel is harder and has more springback, requiring specialized expertise. This is why the knowledge at Hines Bending Systems is so valuable. We understand these material nuances, and our machines are configured for each material type. When you work with a company trusted by NASA, you know every detail has been perfected.

Achieving Precision with the Right Tooling

The right tooling is what separates amateur attempts from professional results. Key components include the bend die (shapes the radius), clamp die (holds the pipe), pressure die (controls material flow), wiper die (prevents wrinkles), and the mandrel (provides internal support).

Using mismatched or inferior tooling leads to wrinkles, flattening, and breakage. This is why specialized Exhaust Pipe Bending Machines are essential. At Hines Bending Systems, our innovative technology ensures perfect harmony between machines and tooling. We provide custom bender solutions, matching the right tools to your specific applications. With the most bender installations worldwide, we’ve solved every conceivable challenge, offering precision-engineered systems backed by decades of real-world experience.

How to Bend Pipes for Exhaust: The Hines Professional Approach

While DIY methods might seem appealing, they come with serious limitations. Kinks, collapsed sections, and inconsistent bends compromise performance and often mean starting over. For quality and reliability, the professional approach is the only one that makes sense.

This is why professionals trust Hines Bending Systems. From custom shops in Miami to government agencies like NASA, our Automotive Exhaust Tube Bender lines deliver results that can’t be matched by improvised methods. We address industry demands with continuous innovation, ensuring you work with the best technology available.

Step 1: Design and Measurement

A successful exhaust system begins with careful planning. This involves mapping the exhaust route to ensure clearance around components and heat-sensitive areas. Modern fabrication uses CAD software to create precise 3D models, allowing you to visualize every angle and length before bending expensive material.

Accurate measurement of angles and lengths is critical, as small errors can throw off the entire system. For complex jobs, a mock-up process using templates can verify fitment. At Hines, we offer comprehensive support and training, empowering fabricators with the knowledge to design and measure accurately, avoiding costly mistakes from the start.

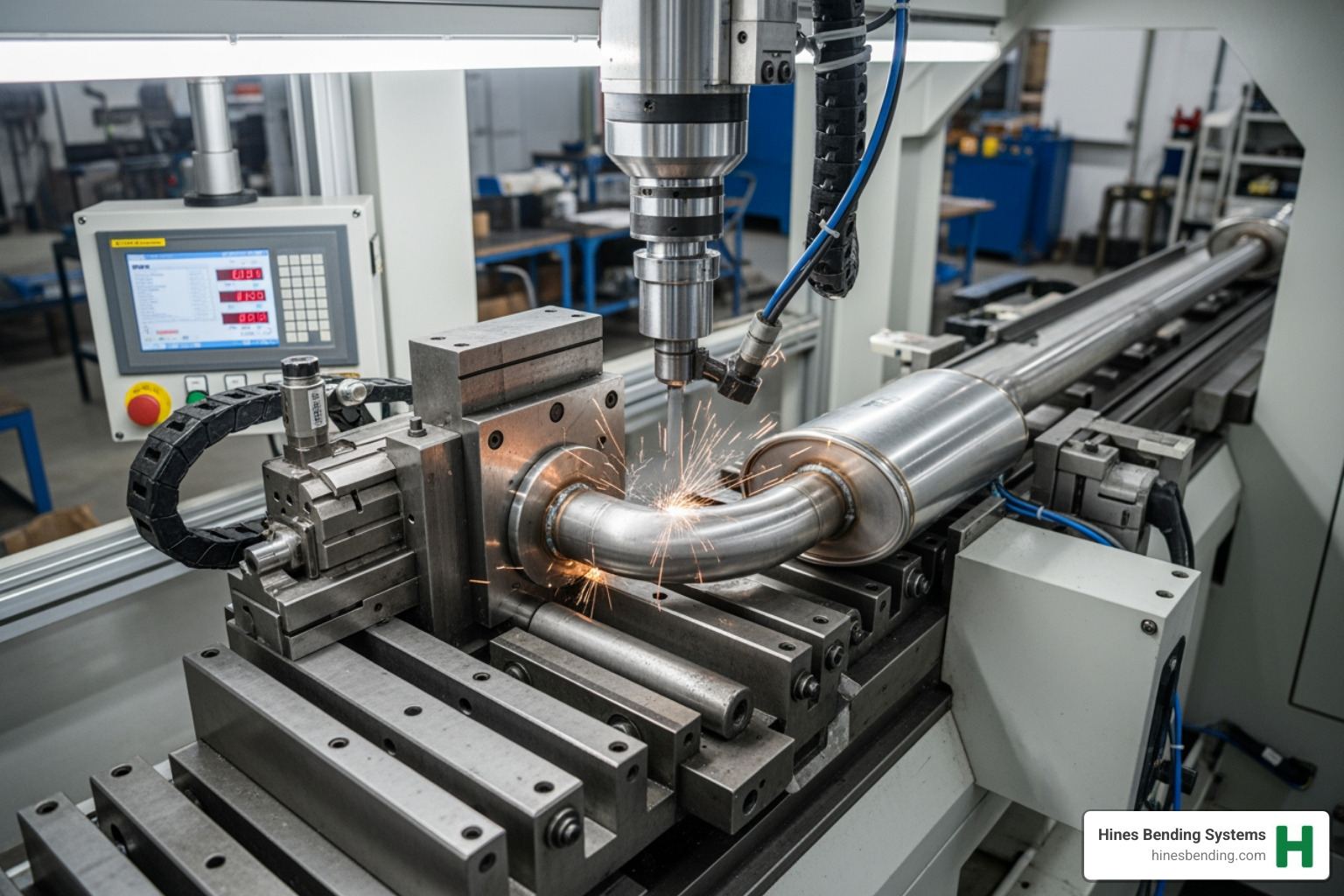

Step 2: Machine Setup and Bending

This is where professional perfection becomes clear. Our advanced CNC benders allow for precise programming of every bend, executing them with perfect consistency. This eliminates human error and speeds up production.

Before bending, selecting the correct tooling is essential. Based on pipe material, diameter, and bend radius, the right dies and mandrels are installed. Our Hines machines accommodate a wide range of tooling for maximum flexibility. For larger or thicker pipes, our induction benders offer distinct advantages, heating a localized section for a smoother bend with less material stress. Throughout the process, our machines monitor everything in real-time, ensuring the highest quality outcome. Our innovative technology, like the Dual Stack CNC Push Bender and Roll Bender, is engineered to handle complex tasks with ease, producing smooth, kink-free results that meet the most stringent standards.

Step 3: Finishing and Installation

The finishing steps are vital for a system that performs flawlessly and lasts. After bending, deburring removes sharp edges that could disrupt gas flow.

When joining sections, welding technique is crucial. For stainless steel, TIG welding is preferred for its clean, strong welds. A pro tip is to purge the pipe’s interior with argon gas during welding to prevent oxidation and ensure a smooth internal bead, which is critical for maintaining optimal airflow.

Once assembled, the system must undergo leak testing to find any gaps. Finally, final fitment ensures the system is installed with proper alignment and secure mounting to avoid rattles or stress points. At Hines Bending Systems, our commitment to quality assurance extends beyond the bend. We provide training and support that improves efficiency for our clients across Florida, from Fort Lauderdale to Jacksonville. When you partner with Hines, you gain access to decades of expertise dedicated to your success.

Frequently Asked Questions about Exhaust Pipe Bending

Can you bend an exhaust pipe without it collapsing?

Yes, but not reliably with DIY methods. The main challenge in learning how to bend pipes for exhaust is preventing the walls from collapsing or kinking, which chokes airflow. Home mechanics often try packing pipes with sand, but this method is inconsistent and can be dangerous if wet sand is heated.

The only guaranteed method for bending a pipe without collapse is using professional equipment, specifically a Mandrel Exhaust Pipe Bender. These machines use a precisely sized internal mandrel that supports the pipe’s interior during the bend, ensuring the diameter remains uniform. Our Hines machines are engineered for this purpose, delivering perfect, kink-free bends every time without guesswork or wasted material.

What is the safest and most effective way to bend an exhaust pipe?

The safest and most effective way is to use professional-grade equipment from a reputable manufacturer like Hines Bending Systems. DIY methods involving open flames and hot metal create serious safety hazards. Beyond the physical risks, a poorly executed bend leads to a collapsed pipe and reduced performance, forcing you to buy new materials and start over.

Even minor kinks create significant flow restrictions, hurting fuel efficiency and performance. Hines machines deliver superior results while ensuring operator safety through advanced design and robust construction. The long-term value of investing in quality equipment—or working with a shop that uses Hines machines—far outweighs the perceived savings of risky, ineffective alternatives.

When should I use custom bending vs. pre-bent pipes?

The answer depends on your project. Pre-bent pipes can work for standard OEM-fit repairs where a specific part is readily available.

However, for unique layouts, performance optimization, or any custom build, custom bending is the only real choice. This is where Hines Bending Systems excels. Our machines offer the flexibility to create bespoke exhaust systems to your exact specifications. Whether you’re building a hot rod in Cape Coral or a specialized industrial system, our technology makes it possible.

Custom bending allows for precise routing that minimizes restrictions and maximizes airflow. You aren’t forced to compromise your design to fit available parts; the parts are made to fit your design. This means perfect fitment, improved durability, and performance that pre-bent pipes cannot match.

The Right Way to Bend Exhaust Pipes

The journey to understanding how to bend pipes for exhaust leads to one conclusion: precision, safety, and quality are essential. We’ve seen that DIY methods and non-professional equipment have inherent limitations that can compromise your project. Collapsed pipes and hidden kinks don’t just look unprofessional—they restrict exhaust flow, rob your engine of power, and lead to costly repairs.

Professional machinery makes all the difference. This is where Hines Bending Systems stands apart. As the #1 worldwide manufacturer of tube and pipe benders, we’ve built our reputation on delivering industry-leading technology to clients ranging from race teams to NASA. That level of trust comes from decades of proven expertise and an unwavering commitment to quality.

Our machines ensure every bend maintains the pipe’s internal diameter, creating smooth, restriction-free pathways for exhaust gases. No compromises, just consistent, professional results that maximize performance. Whether you’re in Fort Myers or Miami, our equipment delivers the reliability you need.

The right equipment is an investment in quality, safety, and success. When you choose Hines Bending Systems, you gain access to unparalleled expertise and support. For any custom exhaust project that demands perfection, explore our range of Exhaust Pipe Benders to see why professionals worldwide trust Hines to deliver the performance their projects demand.