CNC Tube Bending Machine Price: What to Expect in 2026

When evaluating manufacturing equipment investments, few purchases demand as much due diligence as precision tube bending machinery. The question of CNC tube bending machine price isn’t answered with a simple figure—it’s a complex equation involving technology level, production requirements, material capabilities, and long-term operational costs. In 2026, manufacturing decision-makers face an evolving landscape where American-made precision equipment competes on value rather than just initial purchase price.

Understanding what drives tube bending equipment cost helps engineering managers and procurement specialists make informed decisions that impact production efficiency, quality consistency, and bottom-line profitability for years to come. This guide breaks down the pricing structure, technology considerations, and total cost of ownership factors that define the current market for tube bending machines for sale.

Current Price Ranges for CNC Tube Bending Equipment

The 2026 market for CNC tube benders spans a wide spectrum, reflecting significant differences in capability, precision, and manufacturing quality. Entry-level semi-automated benders start around $25,000 to $45,000, suitable for shops with basic bending needs and limited production volumes. These machines typically handle smaller tube diameters and offer limited programming flexibility.

Mid-range CNC tube bending machines, which represent the sweet spot for many manufacturing operations, typically fall between $75,000 and $200,000. These systems offer full CNC control, multi-stack tooling capabilities, and can handle tubes from 0.25 inches to 3 inches in diameter. They’re programmable for complex geometries and provide the repeatability essential for aerospace and oil & gas applications.

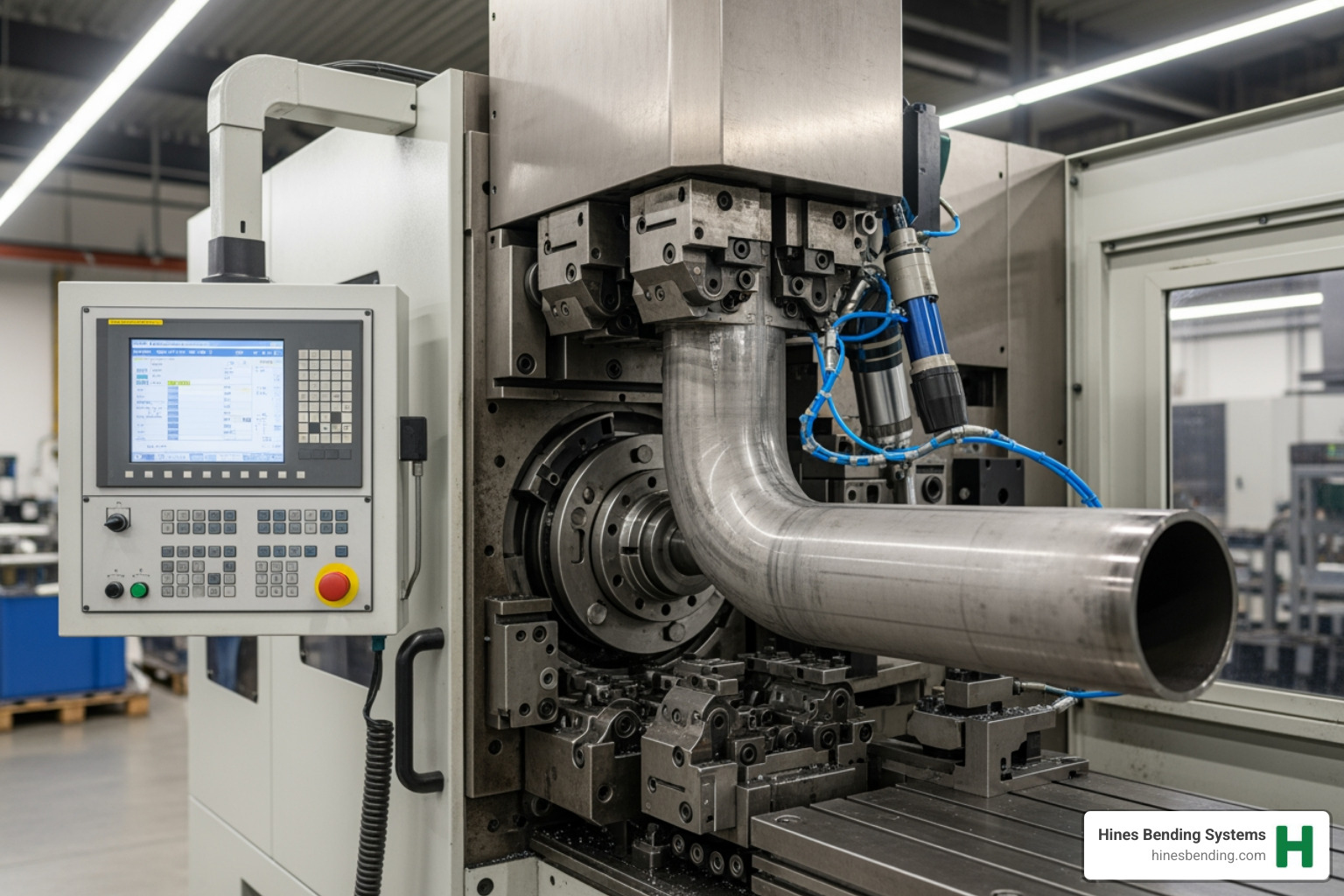

High-end production systems and specialty benders command prices from $200,000 to $600,000 or more. These machines feature advanced servo-electric or all-electric technology, multi-radius bending capabilities, integrated measurement systems, and sophisticated software packages. For critical applications in petrochemical processing or military specifications where tolerances measured in thousandths of an inch matter, this investment tier delivers the necessary precision and reliability.

Technology Level and Its Impact on Investment

The technological sophistication of a CNC tube bender dramatically affects both initial cost and long-term value. Modern all-electric benders, which have gained significant market share in 2026, eliminate hydraulic systems entirely. While they command premium pricing—typically 15-25% higher than comparable hydraulic machines—they offer lower maintenance costs, improved energy efficiency, and cleaner operation critical for cleanroom aerospace applications.

Control systems represent another significant cost variable. Basic programmable logic controllers (PLCs) with limited memory and simple interfaces keep costs down but restrict production flexibility. Advanced CNC controllers with touchscreen interfaces, 3D visualization, simulation capabilities, and network connectivity add $15,000 to $40,000 to machine cost but dramatically reduce setup time and programming errors.

Servo-driven systems provide superior positioning accuracy and repeatability compared to traditional stepper motor configurations. For applications requiring bend angle tolerances within ±0.5 degrees—standard in aerospace tube assemblies—servo technology isn’t optional. The additional investment typically ranges from $10,000 to $30,000 depending on the number of controlled axes.

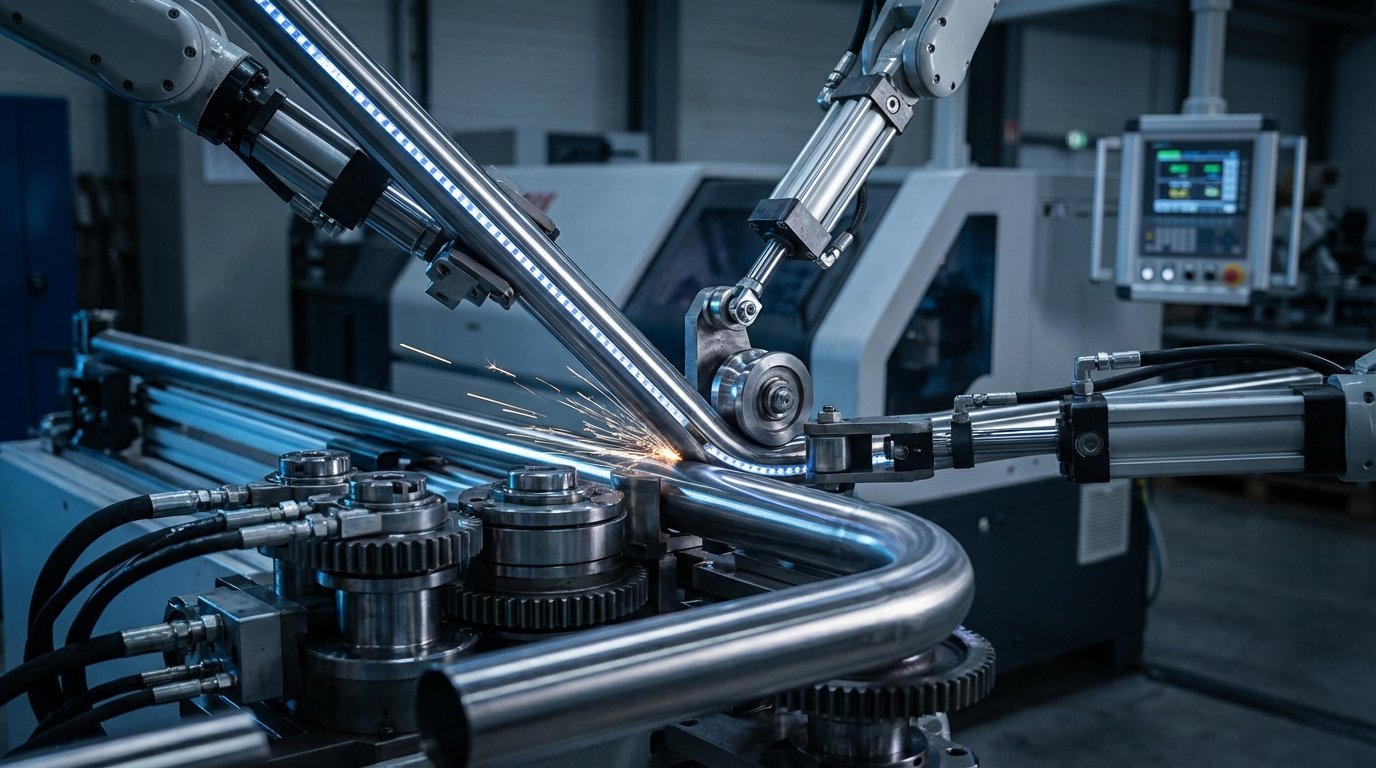

Material Capabilities and Tooling Considerations

A CNC tube bender’s material handling capabilities directly correlate with price. Machines designed exclusively for soft materials like aluminum or copper cost significantly less than those engineered to bend stainless steel, titanium, or exotic alloys common in petrochemical and aerospace applications.

Wall thickness capacity affects both machine structure and tooling requirements. Bending heavy-wall tubing demands greater force, more robust construction, and specialized tooling—all factors that increase manufacturing equipment investment. A machine capable of bending 2-inch diameter schedule 80 stainless steel will cost considerably more than one limited to thin-wall applications.

Tooling itself represents a substantial ongoing investment often overlooked in initial cost analysis. Quality mandrel sets, bend dies, clamp dies, and wiper dies for a single tube size and radius can run $3,000 to $8,000. Operations requiring multiple setups for various tube sizes should budget $20,000 to $50,000 for comprehensive tooling packages. American-made tooling from established manufacturers ensures consistency and longevity, particularly important when bending exotic materials.

Production Volume and ROI Calculations

Evaluating tube bending equipment cost requires aligning machine capabilities with production requirements. For high-volume operations producing thousands of identical bends monthly, investing in faster cycle times and automated loading/unloading systems delivers measurable ROI. A machine that costs $150,000 but reduces cycle time by 30 seconds per part will recoup its premium over a $100,000 alternative within 18-24 months at high production volumes.

Conversely, job shops and custom fabricators handling diverse, low-volume work benefit from flexibility over raw speed. Quick-change tooling systems, extensive programming libraries, and multi-stack capabilities justify higher initial investment by reducing setup time—often the dominant cost factor in short-run production.

Energy efficiency has become increasingly relevant in ROI calculations. Modern servo-electric benders consume 40-60% less energy than traditional hydraulic machines. At industrial electricity rates, this translates to $3,000-$7,000 annual savings for machines running two shifts—a meaningful factor over a typical 15-20 year machine lifespan.

American Manufacturing Quality Premium

In 2026, American-made tube bending machines typically command 20-35% higher prices than imported alternatives. This premium reflects genuine value differences that impact total cost of ownership. Domestic manufacturers provide direct technical support, readily available parts, and service technicians who understand the demanding applications common in U.S. aerospace, defense, and energy sectors.

Companies with proven track records supplying NASA, military contractors, and major oil & gas operators have refined their designs through decades of feedback from the most demanding applications. This institutional knowledge translates into machines that maintain accuracy over millions of cycles, withstand harsh production environments, and deliver consistent results with exotic materials.

For operations requiring DFARS compliance or Buy American Act adherence—common in defense and infrastructure projects—domestic manufacturing isn’t just preferred, it’s mandatory. The apparent price premium disappears when imported alternatives simply cannot qualify for these applications.

Software and Integration Costs

Modern manufacturing environments demand equipment integration with existing systems. CAD/CAM integration, which allows engineers to program bends directly from 3D models, adds $8,000 to $25,000 depending on software sophistication and license structure. For aerospace and automotive applications where complex assemblies require hundreds of precise bends, this capability eliminates programming errors and dramatically reduces engineering time.

Quality management system integration, including statistical process control (SPC) data collection and analysis tools, represents another cost consideration. Systems that automatically document every bend, track tool wear, and flag deviations from specifications cost $5,000 to $15,000 but prove essential for AS9100 aerospace quality management or API specifications in oil & gas applications.

Network connectivity and Industry 4.0 capabilities—remote monitoring, predictive maintenance, and production analytics—increasingly represent standard features rather than options on premium machines. These capabilities support lean manufacturing initiatives and provide the real-time visibility production managers need to optimize operations.

Training, Installation, and Support

The true cost of CNC tube bending machines extends beyond the purchase price. Professional installation by factory-trained technicians typically adds $2,500 to $8,000 depending on machine complexity and site requirements. Proper installation ensures accuracy calibration and prevents problems that compromise precision from day one.

Comprehensive operator training represents a critical investment often underestimated in budget planning. Quality manufacturers provide multi-day on-site training covering programming, tooling setup, material handling, and troubleshooting. While this adds $3,000 to $10,000 to initial costs, it prevents costly mistakes, reduces scrap rates, and accelerates time to full productivity.

Extended warranty and preventive maintenance agreements cost 5-8% of machine price annually but provide predictable maintenance budgets and priority support access. For production-critical operations where downtime costs thousands per hour, these agreements deliver significant value beyond the service costs themselves.

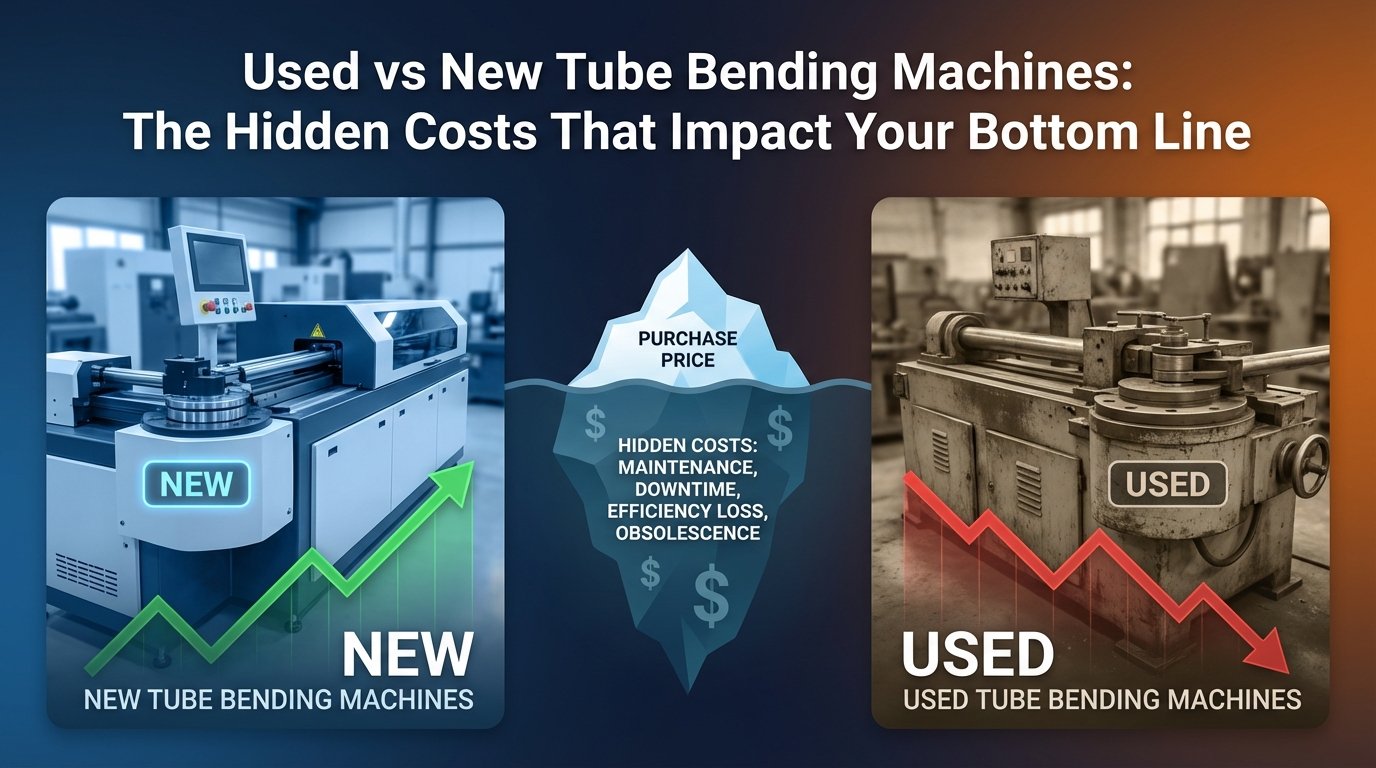

Evaluating Total Cost of Ownership

Smart manufacturing equipment investment decisions look beyond purchase price to total cost of ownership over the machine’s productive life. A $120,000 machine with $8,000 annual maintenance costs and 95% uptime delivers better value than a $90,000 alternative requiring $15,000 yearly maintenance and suffering frequent breakdowns.

Precision retention over time represents another crucial TCO factor. Machines that maintain accuracy specifications for 10-15 years without major rebuilds cost less long-term than those requiring expensive accuracy restoration after 5-7 years. This consideration particularly matters for aerospace and petrochemical applications where dimensional consistency isn’t negotiable.

Obsolescence risk deserves consideration in 2026’s rapidly evolving manufacturing landscape. Machines built on open-architecture controls with documented interfaces adapt to future requirements more readily than proprietary systems. The ability to upgrade software, add automation, or integrate new technologies extends useful life and protects initial investment.

Making the Right Investment Decision

When evaluating CNC tube benders for sale, successful decision-makers balance initial cost against capability match, production requirements, and long-term operational costs. A machine that costs 30% more but delivers 50% faster cycle times, requires 40% less maintenance, and maintains precision twice as long represents superior value despite higher purchase price.

Working with established American manufacturers who understand demanding applications provides access to engineering expertise that informs machine specification. These partnerships help right-size investment—avoiding both under-specification that limits production capability and over-specification that wastes capital on unused features.

The current market offers compelling opportunities for manufacturers ready to upgrade aging equipment or expand tube bending capabilities. Supply chain stabilization and competitive domestic manufacturing have created favorable conditions for organizations making strategic equipment investments. The key lies in thorough analysis that considers total cost of ownership, application-specific requirements, and long-term production goals rather than fixating solely on initial purchase price.

For engineering managers and procurement specialists evaluating tube bending equipment investments in 2026, partnering with proven manufacturers who combine technical expertise, application experience, and comprehensive support delivers the highest probability of long-term success. The right CNC tube bending machine represents not just a capital expense but a strategic asset that enhances competitive position through improved quality, efficiency, and capability.

Ready to discuss your specific tube bending requirements and explore equipment options matched to your applications? Contact our engineering team for a detailed consultation that evaluates your production needs, material requirements, and quality specifications to identify the optimal bending solution for your operation.