Why Custom Exhaust Pipe Fabrication is the Key to Performance and Personalization

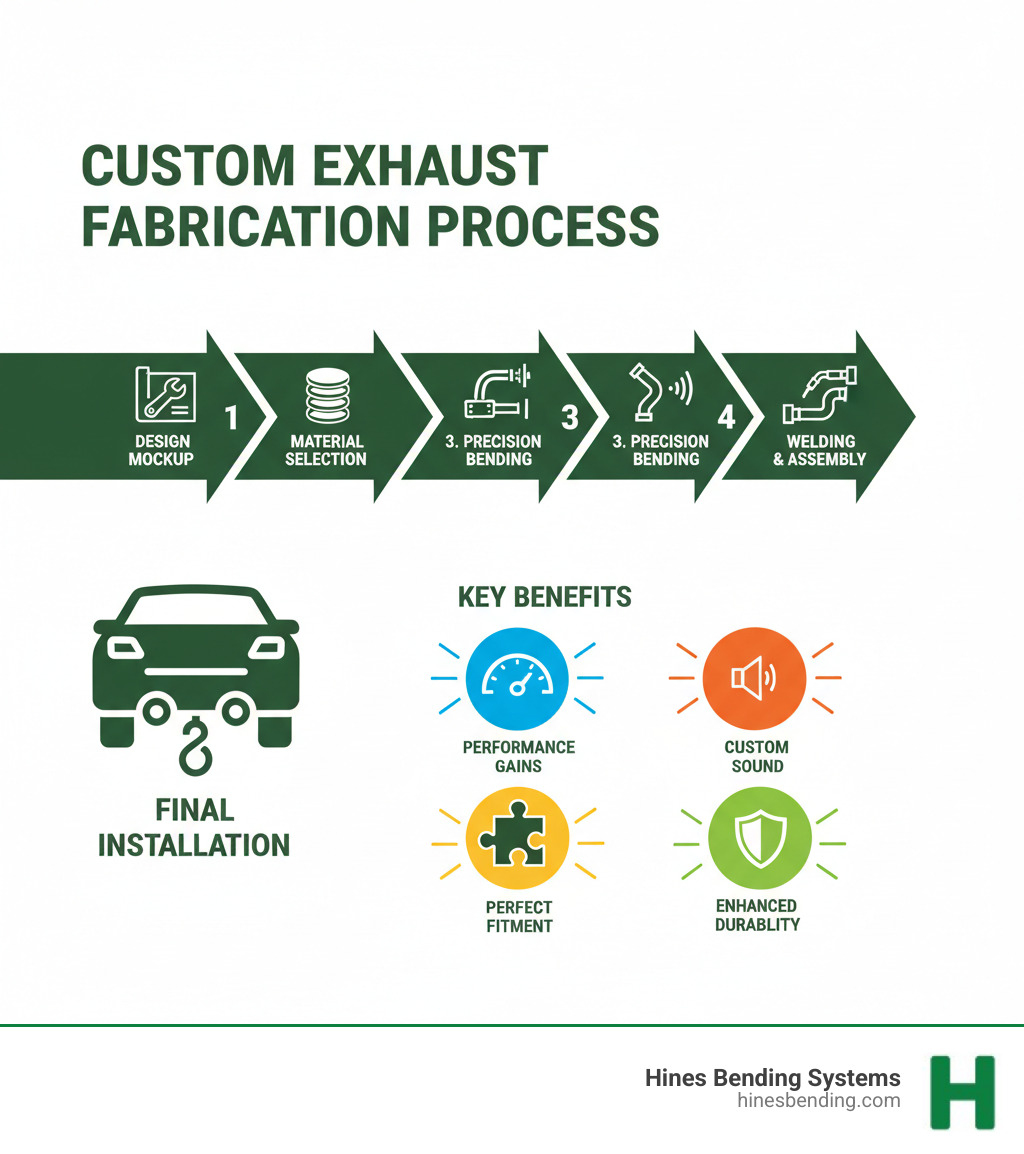

Custom exhaust pipe fabrication is the art of building a bespoke exhaust system for a vehicle, moving beyond one-size-fits-all parts. This process involves careful material selection, precision bending, expert welding, and integrating custom components like mufflers and resonators for optimal performance and sound.

The global automotive exhaust system market is projected to reach $50.2 billion by 2030, up from $35.4 billion in 2023, highlighting a growing demand for the personalization and performance gains that custom systems provide. Whether you want more horsepower, a unique exhaust note, or a perfect fit for a modified vehicle, custom fabrication delivers superior results, including better ground clearance and optimized exhaust flow.

However, a truly exceptional custom exhaust requires more than skill; it demands precision bending equipment to create flawless, consistent bends. The quality of the bending machinery is often what separates a good exhaust from a great one.

For fabrication shops producing custom exhausts at scale, the right equipment is critical. Partnering with an industry leader like Hines Bending Systems—the #1 worldwide manufacturer of tube and pipe benders—is a game-changer. Trusted by clients like NASA, Hines provides the precision machinery and expert solutions needed to produce world-class exhaust systems efficiently and reliably.

Glossary for custom exhaust pipe fabrication:

- exhaust bending machine

- how to bend exhaust pipe

- s bend exhaust pipe

The Foundation: Planning Your Custom Exhaust System

Proper custom exhaust pipe fabrication begins with a solid plan. Before cutting any metal, it’s crucial to define your performance goals, desired sound profile, and material choices. Rushing this stage can lead to a system that underperforms.

Choosing the Right Materials and Dimensions

The material you choose impacts durability, weight, cost, and sound.

- Stainless Steel: The top choice for its excellent corrosion resistance and appearance. 304 stainless is the premium, show-quality option, while 409 stainless offers great durability at a lower cost. Both require skilled welding.

- Mild Steel: A budget-friendly option that is easy to weld but prone to rust if not coated. It’s ideal for coated systems or projects with tight budgets.

- Titanium: The ultimate choice for racing applications where weight is critical. It’s extremely lightweight, strong, and expensive, requiring specialized welding skills.

- Aluminized Steel: A good middle-ground option, offering better corrosion resistance than mild steel at a moderate price.

Tubing diameter is a critical balancing act. Too large, and you lose low-end torque; too small, and you create restrictive backpressure. The right size depends on your engine and performance goals. Wall thickness is a trade-off between durability and weight.

| Material | Properties | Cost | Lifespan (Uncoated) | Best For |

|---|---|---|---|---|

| Stainless Steel | Corrosion resistant, durable, aesthetic | High | Long | Performance, show vehicles, longevity |

| Mild Steel | Easy to work with, prone to rust | Low | Short | Budget builds, coated systems |

| Titanium | Extremely lightweight, strong, corrosion resistant | Very High | Very Long | Racing, ultimate performance |

| Aluminized Steel | Moderate corrosion resistance, good compromise | Medium | Medium | General replacement, moderate climates |

Designing for Performance and Sound

Custom exhaust pipe fabrication is both an art and a science. A well-designed system reduces backpressure and improves the scavenging effect, which helps pull more air-fuel mixture into the cylinders, boosting horsepower and torque.

Sound is just as important as performance. The exhaust note is your car’s voice, and custom components let you tune it perfectly.

- Mufflers: These are the primary tool for controlling volume and tone. Chambered mufflers give a classic rumble, while straight-through designs offer an aggressive sound with maximum flow.

- Resonators: These fine-tune the sound, targeting and eliminating specific frequencies that cause unpleasant drone during highway driving.

- X-pipes and H-pipes: Used in dual exhaust systems, these balance exhaust pulses between cylinder banks. X-pipes generally offer better performance and a sharper sound, while H-pipes create a traditional V8 rumble.

The quality of the pipe bends is paramount, as poor bends create turbulence and restrict flow. This is why professional shops rely on precision exhaust bending machines. For consistent, high-quality results, fabricators turn to industry leaders like Hines Bending Systems, the #1 worldwide manufacturer of tube and pipe benders. The precision and reliability of Hines equipment ensure every system delivers excellence.

The Heart of the Craft: The Custom Exhaust Pipe Fabrication Process

With a plan in place, the hands-on phase of custom exhaust pipe fabrication begins. This is where raw materials are transformed into a high-performance system, and precision is critical to avoid alignment issues, performance loss, or rattles.

From Mockup to Metal: A Step-by-Step Guide

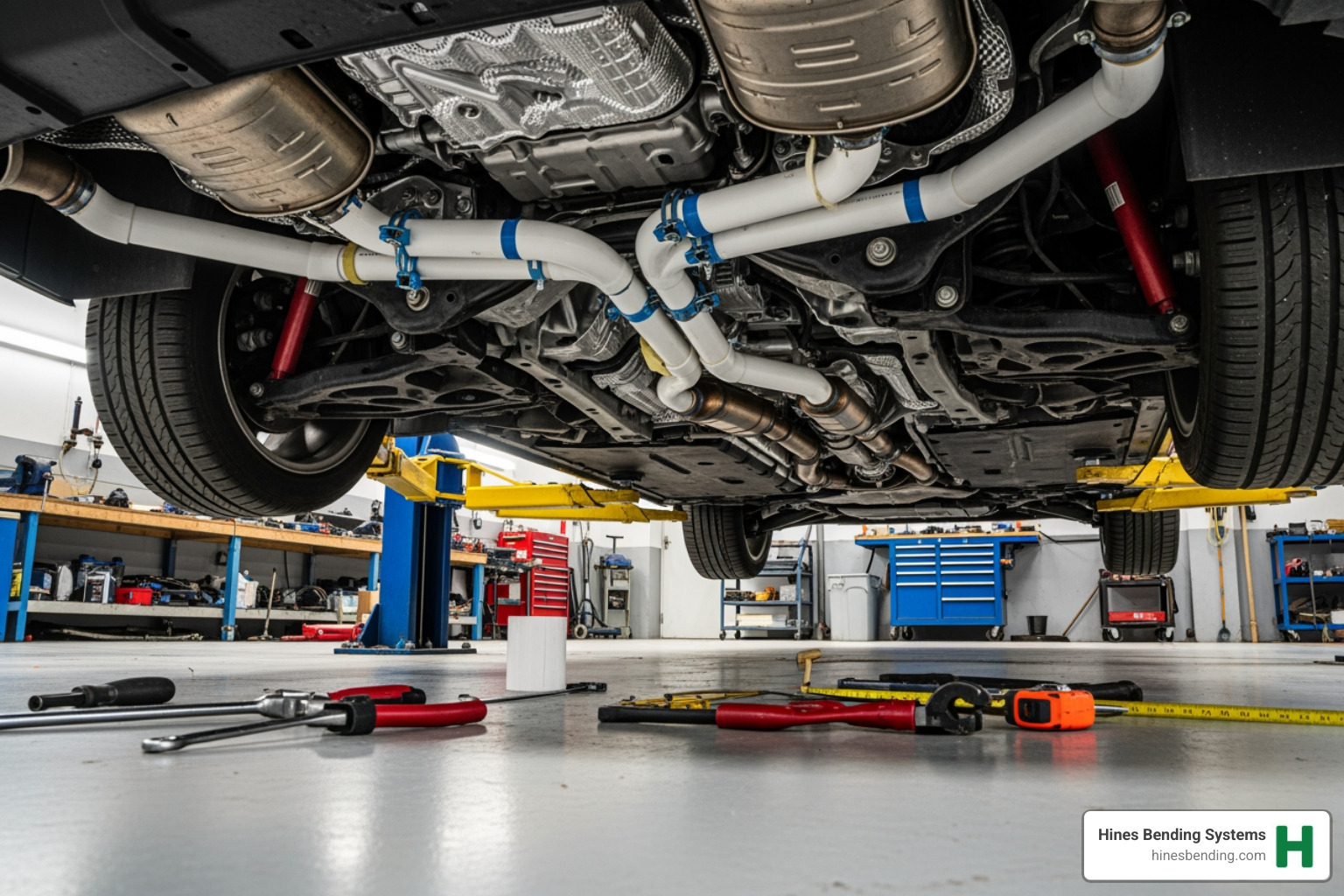

Because modern vehicle undercarriages are so complex, fabricators often use creative solutions to map out the exhaust path.

PVC mockup kits are a game-changer, allowing fabricators to build a full-scale model of the exhaust using inexpensive PVC pipes. This 3D blueprint can be adjusted on the vehicle to perfect clearances before any expensive metal is cut.

The core of quality fabrication is mandrel bending in custom exhaust fabrication. Unlike crush bending, which deforms and restricts the pipe, mandrel bending uses an internal support to create smooth, consistent bends that maintain the pipe’s full diameter. This is essential for optimal exhaust flow and performance. For shops producing custom exhausts at scale, the quality of the bending equipment is paramount. This is why they partner with Hines Bending Systems, the #1 worldwide manufacturer of tube benders. Trusted by clients like NASA, Hines provides the precision machinery needed for wrinkle-free, perfect bends every time.

A key challenge is managing material movement during welding, as stainless steel distorts more than mild steel. To control this, fabricators work in stages, fully welding and fitting one section at a time.

Welding and Assembly Best Practices

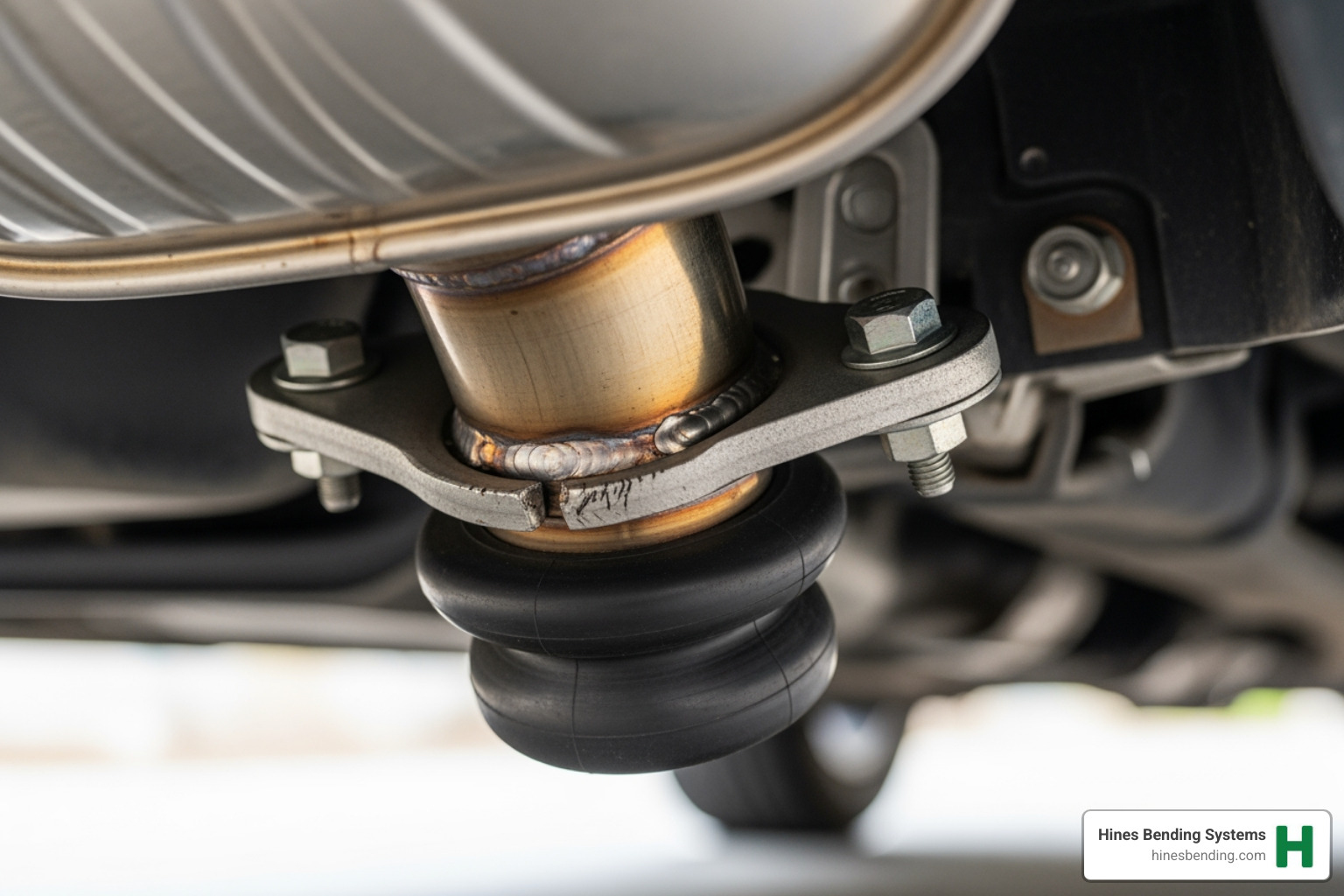

Welding joins the custom-bent pipes into a durable, leak-free system.

- TIG welding is the standard for high-quality work, especially on stainless steel and titanium, producing clean, strong, and visually appealing welds.

- MIG welding is faster and better suited for mild steel or less critical applications.

When TIG welding stainless steel, back-purging is essential. This process floods the inside of the pipe with inert gas to prevent oxidation, ensuring a smooth interior and a strong, corrosion-resistant weld.

Precise alignment is achieved using clamps and tack welds to hold sections in place before final welding. To manage heat distortion and simplify installation, it’s best to build the system in modular sections using components like exhaust vband or exhaust flange connections.

Building from Front to Back: Fabricating Each Section

A successful custom exhaust pipe fabrication project is built methodically from front to back. This section-by-section approach ensures proper alignment, optimal clearance, and a system that functions perfectly.

Fabricating the Down-Pipe and Mid-Section

The down-pipe connects to the exhaust manifold or turbo and steers the tight spaces of the engine bay. Precision is key, and proper bracing is essential to prevent stress on expensive components. Exhaust flexi joints are critical here, as they absorb engine vibrations and movement, preventing cracks and extending the system’s life.

Throughout the process, maintaining ground clearance is a constant balancing act. Every bend and component is placed to avoid scraping on speed bumps or driveways. The mid-section, typically the longest part, is often built in several pieces connected by exhaust vband or exhaust flange connections. This modular design simplifies future maintenance and repairs.

Fitting the Rear Section and Final Touches

The rear section is where function meets personality. It includes the over-axle pipe, which must be carefully routed to clear all suspension components through their full range of motion. This is also where mufflers and resonators are placed to dial in the final sound profile.

Proper exhaust hanger installation is crucial for preventing rattles and stress on welds. A pro tip is to slightly raise the system before adding hangers to preload the rubber mounts, keeping everything tight.

Finally, exhaust tips provide the finishing aesthetic touch. Whether chrome or stainless, dual or single, the choice of tip completes the vehicle’s look. This sectional approach ensures each part of the system receives the attention it needs for a flawless result.

The Professional Edge: Why Precision Bending Matters

While the DIY spirit is admirable, the difference between a good and a great custom exhaust pipe fabrication lies in the quality of the bends. Poorly formed bends with crushed or wrinkled walls create restrictions that kill performance and compromise durability. Even the best welder cannot fix a bad bend.

The Role of High-Quality Bending Machines in Custom Exhaust Pipe Fabrication

Basic methods like crush bending deform the pipe’s internal diameter, creating bottlenecks that defeat the purpose of a custom exhaust. A professional Automotive Exhaust Tube Bender, especially a mandrel bender, is essential. It maintains a consistent internal diameter through every bend, ensuring smooth, unrestricted flow.

For shops scaling their custom exhaust pipe fabrication operations, a CNC Metal Bender offers the ultimate in precision and efficiency. It eliminates human error, ensures perfect repeatability, and reduces material waste, leading to higher quality systems and faster production.

Partnering with Bending Experts for Best Quality

The best machinery is backed by expertise. When investing in equipment for custom exhaust pipe fabrication, you are partnering with the manufacturer’s knowledge and support. This is why top organizations, including NASA, trust manufacturers with proven track records for their critical bending needs.

Hines Bending Systems is the #1 worldwide manufacturer of tube, pipe, and induction benders because we do more than sell equipment. We partner with clients to provide custom solutions custom to their unique challenges. With more experience and installations than anyone in the industry, Hines delivers superior machines, smarter solutions, and unparalleled support.

When you invest in an Exhaust Bending Machine from Hines, you gain a partner dedicated to your success, offering comprehensive training and support to maximize your efficiency and quality. The foundation of a perfect custom exhaust is a perfect bend, and Hines Bending Systems provides the tools and expertise to achieve it.

Frequently Asked Questions about Custom Exhaust Pipe Fabrication

Here are answers to some common questions about custom exhaust pipe fabrication.

What are the main differences between fabricating with stainless steel vs. mild steel?

The choice between stainless and mild steel involves a trade-off between cost, durability, and ease of fabrication.

- Stainless Steel: Offers superior corrosion resistance, a long lifespan, and a professional appearance. It is more expensive and requires more skill to weld, especially with techniques like back-purging.

- Mild Steel: A budget-friendly option that is easy to weld. However, it rusts quickly if not protected with a high-temperature coating.

For long-term durability and a high-quality finish, stainless steel is often worth the investment.

What components are needed for a full custom exhaust system?

A complete custom exhaust system includes:

- Tubing and Mandrel Bends: The foundation of the system, bent to precise specifications.

- Flanges or V-Bands: For creating modular, serviceable connections.

- Flex Joints: To absorb engine vibration and prevent stress cracks.

- Hangers: To securely mount the system to the vehicle.

- Mufflers and Resonators: To control volume and tune the exhaust note.

- Catalytic Converters and O2 Sensor Bungs: For emissions compliance on street vehicles.

- Exhaust Tips: For the final aesthetic touch.

For shops producing these systems, access to precision bending equipment is non-negotiable. Hines Bending Systems provides the industry-leading machines that ensure every mandrel bend is perfect.

What is the typical cost and lead time for custom exhaust fabrication?

The cost and time for custom exhaust pipe fabrication vary widely. Key factors include:

- Materials: Stainless steel is significantly more expensive than mild steel, while titanium is a premium option for racing.

- Complexity: A simple system is cheaper and faster to build than a complex dual exhaust with intricate routing.

- Labor: Costs depend on the fabricator’s skill and location.

- Components: High-performance mufflers, V-bands, and tips add to the total cost.

A basic mild steel system might cost $500-$1,000, while a premium stainless steel build can range from $3,000-$5,000 or more. Lead times can be a few days for simple jobs or several weeks for complex projects. For manufacturers, investing in high-quality equipment from Hines Bending Systems improves efficiency and quality, helping to manage costs and timelines. As the #1 worldwide manufacturer, trusted by clients like NASA, Hines provides the machinery to deliver consistently excellent results.

Conclusion

Custom exhaust pipe fabrication is a rewarding process that combines skill, artistry, and engineering. From material selection and welding to component placement, every step contributes to the final performance, sound, and appearance. However, the foundation of any truly exceptional custom exhaust is a perfectly bent pipe. Without smooth, consistent bends that preserve flow, the entire system is compromised.

For fabrication shops and manufacturers, producing world-class exhaust systems requires world-class machinery. This is why industry leaders partner with Hines Bending Systems, the #1 worldwide manufacturer of tube and pipe benders. Trusted by demanding clients like NASA, Hines offers unparalleled precision and reliability. With more expertise and installations than anyone in the industry, Hines provides custom solutions, training, and support to ensure your operation runs at peak efficiency.

The quality of your bending equipment directly impacts your final product. Nobody brings more experience to the table than Hines Bending Systems.

Ready to lift your fabrication from good to exceptional? Explore our range of Exhaust Pipe Benders and find how the right machinery can transform your work.