Specifying the wrong tube bending machine can cost your operation hundreds of thousands of dollars in lost productivity, scrapped materials, and missed delivery deadlines. Yet procurement decisions are frequently made based on incomplete information or misleading vendor promises. According to industry data, nearly 40% of companies report dissatisfaction with their bending equipment within the first two years—often because fundamental specification errors occurred during the selection process.

This guide identifies the seven most damaging mistakes engineering managers and procurement specialists make when specifying tube bending machines, and provides actionable strategies to avoid them. Whether you’re selecting equipment for aerospace components, petrochemical infrastructure, or high-volume automotive production, understanding these pitfalls will save your organization time, money, and operational headaches.

Mistake #1: Focusing Solely on Initial Purchase Price

The sticker price represents only a fraction of a tube bending machine’s total cost of ownership. Production managers frequently make the expensive error of selecting the lowest-cost option without calculating lifecycle expenses including maintenance, tooling replacement, energy consumption, and downtime.

A CNC tube bending machine with inferior components may cost $75,000 less upfront but require $20,000 annually in additional maintenance and produce 15% more scrap due to inconsistent bend quality. Over a typical 10-year operational life, that “savings” becomes a $200,000+ loss.

Consider these total cost factors when evaluating tube bending machines:

- Tooling durability and replacement frequency

- Energy efficiency and power consumption patterns

- Average downtime for maintenance and repairs

- Availability and cost of replacement parts

- Training requirements and ramp-up time

- Software licensing and update fees

- Service response times and support quality

American-manufactured equipment from established providers typically delivers superior long-term value through higher build quality, readily available domestic parts, and comprehensive technical support that keeps machines running productively.

Mistake #2: Underestimating Future Application Requirements

Specifications often reflect only current production needs without accounting for foreseeable expansion or product evolution. This short-sighted approach forces costly equipment replacement or operational bottlenecks within 24-36 months.

A manufacturer producing 2-inch diameter stainless steel exhaust components may specify a machine with just enough capacity for current orders. When a new customer requires 3-inch diameter bends or high-strength alloy materials eighteen months later, the equipment becomes a business constraint rather than an asset.

Build strategic flexibility into your specifications:

- Specify capacity 30-40% above current maximum requirements

- Evaluate machines capable of handling harder materials than currently needed

- Consider multi-stack tooling options for varying tube sizes

- Assess maximum bend radius and minimum centerline radius capabilities

- Verify compatibility with potential future automation integration

CNC tube bending machine manufacturers with custom solution expertise can design equipment that accommodates growth trajectories specific to your industry sector and anticipated market demands.

Mistake #3: Ignoring Material-Specific Bending Characteristics

Not all tube bending machines handle different materials equally. Specifying equipment without thoroughly analyzing the physical properties of your tube materials—including work hardening rates, springback characteristics, and wall thinning tendencies—leads to quality problems and production inefficiencies.

Aerospace-grade titanium requires completely different bending parameters than mild steel or aluminum. Wall thickness relative to diameter (D/t ratio) dramatically affects achievable bend radii and required machine capabilities. A machine optimized for thin-wall stainless steel tubing may prove inadequate for thick-wall carbon steel pipe applications.

Critical material considerations include:

- Tensile strength and elongation properties affecting springback compensation

- Work hardening characteristics requiring specific tooling approaches

- Wall thickness ratios determining mandrel requirements

- Surface finish preservation needs for visible applications

- Temperature sensitivity for materials requiring heat-assisted bending

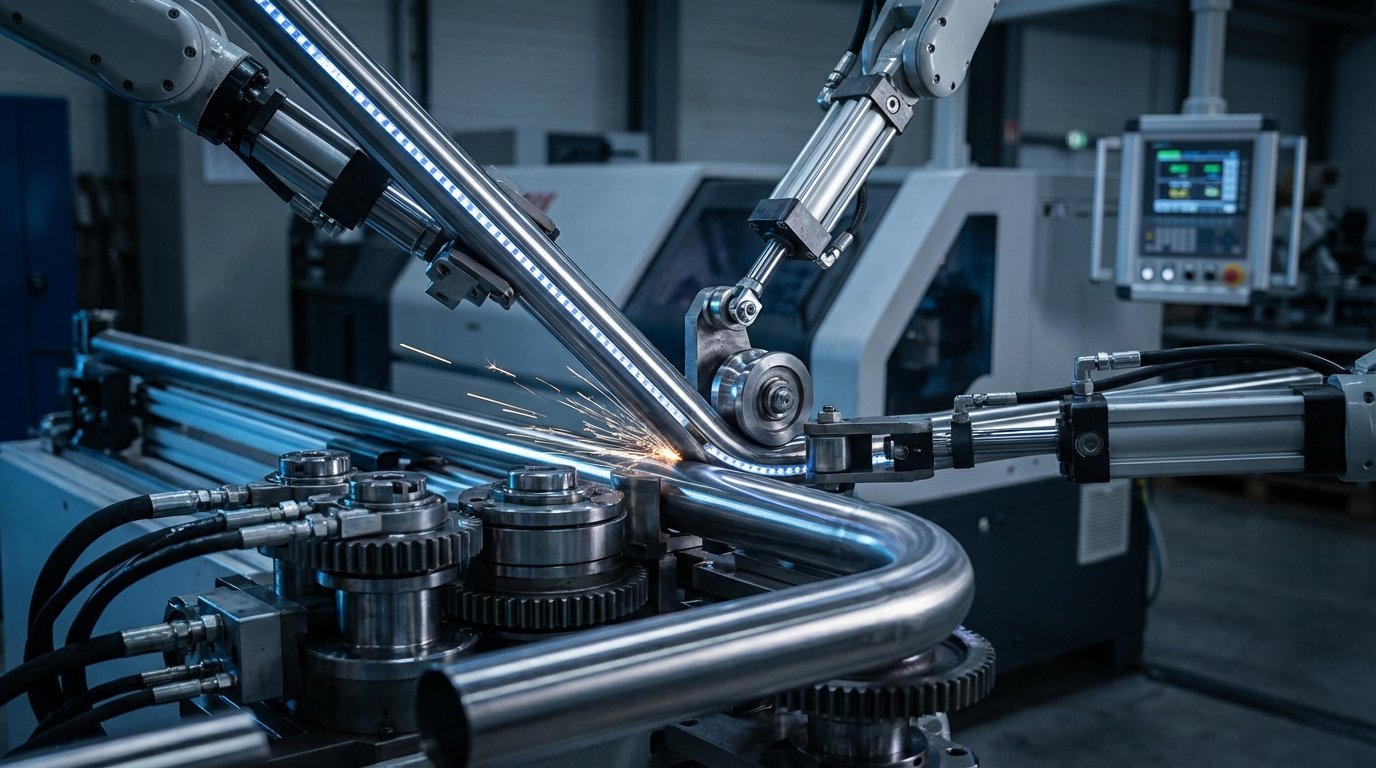

Precision tube bending for demanding applications requires matching machine capabilities precisely to material behavior. Experienced manufacturers provide material-specific guidance based on decades of real-world production experience across diverse applications.

Mistake #4: Overlooking Operator Training and Technical Support Requirements

Even the most capable tube bending machines deliver poor results without proper operator training and ongoing technical support. Organizations frequently underestimate the knowledge transfer required to achieve optimal production quality and efficiency.

A sophisticated CNC bending system might offer incredible precision and repeatability—but only when operators understand bend sequence optimization, proper tooling setup, springback compensation programming, and troubleshooting procedures. Without comprehensive training, shops struggle for months achieving acceptable quality levels.

The best equipment suppliers provide:

- On-site installation and commissioning by factory technicians

- Comprehensive operator training covering setup, programming, and maintenance

- Application-specific process development assistance

- Accessible technical support with minimal response times

- Detailed documentation including maintenance schedules and troubleshooting guides

- Ongoing consultation for new applications or challenging parts

American manufacturers typically provide superior support accessibility compared to overseas suppliers, with technicians available during your production hours and without language barriers complicating technical communication.

Mistake #5: Failing to Specify Adequate Quality Verification Capabilities

Production efficiency means nothing if bent components fail quality inspection. Yet specifications often omit requirements for integrated measurement systems, repeatability verification, or quality documentation capabilities essential for aerospace, medical, or defense applications.

Industries serving NASA, military contractors, or petrochemical facilities require rigorous traceability and statistical process control. Tube bending machines lacking proper measurement integration force time-consuming offline inspection, increase scrap rates, and create compliance documentation gaps.

Quality-critical specifications should include:

- Bend angle accuracy within required tolerances (typically ±0.5° for precision work)

- Repeatability specifications for high-volume production

- Integration capabilities with coordinate measuring machines (CMM)

- Statistical process control (SPC) data collection and reporting

- Automated quality verification features reducing inspection time

- Traceability documentation for regulated industries

Equipment proven in demanding applications—such as aerospace fuel systems or military hydraulics—demonstrates the quality capabilities required for critical components.

Mistake #6: Neglecting Tooling Flexibility and Changeover Efficiency

Job shops and manufacturers handling diverse product mixes often specify machines based on bending capacity alone, without adequately evaluating tooling changeover requirements and multi-setup efficiency.

A machine requiring 4 hours for tooling changeovers between different tube sizes creates significant downtime in high-mix environments. Quick-change tooling systems, multi-stack capabilities, and efficient setup procedures dramatically impact real-world productivity and job profitability.

For variable production environments, prioritize:

- Quick-change tooling systems minimizing setup time

- Multi-stack tooling accommodating multiple tube sizes without changes

- Program storage and recall for repeat jobs

- Tooling availability and lead times for expansion

- Ease of tooling adjustment for process optimization

Manufacturing equipment selection should reflect your actual production patterns—whether high-volume runs of identical parts or diverse low-volume custom components requiring frequent changeovers.

Mistake #7: Accepting Generic Solutions for Application-Specific Challenges

Off-the-shelf tube bending machines work well for common applications, but specialized requirements demand custom solutions. Organizations waste resources forcing standard equipment to handle applications requiring purpose-built capabilities.

Bending large-diameter pipe for oil and gas infrastructure differs fundamentally from precision bending of small-diameter aerospace tubing. Induction bending for heavy-wall petrochemical pipe requires completely different technology than rotary draw bending for automotive exhaust systems.

Complex applications may require:

- Custom bend head configurations for unusual geometries

- Specialized mandrel designs for challenging D/t ratios

- Multi-axis capabilities for 3D spatial bending

- Integration with upstream cutting or downstream welding processes

- Environmental controls for temperature-sensitive materials

- Unique fixturing for asymmetric or pre-fabricated components

CNC tube bending machine manufacturers with custom engineering capabilities—particularly those with proven performance in aerospace and defense applications—deliver solutions optimized for your specific production challenges rather than forcing compromises with standard equipment.

Developing Accurate Tube Bending Machine Specifications

Creating comprehensive, accurate specifications requires systematic analysis of current and anticipated production requirements. Begin by thoroughly documenting all tube characteristics including materials, dimensions, wall thicknesses, and bend geometries. Quantify production volumes, quality tolerances, and changeover frequency.

Engage equipment suppliers early in the specification process. Manufacturers with extensive application experience—particularly those serving demanding industries like aerospace and petrochemical—provide invaluable insights identifying requirements you might overlook and opportunities for process optimization.

Request detailed proposals addressing total cost of ownership, training provisions, support accessibility, and performance guarantees. Verify manufacturer credentials including customer references in similar applications, longevity in the industry, and domestic manufacturing capabilities ensuring parts availability and service responsiveness.

Partner With Proven Tube Bending Machine Manufacturers

Avoiding these seven critical mistakes requires partnering with experienced tube bending machine manufacturers who prioritize customer success over simply closing sales. Since 1975, American manufacturers have provided precision bending solutions for the nation’s most demanding applications—from NASA spacecraft components to military hydraulic systems and petrochemical infrastructure.

Quality equipment backed by comprehensive training, responsive technical support, and custom engineering capabilities delivers decades of productive service rather than years of frustration. When specifying tube bending machines for your operation, focus on proven performance, total ownership cost, and manufacturer commitment to your long-term success.

Ready to specify tube bending equipment that truly meets your production requirements? Contact experienced manufacturers who understand your industry’s unique challenges and can provide guidance based on thousands of successful installations across aerospace, energy, and heavy industry applications.