Authorized Tube Bending Machine Dealers vs Direct Purchase: Making the Right Choice

When your production line demands precision tube bending equipment capable of handling aerospace-grade tolerances or high-volume automotive components, the purchasing decision extends far beyond comparing price tags. Engineering managers face a critical choice: work with an authorized tube bender dealer or pursue direct purchase from manufacturers. This decision impacts not just initial capital expenditure, but long-term operational efficiency, maintenance costs, training accessibility, and equipment uptime for years to come.

The distinction matters significantly in industries where equipment downtime translates to missed delivery deadlines, quality control failures, or safety compliance issues. Understanding the full scope of what each purchasing path offers—and what it doesn’t—determines whether your investment delivers sustained value or becomes a costly liability.

The Authorized Dealer Advantage: Beyond Equipment Sales

Working with an authorized tube bending machine dealer provides access to a comprehensive ecosystem designed to support long-term operational success. These partnerships extend well beyond the initial transaction, offering critical resources that direct purchases often overlook.

Technical Expertise and Application Engineering

Authorized dealers maintain technical staff with deep knowledge of specific equipment lines and their optimal applications. When specifying a CNC tube bender for hydraulic assemblies in aerospace applications versus structural components for construction equipment, application requirements differ dramatically. Material behavior, bend radii capabilities, mandrel selection, and tooling configurations all require specialized knowledge.

An experienced industrial tube bending machine sales team helps translate project requirements into equipment specifications. They understand how wall thickness affects springback compensation, which control systems handle complex multi-plane bending sequences most efficiently, and how production volume projections should influence machine capacity selection. This consultative approach prevents costly specification errors that emerge only after installation.

Comprehensive Training Programs

Equipment capability means nothing without operator proficiency. Authorized tube bending equipment distributors typically provide structured training programs covering:

- Machine operation fundamentals and safety protocols

- CNC programming for complex bend sequences

- Tooling setup and changeover procedures

- Quality control and measurement techniques

- Preventive maintenance schedules and procedures

- Troubleshooting common issues

This training investment significantly reduces the learning curve, minimizing scrap rates and accelerating time-to-productivity. Direct purchases may include basic operational training, but rarely offer the depth or ongoing educational support that authorized dealers provide through their established infrastructure.

Local Service and Support Networks

Geographic proximity matters when equipment requires service. Authorized dealers maintain service territories with field technicians, spare parts inventory, and established response protocols. When a hydraulic system fails or a control component malfunctions, response time directly impacts production losses.

A CNC tube bender dealer with regional service capabilities can often respond within hours rather than days. They stock common replacement parts, understand your specific machine configuration, and maintain relationships with the manufacturer’s technical support team. This infrastructure provides insurance against extended downtime that direct purchase arrangements struggle to match without significant investment in internal maintenance capabilities.

Direct Purchase Considerations: When It Makes Sense

Direct manufacturer purchases aren’t inherently inferior—they simply suit different operational contexts and organizational capabilities. Companies with specific characteristics may find direct relationships more advantageous.

High-Volume Fleet Operations

Organizations operating multiple tube bending machines across several facilities often develop internal expertise that reduces dependence on dealer support. They employ dedicated maintenance teams, stock their own parts inventory, and develop standardized training programs. At this scale, direct manufacturer relationships may offer pricing advantages that offset the loss of dealer support services.

Highly Specialized Applications

Some applications require such specific customization that working directly with engineering teams at the manufacturer becomes necessary. Aerospace components with exotic materials, extreme bend radii requirements, or integration with specialized upstream/downstream equipment may demand this direct collaboration. However, even in these cases, involving an authorized dealer familiar with both the manufacturer’s capabilities and your operational environment often adds value.

International Operations

Companies with global manufacturing footprints may negotiate enterprise-level agreements directly with manufacturers, then work with regional authorized dealers for implementation, training, and support. This hybrid approach attempts to capture benefits from both models—centralized procurement leverage with localized support infrastructure.

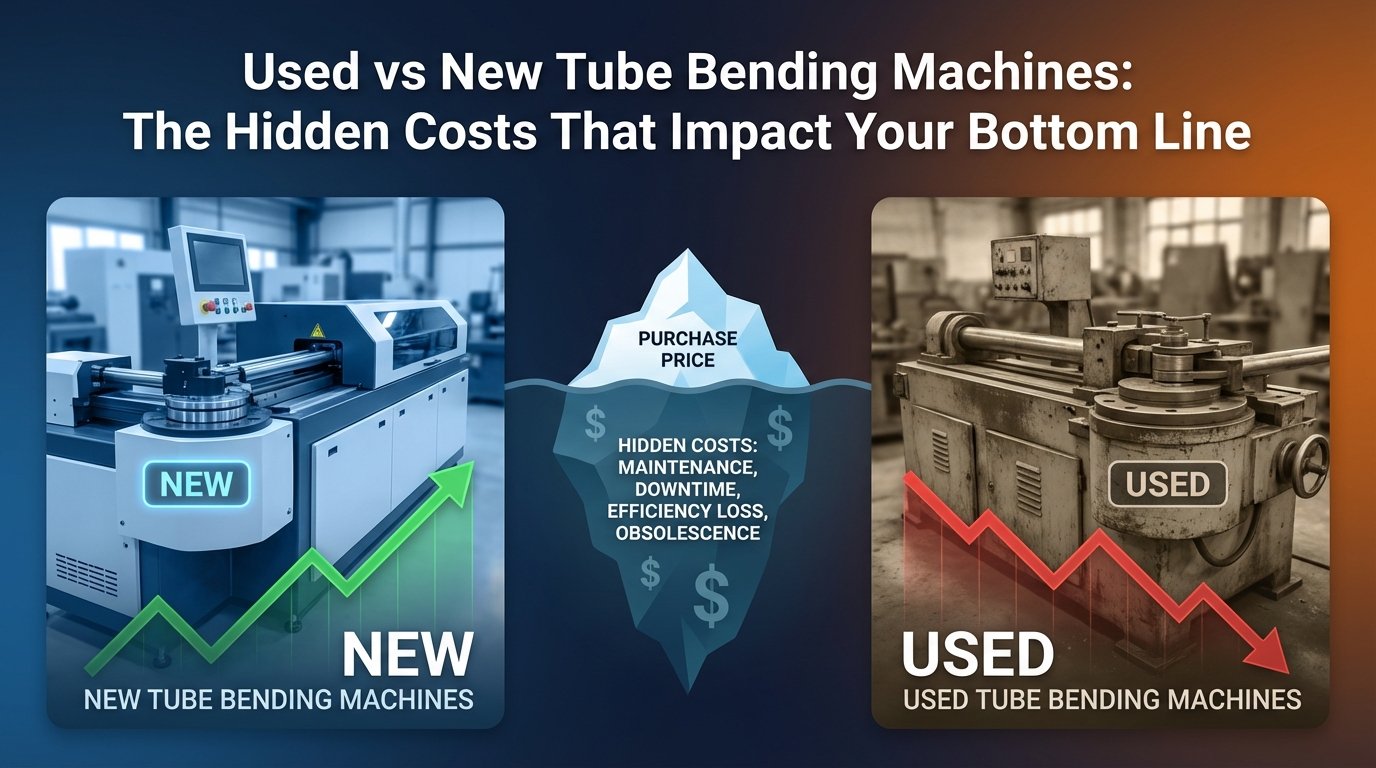

Hidden Costs of Direct Purchase

Initial purchase price represents only one component of total cost of ownership. Direct purchases often shift responsibilities and costs that dealers typically absorb:

Installation and Commissioning

Professional installation ensures equipment operates within specifications from day one. Authorized dealers coordinate delivery logistics, facility preparation, equipment positioning, utility connections, and initial calibration. They verify that environmental conditions meet manufacturer requirements and that safety systems function properly.

Direct purchases may include basic installation, but coordination responsibilities fall on the buyer. Mistakes during installation can void warranties, create safety hazards, or compromise long-term accuracy and reliability.

Warranty Administration and Parts Sourcing

Warranty claims require documentation, communication with manufacturer service departments, and often technical diagnosis to determine root causes. Authorized tube bending equipment distributors handle this administrative burden, leveraging established relationships to expedite resolutions.

Parts sourcing becomes the buyer’s responsibility with direct purchases. Identifying correct part numbers, managing minimum order quantities, and navigating international shipping for imported components adds complexity and potential delays. Dealers maintain parts inventory specifically to eliminate these obstacles.

Technology Updates and Upgrades

Manufacturing technology evolves continuously. Control system software updates, safety enhancements, and productivity improvements emerge regularly. Authorized dealers proactively communicate these opportunities and often provide installation support. Direct purchasers must monitor these developments independently and manage implementation without dealer assistance.

Evaluating Dealer Credentials and Capabilities

Not all dealers deliver equal value. When considering an authorized tube bender dealer, assess these critical factors:

Manufacturer Authorization Status

Verify current authorization directly with manufacturers. Authorized status ensures access to technical support, genuine replacement parts, warranty administration capabilities, and ongoing training. It also indicates the dealer meets manufacturer standards for technical competence and customer support.

Technical Staff Qualifications

Evaluate the technical team’s backgrounds. Do they have hands-on manufacturing experience? Have they completed manufacturer certification programs? Can they discuss material science considerations, tooling selection criteria, and process optimization strategies with engineering credibility?

Application Experience in Your Industry

A dealer’s experience with applications similar to yours provides valuable insight. Someone who has helped aerospace manufacturers meet AS9100 quality requirements or assisted petrochemical facilities with corrosion-resistant material bending brings knowledge that generic equipment sales cannot match.

Service Infrastructure

Understand service response commitments, parts inventory depth, and field technician availability. Ask for customer references specifically regarding service experiences, not just equipment sales. How quickly do they respond to urgent service calls? Do they stock parts for the specific equipment models you’re considering?

Building Long-Term Partnership Value

The most successful equipment acquisitions evolve into ongoing partnerships that deliver value throughout the equipment lifecycle. An industrial tube bending machine sales relationship should provide:

Process Optimization Consulting

As production requirements change, dealers can recommend tooling modifications, programming enhancements, or workflow adjustments that improve throughput and quality. They observe industry trends across multiple customers and can share best practices applicable to your operations.

Capacity Planning Support

When business growth demands additional equipment or capabilities, established dealer relationships streamline the specification and acquisition process. They understand your existing equipment, quality standards, operator skill levels, and facility constraints—knowledge that accelerates decision-making and reduces implementation risk.

Trade-In and Upgrade Paths

Technology advancement or changing production requirements may eventually necessitate equipment upgrades. Dealers facilitate trade-in programs, used equipment sales, and upgrade paths that maximize residual value from existing assets while minimizing disruption during transitions.

Making Your Decision: A Framework

Approach the dealer versus direct purchase decision systematically:

Assess internal capabilities honestly. Do you have technical staff qualified to manage installation, training, maintenance, and troubleshooting independently? Can you commit resources to these ongoing responsibilities?

Calculate total cost of ownership. Include training, installation, maintenance, parts inventory, potential downtime costs, and service support in your analysis. Initial purchase price differences often disappear when viewing the complete picture.

Consider risk tolerance. How severely would extended equipment downtime impact your operations? Industries with tight delivery schedules, high-value work-in-process, or critical safety applications typically benefit from the risk mitigation that robust dealer support provides.

Evaluate relationship quality. Meet with potential dealers. Assess their responsiveness, technical depth, and genuine interest in understanding your requirements. Strong partnerships begin with cultural compatibility and mutual respect.

Verify manufacturer support models. Some manufacturers strongly prefer dealer networks and provide limited support for direct sales. Others maintain robust direct sales operations. Understanding manufacturer preferences helps predict long-term support quality regardless of purchase path.

The American Manufacturing Advantage

When evaluating tube bending equipment, consider manufacturers with proven track records serving demanding applications. Companies that have supplied NASA, military contractors, and aerospace manufacturers demonstrate the quality control, engineering rigor, and performance consistency required for critical applications. American manufacturing heritage often correlates with accessible service networks, English-language technical support, and cultural alignment that simplifies communication and problem-solving.

Custom solution capabilities matter particularly for specialized applications. Manufacturers willing to engineer modifications, develop custom tooling, or adapt standard equipment to unique requirements provide flexibility that imported commodity equipment cannot match. Authorized dealers representing these manufacturers bridge the gap between standard catalog offerings and fully custom solutions.

Moving Forward With Confidence

The authorized dealer versus direct purchase decision fundamentally asks: what capabilities do you want to own internally versus access through partnership? There’s no universally correct answer, but understanding the full implications of each path ensures your decision aligns with operational realities and strategic priorities.

For most organizations, the comprehensive support, local service infrastructure, training resources, and ongoing consultation that authorized tube bending machine dealers provide justify any initial cost premium. The value compounds over years of operation, particularly when equipment performance directly impacts production quality, delivery reliability, and competitive positioning.

Take time to thoroughly evaluate potential dealers, verify their authorization status and capabilities, and build relationships before urgent equipment needs arise. The best time to establish these partnerships is before production pressure demands quick decisions that may overlook critical long-term considerations.

Ready to discuss your specific tube bending requirements with experienced application engineers? Contact Hines Bending Systems to explore how our precision equipment and comprehensive support infrastructure can enhance your production capabilities. Our team brings decades of experience serving aerospace, defense, petrochemical, and industrial manufacturers with American-made bending solutions engineered for demanding applications.