How to Choose the Right Pipe Bending Machine Manufacturer in 2026

Selecting a pipe bending machine manufacturer represents a significant capital investment that will impact your production capabilities for decades. The wrong choice can lead to costly downtime, compromised quality, and expensive retrofits. Yet with dozens of manufacturers claiming precision capabilities, separating genuine expertise from marketing hyperbole requires a systematic evaluation framework.

The landscape of industrial pipe bending equipment has evolved dramatically, with CNC technology, advanced servo systems, and specialized tooling enabling tolerances once considered impossible. However, the sophistication of modern bending equipment makes choosing the right pipe bending machine manufacturer more critical than ever. This decision impacts everything from first-part quality to long-term maintenance costs, training requirements, and your ability to meet increasingly stringent aerospace and energy sector specifications.

Manufacturing Origin and Supply Chain Stability

The origin of your bending equipment directly affects parts availability, service response times, and long-term support. American made pipe benders offer distinct advantages in 2026’s uncertain global environment, particularly for defense contractors and aerospace manufacturers facing strict domestic content requirements.

When evaluating a precision pipe bending manufacturer, investigate their supply chain resilience. Manufacturers who source critical components domestically can provide faster turnaround on replacement parts and modifications. This becomes crucial during production emergencies when a single day of downtime can cost tens of thousands of dollars.

Additionally, domestic manufacturing simplifies compliance with International Traffic in Arms Regulations (ITAR) and Buy American Act provisions. Companies serving defense, military, or federally funded projects should prioritize manufacturers with established ITAR compliance and documented domestic content verification.

Technical Capabilities and Application Expertise

Not all pipe bending machine manufacturers possess equal technical depth across materials and applications. A manufacturer excelling in structural steel bending may lack expertise in thin-wall aerospace tubing or exotic alloys common in petrochemical processing.

Material-Specific Experience

Evaluate manufacturers based on demonstrated experience with your specific materials. Bending titanium tubing for aerospace hydraulic systems requires fundamentally different expertise than forming large-diameter carbon steel pipe for oil and gas infrastructure. Request case studies, sample parts, and reference customers working with similar materials.

Critical material considerations include:

- Wall thickness-to-diameter ratios and collapsing tendencies

- Springback characteristics across different alloys

- Surface finish requirements and mandrel selection

- Heat treatment effects on bend quality

- Weld seam orientation for welded tubing

Bend Complexity and Tooling Capabilities

Complex multi-plane bends, tight centerline radii, and compound geometries separate competent manufacturers from true precision pipe bending specialists. An industrial pipe bending equipment manufacturer should demonstrate capabilities through actual production examples, not theoretical specifications.

Request information on their minimum centerline radius capabilities relative to tube diameter, maximum number of bends per part, and spatial orientation accuracy. Manufacturers with in-house tooling design and fabrication capabilities can optimize bend dies, mandrels, and wipers for your specific applications rather than forcing standard tooling compromises.

CNC Technology and Control Systems

Modern CNC pipe bender manufacturers differ significantly in control system sophistication, programming flexibility, and integration capabilities. The controller represents the brain of your bending operation, affecting cycle times, repeatability, and operator learning curves.

Advanced systems offer parametric programming that automatically compensates for springback based on material properties, reducing trial-and-error setup time. Look for manufacturers incorporating real-time monitoring, adaptive control adjusting for material variation, and integration with CAD/CAM systems for direct file import.

Verify whether the manufacturer provides simulation software allowing virtual bend validation before committing material. This capability proves invaluable when working with expensive aerospace alloys or developing new products with complex geometries.

Proven Track Record in Demanding Applications

Marketing claims mean little without verifiable performance in demanding environments. Manufacturers serving NASA, military contractors, nuclear facilities, and offshore oil platforms must meet rigorous quality standards backed by comprehensive documentation.

Request specific examples of projects similar to your applications. A manufacturer with decades of aerospace experience understands the documentation, traceability, and quality system requirements that extend far beyond the bending process itself. This institutional knowledge proves invaluable when navigating AS9100 certification, first article inspections, and ongoing production part approvals.

For oil and gas applications, verify experience with industry codes including ASME B31.3 for process piping and API specifications. Petrochemical projects demand understanding of material certifications, non-destructive testing requirements, and post-bend heat treatment protocols.

Custom Engineering and Solution Development

Standard catalog machines serve commodity applications adequately, but specialized production requirements often demand custom solutions. The best precision pipe bending manufacturers function as engineering partners, not merely equipment suppliers.

Evaluate their custom capabilities through these questions:

- Can they modify standard machines for unique part geometries or production volumes?

- Do they offer custom tooling design and fabrication in-house?

- Will they conduct material trials and process development before delivery?

- Can they integrate bending equipment into automated production cells?

- Do they provide application engineering support during startup and optimization?

Manufacturers offering turnkey solutions including material handling, end forming, cutting, and inspection equipment can simplify project management and ensure system-level compatibility.

Training, Documentation, and Knowledge Transfer

Sophisticated bending equipment delivers value only when operators and maintenance personnel understand its capabilities. Comprehensive training programs distinguish professional manufacturers from equipment brokers.

Quality training should cover programming fundamentals, tooling selection and setup, quality inspection procedures, preventive maintenance, and troubleshooting. The best programs combine classroom instruction with hands-on practice using your actual parts and materials.

Equally important is documentation quality. Electrical schematics, hydraulic diagrams, PLC code, maintenance schedules, and spare parts lists should be thorough, accurate, and understandable. Poor documentation leads to extended downtime when troubleshooting failures or training new personnel years after installation.

Service and Technical Support Infrastructure

Even the most reliable equipment eventually requires service, and production schedules don’t accommodate extended repair delays. A pipe bending machine manufacturer’s support infrastructure directly impacts your operational uptime.

Assess their service capabilities through specific criteria:

- Geographic proximity of service technicians and response time commitments

- Spare parts inventory and shipping timelines for critical components

- Remote diagnostic capabilities and phone support availability

- Rebuild and retrofit services for aging equipment

- Application support for new products or process optimization

Manufacturers with decades of operating history can support legacy equipment long after initial installation. This longevity matters when specifying equipment expected to remain productive for twenty or thirty years.

Quality Systems and Manufacturing Standards

An industrial pipe bending equipment manufacturer’s internal quality systems reflect the precision and reliability you can expect from their products. ISO 9001 certification represents baseline quality management, while aerospace manufacturers should seek suppliers with AS9100 certification demonstrating aviation-specific quality controls.

Request information on their inspection equipment, calibration procedures, and in-process quality checks. Manufacturers investing in coordinate measuring machines, laser trackers, and automated inspection systems demonstrate commitment to dimensional accuracy.

Understanding their manufacturing processes also reveals capability depth. Do they machine critical components in-house or subcontract fabrication? In-house machining, welding, and assembly provide better quality control and faster turnaround on custom modifications.

Total Cost of Ownership Analysis

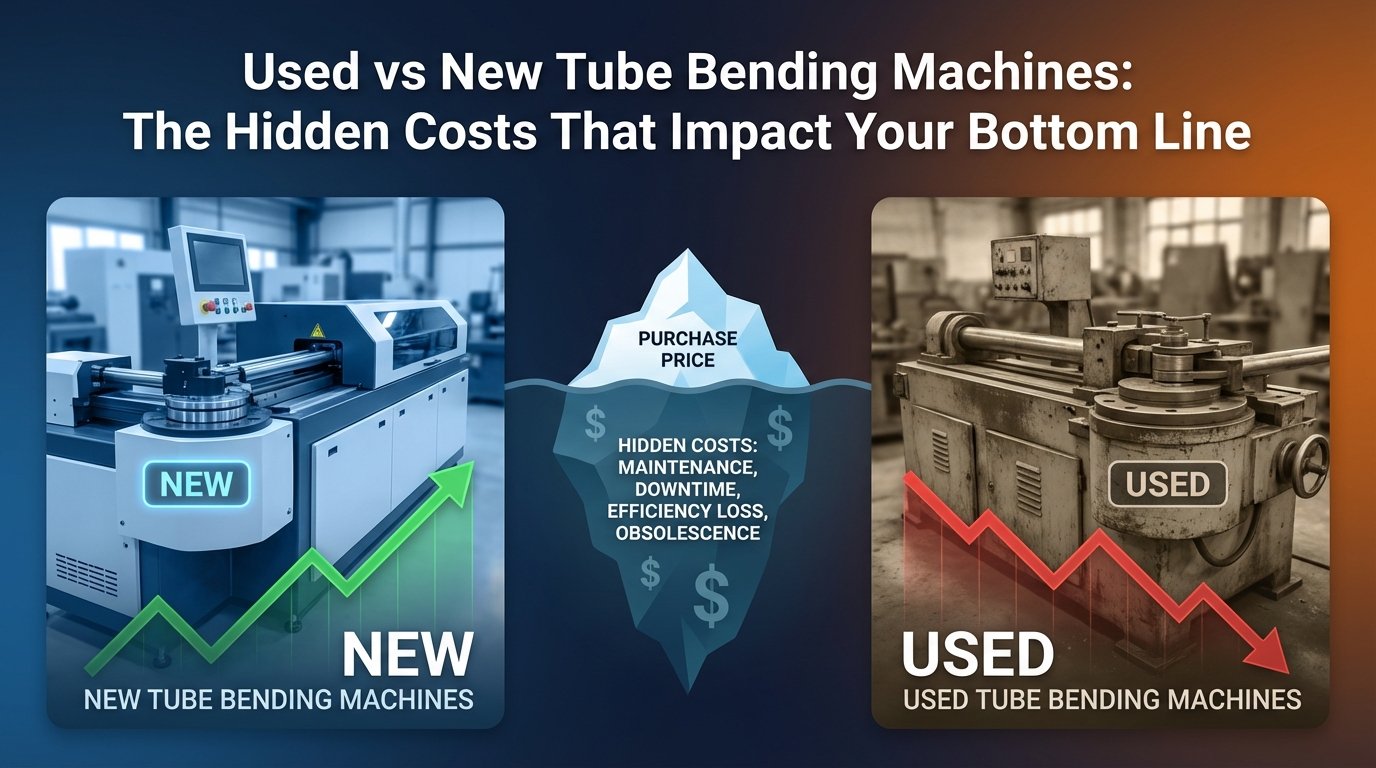

Purchase price represents only one component of total cost of ownership. Energy efficiency, maintenance requirements, consumable tooling costs, and productivity capabilities significantly impact long-term economics.

Modern servo-electric benders consume substantially less energy than older hydraulic machines while providing faster cycle times and improved repeatability. Calculate potential energy savings over the equipment’s expected life when comparing technologies.

Maintenance accessibility and component longevity affect ongoing costs. Well-designed machines provide easy access to wear components, use standard replacement parts where possible, and incorporate robust construction minimizing frequent repairs.

Productivity advantages from faster cycle times, reduced scrap rates, and minimal setup requirements often justify higher initial investment. A CNC pipe bender manufacturer offering simulation software, automatic springback compensation, and rapid tool changeover capabilities may deliver substantially better return on investment despite premium pricing.

Making Your Final Selection

After evaluating technical capabilities, support infrastructure, and total cost of ownership, narrow your selection to manufacturers demonstrating genuine expertise in your specific applications. Schedule facility visits to observe their manufacturing operations, meet engineering staff, and inspect similar equipment in production.

Request detailed proposals including machine specifications, tooling packages, training programs, warranty coverage, and service agreements. Verify lead times and installation requirements to ensure alignment with your production schedule.

Contact reference customers in similar industries to gather unfiltered feedback on equipment performance, manufacturer responsiveness, and long-term satisfaction. These conversations often reveal insights unavailable through formal evaluation processes.

Choosing the right precision pipe bending manufacturer requires balancing technical capabilities, proven performance, support infrastructure, and total cost of ownership. Manufacturers combining American manufacturing heritage, decades of aerospace and defense experience, comprehensive custom engineering capabilities, and unwavering commitment to customer support deliver the reliability and performance that critical applications demand. The decision you make today will impact your production capabilities and competitive position for decades—invest the time to choose wisely.

Ready to discuss your specific pipe bending requirements with a manufacturer offering proven expertise across aerospace, defense, energy, and industrial applications? Contact our engineering team to explore how precision American-made bending solutions can elevate your production capabilities and ensure consistent quality in even the most demanding applications.