When production requirements demand bends in large diameter pipes—think 24 inches and above—conventional bending methods quickly reach their limits. Induction bending emerges as the solution for these challenging applications, offering capabilities that rotary draw bending and mandrel bending simply cannot match at scale. This specialized tube bending technology uses controlled heat application to achieve precise bends in pipe sizes that would be impossible or economically unfeasible with mechanical methods.

Understanding when induction bending is the right choice versus other pipe bending methods can mean the difference between a successful project and costly delays. The decision involves evaluating pipe diameter, material specifications, bend radius requirements, and production volumes—all while maintaining the structural integrity demanded by critical applications in oil and gas, petrochemical facilities, and power generation.

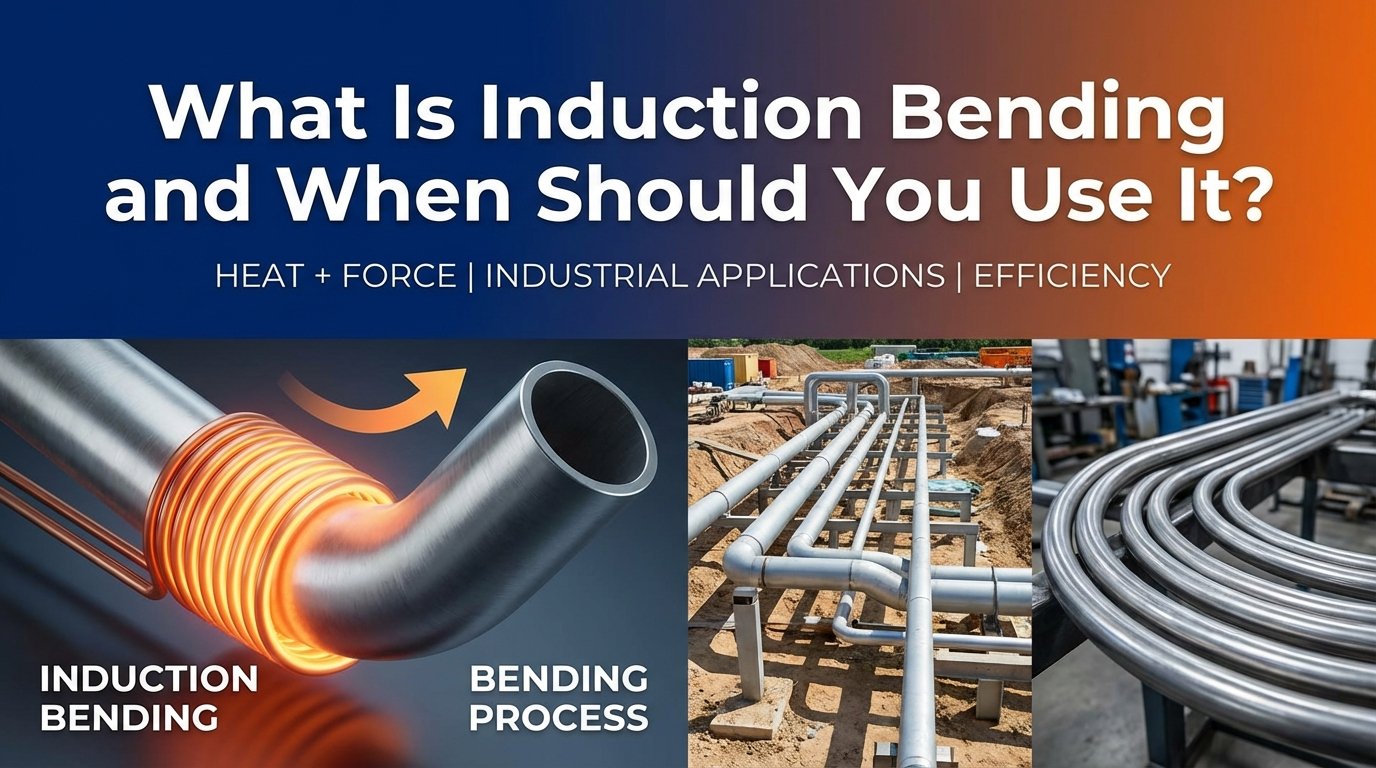

The Induction Bending Process Explained

Induction bending uses electromagnetic induction to heat a narrow, circumferential band of pipe material to temperatures typically between 1600°F and 2200°F, depending on the material composition. As the heated section reaches its plastic deformation range, hydraulic rams apply controlled force to bend the pipe around a fixed radius arm. The pipe advances slowly through the induction coil, creating a continuous bending process with the heated zone progressing along the pipe length.

This approach differs fundamentally from cold bending methods. Rather than applying mechanical force to room-temperature material—which requires enormous tonnage for large diameter pipe bending and risks material failure—induction bending reduces the material’s yield strength through precise heat application. The result is a controlled bend with predictable metallurgical properties and minimal wall thickness variation.

The process includes integrated water quenching immediately after bending, which controls cooling rates and helps maintain desired material properties. This is particularly critical when working with high-strength alloys or materials requiring specific heat-affected zone characteristics. Advanced induction bending systems include automated temperature monitoring and closed-loop control systems that adjust power input in real-time, ensuring consistent results across production runs.

When Induction Bending Is the Right Choice

Large Diameter Applications

Induction bending becomes the practical choice when pipe diameter exceeds the capacity of conventional bending equipment. While rotary draw bending typically maxes out around 6-8 inches for most production applications, induction bending handles pipes from 2 inches up to 56 inches in diameter. For oil and gas pipe bending applications involving pipeline construction or facility piping, this capability is often non-negotiable.

The economics shift dramatically at larger diameters. A rotary draw bender capable of handling 12-inch pipe represents a massive capital investment, with tooling costs adding significantly to project expenses. Induction bending equipment handles multiple diameters with minimal tooling changes, making it cost-effective for large pipes even in relatively low volumes.

Long Radius Bends

When specifications call for bend radii of 5D (five times the pipe diameter) or greater, induction bending excels. The process naturally produces sweeping, long-radius bends ideal for applications where flow characteristics matter. Petrochemical process piping often requires these gentle bends to minimize pressure drop and reduce turbulence that could affect process efficiency or create erosion concerns.

For example, a 24-inch diameter pipe with a 10D bend radius requires a centerline radius of 240 inches—a 20-foot radius curve. Creating this geometry through mechanical means would demand extraordinary forces and specialized fixturing. Induction bending produces it as a standard process output.

Heavy Wall Thickness

Thick-walled pipe presents challenges for cold bending methods, which must overcome the material’s resistance through brute force. Wall thicknesses up to 4 inches or more are routinely handled with induction bending, as the heating process reduces yield strength regardless of wall thickness. This makes the technology essential for high-pressure applications in oil and gas facilities, where schedule 160 pipe or heavier is common.

The process also maintains more consistent wall thickness distribution. Cold bending thick-walled pipe tends to produce significant thinning on the extrados (outer radius) and thickening on the intrados (inner radius). Induction bending minimizes these variations, keeping wall thickness within tighter tolerances—critical when every millimeter affects pressure ratings and code compliance.

High-Strength and Specialty Materials

Materials that resist cold working—including high-strength carbon steels, chrome-moly alloys, stainless steels, duplex and super-duplex stainless, nickel alloys, and titanium—often require induction bending. The controlled heating brings these materials into their workable temperature range without the excessive force that risks cracking or material damage.

Induction bending also offers process advantages for materials requiring specific heat treatment. The bending operation can be integrated with heat treatment protocols, and the controlled cooling phase can be engineered to achieve desired metallurgical outcomes. For aerospace applications using exotic alloys, this capability ensures bends meet stringent material property requirements without additional processing steps.

Comparing Pipe Bending Methods

Selecting the appropriate tube bending technology requires understanding how different methods compare across key parameters:

Rotary Draw Bending uses a rotating bend die and pressure die to pull pipe around a fixed radius while a mandrel supports the interior. This method excels for tight radius bends (1D to 3D), offers excellent repeatability, and produces superior surface finish. However, diameter capacity tops out around 8 inches for most applications, and tooling costs escalate with pipe size. This remains the preferred method for small to medium diameter applications requiring tight radii.

Roll Bending passes pipe through three rolls arranged in a pyramidal or triangular configuration, with adjustable roll positions creating the desired radius. This method handles very large diameters and long lengths, making it ideal for spirals, coils, and very large radius curves. However, it cannot produce tight radii, struggles with heavy wall material, and offers less precision than rotary draw or induction methods.

Induction Bending occupies the middle ground with unique advantages. It handles larger diameters than rotary draw, produces tighter radii than roll bending (down to 1.5D in some applications), and works with materials and wall thicknesses that challenge other methods. The tradeoff is surface finish—the heated zone may show discoloration or scale requiring removal—and slightly lower precision than rotary draw bending’s mechanical consistency.

Critical Considerations for Induction Bending

Material Properties and Heat-Affected Zones

The heating cycle inherent to induction bending creates a heat-affected zone that requires careful consideration. For carbon steels, controlled cooling prevents excessive hardening or brittleness. Stainless steels require attention to carbide precipitation in certain temperature ranges. Aerospace applications may mandate specific heat treatment protocols and material testing to verify that mechanical properties meet specifications post-bending.

Reputable induction bending services provide material test reports documenting tensile strength, yield strength, elongation, and impact properties in the bend zone. When working with critical applications—pressure vessels, aerospace structures, or defense systems—these certifications prove that the bending process hasn’t compromised material integrity.

Dimensional Tolerances

Modern induction bending achieves angular tolerances of ±0.5 degrees and radius tolerances within ±1% for most applications. While this represents excellent precision for a hot-working process, it differs from the tighter tolerances possible with cold rotary draw bending. Engineering specifications should reflect realistic expectations based on the chosen bending method.

Ovality—the difference between maximum and minimum diameters in the bent section—typically stays within 3-5% for induction bending. For applications where tight ovality control matters, post-bend sizing operations can restore circularity, though this adds process steps and cost.

Surface Finish and Post-Processing

The induction heating zone creates surface oxidation and scale, particularly on carbon steel. Many applications require scale removal through abrasive blasting, grinding, or chemical treatment. Stainless steel may show heat tint requiring passivation. Budget for these secondary operations when comparing costs across pipe bending methods.

For applications where external appearance matters less than structural performance—buried pipelines, internal facility piping, structural elements—the surface condition may be acceptable as-bent, reducing overall processing costs.

Real-World Applications Across Industries

Pipeline construction relies heavily on induction bending for directional changes in long-distance transmission lines. Whether moving crude oil across continents or natural gas from wellheads to processing facilities, large diameter pipe bending through induction methods creates the geometry that conventional techniques cannot achieve. Bends replace welded mitered joints, reducing potential leak points and improving flow characteristics.

Petrochemical facilities use induction-bent pipe throughout process units. Reformers, crackers, and distillation columns require large-diameter piping that routes around equipment, crosses structural members, and connects vessels at varying elevations. The combination of size capacity, material compatibility, and reasonable lead times makes induction bending the practical choice for these installations.

Power generation—both conventional and renewable—depends on induction bending for steam piping, cooling water systems, and process connections. Nuclear facilities, coal-fired plants, and combined-cycle gas turbines all incorporate large-diameter bent pipe that meets exacting specifications for pressure, temperature, and code compliance.

Offshore platforms and marine construction utilize induction-bent pipe for risers, subsea connections, and facility piping where space constraints and harsh operating environments demand robust, precisely-engineered solutions. The process’s ability to handle corrosion-resistant alloys proves essential in saltwater environments.

Selecting an Induction Bending Partner

Not all induction bending capabilities are equal. When sourcing for critical applications, evaluate potential partners on several criteria. Equipment capacity determines maximum pipe size, wall thickness, and material types they can process. Quality systems—including ISO certifications, ASME code stamps, and customer-specific approvals—indicate commitment to consistent results.

Material testing capabilities matter significantly. In-house testing laboratories that can verify mechanical properties, chemical composition, and weld integrity provide faster turnaround and better quality assurance than operations dependent on outside testing services.

Experience with your specific application and materials reduces risk. A partner with proven track records in oil and gas pipe bending brings knowledge of industry codes, common specifications, and potential pitfalls. For aerospace or defense work, relevant approvals and security clearances may be non-negotiable requirements.

American manufacturing provides advantages beyond domestic content compliance. Shorter supply chains, easier communication across time zones, and alignment with U.S. quality standards streamline complex projects. For applications involving ITAR-controlled technology or sensitive defense programs, domestic manufacturing may be mandatory.

Moving Forward With Your Bending Requirements

Induction bending represents a powerful solution for applications where pipe size, material, or geometry exceeds the capabilities of conventional methods. Understanding when this technology offers advantages—and when alternative pipe bending methods might be more appropriate—ensures optimal outcomes for demanding industrial applications.

Whether you’re engineering a petrochemical facility expansion, specifying components for aerospace applications, or planning pipeline infrastructure, selecting the right bending approach early in the design phase prevents costly redesigns and delays. Engage with experienced bending partners during the specification stage to optimize designs for manufacturability while meeting performance requirements.

For over six decades, Hines Bending Systems has provided precision tube and pipe bending solutions to the most demanding industries, including proven performance on NASA programs and military applications. Our American manufacturing facility combines advanced technology with deep expertise in rotary draw, mandrel, and induction bending methods. Contact our engineering team to discuss your specific requirements and discover how the right bending solution supports your project success.