Why Understanding Pipe Bending Technology Matters for Manufacturing Excellence

Understanding how does bend pipe machine works is crucial for any manufacturing operation that demands precision, efficiency, and consistent quality. At its core, a pipe bending machine applies controlled force to deform metal tubing around a forming die while maintaining the pipe’s structural integrity and dimensional accuracy.

Quick Answer: How Pipe Bending Machines Work

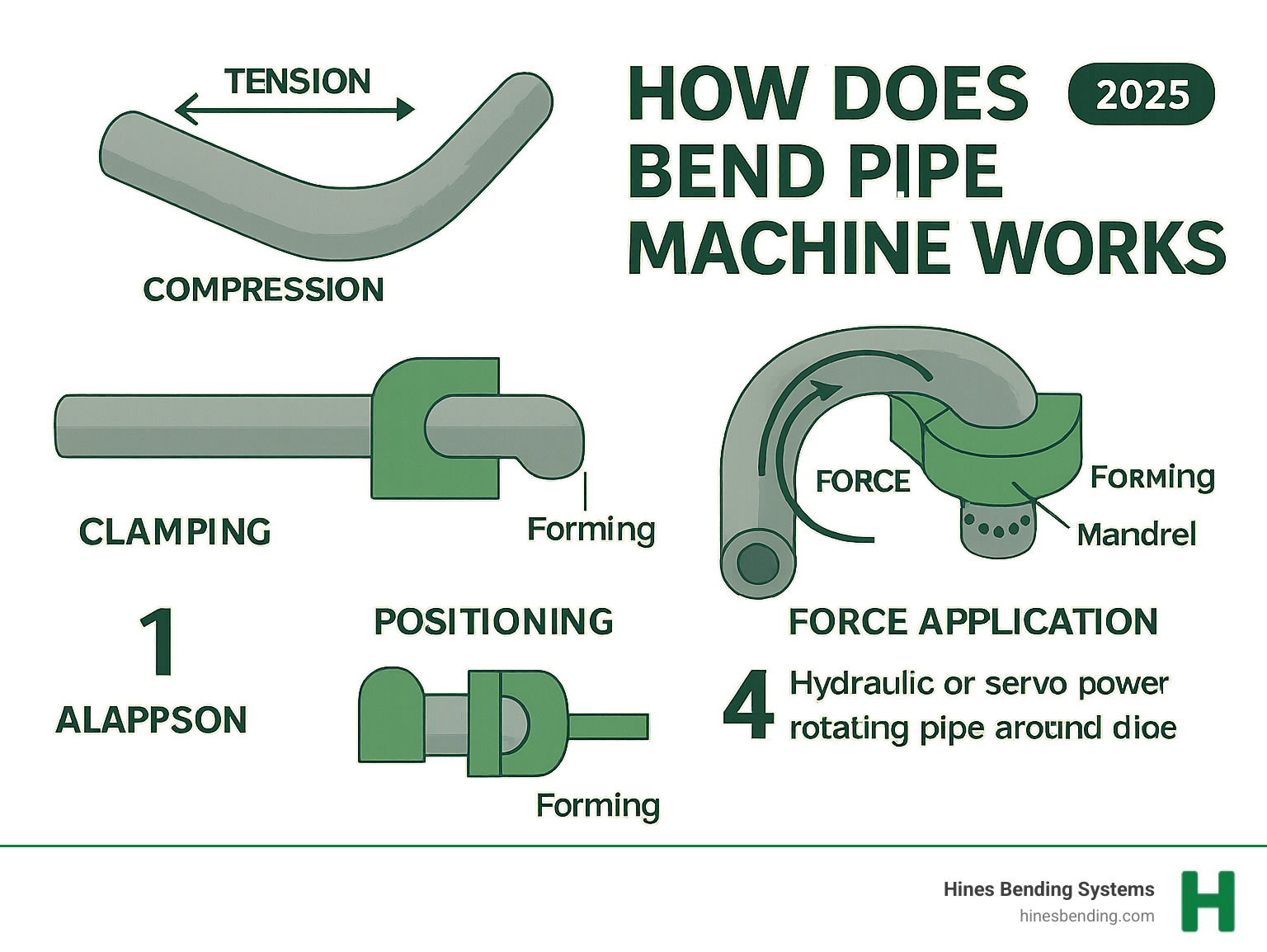

- Clamping: The pipe is secured in a clamp die

- Positioning: A forming die provides the bend radius template

- Force Application: Hydraulic or servo power rotates the pipe around the die

- Support: Internal mandrels prevent collapse and wrinkling

- Release: The bent pipe is removed with precise angle achievement

In modern manufacturing, the difference between success and costly failures often comes down to the quality of your bending equipment. Poor-quality machines can lead to material waste, production delays, and components that fail to meet critical specifications.

Hines Bending Systems stands as the world’s #1 manufacturer of tube benders, pipe benders, and induction benders. With decades of experience serving demanding clients like NASA and major aerospace manufacturers, Hines has perfected the art and science of precision bending.

The complexity of pipe bending goes far beyond simply pushing metal around a curve. Modern applications require machines that can handle everything from thin-wall tubing for medical devices to heavy structural components for construction projects. This is where expertise matters most.

Whether you’re bending exhaust pipes for automotive applications or creating complex fuel lines for aircraft, understanding how your bending machine works helps you make informed decisions about equipment selection, operator training, and quality control processes.

Essential how does bend pipe machine works terms:

The Anatomy of a High-Performance Hines Bender

When you peek inside a Hines bending machine, you’re looking at decades of engineering excellence. Understanding how does bend pipe machine works starts with knowing the five critical components that work together like a well-rehearsed orchestra to create perfect bends every single time.

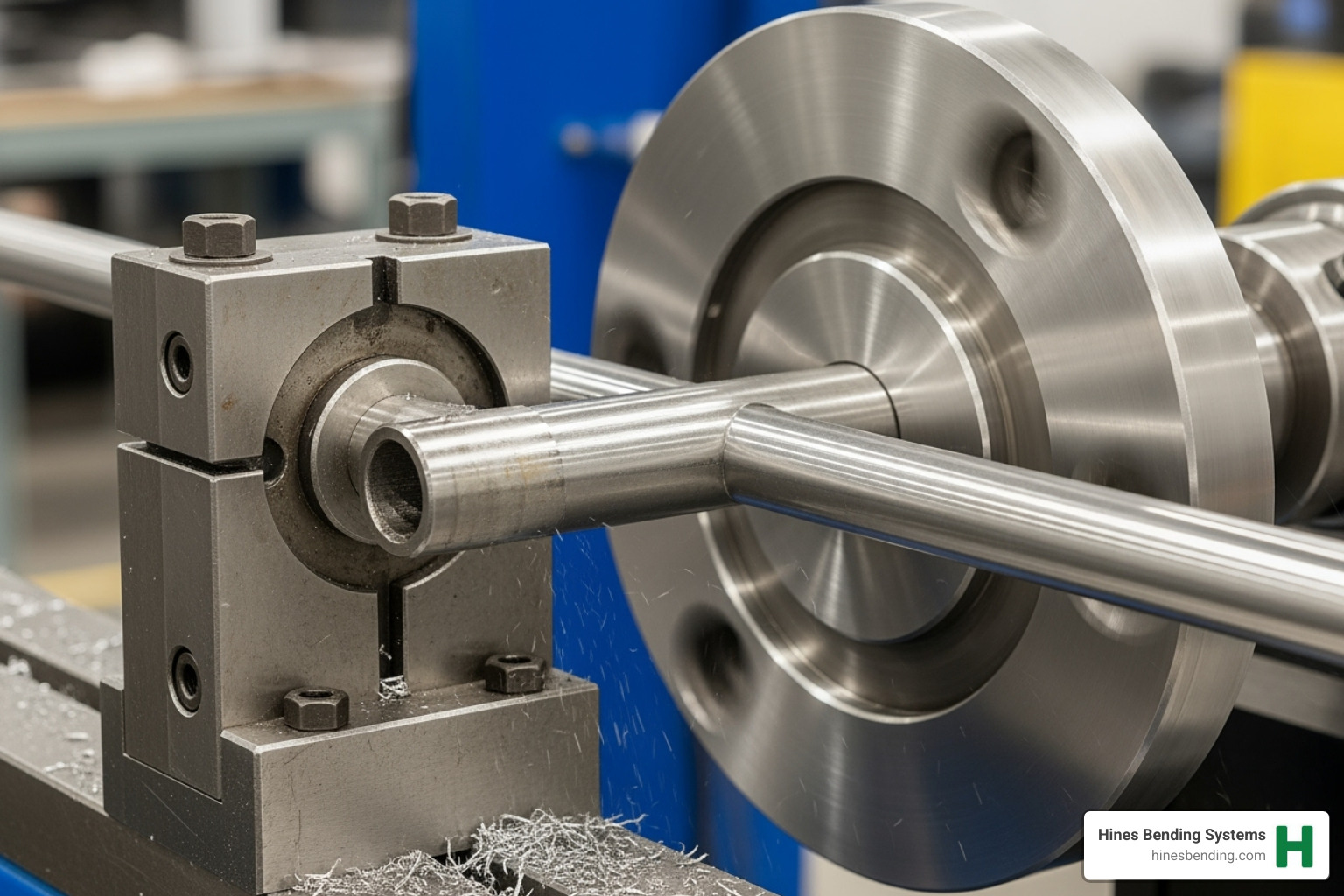

At the heart of every Hines machine sits the bending die – think of it as the template that shapes your pipe’s destiny. This hardened steel component determines the exact radius and curve of your bend. Our dies are precision-machined to tolerances that would make a Swiss watchmaker proud.

Working alongside the bending die is the clamp die, which grips your pipe with the strength of a vise but the gentleness of a craftsman’s hands. This prevents any slippage during bending – because nothing ruins a perfect bend quite like a pipe that decides to slip mid-process.

The pressure die acts like a guiding hand on the outside of your pipe, applying just the right amount of force to prevent wrinkling or buckling. It’s positioned perfectly to support the outer radius as the pipe forms around the bending die.

Hidden inside the pipe but absolutely essential is the mandrel – we’ll dive deep into this unsung hero in just a moment. And finally, there’s the wiper die, positioned right at the bend’s starting point to smooth away any wrinkles that might try to form as the material compresses.

What sets Hines apart isn’t just having these components – it’s how we craft them. Our hardened steel tooling undergoes rigorous quality control because we know that inferior tooling leads to inferior bends. When NASA trusts us with their critical aerospace components, there’s simply no room for compromise.

The magic happens when all these components work in perfect harmony. Each piece supports the others, creating smooth, uniform curves that maintain structural integrity while achieving the precise angles your application demands. For more details about how our specialized approach delivers superior results, check out More info about Hines Mandrel Pipe Benders.

Understanding Mandrels: How Does a Hines Bend Pipe Machine Work Without Deforming the Pipe?

Here’s where things get really interesting. Imagine trying to bend a drinking straw without it collapsing – that’s essentially what we’re doing with metal pipes, except the stakes are much higher. The mandrel is our secret weapon for achieving this seemingly impossible task.

The mandrel provides crucial internal support during the bending process, preventing your pipe from turning into an oval-shaped disaster. Without this internal hero, thin-wall tubing would collapse faster than a house of cards, and tight radius bends would be nothing but a pipe dream (pun intended).

Preventing collapse and preventing wrinkling are the mandrel’s primary jobs, but it’s how Hines has perfected this technology that makes all the difference. Our decades of innovation in mandrel design and application mean we’ve seen every possible bending challenge – and solved them.

For thin-wall tubing applications, we typically use ball mandrels – ingenious devices consisting of multiple articulated balls on a flexible cable. These adapt to the bend’s curve while providing continuous support along the inner radius. Think of them as a flexible backbone that keeps everything in perfect alignment.

When you’re working with thicker materials or gentler bends, our plug mandrels do the job beautifully. These solid, cylindrical supports are simpler but incredibly effective for less demanding applications.

The beauty of working with Hines isn’t just getting a machine – it’s getting our expertise in selecting exactly the right mandrel for your specific application. Whether you’re bending aerospace fuel lines or automotive exhaust components, we know which mandrel design will deliver flawless results. After all, when you’re the world’s #1 manufacturer of tube and pipe benders, you don’t leave anything to chance.

The Core Mechanics: How Does a Hines Bend Pipe Machine Work?

Now that we’ve explored the essential components, let’s dive into the heart of the matter: how does bend pipe machine works. At Hines Bending Systems, we’ve perfected the art of rotary draw bending, the most precise method available for creating accurate bends with tight radii.

Understanding how does bend pipe machine works begins with recognizing that bending is essentially a controlled deformation process. When our Hines machines apply force to bend a pipe, something fascinating happens at the molecular level. The material on the outer radius stretches under tension, becoming slightly thinner, while the inner radius compresses, actually becoming thicker.

Think of it like bending your arm at the elbow – the skin on the outside stretches while the inside bunches up. Our machines must carefully manage these opposing forces to create smooth, precise bends without damaging the pipe.

The magic starts when we securely clamp one end of the pipe to our precision-engineered bending die. As this die rotates, it draws the pipe around its curved form. But here’s where Hines expertise really shines – our pressure die and wiper die work together like a perfectly choreographed dance, guiding and supporting the pipe through every degree of the bend.

A challenge in pipe bending is something called springback. Just like a rubber band snaps back when you release it, metal has an elastic memory. After we remove the bending force, the pipe tries to return to its original straight shape. This is where decades of Hines innovation pay off.

Our engineers have developed sophisticated compensation techniques that account for springback before it happens. We might over-bend slightly (going a few degrees past the target angle) or apply bottoming pressure at the end of the cycle. These aren’t guesswork – they’re precise calculations based on material properties, wall thickness, and bend radius.

The physics behind metal forming involves understanding each material’s yield strength and elastic modulus. Our team at Hines has best expertise in these complex calculations, ensuring our machines deliver exactly the right force and angle settings for every unique bending challenge. This is why major organizations like NASA trust us for their most critical applications. Learn more about our precise bending processes at: More info about the Hines bending process.

The Step-by-Step Bending Process

Creating a perfect bend isn’t just about having the right machine – it’s about following a proven process that ensures consistent, high-quality results every time. At Hines Bending Systems, we’ve refined this process through decades of experience and thousands of installations worldwide.

Material preparation sets the foundation for success. We start by thoroughly cleaning the pipe to remove any debris that could scratch our precision tooling. The pipe is then carefully measured and marked at the exact bending points. Deburring the edges isn’t just good practice – it protects our expensive dies and ensures clean, professional-looking bends.

Machine setup is where our expertise really shows. Selecting the right combination of bending die, clamp die, pressure die, mandrel, and wiper die requires deep understanding of how different materials behave. Our Hines machines make this easier with intuitive controls, but the knowledge of which tools to use comes from experience.

The clamping phase might seem simple, but proper alignment is absolutely critical. Even a slight misalignment can cause the bend to occur in the wrong location or create unwanted distortion. Our machines feature precision clamping systems that ensure the pipe is held exactly where it needs to be.

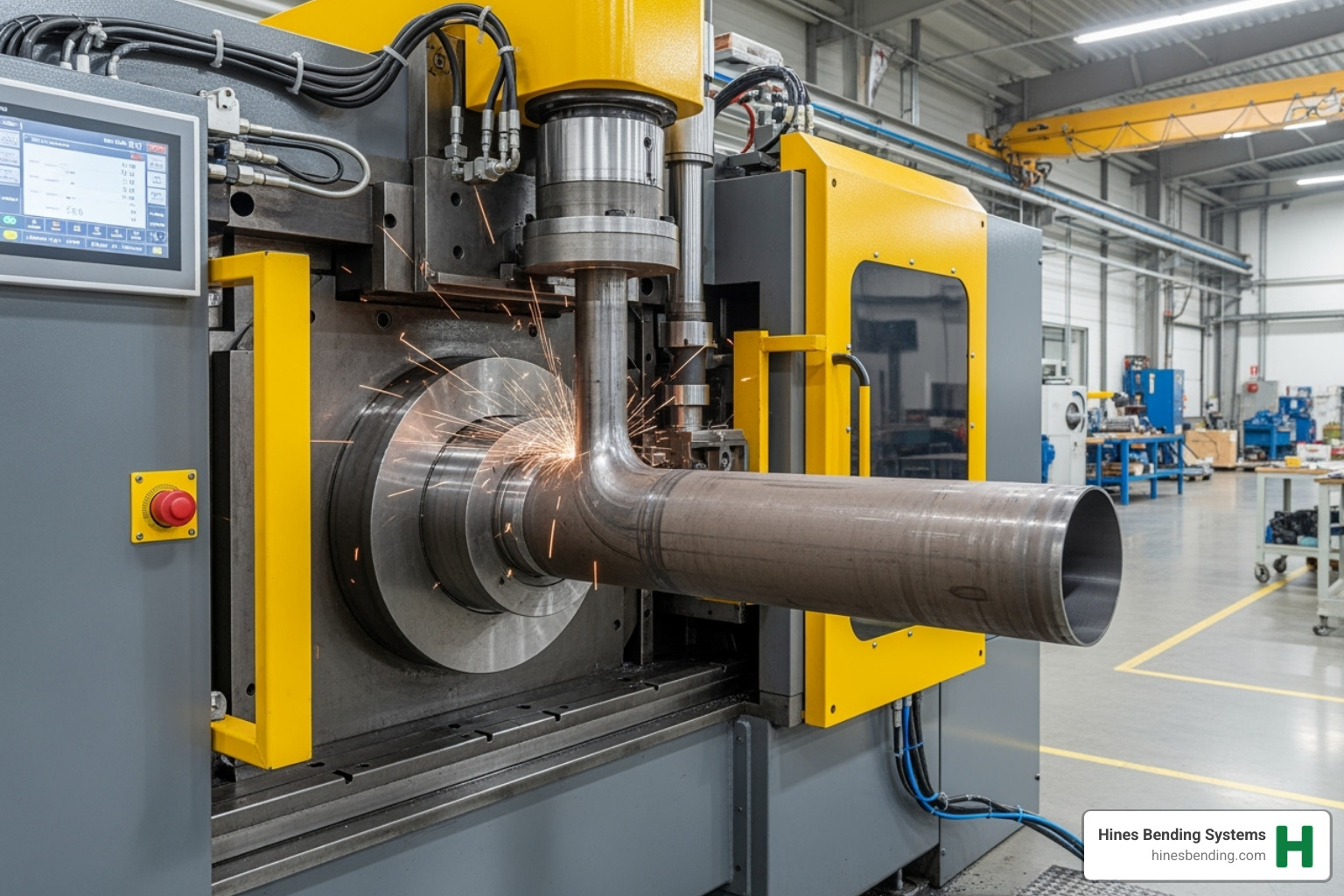

During the bending cycle, everything comes together. The bending die rotates smoothly, drawing the pipe around its form while our pressure die and wiper die provide continuous support. If we’re using a mandrel, it prevents internal collapse throughout the entire bend. Our advanced control systems monitor force and angle in real-time, making micro-adjustments to achieve the programmed specifications.

Quality inspection happens immediately after each bend. Our systems can integrate optical sensors or laser measurement tools that verify bend angle, radius, and overall quality instantly. This immediate feedback allows for quick adjustments if needed, preventing waste and ensuring consistency.

Finally, post-processing may include deburring, cleaning, or stress-relieving treatments depending on the application. Some aerospace components require annealing to remove residual stresses, while exhaust pipes might need surface finishing.

While our Hines machines are designed for intuitive operation, achieving consistent excellence requires proper training. That’s why we provide comprehensive proper Hines training to our clients. We don’t just sell machines – we partner with you to ensure manufacturing success. After all, when you’re supplying critical components to organizations like NASA, there’s no room for error.

Advanced Hines Bending Technologies and Their Impact

The evolution of pipe bending technology tells a fascinating story of innovation, and at Hines Bending Systems, we’ve been writing that story for decades. Understanding how does bend pipe machine works today means appreciating this remarkable journey from manual labor to the sophisticated automated systems we engineer.

Picture the early days of pipe bending – workers wielding simple tools, applying brute force and hoping for consistent results. Those manual methods, while still useful for basic applications, simply couldn’t deliver the precision and efficiency that modern manufacturing demands. The real game-changer came with hydraulic power systems, which revolutionized how we approach metal forming.

Hydraulic pipe bending machines transformed the industry by using controlled hydraulic pressure to generate tremendous force. This breakthrough made it possible to bend larger, thicker pipes with smooth, controlled movements around forming dies. Suddenly, what once required multiple workers and inconsistent results could be accomplished with remarkable precision.

But we didn’t stop there. The introduction of electric servo motors marked another quantum leap in bending technology. These incredibly precise motors offer unparalleled control over every aspect of the bending process, allowing for minute adjustments that make the difference between good and exceptional results.

At Hines, we’ve witnessed how this evolution from manual to automated, then to servo-driven systems has transformed entire industries. Our clients see dramatic improvements in production efficiency, consistent quality, and reduced material waste. This isn’t just technological progress – it’s manufacturing excellence in action.

Our commitment to innovation means we’re constantly integrating the latest advancements into every machine we build. When you partner with Hines Bending Systems, you’re not just getting today’s cutting-edge technology – you’re investing in a company that’s already developing tomorrow’s solutions.

How Hines CNC Technology Revolutionizes Pipe Bending

Computer Numerical Control technology hasn’t just improved pipe bending – it’s completely revolutionized it. At Hines Bending Systems, CNC isn’t merely a feature we add to our machines; it’s the foundation of everything we do, representing our unwavering commitment to precision and efficiency.

When people ask us how does bend pipe machine works with such incredible accuracy, the answer lies in our advanced CNC systems. These sophisticated computers use programmed calculations to determine optimal force and angle settings, automatically employing compensation techniques like over-bending or bottoming to counteract springback – that natural tendency of metal to partially return to its original shape.

The change this technology brings to manufacturing is nothing short of remarkable. Precision and repeatability reach levels that were simply impossible with manual operations. Every bend follows programmed instructions with extreme accuracy, ensuring identical results whether you’re producing ten parts or ten thousand. This consistency eliminates the variations that plague manual operations.

Human error becomes virtually eliminated through automation. Our CNC systems execute bending sequences flawlessly, dramatically reducing material waste and increasing production yields. The peace of mind this brings to our clients – knowing their expensive materials won’t be wasted due to operator mistakes – is invaluable.

Perhaps most impressively, CNC technology handles complex, multi-plane, and multi-radius bends that would challenge even the most skilled manual operator. Our advanced software integrates seamlessly with CAD/CAM programs, translating design blueprints directly into machine instructions. What once took hours of setup and multiple attempts now happens automatically.

The speed and efficiency gains are equally impressive. Programmed bending sequences execute rapidly, dramatically increasing production capacity, especially for high-volume manufacturing. Our clients consistently report production increases of 300% or more when transitioning to our CNC systems.

Material versatility expands exponentially with CNC control. The precise parameter control makes it practical to work with everything from soft copper to robust stainless steel, and even challenging alloys like titanium. Each material gets exactly the treatment it needs for optimal results.

Our decades of expertise in CNC programming and machine design mean that Hines Bending Systems delivers machines that are both state-of-the-art and remarkably user-friendly. We believe advanced technology should make your job easier, not more complicated. Explore our cutting-edge solutions at: Hines CNC Tube Bending Machines.

The Power of Hines Induction Bending

While rotary draw bending excels for countless applications, some challenges demand a completely different approach. When you’re dealing with massive diameter pipes or extremely thick-walled materials, traditional methods simply reach their limits. This is where the specialized power of induction bending – a technique we’ve perfected at Hines Bending Systems – truly shines.

Induction bending works through localized heating magic. An induction coil heats a very specific section of the pipe while a bending arm applies controlled force. We hold one end of the pipe steady while pulling or pushing the other end through the heated coil. The heated zone becomes plastic and pliable, allowing smooth bending with minimal distortion. Our systems typically operate at temperatures ranging from 800 to 2,200 degrees Fahrenheit.

The advantages of this approach are truly impressive. Large diameter pipes and thick-wall materials that would be impossible to bend through traditional methods become manageable. We can accommodate pipe sizes from 1″ OD all the way up to massive 80″ OD pipes – perfect for major infrastructure projects.

No internal mandrel is typically required because the heated material becomes highly pliable. This simplifies the entire process and reduces tooling costs significantly for these specific applications. It’s neat in its simplicity.

Energy efficiency is another major benefit. Since we only heat a small section of the pipe at any given time, the process uses relatively little energy compared to heating entire pipe lengths. This efficiency translates directly to cost savings for our clients.

The superior bend quality for structural applications is what really sets induction bending apart. The process produces bends with excellent dimensional accuracy, minimal ovality, and consistent wall thickness throughout. This makes it perfect for critical structural components in bridges, buildings, and pipelines where failure isn’t an option.

Flexibility in design opens up possibilities that other methods simply can’t match. Free selection of bend radii and angles gives engineers and designers tremendous creative freedom. The results are smooth, uniform curves with no external collapses or internal folds.

Industries like petrochemical, construction, and power generation rely on this technology for their most demanding applications. Our Hines Induction Benders are engineered to deliver unparalleled performance for these challenging tasks, showcasing our ability to provide solutions for every bending challenge, regardless of scale. Find more about this powerful technology: Learn about Hines Induction Benders.

Precision in Practice: Critical Industry Applications

The ability to precisely bend pipes and tubes is not just a manufacturing capability; it’s a fundamental requirement across a vast spectrum of industries where functionality, safety, and efficiency are paramount. At Hines Bending Systems, we take immense pride in the role our machines play in these critical applications.

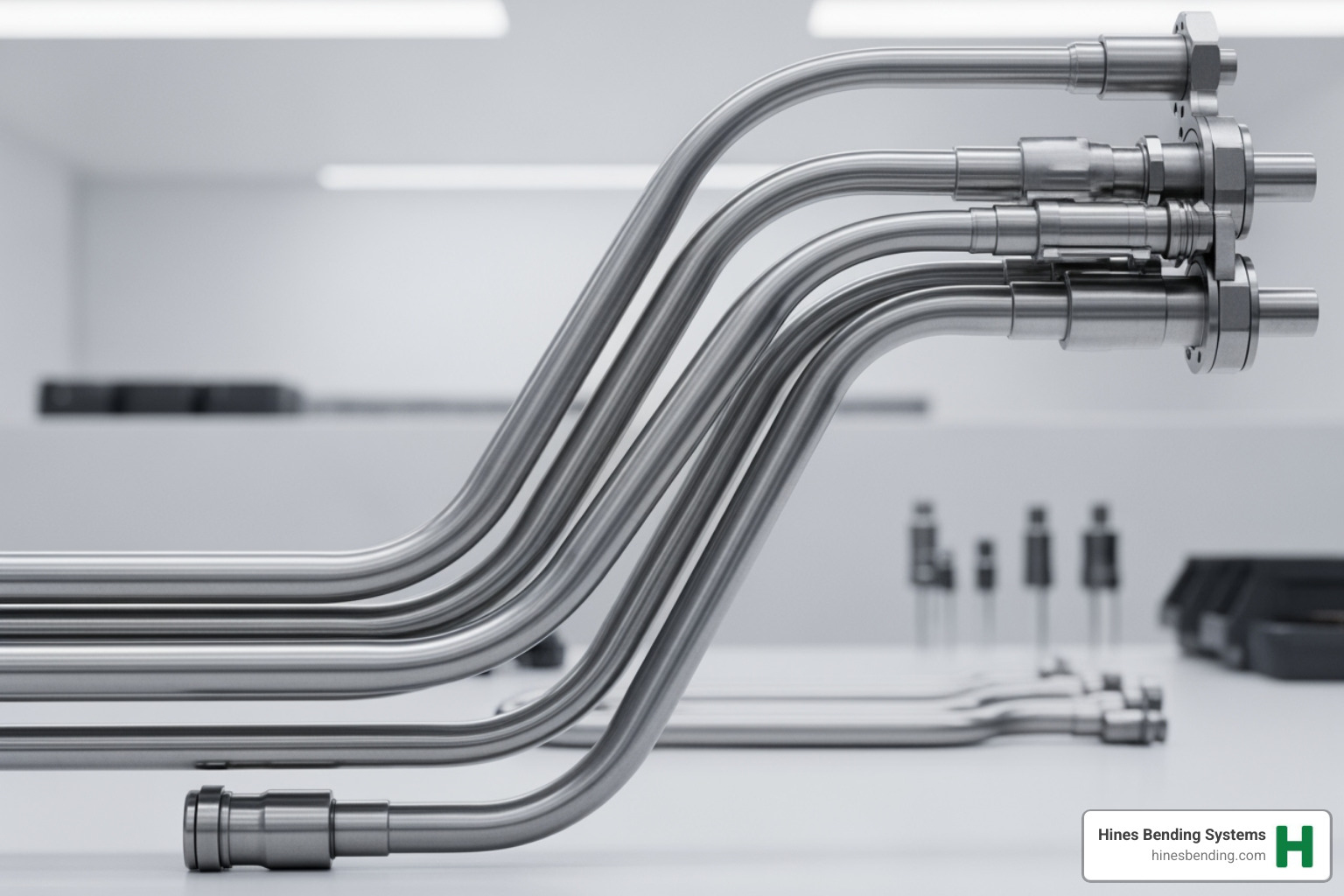

Pipe bending machines are widely used in the automotive industry to manufacture components such as exhaust pipes, fuel lines, and cooling system ducts. The pipes processed by our benders have a smooth and uniform curve, with no external collapses or internal folds, ensuring optimal flow and performance.

In the aerospace industry, pipe bending machines produce critical components like fuel pipes and structural elements for aircraft and satellites. For these applications, precision is not just desired; it’s non-negotiable. Every bend must be perfect to ensure the safety and reliability of aerospace systems. Our machines are trusted by leading aerospace manufacturers precisely because they deliver the zero-failure components required for flight.

Beyond these, our bending machines are essential in:

- Construction: Fabricating curved architectural elements, structural supports for bridges, and complex piping systems for modern buildings.

- Shipbuilding: Creating intricate pipe networks for propulsion, cooling, and various systems within vessels, often involving large diameters and complex layouts.

- Energy and Oil & Gas: Producing pipelines and components for exploration, extraction, and transportation of resources, where durability and integrity are vital.

- Medical Equipment: Bending small, precise tubes for medical devices where sterility and exact dimensions are crucial.

The extensive applications of pipe bending machines underscore their versatility and importance. The pipe bender can bend various metal materials such as stainless steel, iron, copper, aluminum, titanium, and carbon steel. From automotive to aerospace, our Hines machines are the backbone of industries that demand the highest standards. We are incredibly proud to supply massive organizations and government agencies like NASA with bending machines, a testament to our best quality and reliability. Read more about our collaboration: Read about Hines’ work with NASA.

Conclusion: Partnering with Hines for Flawless Results

Understanding how does bend pipe machine works is more than just technical knowledge—it’s about recognizing the intricate balance of engineering expertise, material science, and precision manufacturing that transforms raw materials into the components powering our modern world. From the simplest exhaust bend to the most complex aerospace fuel line, every curve tells a story of innovation and craftsmanship.

At Hines Bending Systems, we’ve spent decades perfecting this story. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, our journey isn’t just about building machines—it’s about building partnerships that last. When you choose Hines, you’re not just buying equipment; you’re gaining access to unparalleled expertise that has earned the trust of organizations like NASA and countless industry leaders worldwide.

The importance of experience cannot be overstated in the bending industry. Every material behaves differently under stress. Every application demands unique considerations. Every production run presents its own challenges. This is where our decades of collective knowledge become your competitive advantage. We don’t just manufacture bending machines; we craft custom bending solutions custom to your specific needs, working closely with you to ensure every detail meets your exacting standards.

The value of superior quality becomes crystal clear when you consider the alternative. Cheaper equipment might seem attractive initially, but the hidden costs of material waste, production delays, and failed components quickly add up. Our Hines machinery is engineered to meet the most stringent industry standards, delivering consistent results that protect your reputation and your bottom line. Nobody in the bending machine industry has more expertise and experience than Hines—and that expertise translates directly into machines that perform flawlessly, day after day, year after year.

Avoiding costly errors starts with choosing the right partner from the beginning. When selecting a bending solution, consider these critical factors: Material Type determines the tooling and machine capabilities you’ll need, while Production Volume influences whether you need flexibility for small batches or efficiency for high-volume runs. Required Precision affects everything from machine selection to operator training, and perhaps most importantly, Supplier Expertise determines whether you’ll have the support and knowledge needed to maximize your investment.

Hines Bending Systems’ industry leadership isn’t just about our impressive client roster or our innovative technologies like the Dual Stack CNC Push Bender and Roll Bender. It’s about our commitment to your success. We believe in the power of proper training and continuing education, enhancing the efficiency of your engineering and production teams. When challenges arise—and they always do in manufacturing—you’ll have the full weight of our expertise behind you.

For the highest quality tube and pipe benders, backed by best expertise and an unwavering commitment to customer satisfaction, we invite you to explore our comprehensive product line. Partner with Hines Bending Systems, and find what it means to bend it better, every time.