Why Electrical PVC Bend Machines Are Essential for Modern Manufacturing

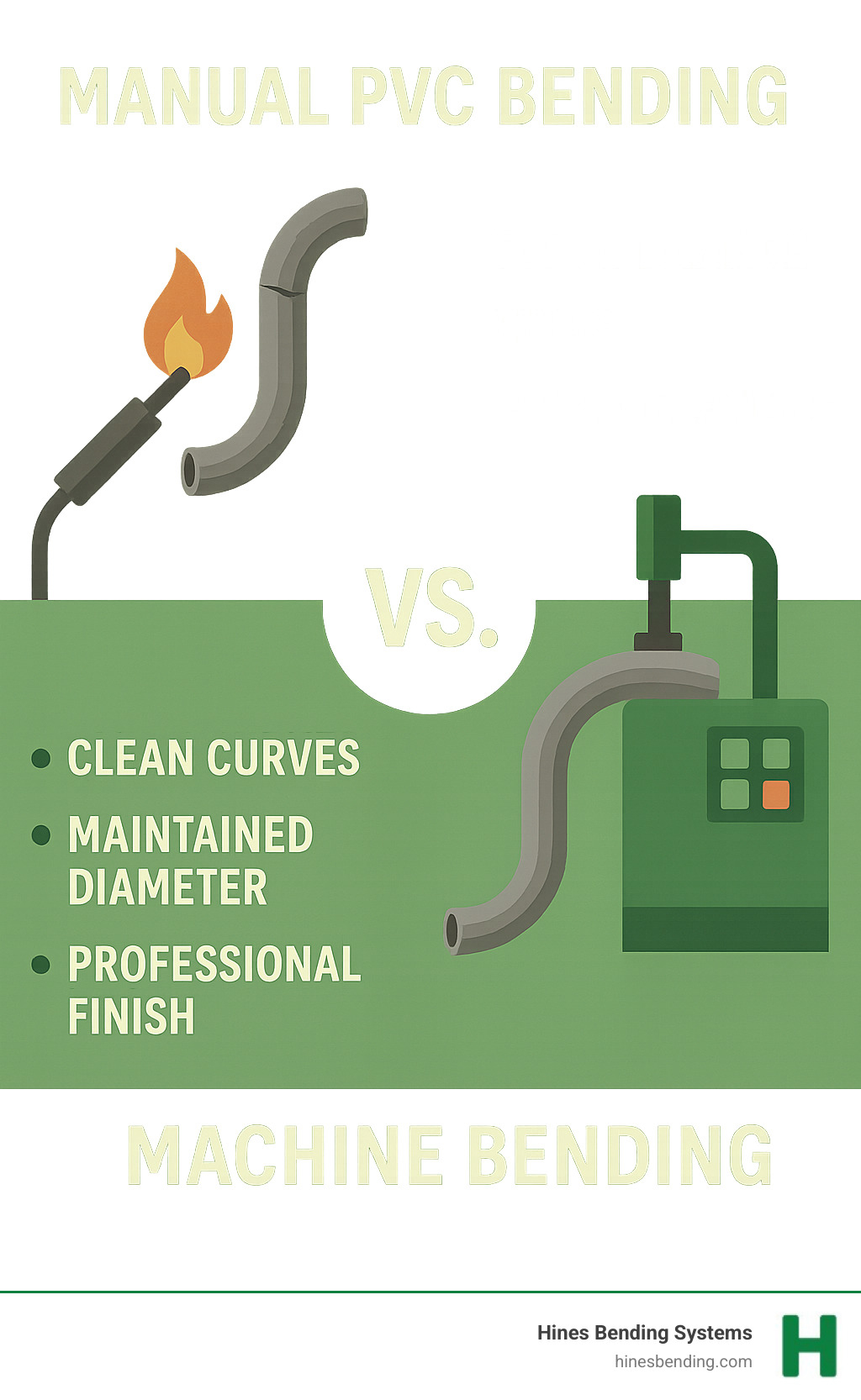

An electrical PVC bend machine uses controlled heat and automated mechanics to create precise angles in PVC conduit, essential for electrical, plumbing, and industrial applications. In electrical work, precision is non-negotiable. Manual bending often leads to kinks, reduced internal diameter, and compromised cable protection, resulting in code violations and safety hazards.

Quality bending machines eliminate these issues, creating consistent, code-compliant bends that maintain structural integrity. For high-volume operations, automated bending delivers superior quality, faster throughput, and lower costs compared to manual methods, which often damage the conduit.

What is an Electrical PVC Bend Machine and Why is Precision Paramount?

An electrical PVC bend machine transforms straight PVC pipes into precisely curved shapes using controlled heat (approx. 250°F) and automated bending arms. This precision is critical in electrical work, where damaged conduit can compromise cable integrity and create safety hazards. Instead of using multiple fittings that create weak points, a machine creates one smooth, continuous bend, ensuring stronger, more reliable conduit runs for complex cable management. Our expertise in Pipe Bending Technology ensures every bend meets exacting standards. For those interested in learning More about PVC, the material’s versatility is clear when shaped with precision.

The Primary Function in Electrical Work

For large commercial projects, an electrical PVC bend machine is essential for steering conduits around structural beams and through walls. It allows for seamless, custom bends that follow the exact path needed, eliminating the patchwork of elbow fittings that create weak points. This results in cleaner, stronger, and more reliable installations. For large-scale projects where reliability is paramount, our Industrial Pipe Benders deliver the required precision.

Advantages Over Manual Bending Methods

Machine bending offers unparalleled consistency and accuracy compared to manual methods. While a skilled technician might produce a few dozen bends an hour, a quality machine can produce up to 1,000 bends per hour with perfect repeatability. This increased speed reduces labor costs and project timelines. Furthermore, it improves worker safety by eliminating open flames, minimizes material waste, and produces superior quality bends that meet code every time. There are compelling Reasons to Invest in Pipe Bending Equipment for any serious operation.

Navigating the Spectrum of Bending Technology

Selecting the right electrical PVC bend machine can be complex, with options ranging from manual tools to advanced CNC systems. The spectrum includes manual, semi-automatic, hydraulic, and fully automated machines. At the pinnacle are CNC systems, like our CNC Tube Bender Machine, offering unparalleled precision for complex jobs.

Instead of getting lost in the options, it’s crucial to consult with experts. At Hines Bending Systems, we leverage our experience as the #1 worldwide bender manufacturer to help you determine What Type of Bending Machine is Best for Me?.

Key Machine Types from Basic to Advanced

Bending technology ranges from simple to highly sophisticated:

- Manual benders are entry-level tools for smaller operations.

- Semi-automatic machines automate key parts of the process for better consistency.

- Automatic Pipe Bending Machine systems are essential for high-volume production.

- Hydraulic benders provide the force for larger diameter pipes.

- CNC systems offer the ultimate in computer-controlled precision.

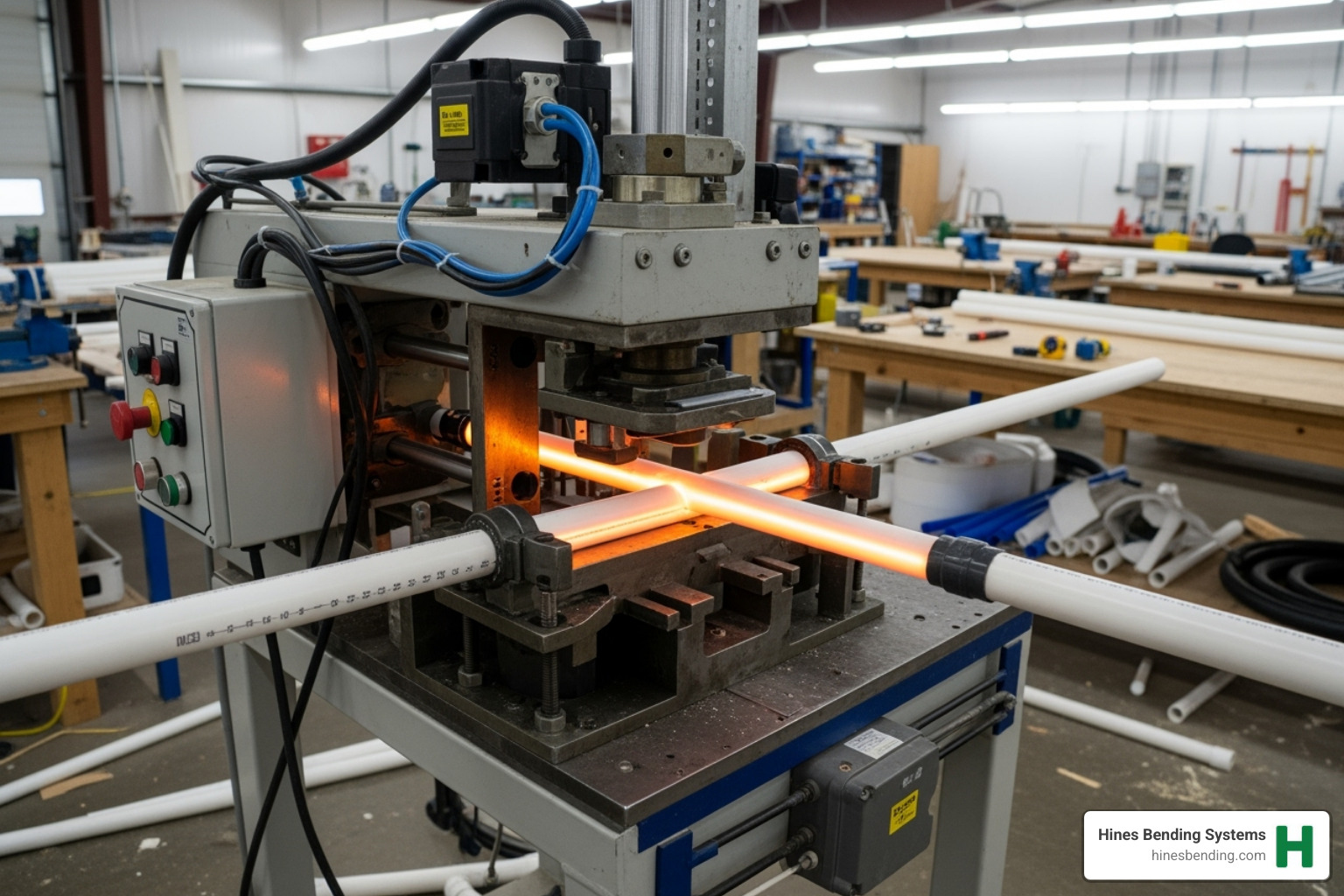

Core Components and Quality Materials

Every electrical PVC bend machine relies on critical components. The quality of the heating element, control panel, bending arm, and clamps directly impacts the final product. We use premium materials like stainless and alloy steel to build our machines, ensuring the durability and performance worthy of clients like NASA. Our precision-engineered Pipe Bender Dies deliver consistent results, batch after batch.

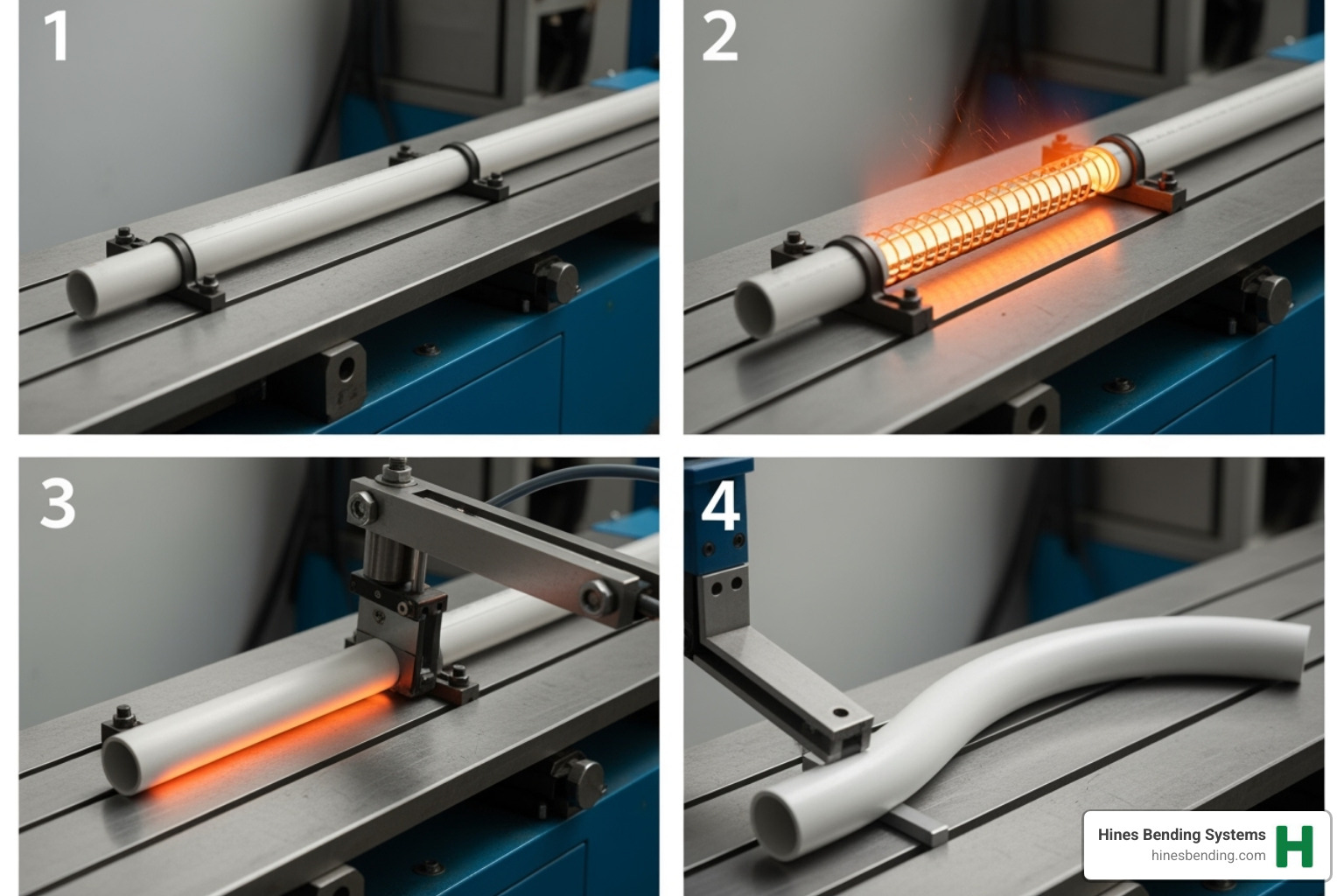

The Operational Process of an Electrical PVC Bend Machine

Watching an electrical PVC bend machine in action reveals a carefully choreographed process of heat and mechanics.

The process is straightforward: the pipe is placed and secured with clamps, the bend angle is set via the control panel, and a heating element warms the pipe to approximately 250°F. Once pliable, a bending arm actuates with smooth precision to form the bend. The pipe is then held in place to cool and set. Proper training makes all the difference, which is why we provide comprehensive Tube and Pipe Bender Training to help you get the most from your investment.

Factors Influencing the Bending Cycle

Several factors influence the bending cycle, including pipe diameter, wall thickness, and material type. A quality machine accounts for these variables. Heating time and temperature must be precise to avoid kinks or material damage. Our machines are engineered for versatility and efficiency, with some consuming as little as 1 KW of power. For specialized applications, technologies like Heat Induction Bending offer superior control.

Achieving High-Precision Bends

Professional-grade machines achieve high-precision bends through sophisticated control systems, like our industry-leading BendPro G2 CNC Control. These systems allow for exact programming of angles and sequences, which is essential for projects with tight tolerances. This capability minimizes waste and streamlines installation, making Precision Pipe Bending a necessity for delivering flawless results.

Industrial Applications and Choosing the Right Partner

The electrical PVC bend machine is vital across numerous industries, including construction, plumbing, HVAC, signage, automotive, and electronics manufacturing.

Its ability to create custom, seamless conduit pathways makes it indispensable for these diverse Pipe Bending Applications.

How to Choose an Electrical PVC Bend Machine

When choosing a machine, look beyond specs to find a true partner. Consider production capacity, material compatibility, accuracy, and long-term value. As the #1 worldwide manufacturer, Hines Bending Systems provides superior engineering and support, making it clear Why Buy a Hines Bender.

Maintenance and Safety Best Practices

Protecting your investment requires consistent maintenance and attention to safety. A simple checklist ensures longevity and safe operation.

Maintenance Checklist:

| Schedule | Task |

|---|---|

| Daily | Clean heating elements, inspect connections, check clamps, verify emergency stops |

| Weekly | Lubricate moving parts, calibrate sensors, test controls, inspect dies |

| Monthly | Deep clean machine, replace worn gaskets, review maintenance logs |

Regular cleaning, lubrication, and inspection are key. Always prioritize operator safety with proper Tube and Pipe Bender Training, PPE, and GFCI protection. Our support team provides the expertise you need to keep your operations running smoothly.

What is an Electrical PVC Bend Machine and Why is Precision Paramount?

An electrical PVC bend machine is a precision tool that uses controlled heat (approx. 250°F) to shape PVC pipes into exact curves for electrical conduit systems. Precision is critical because kinks or a reduced internal diameter can damage wiring and create safety hazards. Hines Bending Systems, the #1 worldwide manufacturer trusted by agencies like NASA, provides machines that deliver flawless bends, ensuring conduit integrity. Our expertise in Pipe Bending Technology means fewer fittings, stronger conduit runs, and installations that meet the highest standards. This technology transforms complex cable management from a challenge into a streamlined, reliable solution. For those wanting to dive deeper, you can learn More about PVC and its unique properties.

What are the different types of electrical PVC bend machines available (manual, automatic, electric, hydraulic, CNC)?

Electrical PVC bend machines range from simple manual tools to highly advanced systems. The main types include:

- Manual benders: For small-scale projects.

- Electric/Semi-Automatic benders: Offer more consistency for medium-sized operations.

- Hydraulic benders: Provide the force needed for larger or thicker pipes.

- Automatic and CNC benders: Deliver the highest speed, precision, and repeatability for high-volume production.

Navigating these options can be daunting. As the #1 worldwide manufacturer with more experience than anyone, Hines Bending Systems excels at guiding clients to the perfect solution, whether it’s a standard Automatic Pipe Bending Machine or a custom CNC Tube Bender Machine for applications demanding ultimate precision, like those for NASA.

3. What materials are commonly used in the construction of electrical PVC bend machines, and why?

When you’re investing in an electrical PVC bend machine, the materials used in its construction can make or break your operation. Think of it this way: you wouldn’t build a house with cardboard, and you shouldn’t settle for a bending machine made with subpar materials.

At Hines Bending Systems, we understand that material selection is absolutely critical. After all, we’ve supplied bending equipment to organizations like NASA – and when you’re building machines for space exploration, there’s no room for compromise.

Stainless steel forms the backbone of quality bending machines. We use it extensively for machine frames, heating chambers, and any surface that comes into contact with the PVC pipe. Why? It’s incredibly resistant to corrosion, maintains its strength under stress, and cleans up easily after those long production runs. When you’re working in demanding industrial environments or construction sites, stainless steel keeps your machine running smoothly year after year.

For the heavy-duty components that do the actual work – like bending arms and clamping mechanisms – alloy steel is the material of choice. These specialized steel blends, improved with elements like chromium, nickel, or molybdenum, provide the muscle needed to bend pipes consistently without wearing out. When your electrical PVC bend machine needs to handle larger diameter pipes or maintain precision through thousands of cycles, alloy steel delivers the durability you need.

Rubber might seem like a simple component, but it plays several crucial roles. You’ll find it in seals, gaskets, and gripping surfaces throughout the machine. Quality rubber provides excellent insulation, absorbs vibrations that could affect bend precision, and grips PVC pipes firmly without leaving marks or scratches. It’s one of those materials that you don’t think about until it fails – which is why we use only the best grades.

For electrical components and internal connections, brass is the gold standard. It conducts electricity reliably, resists corrosion better than many alternatives, and machines beautifully for precise fits. When your control systems need to communicate flawlessly with heating elements and bending mechanisms, brass ensures those connections stay solid.

Finally, high-temperature insulation materials like fiberglass and ceramic fibers surround the heating elements. These materials keep the heat exactly where it needs to be – softening your PVC – rather than warming up the entire machine or, worse yet, creating safety hazards for operators.

As the #1 worldwide manufacturer of bending equipment, we’ve learned that cutting corners on materials is the fastest way to disappoint customers. That’s why every Hines machine is built with premium materials that stand up to real-world demands, ensuring your investment pays dividends for years to come.

4. What are the main industrial applications for electrical PVC bend machines?

Electrical PVC bend machines are versatile tools essential in many industries. Their ability to create custom, seamless pathways makes them invaluable for:

- Construction and Plumbing: Creating custom conduit routes for electrical wiring and plumbing systems, reducing fittings and strengthening the installation.

- HVAC Systems: Forming condensate lines and other pipes to fit into tight, complex spaces.

- Signage and Advertising: Building durable, precisely shaped frames for banners and 3D displays.

- Automotive and Electronics: Manufacturing protective casings and lightweight tubing for wiring harnesses.

- Irrigation Systems: Bending pipes to optimize water flow for agricultural and landscaping projects.

Hines Bending Systems provides custom solutions for all these Pipe Bending Applications, leveraging our expertise to meet the unique demands of each industry.

How to Choose an Electrical PVC Bend Machine

Choosing the right electrical PVC bend machine is about finding a long-term partner, not just a piece of equipment. Key factors to consider are your production volume, material compatibility (PVC, CPVC, etc.), and required accuracy. However, the most important decision is the manufacturer. A cheaper machine often leads to higher costs through waste, downtime, and poor quality. As the #1 worldwide manufacturer, Hines Bending Systems offers the best long-term value. We work with you to understand your needs and provide a custom solution that grows with your business. When you’re ready to invest, find Why Buy a Hines Bender and partner with the most experienced team in the industry.

6. How does an electrical PVC bend machine work, detailing the process from pipe placement to bending?

An electrical PVC bend machine operates on a simple, precise process.

- Placement: An operator places a straight PVC pipe onto the machine’s bed, aligning the bend point with the heating element.

- Clamping: The pipe is securely clamped to prevent movement.

- Programming: The desired bend angle is set on the control panel. On advanced CNC systems, complex multi-bend sequences can be programmed.

- Heating: The machine heats the pipe section to approximately 250°F, making it pliable.

- Bending: A mechanical arm smoothly forms the pipe to the programmed angle, maintaining its internal diameter.

- Cooling: The pipe is held in place as it cools and solidifies, locking in the bend.

This automated process ensures every bend is perfect, eliminating the inconsistency and defects common with manual methods.

7. What are the key components of an electrical PVC bend machine?

Every electrical PVC bend machine is an assembly of critical components engineered for precision. The main parts include:

- Frame/Chassis: The robust steel foundation that ensures stability.

- Heating Element: The heart of the machine, using lamps, plates, or internal rods to soften the PVC.

- Clamping System: Vises or rollers that hold the pipe securely during heating and bending.

- Bending Arm: The mechanism that applies controlled force to shape the pipe.

- Dies and Molds: Forms that guide the pipe to ensure the correct bend radius and angle.

- Control Panel: The interface for setting parameters, ranging from simple dials to sophisticated CNC systems.

The quality of these components determines the machine’s performance and longevity, which is why Hines Bending Systems uses only premium materials.

8. What are the best practices for maintaining an electrical PVC bend machine to ensure longevity and optimal performance?

Proper maintenance ensures your electrical PVC bend machine delivers optimal performance and has a long service life. Follow these best practices:

- Daily: Clean heating elements and the general work area to prevent residue buildup and ensure consistent heating.

- Weekly: Lubricate all moving parts (pivots, gears) and inspect electrical cords for wear.

- Monthly: Check clamps and dies for wear and tear, and verify the machine’s bending accuracy, recalibrating if necessary.

- Always: Store the machine in a clean, dry environment and ensure operators use proper PPE and that electrical work is protected with GFCI protection.

Consult your manufacturer’s manual for specific guidelines. At Hines Bending Systems, we provide detailed protocols to protect your investment, backed by our industry-leading expertise and support. For additional guidance, reliable resources on Proper heat sources for bending PVC can complement your machine’s specific maintenance requirements.

9. What are the advantages of using an electrical PVC bend machine compared to manual bending methods?

Using an electrical PVC bend machine offers significant advantages over manual bending methods, which are often imprecise and unsafe. The key benefits are:

- Accuracy and Consistency: Machines produce identical, code-compliant bends every time, eliminating guesswork.

- Speed and Efficiency: A machine can produce up to 1,000 bends per hour, dramatically increasing productivity and reducing labor costs.

- Reduced Waste: Precision bending minimizes kinked or burned pipes, saving material and money.

- Superior Quality: Machine bends maintain the pipe’s full internal diameter and structural integrity, ensuring easier cable pulling and a more reliable installation.

- Improved Safety: Automated processes eliminate the risks associated with open flames and manual strain.

These advantages are why professionals invest in quality equipment from experienced manufacturers like Hines Bending Systems.

10. Are there specific safety considerations when operating an electrical PVC bend machine?

Safety is paramount when operating an electrical PVC bend machine due to high temperatures and moving parts. Key considerations include:

- Personal Protective Equipment (PPE): Always wear heat-resistant gloves, safety glasses, and appropriate clothing to protect against burns and debris.

- Electrical Safety: Plug the machine into a GFCI-protected outlet and regularly inspect power cords for damage.

- Operational Awareness: Keep the work area clear, never leave a running machine unattended, and ensure proper ventilation to disperse fumes.

- Mechanical Safety: Keep hands and loose clothing away from moving parts like bending arms and clamps.

Proper operator education is the best safety measure. Hines Bending Systems offers comprehensive Tube and Pipe Bender Training to ensure your team can operate equipment safely and confidently.

Conclusion

An electrical PVC bend machine is more than a tool; it’s an investment in precision, efficiency, and professionalism. It lifts your work from the inconsistencies of manual methods to the flawless quality that clients demand. Perfect bends create stronger, more reliable installations and reflect a commitment to excellence.

Choosing the right machine means choosing the right partner. For industries where failure is not an option, from commercial construction to aerospace applications for NASA, partnering with an experienced manufacturer is crucial. As the #1 worldwide leader, Hines Bending Systems provides world-class, customized Bending Equipment and unparalleled expertise. Let’s discuss how our solutions can meet your project’s demands.