Why Smart Manufacturers Choose Quality Over Quick Fixes

Finding a used pipe bender for sale requires careful consideration of value, reliability, and long-term performance. While the used equipment market offers machines ranging from $15 to $4,000, the real cost comes from downtime, poor precision, and lack of support.

Quick Answer for Used Pipe Bender Buyers:

- Best Source: Hines Bending Systems certified used equipment

- Common Types: Manual ($15-$500), Hydraulic ($500-$2,000), CNC ($2,000-$4,000+)

- Top Brands: Hines leads in quality and support

- Key Specs: Pipe diameter (1/4″ to 4″), material compatibility, bend radius

- Critical Factor: Tooling availability and technical support

The marketplace shows hundreds of used benders from various manufacturers, but most lack the precision engineering and ongoing support that serious manufacturing operations require. A generic bender might come with basic dies, but without expert guidance and quality assurance, you’re gambling with your production schedule.

Hines Bending Systems stands apart as the #1 worldwide manufacturer of tube and pipe benders, supplying precision equipment to major agencies including NASA. When you need reliable performance and expert support, Hines offers both new and carefully refurbished machines that deliver consistent results.

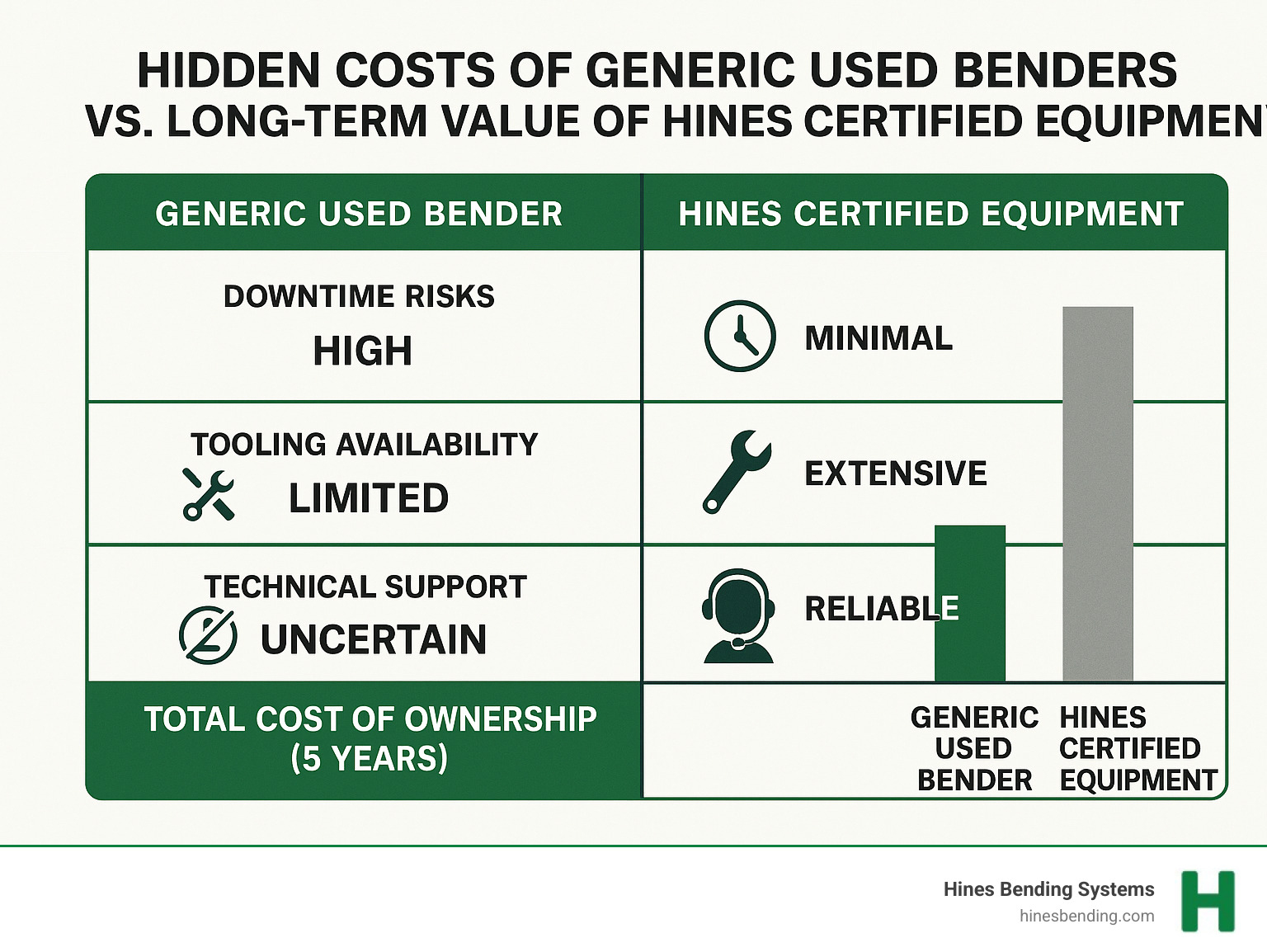

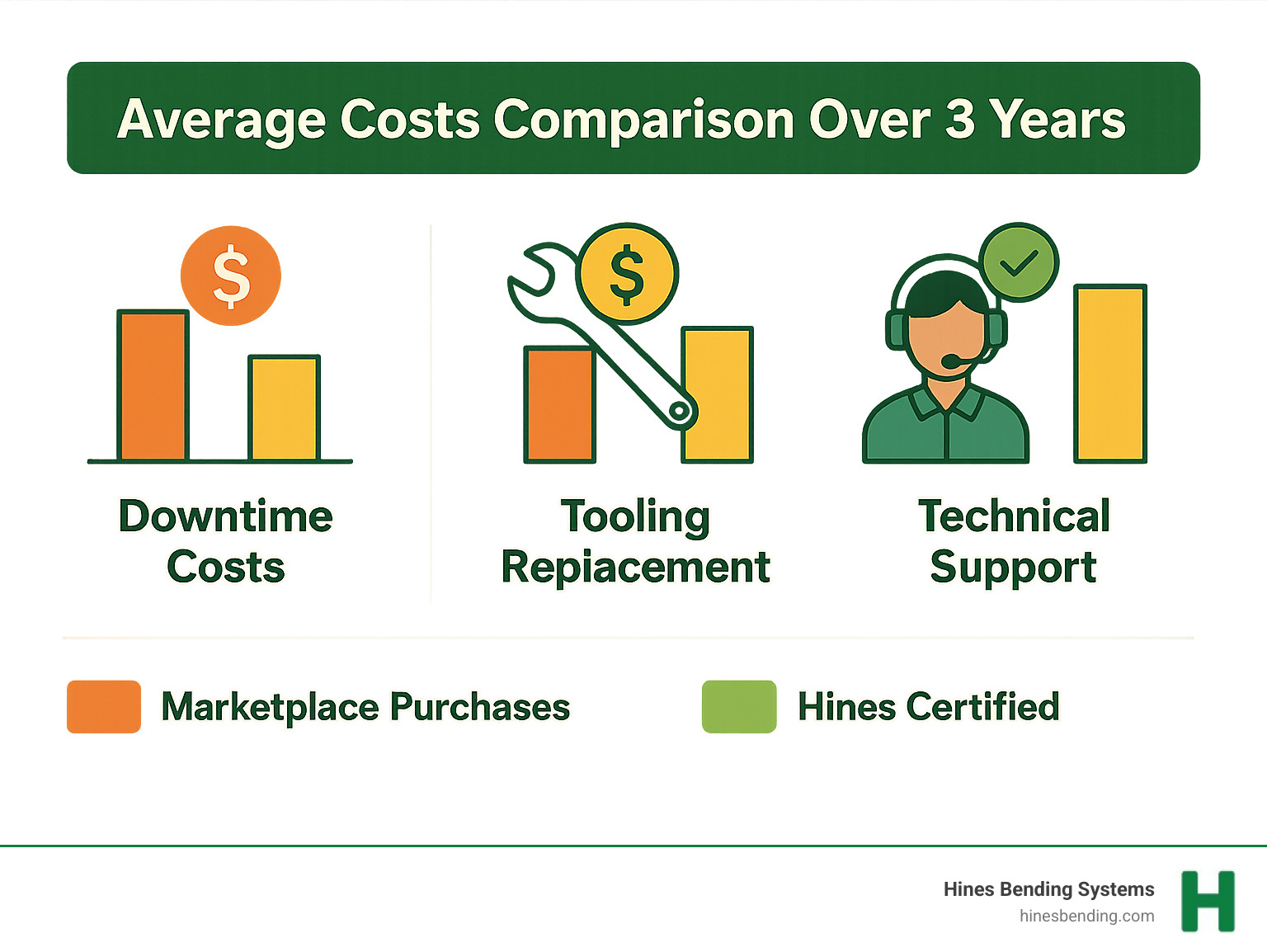

The research reveals that buyers often focus on initial price while overlooking critical factors like tooling compatibility, technical support, and long-term reliability. This approach leads to costly surprises and production delays.

Introduction: Value, Quality, and the Hines Advantage

Smart investment in equipment goes beyond the initial purchase price. Our decades of experience at Hines Bending Systems have shown us that manufacturers who focus solely on finding the cheapest used pipe bender for sale often end up spending significantly more in the long run.

Understanding the risks of used machinery is crucial for making informed decisions. For readers new to the topic, the pipe bending overview on Wikipedia provides a concise primer on general bending concepts and terminology. The research shows that while basic manual benders can be found for as little as $15, and hydraulic models range up to $4,000, these prices don’t tell the complete story. Hidden costs include:

- Calibration issues that affect bend accuracy

- Missing or worn tooling that can cost thousands to replace

- Lack of technical documentation making troubleshooting difficult

- No warranty or support leaving you stranded during breakdowns

- Compatibility problems with modern production requirements

At Hines Bending Systems, we’ve built our reputation on providing solutions that deliver value for decades, not just months. Our expertise spans over 40 years, and we’ve installed more bending machines worldwide than any other manufacturer. This experience allows us to offer certified used equipment that meets our rigorous quality standards.

When major agencies like NASA require precision bending solutions, they turn to Hines. This same level of quality and reliability is what we bring to every piece of used equipment we certify and sell.

The Hines Difference: Types and Capabilities of Hines Used Benders

When you’re searching for a used pipe bender for sale, you’ll quickly find that not all bending machines are created equal. At Hines Bending Systems, we’ve spent over 40 years perfecting our craft, and that expertise shows in every piece of equipment we manufacture—whether new or refurbished.

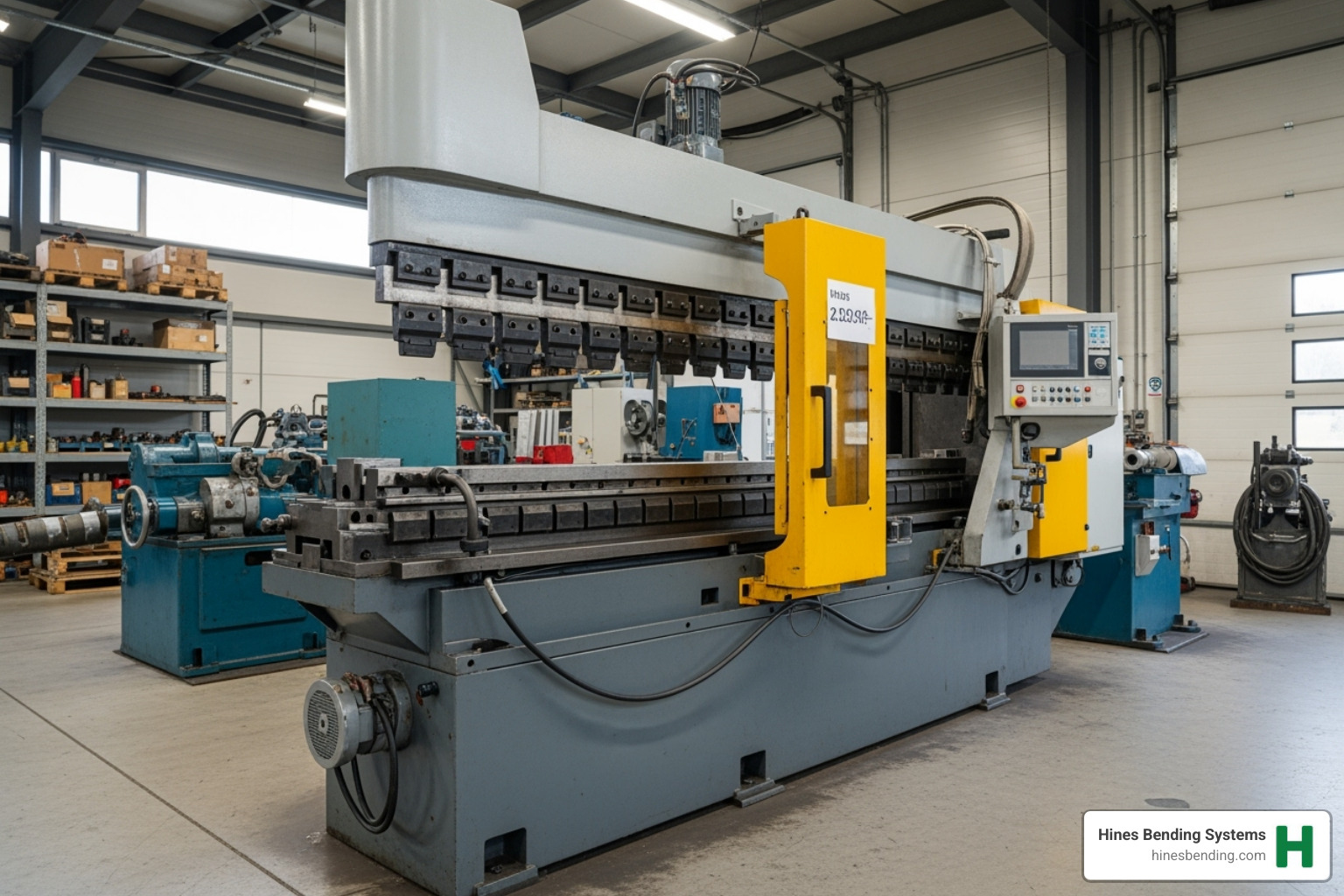

Manual benders represent the foundation of precision bending. Our manual models handle pipe diameters from 1/4″ to 2″ with remarkable accuracy, making them perfect for prototype work, small batch production, or specialized applications where flexibility matters most. What sets Hines manual benders apart is their robust construction—these machines maintain their precision year after year, unlike generic alternatives that quickly lose accuracy.

Hydraulic benders deliver the power and consistency that medium-scale operations demand. While typical hydraulic models range from 12-ton to 16-ton capacity, Hines hydraulic benders provide superior control and repeatability that you simply won’t find in marketplace alternatives. These machines excel at bending thicker-walled materials and larger diameters while maintaining the tight tolerances that serious manufacturers require.

NC benders bring programmable precision to your production floor. Our NC systems eliminate operator error and boost productivity, making them ideal for medium-volume production runs where consistency is absolutely critical. The difference between a Hines NC bender and a generic model becomes apparent after the first few production runs—our machines deliver repeatable results that generic equipment simply cannot match.

CNC benders represent the pinnacle of bending technology, and our Used CNC Bending Machine options provide full automation capabilities that transform your production capabilities. These sophisticated machines handle complex multi-bend operations and integrate seamlessly with modern manufacturing systems. When agencies like NASA need precision bending solutions, they turn to Hines CNC technology.

Our pipe and tube size ranges span from delicate 1/4″ tubing to heavy-duty 4″ pipe applications. This versatility matters because your production needs will evolve, and Hines machines grow with your business. Material compatibility extends across steel, aluminum, copper, stainless steel, and specialty alloys that many generic benders simply cannot handle properly.

Common applications for our used benders include handrail fabrication, exhaust system manufacturing, structural fabrication, and complex industrial projects. Whether you’re creating building decorations or agricultural structures, Hines machines excel in demanding industrial environments where precision and reliability are non-negotiable.

What truly sets us apart is Hines’ expertise in matching the right bender to your needs. Unlike marketplace sellers who simply list specifications and leave you to figure out compatibility, we understand that a machine’s capabilities must align perfectly with your production requirements, material properties, and quality standards. Our engineers work directly with you to ensure your investment delivers exactly what you need.

What to Look for in a Used Pipe Bender from Hines

Finding a quality used pipe bender for sale requires expertise that most buyers simply don’t possess. When you purchase from an unknown source, you’re essentially buying blind—and that’s a risk that can cost you thousands in unexpected repairs and downtime.

Machine condition assessment is where Hines’ decades of experience truly shine. Our rigorous inspection and refurbishment process ensures that every piece of used equipment meets the same exacting standards we apply to our new machines. We examine every component, from the smallest fastener to major structural elements, eliminating the costly surprises that plague buyers of generic used equipment.

Hydraulic and electrical system checks are particularly critical because hydraulic failures rank among the most common and expensive problems with used bending equipment. Our technicians test pressure systems, check for leaks, verify pump performance, and ensure all safety systems function exactly as designed. This thoroughness protects your investment and your operators.

Control panel functionality testing goes far beyond basic operation. We verify that all programming features work correctly, calibrate positioning systems, and ensure that safety interlocks function as designed. Many used machines have control issues that only become apparent during complex operations—problems that our inspection process catches before they become your headache.

Structural integrity assessment prevents the catastrophic failures that can damage workpieces and endanger operators. We use advanced inspection techniques to identify stress fractures, wear patterns, and alignment issues that aren’t visible during casual inspection. This level of scrutiny is what separates Hines-certified equipment from marketplace gambles.

Our Used Pipe Bending Machines in Florida location allows customers to inspect equipment in person before purchase. This transparency contrasts sharply with online marketplaces where you’re buying based solely on photos and descriptions—often with disappointing results.

Confidence in Hines-certified used equipment comes from our willingness to stand behind every machine we sell. While marketplace sellers typically offer no warranty or support, we provide ongoing technical assistance and parts availability that protects your investment for years to come.

Matching Bender Capacity to Your Project Needs with Hines

Selecting the right bending capacity isn’t just about matching specifications—it’s about understanding how your production needs will evolve and ensuring your investment grows with your business. This is where Hines’ expertise becomes invaluable.

Pipe diameter and wall thickness capacity must align precisely with your production requirements. While benders are available for diameters ranging from 1/4″ to over 4″, selecting the wrong capacity leads to poor results or machine damage. Our engineers help you choose equipment that handles your current needs while providing room for growth—a level of consultation you simply won’t find in marketplace transactions.

Material compatibility extends far beyond basic steel and aluminum. Our used machines maintain the precision needed for specialty alloys, thin-walled tubing, and materials that require specific bending techniques. Generic used equipment often lacks the refinement needed for challenging materials, leading to scrapped parts and production delays.

Bend radius limitations significantly impact part design and functionality. Our Used Steel Pipe Benders for Sale maintain tight radius capabilities that many used machines lose over time due to wear and poor maintenance. This precision consistency is what makes Hines equipment a smart long-term investment.

Application suitability goes far beyond basic specifications. Our Used Boiler Tube Bender exemplifies how specialized applications require equipment designed for specific challenges. Generic marketplace machines rarely offer this level of application-specific engineering, leaving you to figure out compatibility issues on your own.

Production volume considerations affect machine selection significantly. A manual bender might work for prototype development, but production requirements demand the consistency and speed of hydraulic or CNC systems. Our experts help you choose equipment that matches your current volume while accommodating future growth.

Hines’ expert guidance in selecting the right machine eliminates costly mistakes that plague buyers who go it alone. Unlike marketplace transactions where you’re on your own after purchase, we provide comprehensive consultation to ensure your investment delivers the results you need—backed by the expertise that has made us the #1 worldwide manufacturer of tube and pipe benders.

Where to Find a Used Pipe Bender for Sale—The Hines Way

When you’re searching for a used pipe bender for sale, the source matters more than you might think. The marketplace is flooded with machines of questionable quality and unknown history, but there’s a better way to find reliable equipment that won’t leave you stranded.

Direct from Hines Bending Systems offers something that random marketplace sellers simply cannot provide: peace of mind. When you purchase from us, you’re not just buying a machine—you’re gaining access to over 40 years of expertise and the kind of ongoing support that keeps your production running smoothly.

Our Used Pipe Bender Sale inventory represents machines that have passed through our rigorous inspection and refurbishment process. Each piece of equipment is thoroughly tested, calibrated, and certified to meet the same standards we apply to our new machines. This attention to detail ensures reliability that marketplace purchases simply cannot guarantee.

The beauty of our New and Used Bending Machines approach is that you can compare options side by side. Sometimes a quality used machine perfectly fits your needs and budget, while other times the additional features of a new machine justify the investment. Our transparent approach helps you make the right choice based on complete information.

Nationwide and global availability means distance doesn’t limit your access to Hines quality. While research shows that geographic location significantly affects used equipment availability in the general market, our global network ensures you can find the right machine regardless of where you’re located. We’ve shipped precision bending equipment to customers on every continent.

Transparent pricing eliminates the frustration common in marketplace transactions. You’ve probably seen those listings that show “Please Contact” instead of actual prices, leaving you to wonder if you’re wasting your time. We provide clear, honest pricing that helps you budget accurately and make informed decisions without games or surprises.

Shipping and logistics support removes the complexity of moving heavy industrial equipment. Our experienced team handles everything from initial quotes to final delivery, ensuring your machine arrives safely and ready for production. We understand that downtime during equipment transition can be costly, so we work efficiently to minimize disruption to your operations.

In-person and virtual inspection options give you confidence before making your investment. Unlike marketplace sellers who may discourage close examination, we welcome thorough inspection of our equipment. We’re confident in our quality, and we want you to be equally confident in your purchase.

Hines’ commitment to customer satisfaction extends far beyond the initial sale. When you need technical support, replacement parts, or operational guidance, we’re here to help. This ongoing partnership ensures that your investment continues delivering value for years to come.

Typical Price Ranges for a Hines Used Pipe Bender

Understanding pricing for quality used equipment helps you budget effectively and recognize true value. The marketplace shows a wide range of prices, but these numbers often don’t tell the complete story about what you’re actually getting.

Manual, hydraulic, and CNC bender pricing varies significantly based on capability, condition, and most importantly, the level of support included. Research shows that basic manual benders can start around $15 in the general market, but these prices typically reflect equipment with severe limitations and unknown reliability.

Our manual benders typically range from $500 to $2,000, reflecting the superior construction and precision that Hines machines provide. While this represents a higher initial investment than marketplace alternatives, the long-term value far exceeds the price difference. You’re investing in equipment that maintains its accuracy and reliability over decades of use.

Hydraulic systems in the general market range from $500 to $2,000, but these prices often exclude critical components like complete die sets, hydraulic units, or mounting hardware. Our hydraulic benders include everything needed for immediate production use, eliminating the surprise costs that plague marketplace purchases.

CNC bender pricing starts around $2,000 for basic used units in the general market and can exceed $4,000 for more capable machines. However, these prices rarely include the comprehensive training, technical documentation, and ongoing support that Hines provides with every purchase.

Factors influencing price include the machine’s age, overall condition, included tooling, and critically, Hines’ reputation for quality. Machines from established manufacturers command higher prices because buyers understand the value of superior engineering and ongoing parts availability.

The value of Hines-certified used machines versus unknown sources becomes apparent over time. While marketplace machines might offer lower initial prices, hidden costs for repairs, missing tooling, calibration issues, and lack of support quickly erode any savings. Our customers consistently report that their Hines investment pays for itself through reduced downtime and consistent performance.

The Critical Importance of Tooling and Support from Hines

When you’re shopping for a used pipe bender for sale, the machine itself is only half the story. The real value lies in the bender dies, mandrels, and wiper dies that make precision bending possible. These critical components can cost thousands of dollars, yet many used machines are sold with worn tooling or missing pieces entirely.

Think of it this way: buying a bender without proper tooling is like buying a car without tires. You might have saved money upfront, but you’re not going anywhere fast. Our Used Mandrel Tube Bender for Sale options come complete with comprehensive tooling packages that get you bending quality parts from day one.

Tooling compatibility creates headaches that most buyers don’t anticipate. Dies and mandrels are precision-engineered for specific machines, and trying to make substitutes work rarely delivers acceptable results. When you purchase from Hines, you’re getting verified tooling that maintains the tight tolerances your applications demand.

Here’s where Hines’ 40+ years of experience really shines. Sourcing spare parts directly from Hines means you’re never left stranded with an obsolete machine. While marketplace purchases often become expensive paperweights when parts become unavailable, we maintain extensive parts inventory and technical documentation for decades.

Hines’ technical support and training transforms your equipment purchase into a long-term partnership. Our experts don’t just sell you a machine and walk away. We provide ongoing guidance on setup, operation, maintenance, and troubleshooting that keeps your production running smoothly.

Our comprehensive Tube and Pipe Bender Accessories ensure you have everything needed for optimal performance. From specialized dies to precision measurement tools, we provide complete solutions rather than leaving you to hunt down components from multiple suppliers.

Minimizing downtime with Hines’ expert service delivers measurable value that far exceeds any initial price savings from marketplace alternatives. Production interruptions cost exponentially more than the price difference between our certified equipment and unknown sources. When NASA needs reliable bending solutions, they turn to Hines because downtime simply isn’t an option.

The difference becomes crystal clear when you need help at 2 AM because a critical job is due the next morning. Hines customers have access to technical support that keeps production moving, while marketplace buyers are often left troubleshooting alone.

Why Hines Quality-First Approach Saves You Money

When you’re searching for a used pipe bender for sale, it’s tempting to focus on the lowest price. But here’s what we’ve learned from four decades in the bending industry: the machines that cost the least upfront often end up being the most expensive in the long run.

Long-term reliability isn’t just a nice-to-have feature—it’s the foundation of profitable manufacturing. Our precision engineering ensures that Hines machines maintain their accuracy and performance for decades, not just the first few months after purchase. While marketplace alternatives might seem attractive initially, they often require constant adjustments, frequent repairs, and eventual replacement.

Think about it this way: a machine that needs recalibration every few weeks isn’t saving you money. It’s costing you time, materials, and the frustration of inconsistent results. Our precision engineering goes far beyond basic functionality because we understand that your reputation depends on consistent, accurate bends every single time.

Our Why Buy a Hines Bender? page details exactly why this precision matters so much. From the superior materials we use to our advanced manufacturing techniques, every aspect of our machines reflects our commitment to excellence. It’s not about showing off—it’s about ensuring your investment pays dividends for years to come.

Custom solutions for every client represent another area where Hines delivers exceptional value. Unlike marketplace machines with fixed capabilities that force you to adapt your processes, we can modify and optimize our equipment for your specific applications. This customization eliminates the compromises that generic equipment often requires.

Meeting exact specifications becomes crucial when your applications demand specific bend radii, material compatibility, or production rates. Generic used equipment might get you “close enough,” but close enough often means scrapped parts and disappointed customers. Our machines deliver precisely what you need, when you need it.

Industry-leading expertise spanning over four decades means we’ve seen every challenge the bending industry can throw at us. No other manufacturer has more experience in bending technology, and this expertise benefits every customer through superior machine design and deep application knowledge. When you choose Hines, you’re not just buying equipment—you’re gaining access to decades of problem-solving experience.

Supplying top agencies like NASA isn’t something we mention to impress you (though we’re certainly proud of it). Our Hines Working Together with NASA partnership demonstrates our capability to meet the most demanding requirements. The same level of precision and reliability that NASA requires is what we bring to every project, whether you’re bending handrails or spacecraft components.

Operator training and support maximizes your investment value in ways that marketplace purchases simply cannot match. Our Tube and Pipe Bender Training programs ensure that your team can fully use your equipment’s capabilities while maintaining safety and efficiency. This training often pays for itself within the first few months through improved productivity and reduced waste.

Guaranteed performance and peace of mind come standard with every Hines machine. While marketplace purchases involve significant risk and uncertainty—Will it work as advertised? Can I get parts? Who do I call when something goes wrong?—our commitment to customer satisfaction ensures that your investment delivers the results you expect.

The math is simple: reliable equipment that produces consistent results with ongoing support costs less over time than cheap alternatives that require constant attention and eventual replacement. When you choose Hines, you’re choosing a partner who’s invested in your long-term success.

Conclusion: Invest in Your Success with Hines Bending Systems

The evidence is clear: purchasing a used pipe bender for sale from unknown sources carries significant risks that far outweigh any initial savings. From missing tooling to complete lack of support, marketplace purchases often transform into expensive headaches that disrupt production and compromise quality.

The superior value of Hines quality and support becomes apparent from day one. When you choose our certified used equipment, you’re not just buying a machine—you’re investing in decades of engineering excellence and ongoing partnership. Our rigorous inspection process ensures that every piece of equipment meets the same standards that have made us the #1 worldwide manufacturer of tube and pipe benders.

Long-term ROI calculations consistently favor Hines equipment over marketplace alternatives. Consider the real costs: reduced downtime means uninterrupted production schedules, lower maintenance costs protect your budget, superior precision eliminates waste and rework, and comprehensive support prevents costly surprises. When you factor in these tangible benefits, the value proposition becomes undeniable.

Choosing Hines as your partner ensures precision, efficiency, and confidence for years to come. Our commitment extends far beyond the initial sale to encompass ongoing support, training, and parts availability that protects your investment. Whether you need a simple manual bender for occasional use or a sophisticated CNC system for high-volume production, we have the expertise and inventory to meet your exact requirements.

Our global experience, combined with local support, ensures that you receive the best possible solution for your specific needs. When major agencies like NASA require precision bending solutions, they trust Hines. This same level of quality and reliability is what we bring to every customer, regardless of project size.

Don’t gamble with your production schedule and quality standards. Choose the proven reliability and comprehensive support that only Hines Bending Systems can provide. Explore Our Full Range of Bending Machines and find why manufacturers worldwide trust Hines for their most critical bending applications.