Why Smart Manufacturers Choose Quality Used Tube Benders

Finding the right used tube bender for sale can slash your equipment costs while delivering the precision and reliability your production demands. With the tube bending machine market growing from $1.5 billion in 2022 to a projected $2.1 billion by 2029, smart manufacturers are finding that quality pre-owned equipment offers immediate value without the wait times or depreciation of new machines. If you’d like a quick refresher on how tube bending fits into modern fabrication, the overview on tube bending provides helpful background.

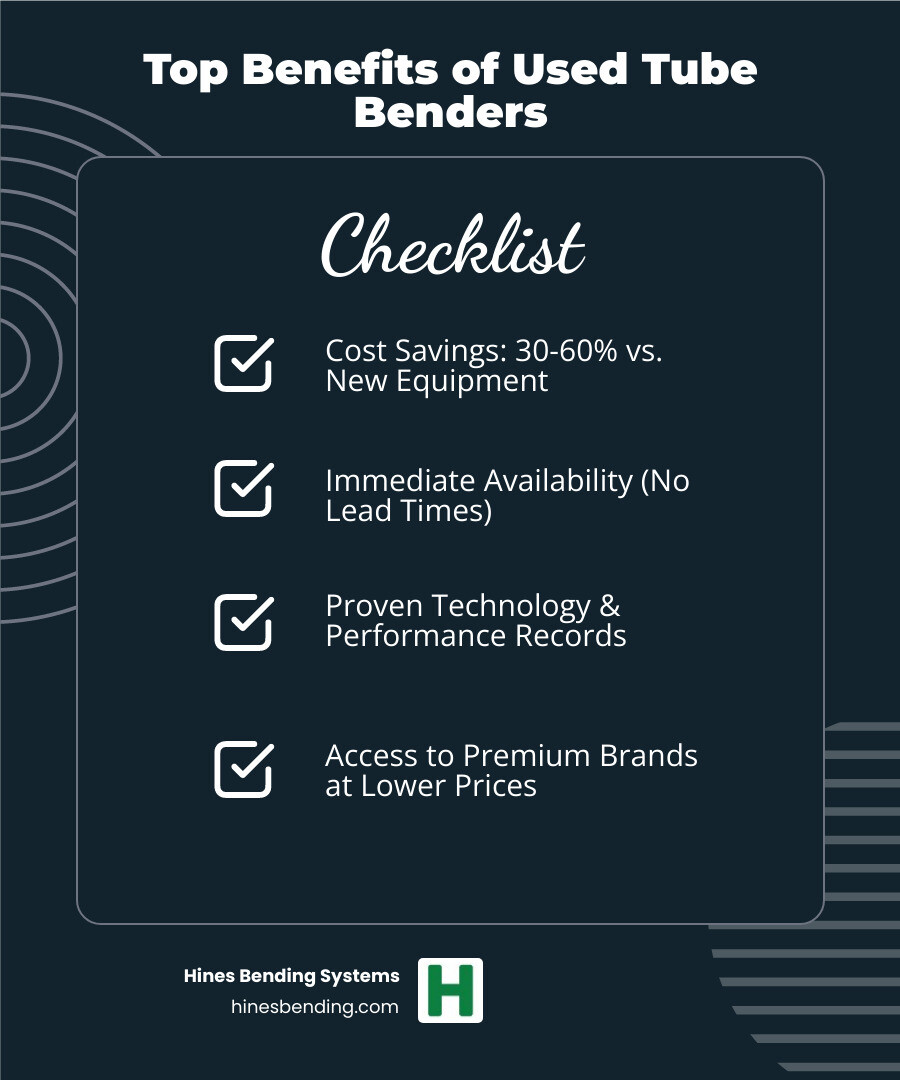

Top Benefits of Buying a Quality Used Tube Bender:

- Cost savings of 30-60% compared to new equipment

- Immediate availability – no 6-12 month lead times

- Proven technology with established performance records

- Access to premium brands at accessible price points

The used machinery market has become a significant segment of the industrial equipment landscape, offering cost-effective solutions for businesses of all sizes. Whether you need a manual bender for prototyping or a CNC system for high-volume production, the secondary market provides access to proven technology from industry leaders.

Manufacturing operations managers are increasingly turning to quality used equipment to meet complex bending requirements while controlling production costs. The key is finding machines that deliver precision, reliability, and ongoing manufacturer support – factors that separate professional-grade equipment from cheaper alternatives that compromise production integrity.

Used tube bender for sale terms you need:

Why a High-Quality Used Bender is a Smart Investment

When you’re searching for a used tube bender for sale, you’re making one of the smartest financial decisions for your manufacturing operation. The numbers speak for themselves – quality pre-owned equipment typically costs 30-60% less than new machines, giving you access to professional-grade technology without the premium price tag.

Think about it: that significant cost savings means you can either invest in a more capable machine than your budget originally allowed, or allocate those saved dollars to other critical areas of your business. It’s not just about spending less; it’s about spending smarter.

No more waiting around for your equipment to arrive. While new machines often come with lead times stretching weeks or even months, a quality used bender is usually ready to ship immediately. Your production line doesn’t have to sit idle, and you can start seeing returns on your investment right away.

Here’s something many manufacturers overlook: when you buy a proven, reliable model that’s been field-tested, you’re getting technology with a track record. These machines have already demonstrated their capabilities in real-world conditions. You’re not taking a gamble on an untested design – you’re investing in equipment that’s proven its worth.

Lower depreciation is another hidden benefit. Just like buying a car, new machines experience their steepest value drop in the first few years. When you buy used, you bypass this initial depreciation hit, meaning your investment holds its value more effectively over time.

The key to long-term performance lies in choosing quality equipment from a manufacturer that stands behind their machines. At Hines Bending Systems, we’ve earned our reputation as the #1 worldwide manufacturer through decades of innovation and reliability. When NASA needs precision bending equipment, they turn to us – and that same commitment to excellence extends to our used equipment offerings.

Our extensive expertise means we know exactly what to look for in pre-owned machines. We ensure every used tube bender for sale in our inventory meets the same rigorous standards that have made us the industry leader. You’re not just buying a machine; you’re partnering with the company that has more bending installations worldwide than anyone else.

To learn more about the advantages of partnering with us, explore Why Buy a Hines Bender.

Key Factors to Evaluate When Searching for a Used Tube Bender for Sale

When you’re hunting for a used tube bender for sale, think of it like buying a reliable workhorse for your shop. You wouldn’t buy a truck without checking under the hood, and the same careful approach applies here. The right machine can transform your production capabilities, while the wrong choice can leave you frustrated and out of pocket.

The first thing you need to nail down is bending capacity. This isn’t just about what the machine can do – it’s about what it can do reliably, day after day. Consider both the tube diameter and wall thickness you’ll be working with most often. A machine that handles 3/16 inch tubing beautifully might struggle with 7-inch diameter pipes. Make sure there’s some headroom in the capacity too, because projects have a way of growing beyond initial specifications.

Material type is equally critical. Copper bends differently than stainless steel, and aluminum has its own personality entirely. The machine’s hydraulic system and tooling need to match your materials. A bender designed for soft copper might not have the muscle for thick-walled steel applications.

Here’s where many buyers get tripped up: tooling availability. A fantastic machine is worthless if you can’t get the dies and mandrels you need. Check what comes with the machine and what’s available from the manufacturer. Sometimes a slightly more expensive machine with comprehensive tooling ends up being the better deal.

Machine condition requires a detective’s eye. Look for machines described as “In Plant,” “Low Hours,” or “Under Power” – these phrases usually indicate well-maintained equipment you can actually see running. Watch for hydraulic leaks, worn tooling, and signs of heavy wear. A machine that’s been refurbished by a reputable manufacturer often offers excellent value with renewed reliability.

Don’t underestimate manufacturer reputation and after-sales support. At Hines Bending Systems, we’ve been the #1 worldwide manufacturer of tube benders for good reason. Our machines aren’t just built to last – they’re backed by decades of expertise and ongoing support. When NASA needs precision bending equipment, they come to us. That same level of quality and support extends to our used equipment.

The beauty of buying from an established manufacturer like Hines is that we stand behind our machines throughout their entire lifecycle. Parts availability, technical expertise, and troubleshooting support don’t disappear just because a machine changes hands.

Take your time evaluating these factors. A hasty decision often leads to costly mistakes, while a thoughtful approach leads to years of reliable service. Browse our selection of Used CNC Bending Machines For Sale to see how we maintain our quality standards even in the secondary market.

Navigating the Different Types of Used Benders on the Market

The world of tube bending equipment is vast, with options ranging from simple manual benders to sophisticated CNC systems. When you’re looking for a used tube bender for sale, the key isn’t just understanding the technology, but partnering with an expert who can guide you to the right fit for your application and budget.

Manual and hydraulic benders are excellent for prototypes, repairs, and small production runs. They offer simple operation and a lower initial investment. However, they require more operator skill and may lack the power for tougher materials or the precision for complex jobs.

For operations demanding precision, repeatability, and complex geometries, a Used CNC Bending Machine is the gold standard. These machines deliver the tightest tolerances, essential for industries like aerospace and automotive. The ability to program and repeat complex bend sequences boosts production speed and eliminates human error, providing a significant return on investment.

Regardless of the type, a thorough inspection is critical. Look for:

- Signs of wear: Check tooling, dies, mandrels, and pivot points. Worn components can lead to poor bend quality and immediate replacement costs.

- Hydraulic leaks: For hydraulic and CNC machines, leaks can signal expensive repairs.

- Functionality: Always request a demonstration. Verify that the machine operates smoothly and produces accurate bends.

At Hines Bending Systems, our unparalleled expertise means we can help you steer these choices. As the #1 worldwide manufacturer, we know what separates a reliable machine from a liability. We ensure any used equipment we offer, like a Used Pipe Bender Machine, has been rigorously inspected to meet the same quality standards that organizations like NASA trust. We help you look beyond the machine type to find a solution that truly fits your needs, considering everything from tooling to long-term support.

How to Verify Quality and Avoid Common Pitfalls

Finding a high-quality used tube bender for sale requires a detailed inspection to avoid costly surprises. With our experience as the world’s #1 bender manufacturer, we know exactly where to look to separate a great investment from a future headache.

Use this pre-purchase checklist to guide your evaluation:

- Structural and Mechanical Integrity: Examine the frame for cracks or repairs. Check the main spindle, clamps, and pressure dies for excessive wear. A machine that groans or stutters during operation is a major red flag.

- Electrical and Hydraulic Systems: Inspect wiring for damage, especially on CNC models. Test all safety features. On hydraulic systems, listen to the pump and check for leaks.

- Tooling Condition: Worn or damaged tooling produces poor-quality bends and can be expensive to replace. Inspect all included dies and mandrels carefully.

- Live Demonstration: This is non-negotiable. Ask the seller to run the machine with materials similar to yours. If you can’t be there in person, request a detailed video.

- Service Records: Maintenance logs provide invaluable insight into the machine’s history and how it was cared for.

Beyond the machine itself, consider the need for operator training. The best bender is only as effective as its operator. At Hines Bending Systems, we provide comprehensive Tube and Pipe Bender Training to ensure your team can maximize efficiency and safety.

Our unparalleled expertise means we can help you steer this process. We supply solutions to demanding clients like NASA because we understand what true quality and reliability look like. Partnering with Hines gives you access to that knowledge, ensuring you make an informed decision and avoid common pitfalls.

Frequently Asked Questions about Used Tube Benders

When you’re considering a used tube bender for sale, it’s natural to have questions. We’ve been helping manufacturers steer these decisions for decades, and we’re here to share the insights we’ve gained from being the #1 worldwide manufacturer in the bending industry.

What is a realistic price for a used tube bender?

Pricing for used tube benders varies widely based on several key factors. The machine type is the biggest driver; a simple manual bender may cost a few hundred dollars, while a high-capacity CNC bender can be a significant investment. Capacity and condition also play huge roles, with low-hour or refurbished machines commanding higher prices.

Brand reputation is critical in the used market. Machines from established manufacturers like Hines Bending Systems hold their value better because buyers know they are getting proven technology backed by ongoing support. The included tooling package also adds substantial value. While online guides exist, nothing replaces direct industry expertise. Our team’s unparalleled experience means we can provide invaluable insights that go beyond simple pricing, helping you understand the true value of any machine you’re considering.

Where are the best places to find used tube benders?

Finding the right used tube bender for sale is about knowing where to look and who to trust.

- Manufacturer-Direct Sales: This is your safest bet. Buying directly from an OEM like Hines Bending Systems means you’re getting equipment inspected and serviced by the people who built it. This provides best confidence and quality assurance.

- Certified Resellers: Reputable dealers who specialize in industrial machinery can be a good source, as they often provide some level of inspection and support.

- Online Marketplaces and Private Sellers: While these channels offer a vast selection, they carry the highest risk. Listings are often “as-is” with little to no recourse if a problem arises. Extreme caution and thorough vetting are required.

We always recommend sourcing from reliable providers. Our position as the industry leader, supplying agencies like NASA, means we have the expertise to ensure any machine we offer meets our exacting standards.

Is it possible to get support and parts for a used machine?

Yes, but this is where the manufacturer’s reputation is paramount. At Hines Bending Systems, we pride ourselves on supporting our legacy equipment with the same dedication we show new machine buyers. Our comprehensive after-sales support, technical assistance, and parts availability extend to machines that have been in the field for years.

This long-term commitment is a distinct advantage of choosing an established OEM. Our Used Hines Model 300 Semi Automatic Tube Pipe Bender perfectly illustrates this. When you invest in any Hines machine, new or used, you gain a partnership with the industry’s most experienced team, dedicated to your long-term success.

Conclusion: Partner with an Industry Leader for Your Bending Needs

When you’re searching for a used tube bender for sale, the decision you make today will impact your production capabilities for years to come. Quality, reliability, and ongoing support aren’t just nice-to-have features – they’re the foundation of a smart investment that keeps your operation running smoothly.

At Hines Bending Systems, we understand that buying used equipment requires confidence in both the machine and the company behind it. That’s why we’re proud to be the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. Our track record speaks for itself – we’ve completed more bender installations globally than anyone else in the industry, giving us best insight into what works in real-world applications.

Our credentials include supplying bending machines to The National Aeronautics and Space Administration (NASA) and other major agencies and companies. When organizations with such exacting standards trust us with their critical projects, you can feel confident that we’ll deliver the same level of excellence for your operation, whether you’re buying new or used equipment.

What sets us apart isn’t just our manufacturing capabilities – it’s our commitment to custom bending solutions custom to your specific needs. We work closely with each client to understand their unique requirements, ensuring that every machine we recommend or refurbish meets the exact demands of their application. This personalized approach means you’re not just getting a machine; you’re getting a solution designed for your success.

Nobody in the bending machine industry has more expertise and experience than Hines. This expertise extends to our used equipment selection, where we apply the same rigorous quality standards that define our new machines. When you partner with us, you gain access to decades of knowledge, comprehensive support, and the peace of mind that comes from working with true industry leaders.

Whether you need a reliable workhorse for everyday production or a precision machine for complex geometries, we’re here to ensure you get a reliable, high-performance machine that delivers consistent results. Our commitment to your success doesn’t end with the sale – we provide ongoing support, training, and technical expertise to help you maximize your investment.

Ready to find the Hines difference? Explore Our Used Equipment Inventory and see how partnering with industry leaders can transform your bending capabilities.