Understanding the Investment in Precision Bending Technology

CNC tube bending machine price varies dramatically based on your needs. Here’s a quick overview of what you can expect to invest:

Quick Price Overview:

- Entry-level CNC benders: $50,000 – $150,000

- Mid-range automated systems: $150,000 – $500,000

- High-end specialized machines: $500,000 – $1,000,000+

- Used equipment: $15,000 – $45,000 (condition varies)

When you’re shopping for a CNC tube bending machine, price is just the beginning of the conversation. The real question isn’t “How much does it cost?” but rather “What value will this machine deliver to my operation?”

While basic manual benders are inexpensive, advanced CNC machines with high precision and automation can cost from $50,000 to over a million dollars for specialized systems. What most buyers miss is that the initial purchase price is only a fraction of the total investment. Installation, training, custom tooling, and ongoing support can add 20-40% to your base machine cost.

At Hines Bending Systems, the #1 worldwide manufacturer of tube benders, we supply precision equipment to organizations like NASA. Our experience has taught us that the cheapest machine is rarely the most economical choice over its lifetime. The key is understanding what drives these price differences and how to calculate the true return on your investment.

Cnc tube bending machine price vocab to learn:

Understanding the Spectrum of CNC Tube Bender Prices

The cnc tube bending machine price spectrum is incredibly wide, ranging from straightforward benders to the precision powerhouses we build for NASA. Understanding this range of tube bending technology is key to finding the right fit for your needs.

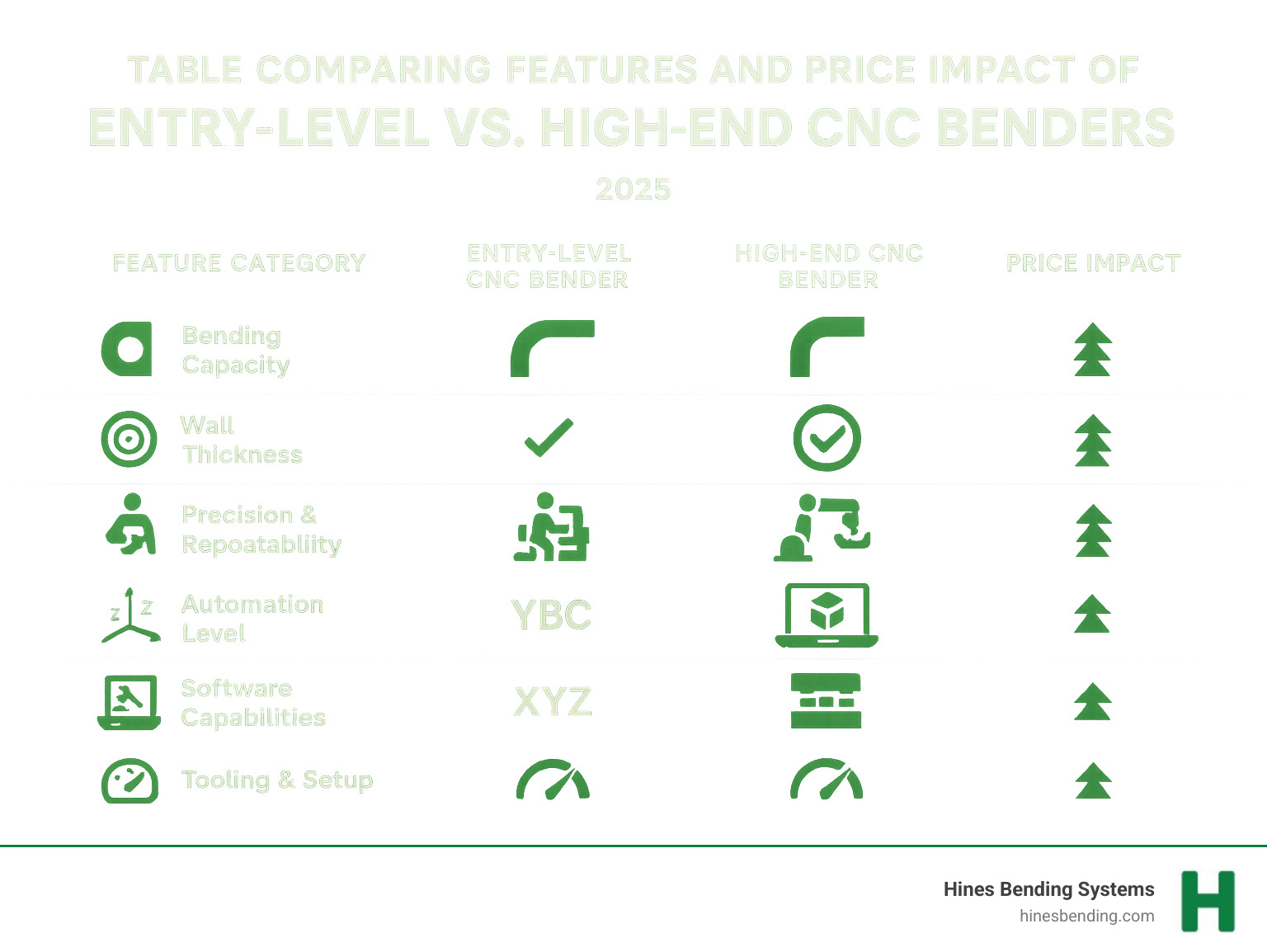

At one end of the spectrum are entry-level machines for small shops, while at the other are the sophisticated, multi-axis systems for demanding applications. The price reflects dramatic differences in capability, precision, and automation. The key is matching your investment to your actual needs and future growth.

Typical Price Ranges for New Machines

The cnc tube bending machine price for new equipment tells a story about its capabilities. Here’s what to expect at different investment levels.

Semi-automatic models ($50,000 – $150,000) are an entry point into CNC bending. They offer precision for angles and rotation but require manual loading. They are reliable workhorses for repetitive tasks.

Fully automatic CNC benders ($150,000 – $500,000) significantly step up automation. These machines can load, bend, and unload without constant operator attention, boosting throughput and reducing labor costs.

Multi-axis machines ($500,000 – $1,000,000+) are for creating complex, multi-plane bends seen in high-end automotive or aerospace components. Their precision and flexibility allow you to bid on jobs impossible with simpler equipment.

The price variation directly reflects capability: more axes for complex geometries, higher capacity for larger tubes, and advanced software for faster programming and quality control.

The Market for Used or Pre-Owned Benders

The used market is tempting, with a cnc tube bending machine price often between $15,000 and $45,000. However, buying used requires caution. Maintenance history is critical. A well-maintained machine from a quality manufacturer can be a great value, but a poorly maintained one is a future headache.

Older machines also have technology limitations, such as clunky controls or software that can’t integrate with modern systems. At Hines Bending Systems, we carefully inspect and refurbish our used equipment. When we put our name on a pre-owned machine, it meets our high quality standards. The key is working with a manufacturer who stands behind their equipment, new or used. That’s the difference between a good deal and a good investment.

Key Capabilities That Drive the CNC Tube Bending Machine Price

Understanding what influences the cnc tube bending machine price is about recognizing that higher cost corresponds to greater capability and reliability. At Hines Bending Systems, the #1 worldwide manufacturer of tube benders, we know the price reflects the incredible range of capabilities packed into each machine.

The key factors driving price include bending capacity (tube diameter and wall thickness), machine precision and repeatability, automation level (from manual to robotic), and software capabilities (from basic programming to 3D simulation). Control systems and the ability to handle various materials also play a major role.

How Bending Capacity and Precision Affect Cost

The cnc tube bending machine price is heavily influenced by capacity and precision. Bending larger diameter or thicker-walled tubes requires a more robust and powerful machine. This is simple physics; the required force and structural integrity increase significantly with size.

For clients like NASA, precision is absolutely critical. High-tolerance bending with exceptional repeatability demands superior engineering, advanced controls, and premium components. Every bend must be identical, often within sub-millimeter tolerances.

Our CNC Mandrel Tube Bender For Sale models exemplify this commitment. They are engineered to handle thick materials while maintaining incredible accuracy. The impact on the cnc tube bending machine price reflects the sophisticated technology needed to achieve this level of performance.

Automation and Software: The Price of Efficiency

Automation and software can significantly increase the cnc tube bending machine price, but they also deliver the most dramatic returns. The difference between manual and automatic systems is like comparing a hand tool to a smart factory.

Manual vs. automatic loading is a fundamental operational shift. Manual loading is labor-intensive, while our automated systems use feeding mechanisms and robotics to increase parts-per-hour and reduce labor costs.

Bending speed is another crucial factor. Advanced machines use high-speed hydraulics or all-electric servo drives for rapid movements and fast setup times, which translates directly to profitability in high-volume production.

Advanced software features are a game-changer. Modern Hines systems include 3D simulation to visualize the bending process, identifying potential issues before wasting material. Data integration allows CAD files to be sent directly to the machine, eliminating programming errors and accelerating setup. Our software also provides real-time monitoring and diagnostics for peak performance. This commitment to smart automation and efficiency is what justifies the investment in a premium cnc tube bending machine price.

New vs. Used: A Critical Cost-Benefit Analysis

Choosing between new and used equipment is a pivotal decision when considering the cnc tube bending machine price. The choice impacts long-term value, reliability, and capability. At Hines Bending Systems, we guide clients to make an informed choice that aligns with their business goals.

The Advantages of Investing in New Equipment

Investing in a new CNC tube bender, despite a higher initial cnc tube bending machine price, offers advantages that lead to a superior long-term ROI.

- Latest technology: New machines feature the latest advancements, including precise servo controls, faster speeds, and sophisticated software for higher accuracy and repeatability.

- Manufacturer warranty and support: A new machine includes a comprehensive warranty and full technical support from the manufacturer, ensuring prompt assistance and genuine parts. Our commitment at Hines extends far beyond the sale.

- Custom-built solutions: Purchasing new from Hines allows for a solution customized to your unique needs, including materials and production volumes. This is rarely possible with used equipment.

- Peak performance and reliability: New machines are engineered for peak performance and reliability, minimizing downtime and maximizing productivity. This ensures consistent product quality and reduced scrap. Learn more about the Advantages of CNC Tube Bending Machine For Sale.

Considerations for Buying a Used CNC Bender

While the lower initial cnc tube bending machine price of a used machine is tempting, it’s important to understand the potential drawbacks.

- Budget constraints: For shops with tight budgets, a used machine can be a viable entry into CNC capability.

- Machine condition: The condition is the biggest variable. A machine may have hidden wear, leading to costly repairs and downtime without an expert inspection.

- Availability of parts: Parts for older models can be difficult or expensive to source, leading to prolonged downtime.

- Lack of support: Used benders typically lack a manufacturer warranty or support, leaving you to handle troubleshooting and repairs alone.

- Outdated technology: Older controls and software may lack the efficiency, precision, and connectivity of modern benders.

At Hines Bending Systems, we sometimes offer inspected and refurbished units, like our Used 600CNC Demo Unit For Sale. When we offer a used machine, it meets our rigorous standards, providing peace of mind that a typical used purchase might not.

Calculating the True ROI: Beyond the Initial Purchase

Evaluating the cnc tube bending machine price requires looking beyond the sticker price to the Total Cost of Ownership (TCO) and Return on Investment (ROI). A higher initial price for a superior machine often yields a better ROI through increased efficiency, reduced waste, and expanded capabilities.

At Hines Bending Systems, we’ve seen clients transform their businesses by focusing on long-term value. Our machines are engineered to optimize your operations, delivering increased throughput, reduced scrap, and substantial labor savings. A machine that costs $200,000 but produces 30% more parts with 50% less waste will quickly outperform a cheaper, less consistent alternative. This is the experience we bring from serving clients from small shops to NASA.

Factoring in the Total CNC Tube Bending Machine Price

The base cnc tube bending machine price is just the start. Smart buyers budget for the complete picture, and we ensure our clients understand the full investment.

- Installation costs: Site preparation, electrical work, and professional setup are crucial for optimal performance and safety.

- Operator training: Comprehensive training open ups a machine’s full potential, boosting efficiency and reducing errors. Our NC vs CNC: Which Bending Machine is Right for You? guide explains this further.

- Custom tooling: Specific tooling is required for different tubes, radii, and materials. Quality tooling ensures consistent results.

- Maintenance plans: Preventive maintenance maximizes uptime and protects your investment.

- Consumables: Bending lubricants and cleaning agents add up but improve results and reduce tool wear.

We believe in full transparency on these costs to help you make the best decision.

Long-Term Benefits of a High-Quality CNC Bender

The initial cnc tube bending machine price for a premium Hines machine is higher, but the long-term benefits make it a smart investment.

- Production efficiency: Faster cycle times and quick setups directly impact your bottom line.

- Consistent quality: Meeting exact specifications reduces scrap and builds a reputation for precision.

- Reduced downtime: Robust construction means fewer breakdowns, which is essential for profitability.

- Ability to bid on complex jobs: Advanced capabilities open doors to high-value contracts that were previously out of reach.

- Improved shop capabilities: Quality equipment attracts skilled workers and positions you as an industry leader.

Our machines are built for the long haul. Combined with our Tube and Pipe Bender Training programs, you’re investing in a partnership for success.

Frequently Asked Questions about CNC Bender Costs

Clients often ask us at Hines Bending Systems about the cnc tube bending machine price and what it means for their business. After decades as the #1 worldwide manufacturer, serving everyone from small shops to NASA, we’ve learned the most important questions are about making smart, long-term investments.

What is a realistic budget for a small shop’s first CNC tube bender?

For a small shop’s first new machine, we recommend budgeting $50,000 to $150,000. This range provides genuine CNC capability with the reliability and precision to support your growth. Remember to add 20-40% to this initial cnc tube bending machine price for installation, tooling, and operator training to ensure you’re production-ready.

While used machines are available from $15,000 to $45,000, they carry risks like hidden wear or outdated controls. We’ve seen many shops get burned by a seemingly good deal. Instead of gambling, consider financing a new entry-level Hines machine. The warranty, support, and peace of mind are often worth the investment, giving you a machine that can scale with your business.

How much does custom tooling add to the overall price?

Tooling transforms a general bender into a precision tool for your specific needs, and its cost varies. The primary factors are tooling complexity, material type, and the number of die sets required. Simple, single-radius tooling may cost a few thousand dollars, but complex geometries require more specialized, and thus more expensive, solutions.

Mandrel requirements and wiper dies are also critical for precision work, especially with thin-walled tubing or tight radii, as they prevent wrinkles and ensure accuracy. These sophisticated components add to the cost. Realistically, a tooling package can range from $10,000 to $50,000 or more. At Hines, we leverage our expertise to design cost-effective tooling that delivers the precision you need.

Why is a high-quality machine a better long-term investment?

This question gets to the heart of why Hines is the trusted choice for demanding applications. While the initial cnc tube bending machine price is higher, the long-term value is superior.

- Durability: Our machines are built with robust components for a longer operational lifespan and fewer breakdowns.

- Precision: Consistent, exact bends eliminate scrap and rework, which pays for the machine over time.

- Manufacturer Support: Investing in Hines means gaining access to our expert team, spare parts, and ongoing technical assistance for decades to come.

- Lower Lifetime Costs: A quality machine requires less maintenance and has higher uptime, reducing the total cost of ownership.

- Uptime Reliability: Consistent operation is invaluable. It allows you to meet deadlines, satisfy customers, and build a reputation for growth—the same reliability NASA counts on from us.

Finding the Right Bending Solution for Your Business

Navigating the cnc tube bending machine price landscape is about more than numbers; it’s about finding a partner who delivers a transformative solution. The best investment prioritizes partnership over price.

At Hines Bending Systems, we know that price versus partnership makes all the difference. We are committed to understanding your specific bending requirements and production goals.

Our expertise truly matters. As the #1 worldwide manufacturer of tube, pipe, and induction benders, we have installed more bending systems than anyone. This represents an unparalleled understanding of what works in real-world production environments.

What sets us apart is our commitment to quality components and custom engineering. Every Hines machine is built with superior materials for consistent performance. We don’t cut corners, because your success depends on reliable, precise equipment.

The fact that we’re a trusted NASA supplier speaks volumes. The same engineering excellence that meets NASA’s demanding requirements goes into every machine we build, for any size shop.

When you partner with Hines, you’re investing in the best experience in the bending industry. We work with each client to design custom solutions that address their specific needs. Our approach to custom engineering means we engineer the machine around your requirements, ensuring optimal performance and maximum return on your investment. This level of customization, combined with our training and support, delivers value far beyond the initial purchase price.

Ready to find what makes Hines Bending Systems the industry leader? Learn more about Why Buy a Hines Bender? and experience the difference that true expertise and partnership can make.