Exhaust pipe bending in the auto industry requires precision and reliability. Bending tubing into exhaust pipes, in general, carries its own unique challenges. An automotive exhaust pipe bender is designed to overcome those challenges and deliver reliable, high-quality results again and again.

Tube Bending

One of the more challenging aspects of exhaust pipe bending for the automotive industry is the size of the tubing. Often, the tubing that is used will have a small diameter, which causes complications. In addition to creating precise bends without buckling or wrinkles, the exhaust pipe will also need to be protected from wall thinning.

On top of that, some of the bends could be rather complex, depending on the intended application. An automotive exhaust pipe bender addresses these difficulties and gives users more control while working the tubing. Let’s take a closer look at some of the benefits of using an exhaust pipe bender for automotive applications.

Automotive Exhaust Pipe Bender

There are a number of useful advantages for using an automotive exhaust pipe bender, such as reliability, consistency, and control. The ability to produce high-quality pipe and tube bends consistently is extremely important, especially for precise specifications in car, truck, and motorcycle parts.

With an automotive exhaust pipe bender, the complexities of bending small diameter tubing are easily overcome. Not only will meeting the usual specifications be achievable, but there is also considerably less concern over wall thinning thanks to the remarkable degree of control exhaust pipe benders present.

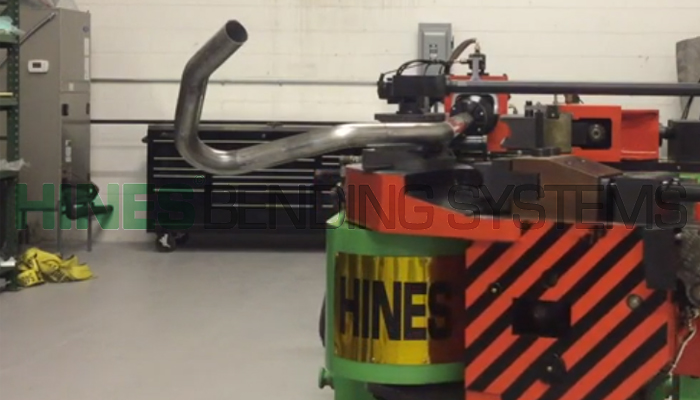

The Hines 300 CNC Tube Bender is our most popular exhaust pipe bender for the car exhaust and automotive industry. It is equipped with the power requirements necessary to ensure the tube bending process is successful from start to finish. In addition to that, it is capable of bending various materials, such as stainless steel, aluminum, and even copper.

Why Hines Bending Systems?

Hines Bending Systems is the world’s leading bending machines manufacture. Our large collection of tube and pipe bending equipment for sale includes everything from mandrel benders to CNC benders, induction benders, and roll benders. Our team prides itself on being able to find the perfect bending solution to match all of our client’s needs.

So whether you are looking at bending machines for small radius tubing or large OD benders, we can help you to make the most out of your investment. Additionally, we will help to demonstrate the unit so that you are confident in your decision to take control of your bending production.

Email Hines Bending Systems to discuss your requirements and a member of our staff will promptly answer any inquiries you might have. To speak to a representative directly, please call us at 800-949-8344.