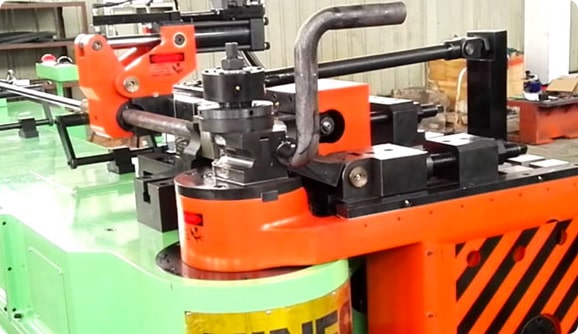

You’ve found the right place if you are looking to invest in a high-quality, steel pipe bender. You can find a wide range of pipe and tube benders to help you produce high-quality bends with consistency and precision, including semi-automatic and manual, as well as CNC bending machines. For the best Steel Pipe Benders in South Florida feel free to give Hines Bending a call at 239-433-2132.

It is important to take into account price, precision, consistency, and other factors when choosing the right type of tube bending machine. Here is a list that will help you choose the right steel pipe bender.

Contact Hines Bending Systems to speak directly with machine manufacturers about the best pipe-bending machine for you.

Things to consider before purchasing pipe bending equipment

- Cost of Tube Bending Machines The size of the steel pipe bender will affect its cost. Large bending machines can be built to the customer’s specifications.

- Expected Return On Investment: This is a key factor in determining the success of any company. It refers to the return on investment (ROI), after making significant investments. Each company has its own profit goals to ensure that it keeps spending within a budget. A company can be doomed to fail if it tries to expand its finances without achieving a favorable ROI.

- Output: When choosing a steel pipe bender to use, it is important to take into account its output capacity. This is the number of parts per hour produced. The production capacity of any pipe-bending machine will be affected by factors like the size and shape of the tubes, as well as the proficiency of the operator.

- Upgrade in time: Semi-automatic benders can be upgraded to CNC bending machines. CNC bending machines can be programmed to perform a particular function. Some small shops may have different production requirements, which can lead to higher labor costs.

- Scrap Rate: When choosing tube and pipe bending equipment, it is important to consider the amount of scrap produced. Companies that use expensive materials need to consider the scrap rate. Both the efficiency of the operator and the bending machine determine the scrap rate. Semi-automatic bending equipment produces more scrap than CNC bending machines. Semi-automatic benders produce more scrap when the operator is less efficient.

- Precision and consistency: Pipe benders are most efficient when they can accurately repeat their movements. It is possible to ensure precision and consistency with CNC bending. However, accuracy in bends is also dependent on how well the machine is maintained.