Understanding CNC Tube Benders

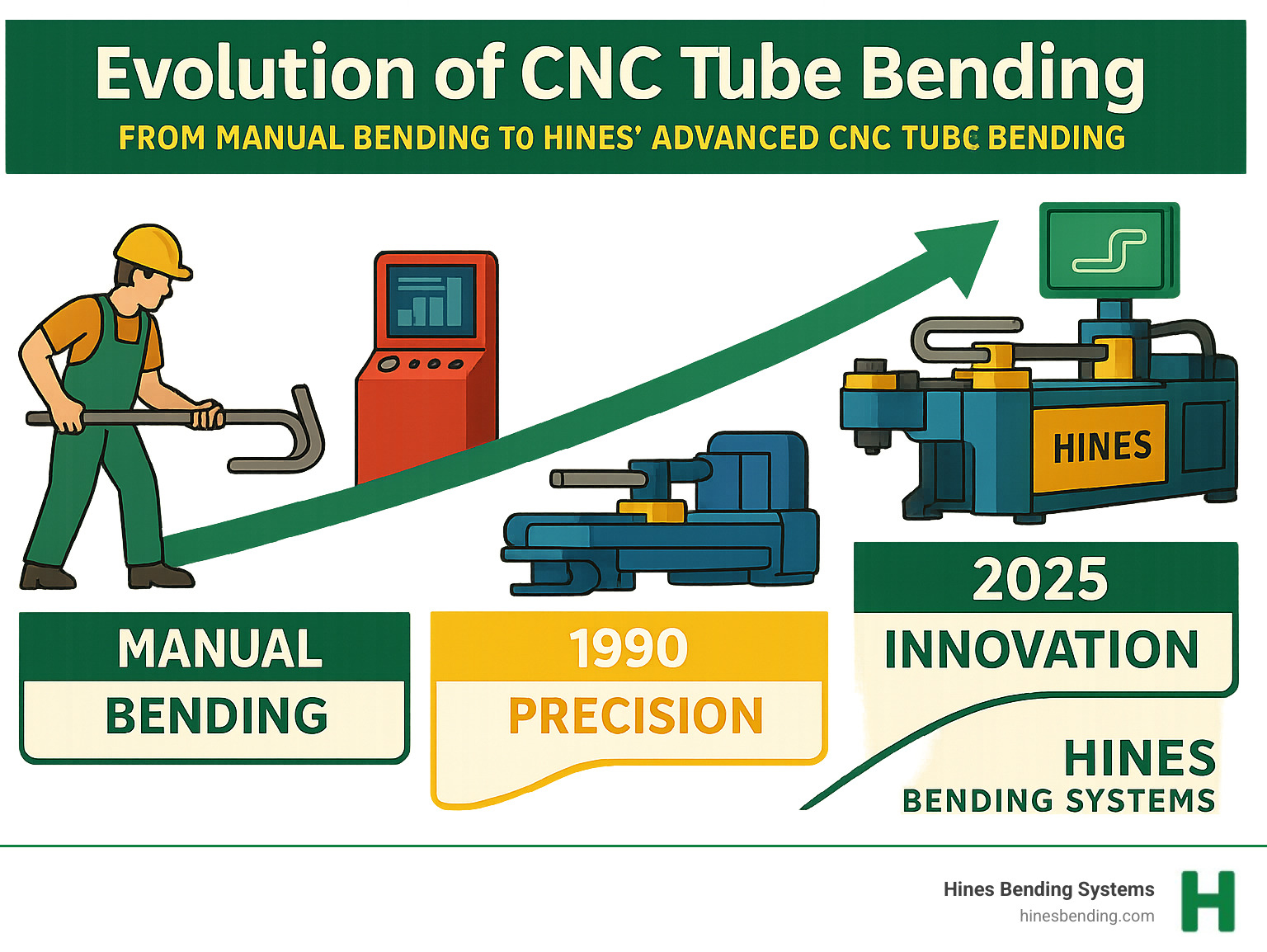

A cnc tube bender machine is a powerful tool in modern manufacturing. It uses Computer Numerical Control (CNC) to precisely and automatically bend metal tubes and pipes.

Here’s a quick look at what they do:

- Definition: An industrial machine that shapes metal tubes using computer-programmed instructions.

- Primary Function: To create accurate, repeatable, and complex bends in tubes and pipes for various applications.

- Key Advantage: Replaces manual bending with automated precision, greatly improving quality and efficiency.

- Industry Impact: Essential for industries needing high-quality tubular components, from automotive to aerospace.

In modern manufacturing, where precision and efficiency are paramount, manual bending methods often result in errors, waste, and slow production. Advanced bending technology solves this by ensuring every bend is perfect, every time.

Hines Bending Systems has been at the forefront of this technology for decades. We are the #1 worldwide manufacturer of tube benders, providing superior quality machines and custom solutions to meet the toughest industry standards. Our expertise is best, and we even supply massive agencies like NASA.

This guide explains how these amazing machines work, their benefits, and why Hines Bending Systems is your ultimate partner for bending mastery.

Must-know cnc tube bender machine terms:

What is a CNC tube bender machine and what is its function?

At its core, a cnc tube bender machine is sophisticated equipment that transforms raw tubing into precise, 3D shapes. The “CNC” means a computer program governs the entire process, allowing for unparalleled accuracy, repeatability, and the creation of complex geometries impossible with traditional methods.

Our primary function at Hines Bending Systems is to harness this technology to provide solutions that are cornerstones of modern metal fabrication. We understand that shaping tubes and pipes isn’t just about making a bend; it’s about creating components that meet exacting specifications for critical applications. Our leadership in CNC tube bending technology ensures that every machine we deliver is ready to meet the demands of high-precision manufacturing.

The Critical Role of Precision in Modern Manufacturing

Precision is a fundamental requirement in manufacturing. In the aerospace industry, for example, a minuscule error in a hydraulic line can have catastrophic consequences. Likewise, in automotive, consistent quality directly impacts vehicle safety and performance. For these industries, structural integrity is paramount, leaving no room for human error.

Our cnc tube bender machine technology excels in this regard, virtually eliminating the variability inherent in manual processes. This leads to consistent production efficiency and parts that meet the tightest tolerances, every single time. At Hines Bending Systems, our commitment to quality and accuracy is unwavering. When you invest in one of our machines, you’re investing in the future of your production, ensuring your parts are right from the start. You can learn more about how our CNC technology improves precision by understanding CNC Metal Bending.

How Hines CNC Tube Benders Achieve Flawless Bends

Watching a Hines cnc tube bender machine in action reveals decades of engineering excellence. The secret to our flawless bends is the perfected rotary draw bending process—a sophisticated coordination of precision components working seamlessly. Our machines transform raw materials into precision components that meet the most demanding specifications, delivering consistently perfect results.

The beauty of our system is its orchestrated automation. Unlike other manufacturers who may struggle with consistency, our cnc tube bender machine technology delivers the same perfect result every time. You can explore more about our capabilities in our General CNC Bending Machine Info section.

The Step-by-Step Bending Process

Here’s a walkthrough of the precision-driven process in a Hines machine:

- Tube loading: The operator carefully positions the tube in the clamp, ensuring perfect alignment, as every millimeter is critical for the subsequent bends.

- Programming coordinates using our YBC system: Using our intuitive YBC system, the operator inputs the exact bend angle, radius, and length. This CNC control simplifies programming for even complex, multi-bend parts.

- Clamping process: The tube is clamped with precise force to prevent slippage without damaging the material, which is crucial for a stable bend.

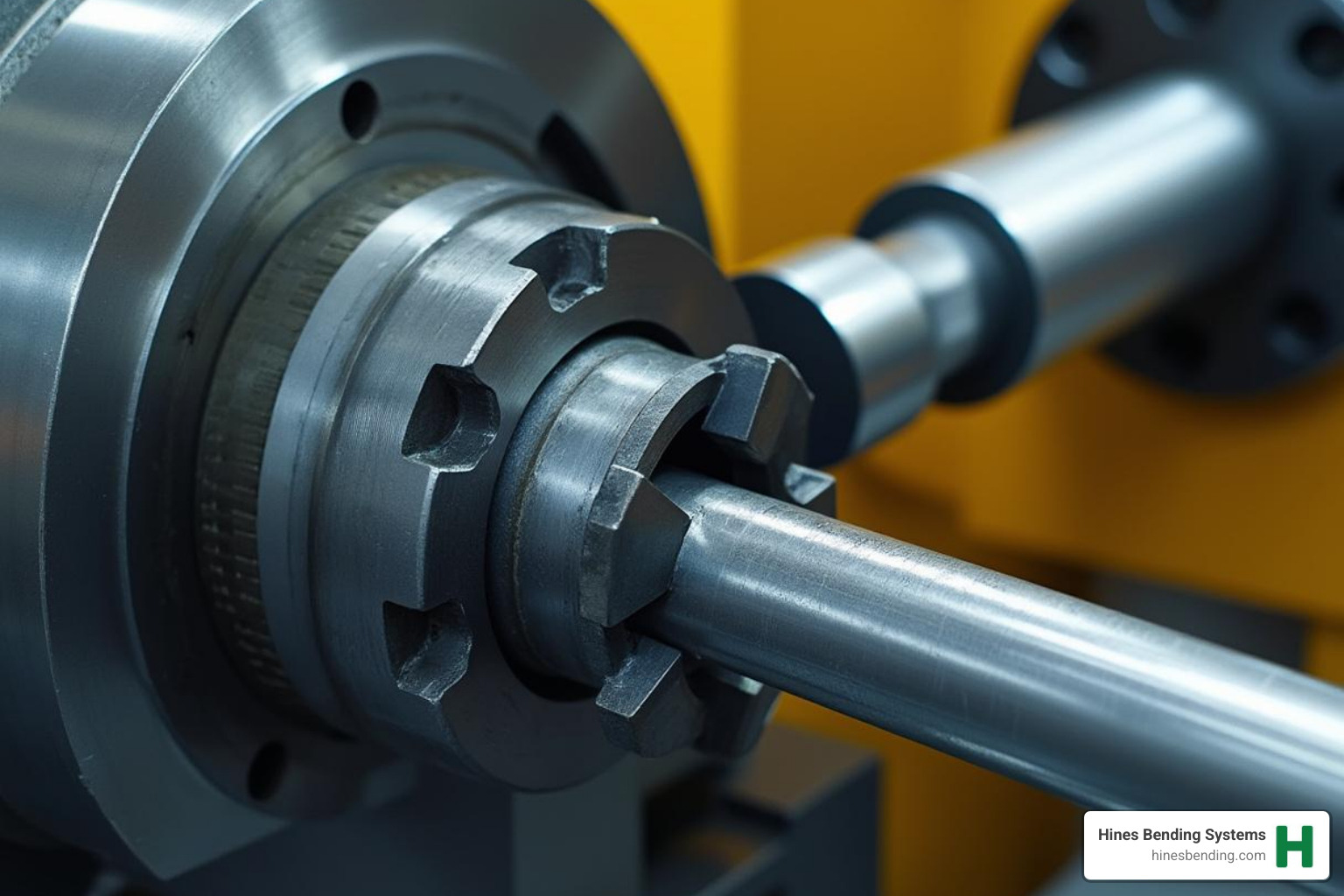

- Mandrel insertion: A mandrel is inserted to provide internal support, allowing for tight bends without crushing or wrinkling the tube. This is key for thin-walled materials and perfect interior finishes.

- Pressure die assistance: The pressure die provides counter-pressure, ensuring smooth material flow around the bend. Our expertise in calibrating this pressure ensures professional results.

- Bending motion: The tube is drawn around the bend die with incredible precision, maintaining consistent speed and pressure throughout the entire arc.

- Part rotation and advancement: After a bend, the machine automatically rotates and advances the tube for the next one. This multi-axis movement enables complex, multi-plane bends impossible with manual methods.

- Unloading: The cycle completes with unloading, leaving a perfectly formed part that exactly matches specifications.

Our BendPro G2 CNC Control System is the brain behind this entire process, showcasing our commitment to process optimization and making intricate bending sequences feel effortless.

Key Components and Their Functions

The precision of every Hines cnc tube bender machine comes from the superior engineering of its components. Each part is critical for achieving a perfect bend.

- CNC Controller: The brain of the operation, this intelligent system processes programmed instructions and controls all motion with incredible precision. Our advanced controllers handle extensive programming—up to 400 sets of file editors, with each set defining 16 bend angles.

- Bend Die: The primary shaping tool that the tube is drawn around to create the exact bend radius.

- Clamp Die: Secures the tube firmly during bending, ensuring rock-solid stability for precision.

- Pressure Die: Applies counter-pressure to ensure smooth material flow and prevent flattening.

- Wiper Die: Prevents wrinkles on the inside radius of a bend, smoothing the material as it flows.

- Mandrel: Provides internal support to maintain the tube’s round cross-section and wall thickness, which is essential for tight bend radii.

At Hines Bending Systems, our dedication to superior component engineering makes our machines the choice of industry leaders worldwide. When NASA needs precision bending, they come to us. When automotive manufacturers need reliability, they choose Hines. That’s the difference decades of engineering excellence makes.

The Best Advantages of a Hines CNC Tube Bender Machine

Investing in a Hines cnc tube bender machine transforms your manufacturing operation. The advantages extend beyond automation, impacting everything from part quality to your bottom line. Hines machines address common manufacturing challenges like maintaining quality, boosting productivity, and reducing waste, thanks to our advanced technology and decades of expertise. You can Learn about the advantages of CNC tube bending machines in more detail on our site.

Superior Quality and Consistency

Hines cnc tube bender machines deliver unwavering accuracy that manual processes can’t match. The first part is identical to the thousandth, ensuring perfect consistency. This perfect repeatability eliminates part variation, leading to smoother assembly, fewer rejections, and happier customers. Our machines also deliver reduced distortion through precise process control, allowing you to produce quality parts immediately without wasteful trial-and-error. This is why NASA trusts Hines for its most critical applications.

Our commitment to industry-leading quality assurance is built into every machine we make. You can see this in action by reading how Wachs Services installs CNC benders and experiences these quality benefits firsthand.

Boosting Productivity and Efficiency

Our cnc tube bender machines are designed to maximize your time. Faster cycle times can double or triple your output, while automated operation and reduced setup time significantly lower labor costs. Your skilled operators can then focus on higher-value tasks. Our all-electric models offer energy savings up to 70%, and high-speed operations reach up to 10 meters per minute. With minimized material waste from perfect first-time bends, our focus is always on maximizing client ROI.

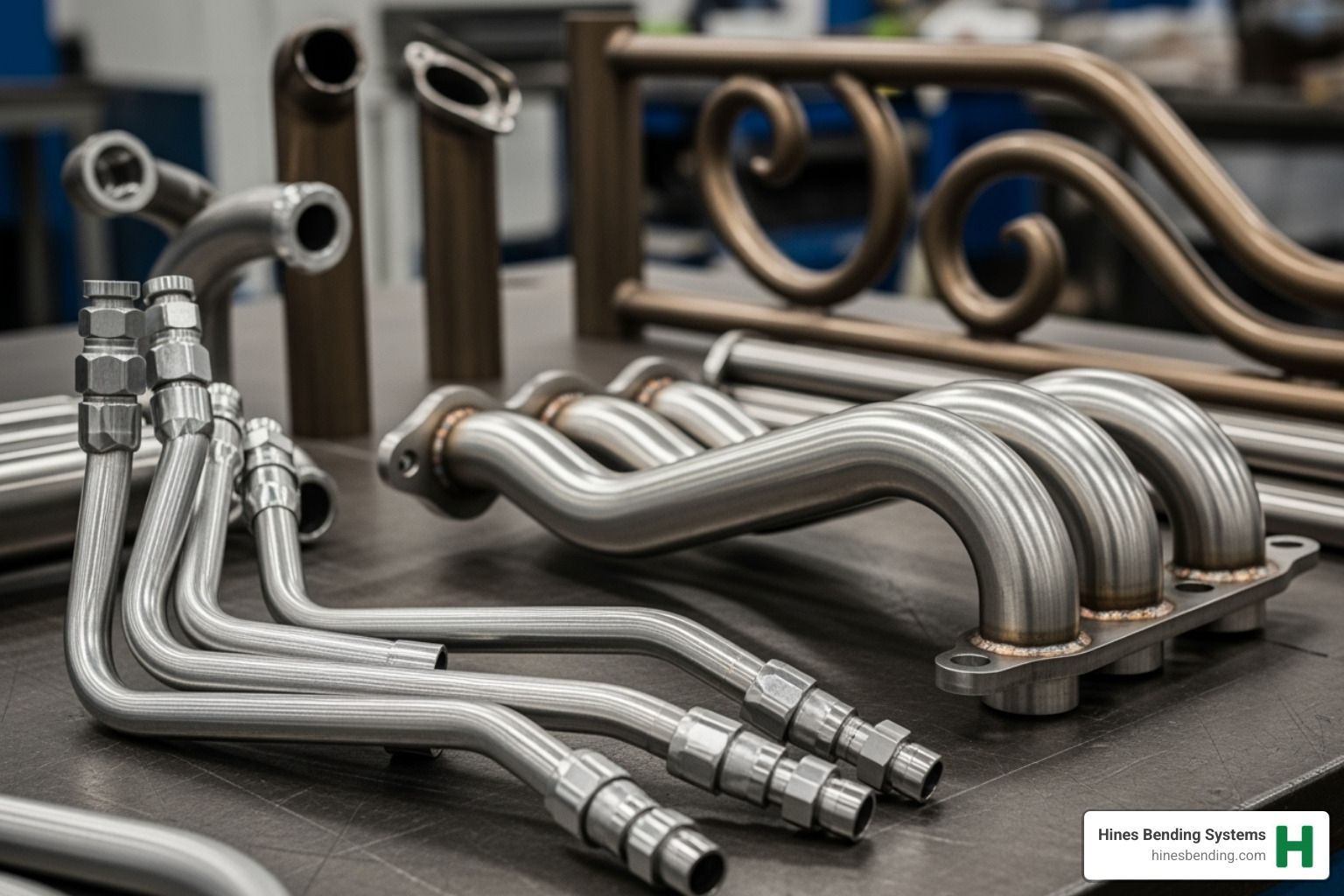

Versatility for Complex Designs

The versatility of a Hines cnc tube bender machine is incredible. Our multi-axis bending capabilities, including 3-axis and 5-axis systems, open up new design possibilities. We handle bending angles up to 190 degrees and tight bend radii as small as 1D with ease. This ability to create complex geometries gives you a competitive edge. Whether for rapid prototyping or high-volume mass production, our machines adapt to your needs, seamlessly scaling from a single part to thousands.

We invite you to Explore our 300 CNC Tube Benders to see the full range of custom solutions we offer for every application. From simple to complex parts, Hines has the technology to make it happen.

Industries Transformed by Hines CNC Bending Technology

The impact of a Hines cnc tube bender machine extends far beyond the factory floor, revolutionizing industries by enabling the creation of critical components for everything from spacecraft to cars. Our technology adapts to meet the unique demands of any sector, from bending exotic metals for aerospace to mass-producing identical automotive parts.

Aerospace and Defense

In aerospace and defense, failure isn’t an option. Every hydraulic line, fuel line, and structural frame must perform flawlessly. That’s why our cnc tube bender machines are trusted to create these mission-critical components. We have specialized expertise in working with exotic alloys like titanium and Inconel, which are notoriously difficult to bend. Our machines handle these challenges with ease, maintaining the uncompromising quality standards that aerospace applications demand. The ultimate validation of our expertise? We work directly with NASA. When the world’s premier space agency needs precision bending solutions, they turn to Hines Bending Systems. You can Find how we work with NASA and see how our trusted expertise contributes to space exploration.

Automotive and Transportation

The automotive world moves fast, and our cnc tube bender machines keep pace with high-volume production demands. From exhaust systems to the chassis components that keep passengers safe, our machines are essential partners in automotive manufacturing. The complexity of a modern vehicle’s brake lines or roll cages requires perfect bends, as lives depend on it. Our proven track record shows why major manufacturers trust us with their most critical components. Even in specialized applications like motorcycle handlebars, our machines deliver the precision and consistency that riders depend on.

HVAC, Shipbuilding, and Architecture

The versatility of our cnc tube bender machines shines in industries that demand both precision and power. In HVAC, our machines create intricate heat pump coils with the exact specifications needed for optimal energy efficiency. For shipyard piping, our machines handle complex routing and large-scale requirements with ease, creating reliable systems that keep vessels operating safely. In architecture, our solutions bring beauty and strength to modern buildings, from neat handrails to bold structural and decorative elements. With the capability to handle tubes up to 6.5 inches (165 mm) in diameter, we provide solutions for diverse industries that others simply can’t match.

Selecting the Right Hines Bending Solution for Peak Performance

Choosing the right cnc tube bender machine can be complex, but at Hines Bending Systems, we partner with you to find the ideal solution for your unique operation. With more bender installations worldwide than any other manufacturer, we’ve seen it all. Our approach is always consultative first, transactional second.

Factors for Choosing the Right Hines CNC Tube Bender Machine

When you’re ready to invest in a cnc tube bender machine, several critical factors will shape your decision. Our team works with you to define these requirements, saving you time and money by getting it right from the start.

- Material type: Whether you’re working with steel, aluminum, copper, stainless steel, titanium, brass, or exotic alloys, each has its own bending personality. We know which machine configuration will handle your materials beautifully.

- Tube diameter and wall thickness: These factors directly impact which machine series you’ll need. Our machines handle everything from delicate 0.12-inch (3 mm) tubes up to robust 6.5-inch (165 mm) profiles.

- Required bend radius: Need super-tight 1D bends or gentler curves? We have solutions that excel at both.

- Production volume: We’ll match the automation level to your actual needs, whether you’re prototyping or in high-volume production.

- Part complexity: For multi-plane parts with dozens of bends, our advanced control systems and multi-axis capabilities prove their worth.

Take a look at our comprehensive guide to Explore the different types of CNC tube benders to get a feel for the options available. Then give us a call to discuss your project.

Understanding Hines Machine Capabilities

Our cnc tube bender machine lineup is thoughtfully designed to handle real-world manufacturing challenges. We’ve built our reputation on delivering machines that perform flawlessly on your shop floor, day after day.

Mandrel versus non-mandrel bending is a key consideration. For pristine, wrinkle-free bends on thin-walled or critical tubing, mandrel bending is essential. It uses internal support to prevent collapse and maintain a round cross-section. For less critical jobs, non-mandrel bending can be more cost-effective. We offer both, and you can Find a CNC Mandrel Tube Bender for Sale in our inventory.

All-electric versus hydraulic systems is another key decision. Our all-electric machines are incredibly accurate, quiet, and can cut energy costs by up to 70%. Our hydraulic systems bring the muscle for heavy-duty work. We’ll help you determine which fits your operation best.

Multi-stack tooling minimizes downtime by allowing you to set up multiple configurations simultaneously, like having several machines in one.

Beyond traditional methods, we’ve innovated with push bending for large radius bends and roll bending for continuous curves. Our Dual Stack CNC Push Bender and Roll Bender represent the cutting edge of bending technology.

What truly sets us apart is our commitment to innovative technology and training. When you partner with Hines, you gain access to decades of accumulated knowledge and ongoing support. To better understand your options, check out our comparison guide to Understand the difference between NC vs CNC bending machines.

The Future of Tube Bending: Advanced Technology and Innovation with Hines

At Hines Bending Systems, we’re not just following manufacturing trends; we’re shaping them. The future of tube bending involves pushing boundaries, integrating smarter technologies, and embracing sustainable practices to make your production lines more precise, productive, and future-proof.

Integrated Technologies for Smart Manufacturing

Today’s cnc tube bender machine is an intelligent partner in your manufacturing process. We integrate advanced control systems for seamless operation and real-time data feedback. Our cutting-edge 3D CAD-to-part software allows direct design transfer, while pre-operation bending simulation ensures flawless execution from the start. The drive towards automation is stronger than ever, with robotic loading and unloading systems turning individual machines into fully automated fabrication cells. This boosts productivity and improves workplace safety. At Hines, we’re committed to this kind of innovation, always pushing the industry forward. You can Find out more about advanced CNC machines and how we’re making the future of bending a reality, today.

Future Trends: Industry 5.0 and Beyond

As we look ahead, the concept of Industry 5.0—a harmonious collaboration between humans and machines—is truly exciting. At Hines, our future innovations are focused on making your operations smarter and more intuitive than ever before. We’re developing technologies that will bring you:

- Real-time quality monitoring: Know with certainty that every bend is perfect, thanks to continuous feedback loops from the machine.

- Predictive maintenance: Smart data analytics will anticipate and prevent downtime, maximizing uptime.

- Increased energy efficiency: We’re striving for even greater sustainability, building on the 70% energy savings of our all-electric models.

- Sustainable manufacturing: We design machines and processes that minimize environmental impact.

At Hines Bending Systems, our vision is one where your cnc tube bender machines are intelligent partners, helping you achieve unparalleled efficiency, precision, and a truly sustainable operation.

Conclusion: Partnering with Hines for Bending Mastery

You know, achieving manufacturing excellence isn’t just about the machines you have in your workshop. It’s about finding the right partner, a true leader who stands by your side. And for decades, that partner has been Hines Bending Systems. We’ve proudly set the global standard, crafting the highest quality tube, pipe, and induction benders that serve the world’s most demanding industries – yes, even agencies like NASA!

We truly believe that nobody in the bending machine industry boasts more expertise and experience than our team. With the highest number of bender installations worldwide, we bring a wealth of knowledge to every project. What does that mean for you? It means our dedicated team works directly with you, diving deep into your specific needs to develop custom solutions. We’re not just selling machines; we’re guaranteeing precision, reliability, and peak performance for your operations.

So, when it comes to your critical bending needs, why settle for anything less than the very best? Let Hines Bending Systems be your trusted guide to bending mastery.

Lift your production with our industry-leading CNC Bending Machines