Why Right and Left CNC Bending Technology Matters for Modern Manufacturing

A right and left CNC tube bender is a dual-direction bending machine that can bend tubes both clockwise and counterclockwise in a single setup, eliminating the need for multiple operations or manual repositioning.

Key Features:

- Clockwise bending (right-hand) for tight radius bends and precise control

- Counterclockwise bending (left-hand) for larger radius bends and complex geometries

- 360° rotating bend head for seamless direction changes

- All-electric servo systems providing up to 70% energy savings

- Synchronized axes for optimized cycle times

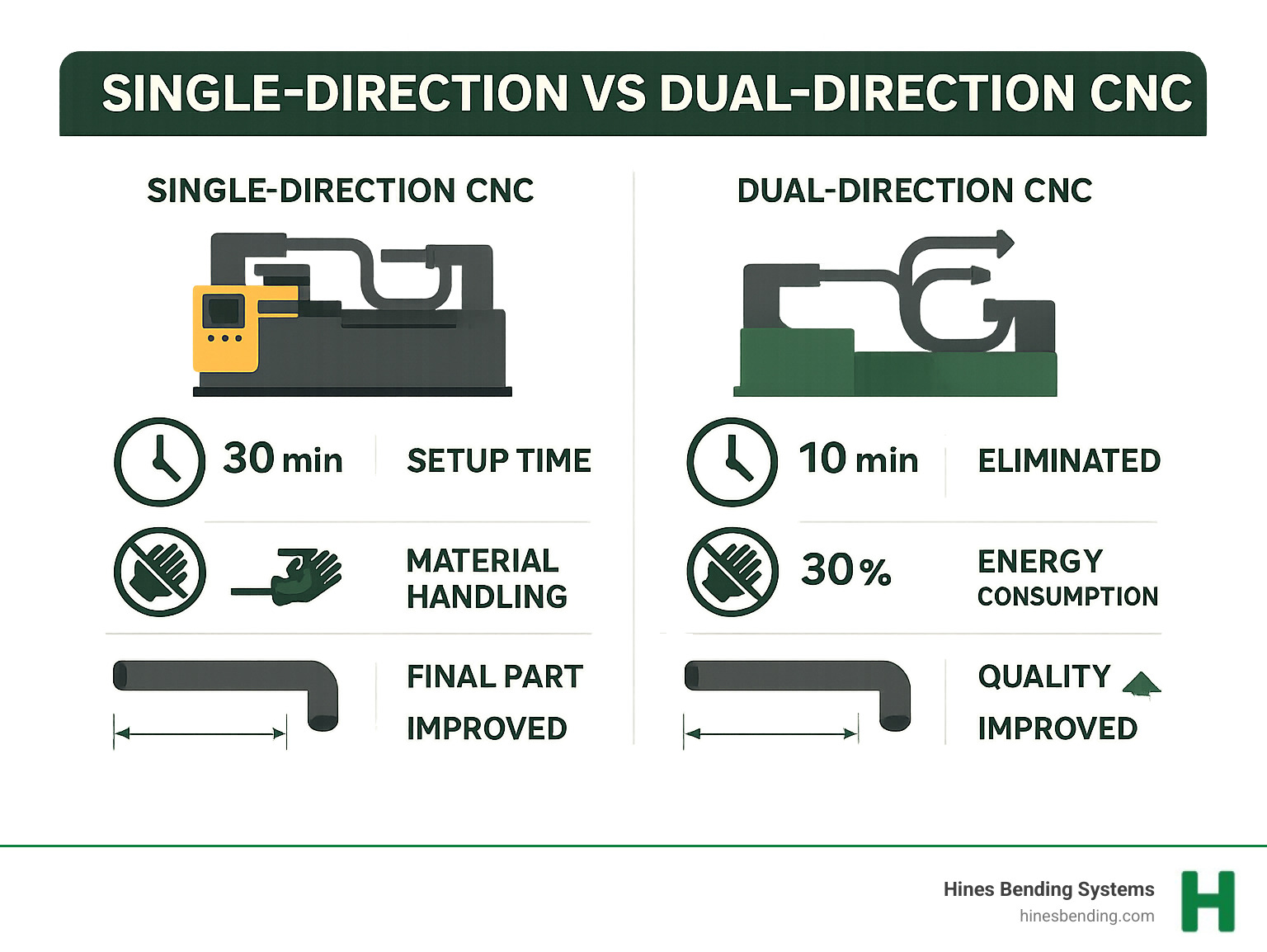

Manufacturing operations managers face constant pressure to reduce costs while maintaining precision. Traditional single-direction benders force you to choose between setup complexity or part limitations.

Right and left bending technology changes this equation completely.

Instead of repositioning parts or using multiple machines, dual-direction benders handle complex geometries in one continuous process. This means faster production, fewer handling errors, and stronger finished parts with minimal welds.

The technology isn’t just about convenience – it’s about open uping design possibilities that were previously impossible or too expensive to manufacture. From NASA’s critical aerospace components to automotive exhaust systems, industries demanding the highest precision rely on this dual-direction capability.

As the #1 worldwide manufacturer of tube benders, Hines Bending Systems has pioneered many of the innovations that make right and left bending both reliable and cost-effective for serious manufacturing operations.

Right and left cnc tube bender terms simplified:

What is a Right and Left CNC Tube Bender and How Does It Work?

Think of traditional tube benders as one-handed workers – they’re skilled, but they can only bend in one direction at a time. A right and left CNC tube bender is like having an ambidextrous craftsperson who can seamlessly switch between clockwise bending and counter-clockwise bending without missing a beat.

This dual-direction capability transforms what used to be a multi-step headache into a smooth, single-process operation. Instead of stopping to flip your tube, reposition your tooling, or move to a different machine, the bender handles complex geometries with alternating bend directions in one continuous flow.

The real magic happens when you compare this to traditional benders. Where older machines force you to choose between setup complexity or design limitations, dual-direction technology gives you the best of both worlds. You get single-process efficiency that dramatically cuts production time while opening up design possibilities that were previously too expensive or complicated to manufacture.

At Hines Bending Systems, we’ve been perfecting this technology for decades. As the #1 worldwide manufacturer of tube benders, we understand that modern manufacturing demands both speed and precision. Our right and left CNC tube benders deliver exactly that – the flexibility to create intricate parts without the traditional compromises.

Whether you’re bending titanium fuel lines for aerospace applications or creating complex automotive exhaust systems, this technology ensures your parts maintain structural integrity while reducing the number of welds needed. Fewer welds mean stronger parts and lower production costs.

The Technology Behind Dual-Direction Bending

The heart of dual-direction bending lies in sophisticated all-electric systems that deliver both precision and efficiency. These servo-driven machines offer up to 70% energy savings compared to traditional hydraulic systems, which means lower operating costs and a smaller environmental footprint.

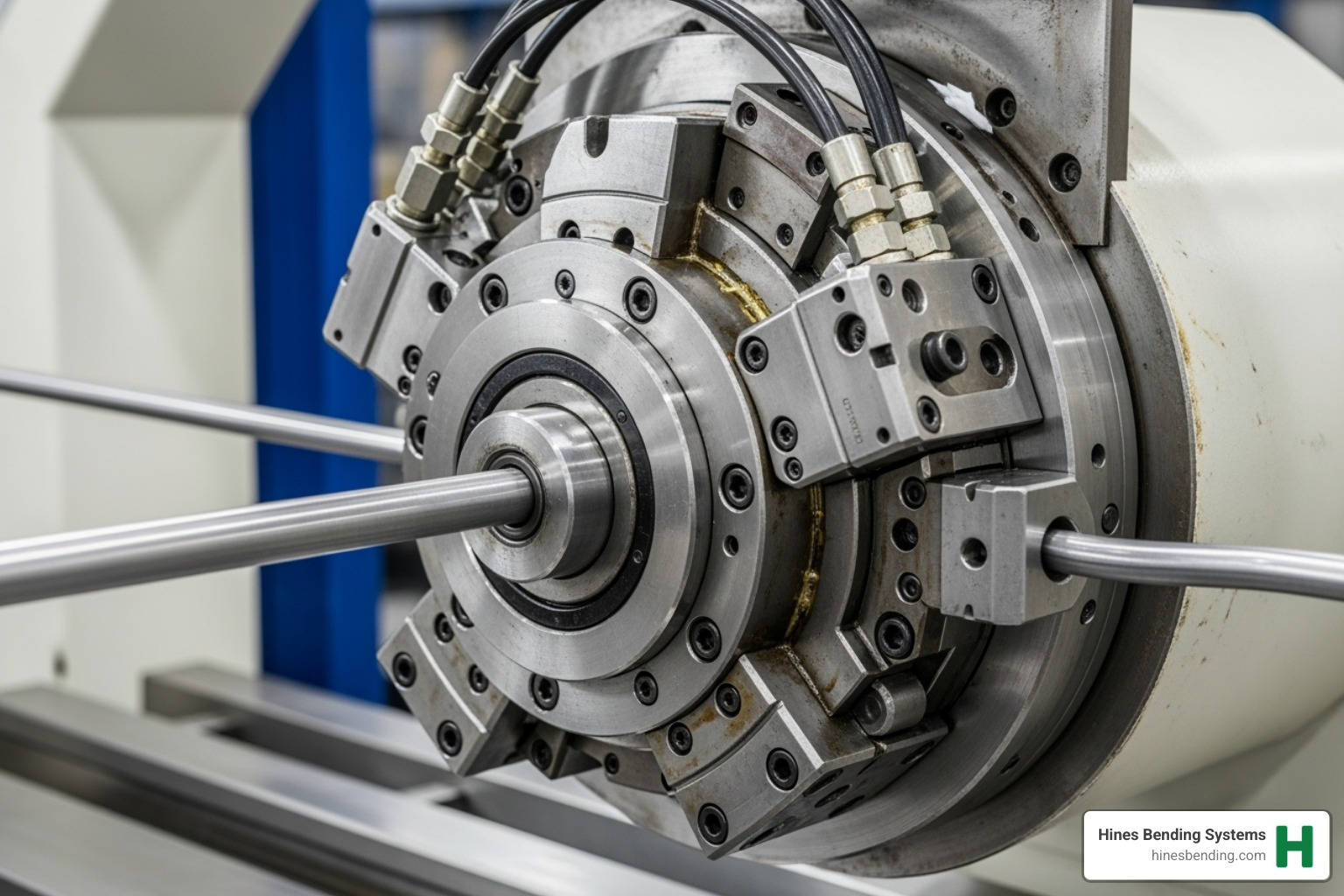

The star of the show is the rotational bend head that spins 360 degrees without breaking stride. This component allows the machine to switch from right-hand to left-hand bends instantly, eliminating the stop-and-go rhythm that slows down traditional bending operations.

Multi-stack tooling takes this efficiency even further. Instead of changing tools for different bend radii or tube sizes, the machine holds multiple tool sets simultaneously. Combined with the rotating head, this means you can create parts with varying radii and complex bend sequences without any manual intervention.

Everything works together through synchronized axes that move in perfect harmony. The bending, rotation, and feed axes coordinate their movements with computer precision, optimizing cycle times while ensuring each bend meets exact specifications.

This intelligent coordination is powered by advanced control systems like our BendPro G2 CNC Control. This sophisticated brain manages the complex choreography of dual-direction bending, ensuring smooth transitions and flawless execution every time.

At Hines Bending, we’ve installed more bending systems worldwide than any other manufacturer. This experience has taught us that the technology is only as good as the expertise behind it. That’s why agencies like NASA trust us with their most critical applications – they know our dual-direction bending technology delivers the reliability and precision their missions demand.

Understanding what is CNC tube bending is the first step toward appreciating how dual-direction capability can revolutionize your manufacturing process.

The Strategic Benefits of Right and Left Bending Technology

When you invest in a right and left CNC tube bender, you’re not just buying a machine – you’re making a strategic decision that transforms your entire manufacturing operation. Our customers at Hines Bending Systems consistently tell us about the dramatic improvements they see across their facilities, from faster production times to happier bottom lines.

The most noticeable change is increased productivity. Think about it this way: instead of stopping to flip parts or move them between machines, your tube stays put while the machine does all the work. Complex parts that used to take hours can now be completed in a fraction of the time. One of our automotive clients recently told us they doubled their output on exhaust manifolds just by switching to dual-direction bending.

This productivity boost comes largely from reduced setup time. Traditional bending often feels like a puzzle – you’re constantly reconfiguring tooling and recalibrating for different bend directions. With right and left bending technology, you set up once and let the machine handle the complexity. Some of our machines can even change tooling configurations in under five minutes, which means more time bending and less time adjusting.

Minimized material handling is another game-changer that our customers love. Every time someone picks up a part, moves it, or repositions it, there’s risk involved. Risk of scratches, dents, or simply dropping an expensive piece. With a right and left CNC tube bender, your tube goes in one end and comes out the other as a finished part. No handling errors, no damaged materials, and definitely no frustrated operators.

This seamless process directly leads to improved part quality. When a tube never leaves the machine’s grip, every bend is executed with perfect precision. You get consistent, repeatable results that meet the tightest specifications. For industries like aerospace, where we supply NASA with critical bending solutions, this level of precision isn’t just nice to have – it’s absolutely essential.

Here’s something that really excites engineers: fewer welds in their final assemblies. Traditional manufacturing often requires multiple bent sections to be welded together to achieve complex shapes. But when you can create intricate single-piece components with dual-direction bending, you eliminate many of these weld joints. This means improved structural integrity because every weld is a potential weak point. Fewer welds equal stronger, more reliable parts.

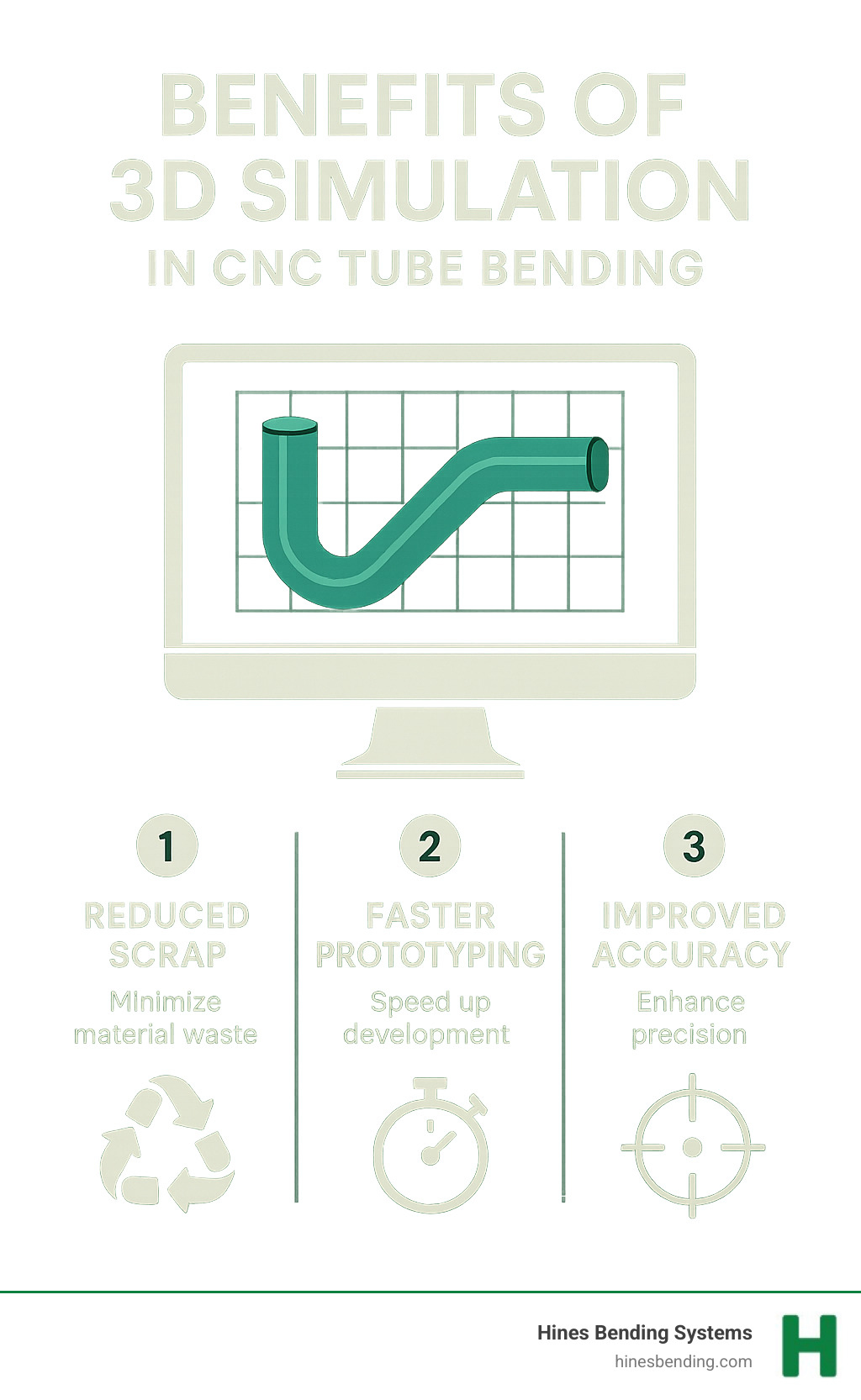

All these benefits add up to serious cost-effectiveness. Lower cycle times, reduced energy consumption, less material waste, and decreased labor costs – it’s like getting a raise for your entire operation. The reduced scrap alone can justify the investment. When parts come out right the first time, every time, you’re not throwing money away on mistakes.

At Hines Bending Systems, we’ve seen manufacturers recoup their investment in our dual-direction bending technology faster than they expected. The operational efficiencies are that significant. You can learn more about these proven advantages on our page about the Advantages of CNC Tube Bending Machine For Sale.

Opening Unprecedented Design Freedom

This is where things get really exciting for designers and engineers. A right and left CNC tube bender doesn’t just make existing designs easier to manufacture – it opens up entirely new possibilities that were previously impossible or too expensive to consider.

Complex part creation becomes your playground instead of your nightmare. Engineers can now design intricate, multi-plane geometries with confidence, knowing that alternating bend directions won’t require multiple setups or compromise quality. We’ve had furniture manufacturers create flowing, artistic pieces that look like they were sculpted rather than bent. Automotive engineers design exhaust systems with optimal flow characteristics that would have been prohibitively complex before.

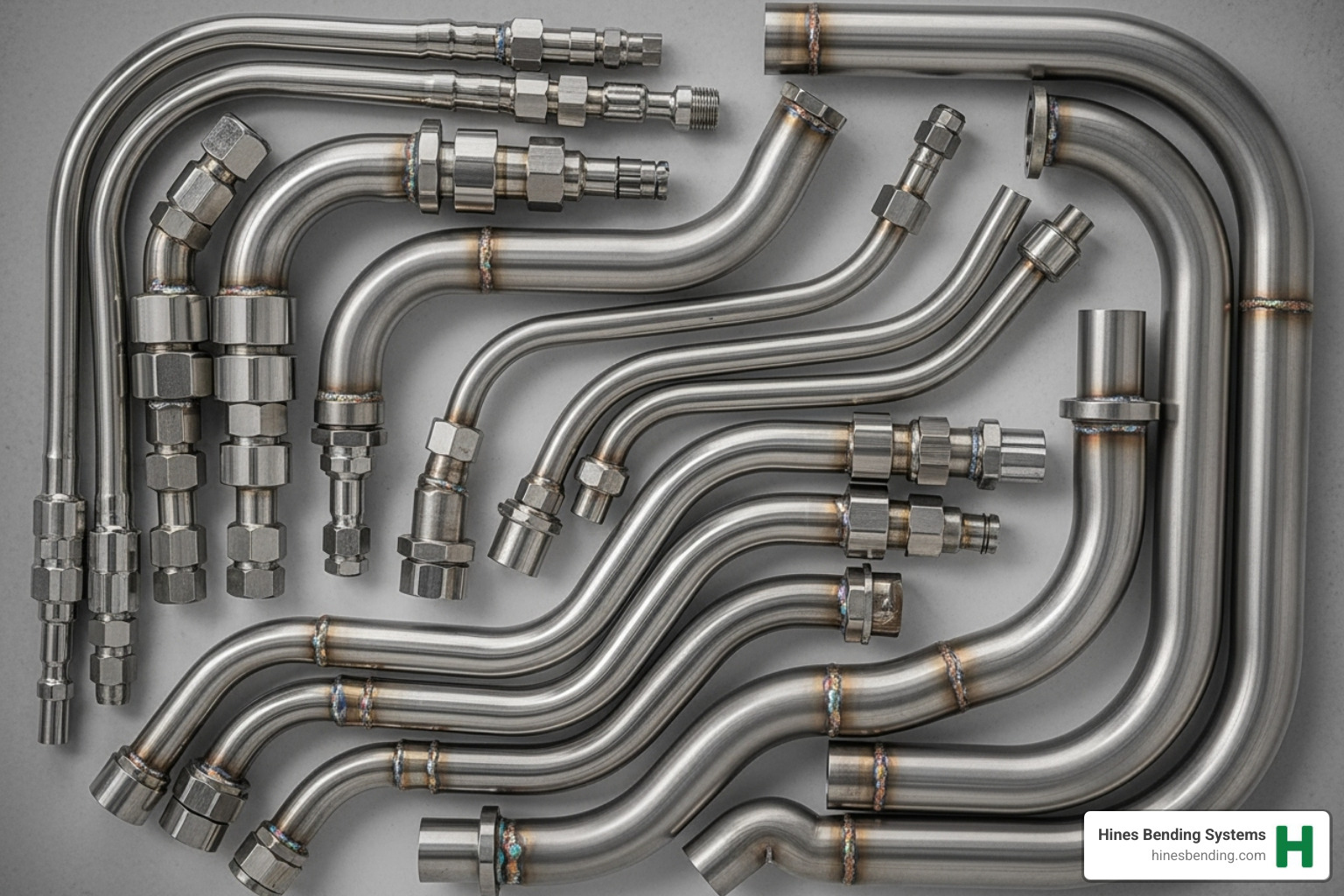

The geometric possibilities are practically limitless. Tight S-curves, serpentine shapes, complex coils – if you can imagine it, the machine can probably bend it. This capability often means eliminating secondary operations entirely. Parts that used to require bending, then welding, then more bending can now be created as single, continuous pieces.

Beyond pure functionality, this technology enables remarkable aesthetic improvements. In architectural applications, seamless tube structures without visible joints create clean, modern looks. Furniture designers can create organic, flowing shapes that feel more like art than industrial products. The visual appeal of seamless, continuously bent structures is simply stunning.

This design freedom drives innovative product design across industries. We’re seeing products that couldn’t exist without dual-direction bending technology. From medical devices with complex internal pathways to aerospace components with optimized fluid dynamics, the possibilities keep expanding.

At Hines Bending Systems, we’re proud to be at the forefront of this innovation. Our continuous improvements to technology, including recent advances in our Dual Stack systems, directly address the growing demand for complex geometries. You can read about how Hines Bending Brings New Innovation to Dual Stack CNC Push Bender and Roll Bender.

As the #1 worldwide manufacturer of tube benders, we understand that great design deserves great manufacturing capability. That’s exactly what our right and left bending technology delivers.

Industries and Applications Demanding Right and Left Bending Precision

When we look at the manufacturing landscape today, certain industries simply can’t afford to compromise on tube bending precision. A right and left CNC tube bender isn’t just a nice-to-have for these sectors – it’s absolutely essential for creating the complex components that keep their operations running safely and efficiently.

Take the aerospace industry, where every component must meet the most rigorous standards imaginable. Aircraft fuel lines snake through tight spaces with multiple direction changes, while hydraulic systems require flawless bends in exotic materials like titanium. There’s no room for “close enough” when lives depend on the integrity of every single bend.

The automotive sector presents its own unique challenges. Modern vehicle exhaust systems must steer around increasingly complex chassis designs, often requiring alternating left and right bends to optimize both performance and fit. Roll cages for racing vehicles and off-road equipment demand structural perfection – a poorly executed bend could mean the difference between protection and catastrophe during a crash.

In HVACR applications, precision takes on a different meaning. Heat exchangers and refrigeration coils require copper and aluminum tubing bent to exact specifications for optimal heat transfer. The complex serpentine patterns needed for maximum efficiency are only possible with dual-direction bending capabilities.

Medical equipment manufacturing brings another layer of complexity. Hospital bed frames, surgical instruments, and mobility aids all require tubes bent to precise angles and radii. Beyond the technical requirements, these applications demand the highest levels of cleanliness and repeatability – qualities that Hines Bending Systems has built into every machine we manufacture.

Even furniture manufacturing has acceptd the possibilities that dual-direction bending offers. Modern chair frames and table bases can now feature flowing, continuous curves that would have been impossible or prohibitively expensive to create just a few years ago.

At Hines Bending Systems, we’ve worked with manufacturers across all these industries, providing custom solutions custom to their specific challenges. Our expertise spans from the smallest medical device components to massive industrial applications, ensuring that every client receives exactly the bending capability they need.

High-Stakes Applications for a right and left cnc tube bender

Some applications go beyond demanding precision – they require absolute perfection. These are the scenarios where failure isn’t just costly; it’s potentially catastrophic. This is where the true value of a right and left CNC tube bender from Hines Bending Systems becomes crystal clear.

Consider aircraft fuel lines operating at 35,000 feet. These components face extreme pressure differentials and temperature swings that would destroy inferior bending work. Every bend must be flawless, with no stress concentrations or weak points that could lead to system failure.

Hydraulic systems in aircraft present similar challenges. The complex routing required in modern aircraft often demands multiple direction changes in a single tube run. Traditional bending methods might require multiple pieces welded together, creating potential failure points. Our dual-direction bending capability allows these critical components to be formed from a single piece of tubing, dramatically improving reliability.

Perhaps our most prestigious validation comes from our partnership with NASA. When the world’s premier space agency needs bending equipment, they turn to Hines Bending Systems. Our machines help create components that must function flawlessly in the harshest environment imaginable – space itself. You can learn more about this incredible partnership at Hines Working Together with NASA.

Back on Earth, vehicle exhaust systems in high-performance applications face their own extreme conditions. Racing exhaust systems must route around complex suspension components while maintaining optimal flow characteristics. The ability to create these intricate paths in a single bending operation ensures both performance and durability.

Roll cages and chassis components represent another category where perfection isn’t optional. In motorsports or off-road applications, these structures are literally life-saving devices. Every bend must meet exact specifications for strength and fit, with no room for the inconsistencies that can occur with multiple setups or manual repositioning.

What sets Hines Bending Systems apart in these high-stakes applications is our unwavering commitment to quality and precision. We understand that when failure isn’t an option, you need equipment that delivers perfect results every single time. Our machines are engineered and built to meet these exacting standards, backed by decades of experience and continuous innovation in bending technology.

Critical Considerations for Optimal Bending with a right and left cnc tube bender

Getting the best results from your right and left CNC tube bender goes far beyond just pressing the start button. Think of it like cooking a perfect meal – you need the right ingredients, the right technique, and a deep understanding of how everything works together. At Hines Bending Systems, we’ve spent decades perfecting this recipe for bending success, and nobody in the bending machine industry has more expertise and experience than us.

The foundation of any successful bend starts with material selection. Each metal has its own personality, if you will. Titanium is like that strong, stubborn friend – incredibly reliable and lightweight, but it has serious springback issues that can drive you crazy if you don’t know how to handle it. Stainless steel offers fantastic corrosion resistance and strength, but it can be finicky about tooling and requires careful attention to prevent galling and achieve those smooth, professional bends you’re after. Aluminum is the agreeable one – lightweight and generally cooperative, but it can wrinkle or become oval if you don’t give it proper support during the bending process.

We work with all these materials and many exotic alloys besides. Understanding their unique properties isn’t just helpful – it’s absolutely critical for predicting springback and setting your machine parameters correctly. This is where our decades of experience really shine through.

The geometry of your bend is equally crucial. Your bend radius – that’s the internal radius of the curve – has a huge impact on whether your bend will be successful or not. Tighter radii put more stress on the material, which increases your risk of wall thinning, wrinkling, or even complete fracture. Our right and left CNC tube bender systems with multi-stack tooling can handle various bend radii, but smart planning is essential.

Tube diameter and wall thickness create their own challenges. Larger diameters with thinner walls are like trying to bend a drinking straw – they want to collapse or wrinkle without proper internal support. On the flip side, very thick walls might need more bending force and specialized machine capabilities. Our machines are engineered to handle everything from tiny aerospace tubes to large industrial pipes, maintaining consistent quality across the entire range.

For the highest quality results, especially with thin-walled or large-diameter tubing, mandrel bending becomes your best friend. We have extensive expertise in this specialized area, which you can explore further on our page about CNC Tube Bending Machines Near Me: Mandrel Bent. We work closely with every client to provide custom bender solutions that account for all these variables, ensuring your specific needs are met and your products exceed quality standards.

The Role of Advanced Software and Expert Tooling

The magic behind every perfect bend from a right and left CNC tube bender happens long before the metal starts moving. It’s the sophisticated software and expertly configured tooling working behind the scenes that make the impossible look effortless.

CAD/CAM programming transforms your design dreams into reality. Your CAD designs can flow directly into our machine’s control system, eliminating the tedious manual data entry that leads to costly human errors. It’s like having a direct conversation between your imagination and the machine.

But here’s where things get really exciting – 3D simulation lets you bend tubes virtually before touching a single piece of material. Our software creates a complete virtual bending sequence, identifying potential collision detection issues between the tube, machine, and tooling. This feasibility testing ensures that your proposed bends are actually achievable with your specific material and machine setup. Think of it as a crystal ball for bending – you can see problems before they happen and fix them without wasting expensive materials.

The right tooling makes all the difference between a good bend and a perfect one. Mandrel tooling provides crucial internal support to prevent tube collapse or wrinkling during bending – especially vital for thin-walled applications. Wiper dies eliminate those unsightly wrinkles on the inside radius of your bends. The complete tooling system – including bend dies, clamp dies, and pressure dies – works together like a well-orchestrated team to form precise bends while holding your tube securely throughout the process.

Expert configuration of these tools separates the professionals from the amateurs. Even the most advanced machine won’t deliver optimal results with incorrect or poorly maintained tooling. Our expertise at Hines Bending Systems extends far beyond just selling machines – we provide comprehensive guidance on tooling selection and setup. We offer an extensive range of Tube and Pipe Bender Accessories specifically designed to complement our machines perfectly.

We also emphasize the importance of training and continuing education, which we provide to dramatically improve the efficiency of engineering and production for our clients. This holistic approach ensures you don’t just get the best machines – you get the knowledge and ongoing support to maximize their potential for years to come.

Conclusion: Partnering with an Expert for Superior Bending Solutions

When you step back and look at the complete picture, it becomes clear that a right and left CNC tube bender isn’t just another piece of equipment – it’s a gateway to manufacturing excellence. This technology summary reveals machines that deliver dual-direction bending, energy-efficient all-electric systems, and the ability to create complex geometries that push the boundaries of what’s possible in tube fabrication.

The manufacturing advantage is undeniable. You get faster production cycles, better part quality, reduced waste, and the flexibility to tackle designs that once seemed impossible. But here’s the thing – having advanced technology is only half the battle. The real magic happens when that technology is backed by genuine expertise and unwavering support.

This is where the importance of expertise becomes crystal clear. Anyone can sell you a machine, but not everyone can ensure you get the most out of it. The difference between struggling with a bending challenge and conquering it often comes down to having the right partner by your side.

At Hines Bending Systems, we’ve built our reputation on being that partner. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we bring something to the table that’s hard to find elsewhere – genuine, deep-rooted experience. Nobody in the bending machine industry has more expertise and experience than us, and that’s not just a claim – it’s a promise backed by decades of innovation and thousands of successful installations worldwide.

Our approach to custom solutions sets us apart from the crowd. We don’t believe in cookie-cutter answers because every manufacturing challenge is unique. When you work with us, we take the time to understand your specific needs, your production goals, and your quality requirements. Whether you’re a small specialty shop or a massive organization like NASA – yes, we supply The National Aeronautics and Space Administration with our bending machines – we tailor our solutions to fit your exact requirements.

Quality assurance isn’t just a department here; it’s woven into everything we do. Our machines are engineered to meet the most stringent industry standards because we understand that your reputation depends on the quality of your products. When you choose Hines, you’re choosing machines designed for reliability, precision, and longevity.

The beauty of partnering with true experts is that your relationship doesn’t end when the machine arrives. We provide comprehensive training, ongoing support, and continue to innovate to meet the evolving needs of modern manufacturing. Our worldwide leadership position means we’re constantly pushing the envelope, developing new technologies and refining existing ones to help our customers stay ahead of the curve.

Ready to lift your production? Explore our advanced CNC Bending Machines and find how the right partner can transform your manufacturing capabilities.