[vc_row][vc_column][vc_column_text]Owning a mandrel exhaust pipe bender presents various advantages for shop owners. The cost of outsourcing your exhaust pipe bending duties to off-site facilities adds up quickly while leaving you dependent on sources out of your control.

Why continue to leave your production levels in someone else’s hands? Why pay for services when a simple solution could not only save you money but soon enable you to turn a profit yourself?

If you’re a savvy auto facility owner or operator who knows the value of every dollar, considering your investments should always be a priority. Fortunately, investing in the right mandrel exhaust pipe bender offers you an efficient and fortuitous solution.

Owning A Mandrel Exhaust Pipe Bender

Like most manufacturing jobs, running a truck or auto parts facility is a demanding position with ongoing challenges. One of the primary problems you’ll face is finding sources you can trust to supply the materials you’ll need when you need them.

The decision to outsource your exhaust pipe bending duties only adds to an already complex system of moving parts. Worse still, it adds further stress on both your finances and production concerns in the event of a shortage.

As the demand for exhaust bends continues to increase, so do the prices you will be paying for aftermarket exhaust bends. The chances of this improving also seem highly unlikely unless you give up your dependence on the entire volatile system.

Owning the right mandrel exhaust pipe bender gives you exactly that opportunity. Rather than sitting by and paying others, you gave the advantage of having fully independent production capabilities.

What this translates to is obvious – control and customization. You are able to control the overall production timeline and meet the demands you aspire to without falling victim to outside fluctuations.

Buying The Right Exhaust Bending Machine

If the idea of gaining control over your production and improving your timeline seems expensive or too good to be true, you’re in luck. Hines Bending Systems is the worldwide leading manufacturer of bending machines with a variety of new and used exhaust pipe benders for sale.

Our diverse collection of different CNC pipe benders gives you the opportunity to find the perfect solution for your production needs. We have a long history of reliability and share a passion for presenting facilities with the bending solution they need to further their own growth.

We also carefully maintain our demo bending machines and ensure they are in top working condition for quality assurance before ever listing used pipe benders for sale. As a result, you are able to buy used exhaust pipe benders with low hours at affordable rates directly from the manufacturer.

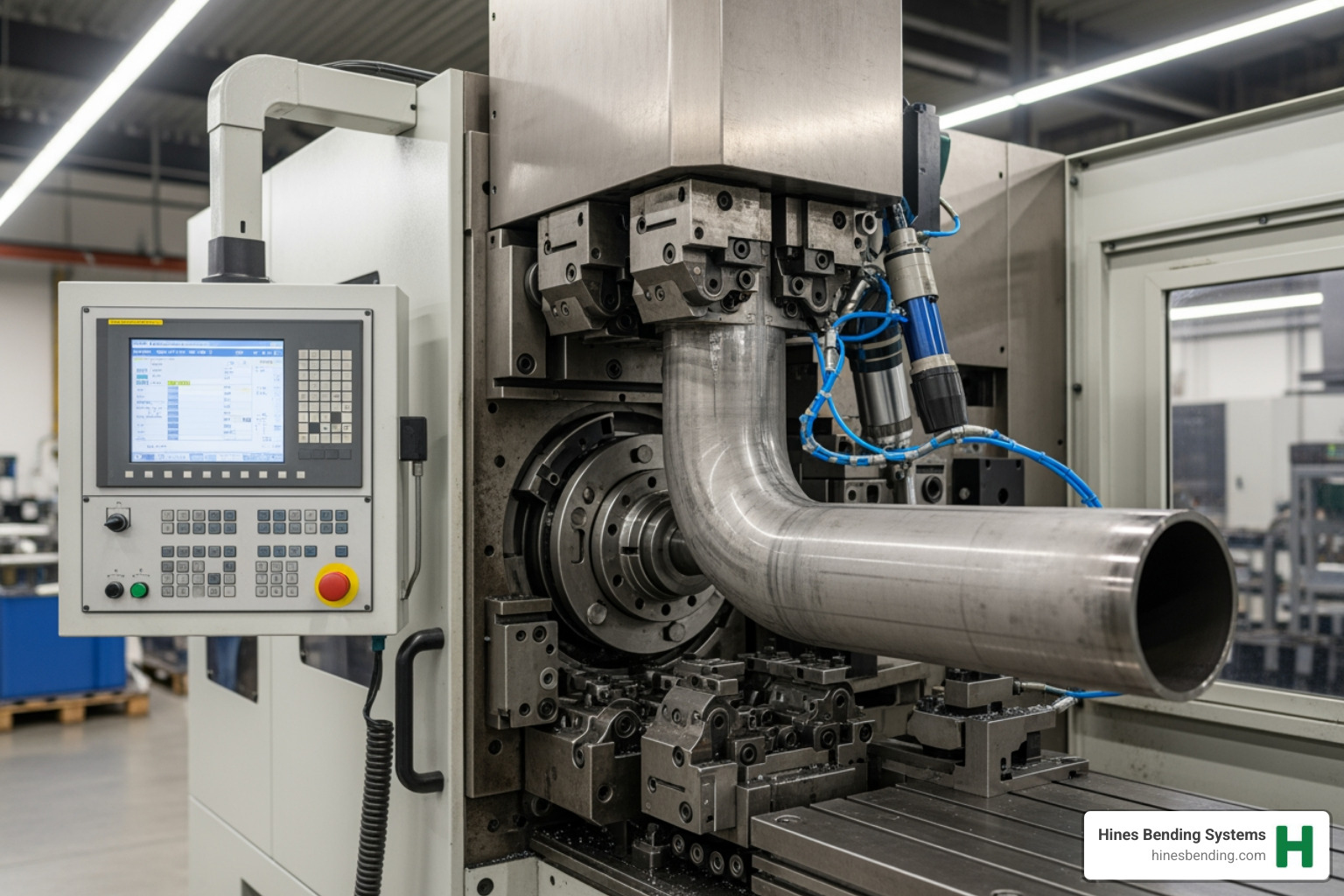

300 CNC Tube Bender

The 300 CNC Tube Bender is an ideal mandrel exhaust pipe bender for bending mid-large exhausts in the automotive industry.

Specifications of the 300 CNC Tube Bender:

- Capacity: 4.25″ OD x .200 Wall

- Maximum Feeding: 33ft/min

- Maximum POB: 20 r/min

- Standard Maximum Radius: 14 inch

- Maximum Bend Angle: 190 degrees

- Operating Pressure: 2000 psi

- Reservoir Capacity: 175 US gallons

- Approximate Weight: 14500 lbs

- Approximate Dimensions: 20′ L x 5′ W x 6′ H

- Voltage: 220 volt/440/3 Phase 60 Hz, 50 Hz optional

- Bend angle accuracy +/-: 0.1 degree

- Bend arm speed: 2rpm

- Maximum tube length over mandrel: 9 1/2 ft

- Motor: 30HP

Please contact Hines Bending Systems to speak with a friendly member of our staff if you’d like to learn more. To speak to a bending specialist directly, call (800) 949-8344 for assistance.[/vc_column_text][/vc_column][/vc_row]