Why CNC Tube Bending Revolutionizes Manufacturing

What is CNC tube bending is a computer-controlled manufacturing process that uses automated machinery to bend tubes and pipes with extreme precision and consistency. Unlike manual bending methods that rely on operator skill and often produce inconsistent results, CNC (Computer Numerical Control) tube bending delivers repeatable accuracy within ±0.05 degrees.

Quick Answer:

– Definition: Automated tube bending using computer-controlled machines

– Key Benefits: Superior precision, repeatability, and efficiency

– Tolerance: As tight as ±0.05 degrees for high-volume production

– Speed: Cycle times as fast as 2 seconds per bend

– Materials: Works with aluminum, stainless steel, titanium, copper, and more

– Applications: Automotive, aerospace, HVAC, furniture, and medical equipment

CNC tube bending machines can process tubes from 6.35mm to 150mm in diameter and achieve bend angles up to 180 degrees without affecting accuracy. The technology uses servo-electric or hydraulic systems to control multiple axes simultaneously, creating complex geometries that would be impossible with manual methods.

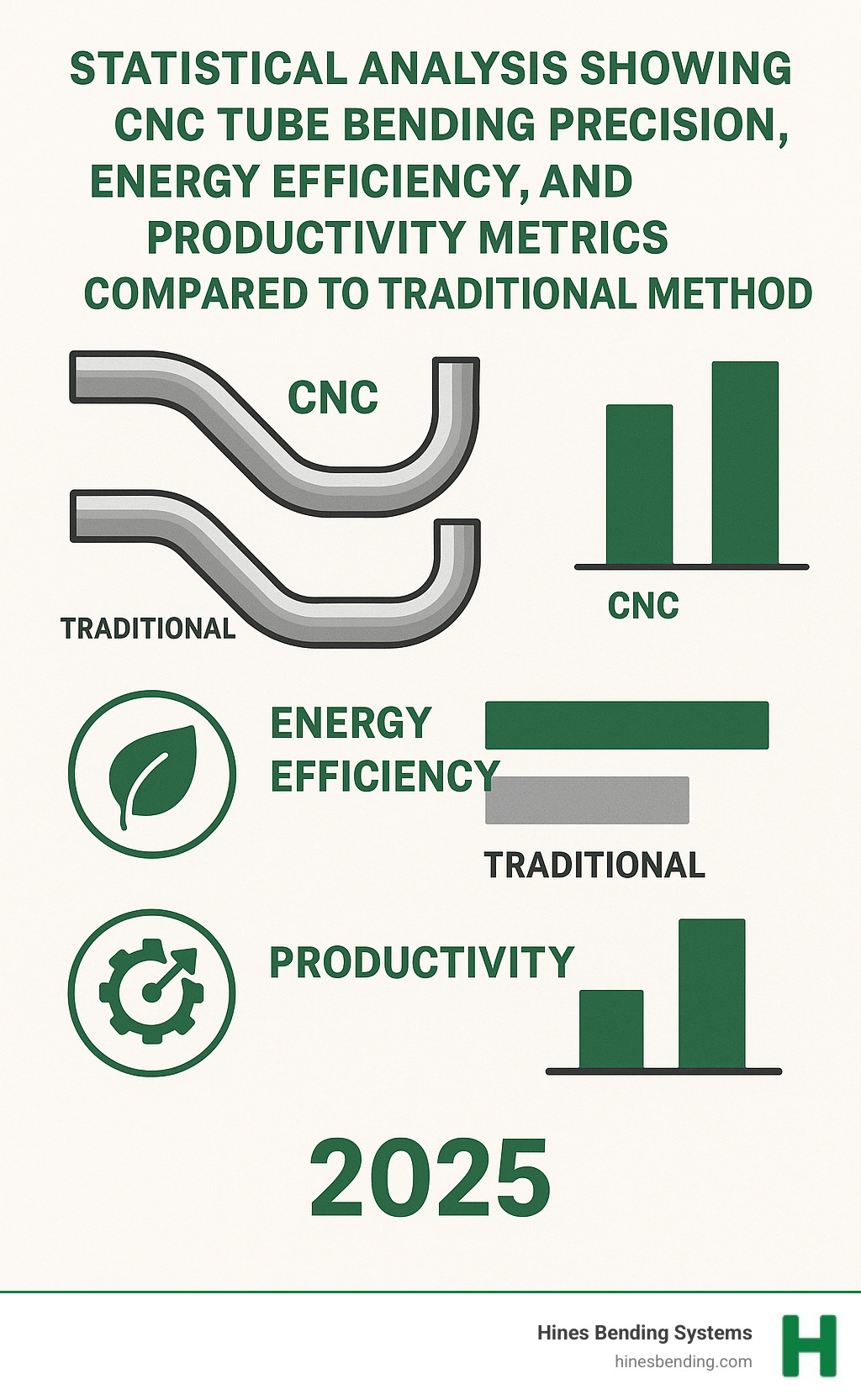

For manufacturing operations managers dealing with complex bending requirements and high production costs, CNC tube bending offers a game-changing solution. The technology reduces energy consumption by up to 70% compared to traditional methods while delivering the precision and consistency needed for today’s demanding applications.

As the #1 worldwide manufacturer of tube benders, Hines Bending Systems has supplied advanced CNC bending solutions to major organizations including NASA, proving that when precision and reliability matter most, industry leaders trust Hines for their critical applications.

Key terms for what is cnc tube bending:

– precision tube bender

– bending machine suppliers

– electric pipe bending machine

What Is CNC Tube Bending?

When you’re trying to understand what is CNC tube bending, think of it as the difference between a master craftsman and a robot working together. CNC stands for Computer Numerical Control, which means sophisticated computer programs control every movement of the bending machine with mathematical precision.

The key distinction between tube and pipe bending often confuses people, but it’s actually straightforward. Tubes are measured by their actual outside diameter and wall thickness, while pipes use nominal sizing that doesn’t match their real dimensions. Tubes come in various shapes – round, square, or oval – while pipes are always round with thicker walls designed to handle pressure.

At Hines Bending Systems, we’ve mastered both servo-electric and hydraulic drive systems for our CNC machines. Servo-electric systems deliver incredible energy efficiency and pinpoint accuracy, while hydraulic systems provide the raw muscle needed for larger diameter tubes and thick-wall materials.

The computer control eliminates the guesswork that plagues manual bending operations. Instead of crossing your fingers and hoping the operator gets it right, the CNC system coordinates multiple axes simultaneously with mechanical precision.

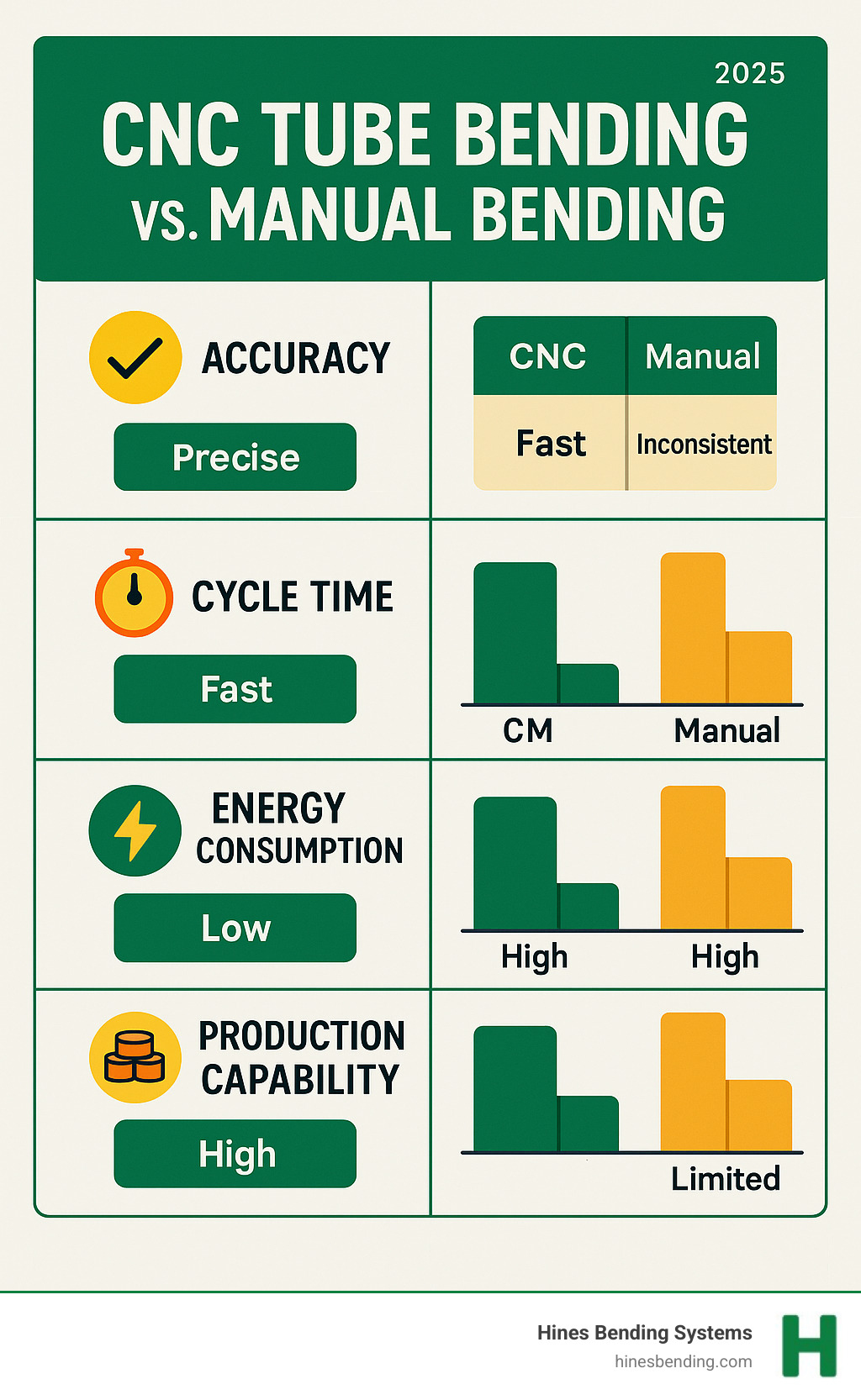

| Aspect | Manual Bending | CNC Bending |

|---|---|---|

| Accuracy | ±2-5 degrees | ±0.05 degrees |

| Repeatability | Variable | Exact |

| Setup Time | 30-60 minutes | 5-15 minutes |

| Operator Skill | High | Minimal |

| Complex Shapes | Limited | Unlimited |

| Production Speed | Slow | Fast |

As the #1 worldwide manufacturer of tube benders, Hines has supplied advanced CNC solutions to organizations like NASA, where precision isn’t just important – it’s mission-critical.

For comprehensive technical terminology, explore our detailed guide on CNC Bending Machine Terms.

Understanding what is cnc tube bending at a glance

The precision achieved by modern CNC tube bending is genuinely impressive. Hines machines deliver bend angle repeatability within ±0.05 degrees, which is essential when you’re producing thousands of identical components.

Multi-axis capability means our machines create complex three-dimensional bends during a single setup cycle. Instead of requiring multiple operations and fixtures, the CNC system produces spiral shapes, compound bends, and intricate geometries that would challenge even the most skilled manual operator.

Closed-loop feedback systems continuously monitor the entire bending process using precision sensors and encoders. When the system detects any deviation from programmed parameters, it automatically makes micro-adjustments to maintain accuracy.

Common myths about what is cnc tube bending

One stubborn myth claims that springback makes CNC bending unreliable. This couldn’t be further from the truth. Hines CNC systems actually compensate for material springback by calculating the exact overbend required for each specific material and wall thickness combination.

Another misconception suggests that thin-wall tubes will collapse during CNC bending. While thin-wall materials do present unique challenges, proper tooling selection and optimized process parameters prevent collapse entirely.

The third major myth involves cost barriers that supposedly make CNC bending unaffordable. While CNC machines require higher initial investment, the total cost of ownership typically proves lower due to reduced labor costs, minimal material waste, and faster cycle times.

With over four decades of experience and more bender installations worldwide than any other manufacturer, Hines Bending Systems has the expertise to separate fact from fiction in CNC tube bending technology.

Core Components & Processes

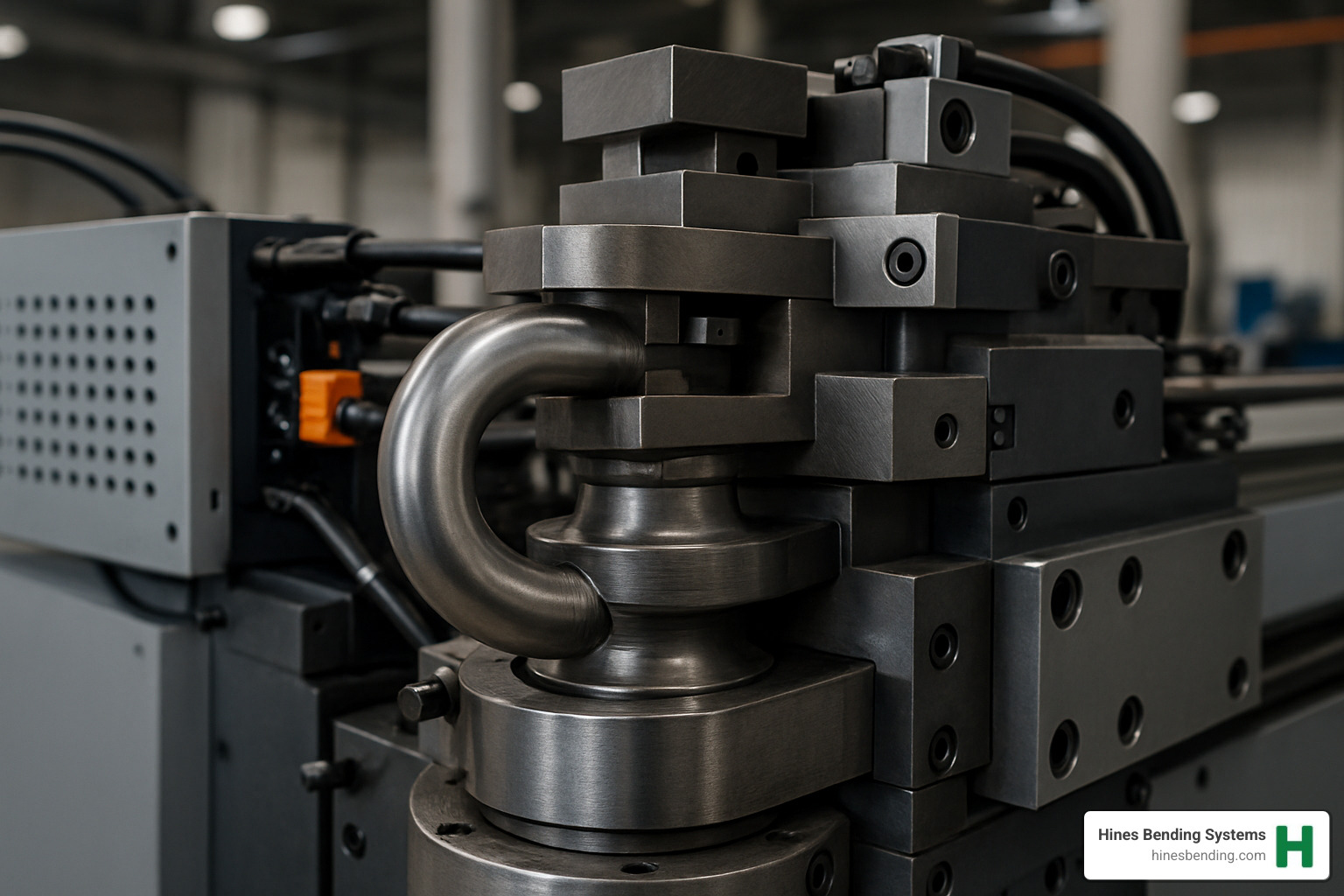

When you understand how CNC tube bending works at the component level, the precision becomes much clearer. Think of it like a perfectly choreographed dance where five key players work together to create flawless bends every single time.

At the heart of every quality tube bender sits the bend die – this hardened steel component determines your centerline radius and literally draws the tube around its contour as it rotates. Working hand-in-hand with the bend die, the clamp die locks the tube securely in place, preventing any slippage that could ruin your bend.

The mandrel slides inside your tube to provide internal support, preventing collapse or ugly wrinkles during tight-radius bends. Modern CNC systems from Hines Bending can time mandrel insertion and withdrawal with surgical precision, giving you results that manual methods simply cannot match.

The wiper die plays a crucial role in maintaining smooth material flow and preventing wrinkles on the inside radius. Meanwhile, the pressure die applies controlled force as the tube feeds into the bend zone, minimizing wall thinning while supporting the material throughout the entire process.

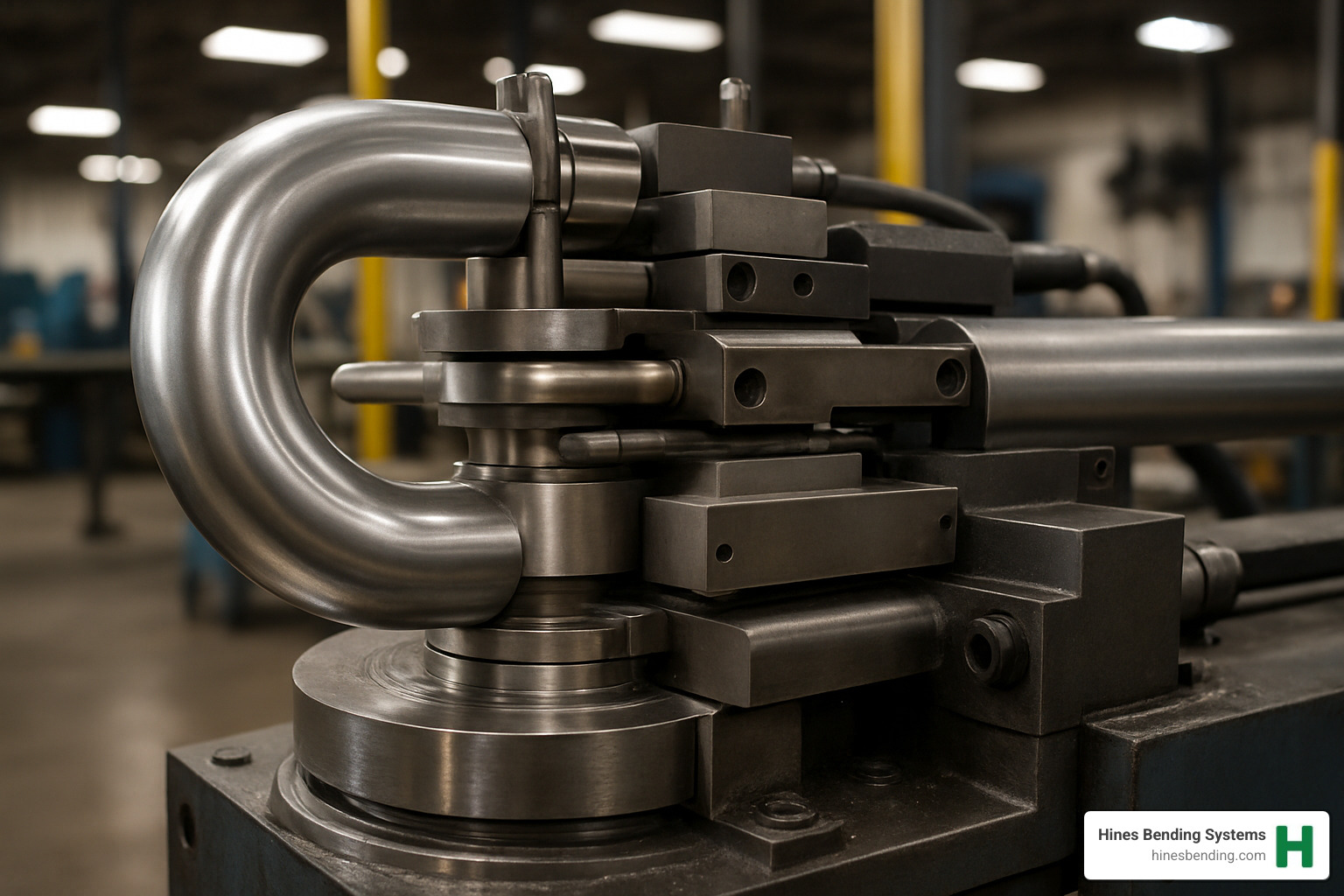

Now, let’s talk about the three main bending processes. Rotary draw bending is the workhorse of the industry – it uses that rotating bend die to pull your tube around the desired radius with incredible accuracy and surface finish quality. This is what Hines Bending Systems has perfected over decades of innovation.

Roll bending takes a different approach, using three rollers to create those beautiful large-radius curves you see in architectural applications. The adjustable center roll gives you amazing flexibility for varying requirements.

Compression bending applies direct force to push the tube against a stationary die. While it’s faster for simple bends, it’s limited to angles of 120 degrees or less and may create oval cross-sections.

Boosting technology available in advanced CNC systems applies additional force through the pressure die. This breakthrough minimizes wall thinning and enables tighter bend radii than traditional methods ever could achieve.

As the #1 worldwide manufacturer of tube benders, Hines Bending Systems has supplied these advanced technologies to organizations like NASA, proving that when precision matters most, industry leaders trust Hines for their critical applications.

For a complete overview of different bending machine types and how Hines can customize solutions for your needs, explore our detailed guide on CNC Bending Machine Types.

Key Technical Parameters

The capabilities of modern CNC tube bending are truly impressive. Hines Bending Systems machines handle everything from tiny 6mm diameter tubes for precision instruments all the way up to massive 150mm diameter tubes for structural applications.

Understanding centerline radius (CLR) is crucial – this represents the distance from the center of your bend to the centerline of the tube. Most quality CNC benders can achieve radii from 1.5 times the tube diameter up to 8 times the diameter.

When it comes to maximum bend angles, you can reach 180 degrees on most machines, though some specialized Hines systems can achieve even greater angles.

What sets Hines apart is our deep understanding of how these parameters interact with real-world materials and applications. Nobody in the bending machine industry has more expertise applying these technical parameters to solve actual manufacturing challenges.

Benefits & Limitations

When manufacturers find what is CNC tube bending can do for their operations, the benefits often exceed their expectations. The precision alone transforms how companies approach complex bending projects – we’re talking about accuracy within ±0.05 degrees, which makes manual methods look like guesswork by comparison.

Energy efficiency represents a game-changer for cost-conscious operations. Modern CNC systems slash energy consumption by up to 70% compared to traditional hydraulic systems. All-electric servo systems only consume power during actual movement, unlike older hydraulic systems that run continuously.

The speed improvements are remarkable. With cycle times as fast as 2 seconds per bend, manufacturers can achieve production volumes that seemed impossible just a few years ago. When Hines Bending Systems designs a custom solution, we often integrate automated loading and unloading systems that create seamless manufacturing cells.

Complex geometries become routine rather than challenging. Those spiral shapes, compound bends, and three-dimensional forms that used to require multiple setups and skilled operators? A properly programmed CNC system handles them in a single cycle.

For thin-wall applications, CNC bending provides the precise control needed to prevent collapse. Through careful mandrel selection and process optimization, materials that would crumple with manual methods bend perfectly.

However, let’s be honest about the limitations. Large radius bends may require specialized roll bending equipment rather than standard rotary draw systems. Material springback varies significantly between alloys and heat treatments, requiring careful process development.

The initial investment is higher than manual tooling, though experienced manufacturers understand that total cost of ownership tells the real story. When you factor in labor savings, waste reduction, and quality improvements, CNC systems typically pay for themselves within 12-18 months.

For detailed insights into how these advantages translate to real-world applications, explore our comprehensive analysis of Advantages of CNC Tube Bending Machine for Sale.

CNC Tube Bending vs Manual Methods

The change from manual to CNC bending resembles the difference between handwriting and printing – both accomplish the task, but one delivers consistent, professional results every time.

Waste reduction occurs naturally when every part comes out right the first time. Manual bending often involves trial-and-error adjustments, creating scrap material and frustration. CNC systems eliminate this waste by calculating exact parameters before the first bend begins.

Consistency ensures that part number one and part number ten thousand are identical. This repeatability is essential for assembly operations where components must fit together perfectly. When NASA chooses Hines Bending Systems for critical applications, they’re counting on this level of precision.

Scalability allows production volumes to increase without proportional increases in labor costs or setup time. A single CNC system often replaces multiple manual bending stations while improving quality and reducing floor space requirements.

The productivity gains extend far beyond simple speed improvements. CNC systems operate with minimal supervision, allowing skilled operators to focus on value-added activities like quality control and process optimization.

At Hines Bending Systems, we’ve seen manufacturers transform their operations by making this transition. Our expertise in custom solutions ensures that each system is optimized for specific applications, maximizing the benefits while minimizing the learning curve.

Choosing the Right CNC Tube Bender

Selecting the perfect CNC tube bender isn’t just about finding the biggest or fastest machine – it’s about finding the right partner who understands your unique requirements. Capacity forms the foundation of your decision, but smart buyers look beyond just diameter and wall thickness capabilities.

At Hines Bending Systems, we’ve learned that the best machine selection starts with understanding not just what you’re bending today, but where your business is heading tomorrow. Our team works directly with customers to analyze their current needs while building in room for growth and new applications.

Material compatibility goes deeper than most people realize. Aluminum bends differently than stainless steel, but heat treatment, grain structure, and even supplier variations can affect your results. That’s where Hines’ decades of experience become invaluable – we’ve seen it all and can guide you toward the optimal machine configuration.

The software capabilities of modern CNC systems can make or break your productivity gains. Offline programming means your operators can create and test new programs while the machine keeps running production parts. 3D simulation catches problems before they become expensive mistakes.

Tooling flexibility might seem like a nice-to-have feature, but it often determines whether your investment pays off quickly or slowly. Quick-change systems and multi-stack configurations can transform setup times from hours to minutes.

Training requirements vary dramatically between different systems. Hines provides comprehensive training programs that get your team productive fast, but starting with user-friendly systems makes the transition smoother.

ROI calculations should look beyond the purchase price. Labor savings, waste reduction, energy efficiency, and quality improvements often deliver payback within 12-24 months. More importantly, the competitive advantage of consistent, high-quality parts can be worth far more than the direct cost savings.

The reality is that choosing the right CNC tube bender is as much about choosing the right manufacturer as it is about specifications. When NASA needs precision bending equipment, they turn to Hines because they know our expertise and experience are best in the industry.

For comprehensive guidance on making the best machine selection decision, review our detailed article What to Know About Buying a Metal Tube Bender for Sale.

Role of Software & Automation

The software running your CNC tube bender can be just as important as the mechanical components. Offline programming transforms productivity by allowing operators to create and test new programs without stopping production.

Simulation capabilities have become incredibly sophisticated, letting you visualize the complete bending sequence in 3D before cutting any material. You can spot potential collisions, optimize tooling arrangements, and perfect your process parameters in the virtual world.

Real-time monitoring gives you unprecedented visibility into your bending processes. Track machine performance, monitor tooling wear patterns, and receive alerts before small issues become big problems.

Advanced software features like automatic spring-back compensation and tooling optimization algorithms reduce the skill requirements for operators while improving overall system performance.

Hines Bending Systems has always been at the forefront of control system innovation. Our machines integrate seamlessly with modern manufacturing environments while remaining intuitive enough for operators to master quickly.

For more information about software integration in tube processing, explore Manufacturing Execution Systems and learn about specialized applications in Tube processing machines for HVACR systems.

Frequently Asked Questions about CNC Tube Bending

What materials can be bent?

When customers ask us what is cnc tube bending capable of handling, the answer often surprises them with its versatility. At Hines Bending Systems, our CNC machines work with virtually every material you can imagine, and our decades of experience mean we know exactly how to handle each one.

Aluminum tops the list as our most popular material. It bends beautifully with minimal spring-back, making it perfect for everything from aircraft components to architectural features. We’ve helped countless aerospace companies achieve the precise tolerances they need, including our work with NASA on critical space program components.

Stainless steel requires more muscle from the machine, but that’s exactly what our CNC systems deliver. Whether you’re working with 304 for food processing equipment or 316 for marine applications, we’ll configure your machine with the right force and tooling.

Titanium represents the ultimate challenge in tube bending, but it’s also where Hines Bending Systems truly shines. Our engineering team has developed specialized processes that tame this notoriously difficult material. When aerospace manufacturers need titanium components bent to impossible tolerances, they come to us because nobody else has our level of expertise.

Copper and brass might seem easy to bend, but they can fool you with rapid work-hardening if the process isn’t perfect. Our CNC systems handle these materials with the gentle precision they require.

Beyond these common materials, we regularly bend carbon steel, Inconel, Hastelloy, and exotic alloys that other manufacturers won’t even attempt. That’s the advantage of working with the #1 worldwide manufacturer of tube benders.

How is precision ensured?

The precision question gets to the heart of why what is cnc tube bending represents such an advancement over manual methods. At Hines Bending Systems, precision isn’t just a specification – it’s our obsession.

Servo motors form the foundation of our precision systems. These aren’t ordinary motors; they’re high-resolution positioning systems that can move and hold position within thousandths of an inch. When NASA trusts us with their critical components, this level of precision is exactly what they’re counting on.

Sensors throughout our machines act like a nervous system, constantly monitoring every aspect of the bending process. Laser measurement systems verify bend angles in real-time, while linear encoders track each axis position with microscopic accuracy.

Calibration procedures keep everything running perfectly over years of operation. We don’t just build precise machines; we show you how to maintain that precision through regular calibration checks and tooling inspections.

The closed-loop feedback systems continuously compare what’s happening to what should be happening, making automatic micro-adjustments throughout each bend cycle.

What is the difference between tube and pipe bending?

This question comes up constantly, and the confusion is understandable since people often use the terms interchangeably. Understanding the difference helps explain why what is cnc tube bending requires such specialized expertise.

Nominal versus actual sizing creates the biggest confusion. When someone orders a 2-inch pipe, they actually get something with a 2.375-inch outside diameter. Tubes, on the other hand, are specified by their actual dimensions – a 2-inch tube actually measures 2 inches across.

Shape variety represents another key difference. Tubes can be round, square, rectangular, or oval, while pipes are always round. This variety is why our CNC systems need such flexible tooling capabilities.

From a bending perspective, pipes usually need higher forces due to their thicker walls, while tube bending often focuses more on surface finish and dimensional accuracy. Our engineering team understands these nuances completely, which is why major companies trust us to recommend the perfect solution for their specific requirements.

Whether you’re bending tubes or pipes, the key is working with a manufacturer who understands the differences and has the experience to handle both perfectly. That’s exactly what you get with Hines Bending Systems.

Conclusion

What is CNC tube bending represents far more than just automated machinery – it’s a complete manufacturing revolution that transforms how we approach precision tube forming. The technology delivers accuracy, efficiency, and consistency that simply wasn’t possible with traditional manual methods, opening doors to complex geometries and tight tolerances that meet today’s most demanding applications.

The change extends throughout your entire manufacturing process. Energy savings of up to 70% support your sustainability goals while cycle times as fast as 2 seconds per bend keep you competitive in high-volume markets. Reduced labor costs, minimal material waste, and improved quality create a compelling business case that most manufacturers find pays for itself within 12-24 months.

But here’s the thing – not all CNC bending systems are created equal. Quality matters tremendously when your reputation depends on consistent, precise results. Cheaper alternatives might seem attractive initially, but they often compromise the accuracy, reliability, and long-term performance that your customers expect.

Custom solutions make all the difference in CNC bending success. Every application brings unique challenges – different tube sizes, materials, bend geometries, and production volumes. The ability to configure machines specifically for your needs, rather than accepting a one-size-fits-all approach, can determine whether your investment becomes a competitive advantage.

At Hines Bending Systems, we’ve earned our position as the #1 worldwide manufacturer of tube benders by focusing relentlessly on quality and customer success. Our track record speaks for itself – when organizations like NASA need precision bending solutions for critical applications, they trust Hines to deliver.

Nobody in the bending machine industry has more expertise and experience than Hines. This knowledge translates directly into better solutions for our customers, whether they need a single machine or a complete automated production system. We work closely with every customer to understand their specific requirements and provide custom bender solutions that optimize their production process.

Our commitment extends beyond just selling equipment. Training and continuing education ensure that your team can maximize the efficiency and capability of their Hines bending system. Our continuous innovation, including advanced Dual Stack CNC Push Bender and Roll Bender technologies, addresses the growing demands of various industries while maintaining the reliability and precision that our customers depend on.

For manufacturers considering their bending equipment options, we encourage you to explore our comprehensive guide on Reasons to Invest in Pipe Bending Equipment to understand the full value proposition of quality CNC bending systems.

When you’re ready to discuss your specific requirements and learn how Hines Bending Systems can provide the optimal solution for your application, our team of experts is ready to help. Contact us to find why more manufacturers worldwide choose Hines for their critical bending applications.