Why Second-Hand Bending Machines Are Smart Business Investments

Bending machines for sale second hand offer manufacturing operations managers a path to expand capabilities with reduced upfront costs compared to new equipment. Based on current market data, used bending machines can save you 40-70% compared to new models, though buyers must carefully evaluate quality and long-term reliability.

Quick Answer for Buyers:

- Price Range: €1,550 – €36,000 for quality used machines

- Best Sources: Used-Machines.com (200+ listings), Machineryline.ca (201 ads), specialized dealers

- Key Types: Mandrel tube benders, CNC hydraulic units, manual pipe benders

- Typical Savings: 50-65% off new machine prices

- Important Consideration: While used machines offer lower initial costs, custom solutions from industry leaders often provide superior long-term value

The second-hand bending machine market is active, with over 200 used mandrel tube bending machines currently available across major European marketplaces alone. Germany leads the market with the highest concentration of quality used equipment, followed by other European manufacturing hubs.

While the used market offers compelling savings, smart buyers understand that quality and long-term support matter more than initial purchase price. This is where Hines Bending Systems – the world’s #1 manufacturer of tube benders, pipe benders, and induction benders – provides custom solutions that deliver superior long-term value compared to any used alternative. Their machines serve industry leaders like NASA and come with best expertise and support that no used equipment purchase can match.

When evaluating used equipment, consider that a custom solution from Hines Bending Systems often delivers better productivity, reliability, and total cost of ownership than even the best-maintained used machines.

Best Bending Machines for Sale Second Hand: 2024 Picks

The used bending machine market offers variety for buyers willing to do extensive research and accept the risks associated with older equipment. However, before exploring used options, consider that Hines Bending Systems’ custom solutions often provide better value through superior reliability, precision, and long-term support.

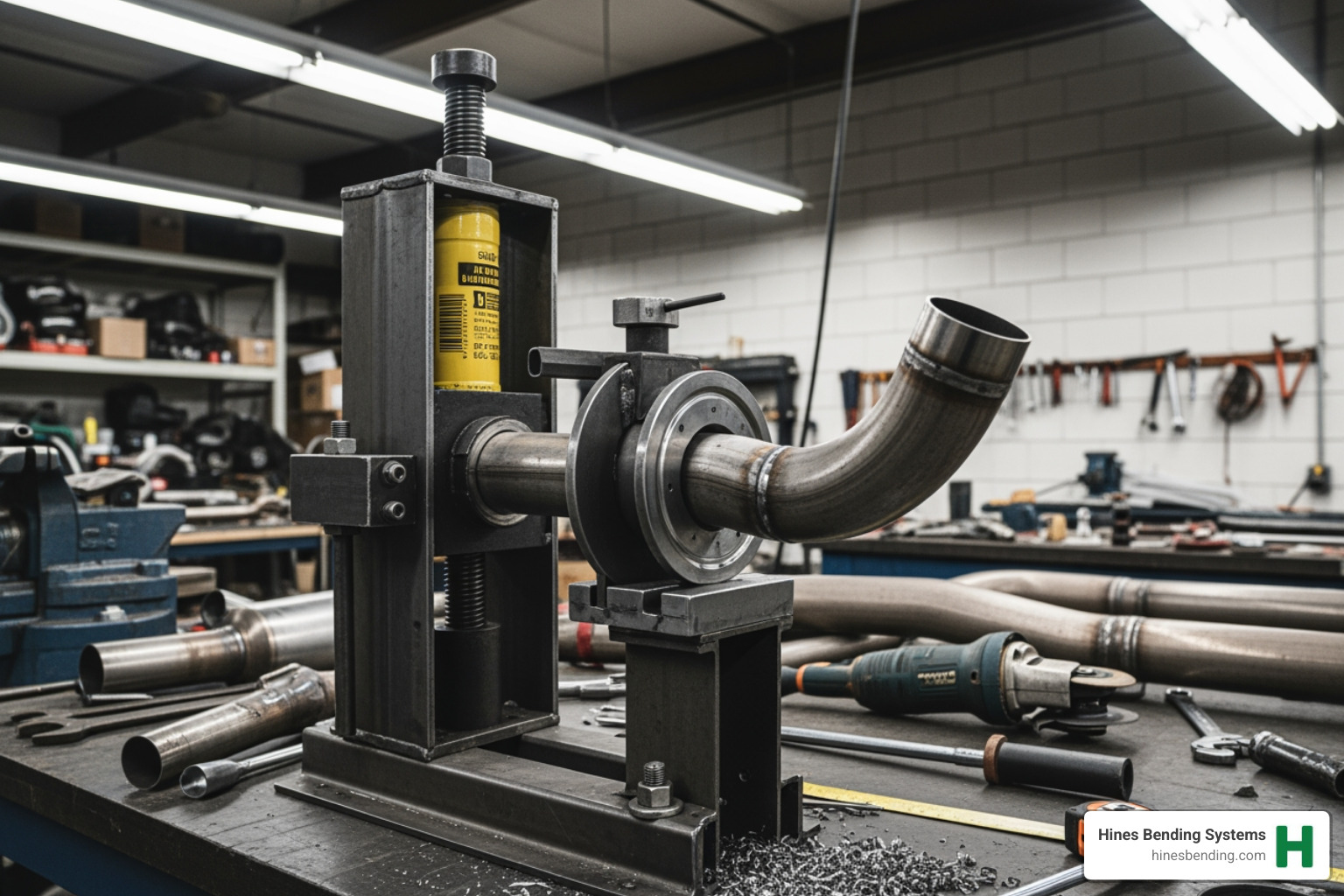

Pipe & Tube Benders – bending machines for sale second hand

Pipe and tube benders dominate the used market, with 201 active listings currently available on major platforms. These machines handle various materials including aluminum, stainless steel, mild steel, brass, and copper – making them versatile for heating construction, automotive, and offshore applications.

Used Market Characteristics:

- Price Range: Starting at €7,999 for basic models

- Auction Finds: Some units found for as low as $590 (approximately €550)

- Power Ratings: Typically range from 0.75 kW to 40 kW

- Age Considerations: Many units from the 1970s and 1980s still operate, though with limited precision and support

While older pipe benders were built to last, they lack the precision, efficiency, and advanced features of modern equipment. For critical applications requiring consistent quality and reliable support, Hines Bending Systems provides custom pipe bending solutions that far exceed what any used machine can deliver.

More info about Used Pipe Bending Machines in Florida

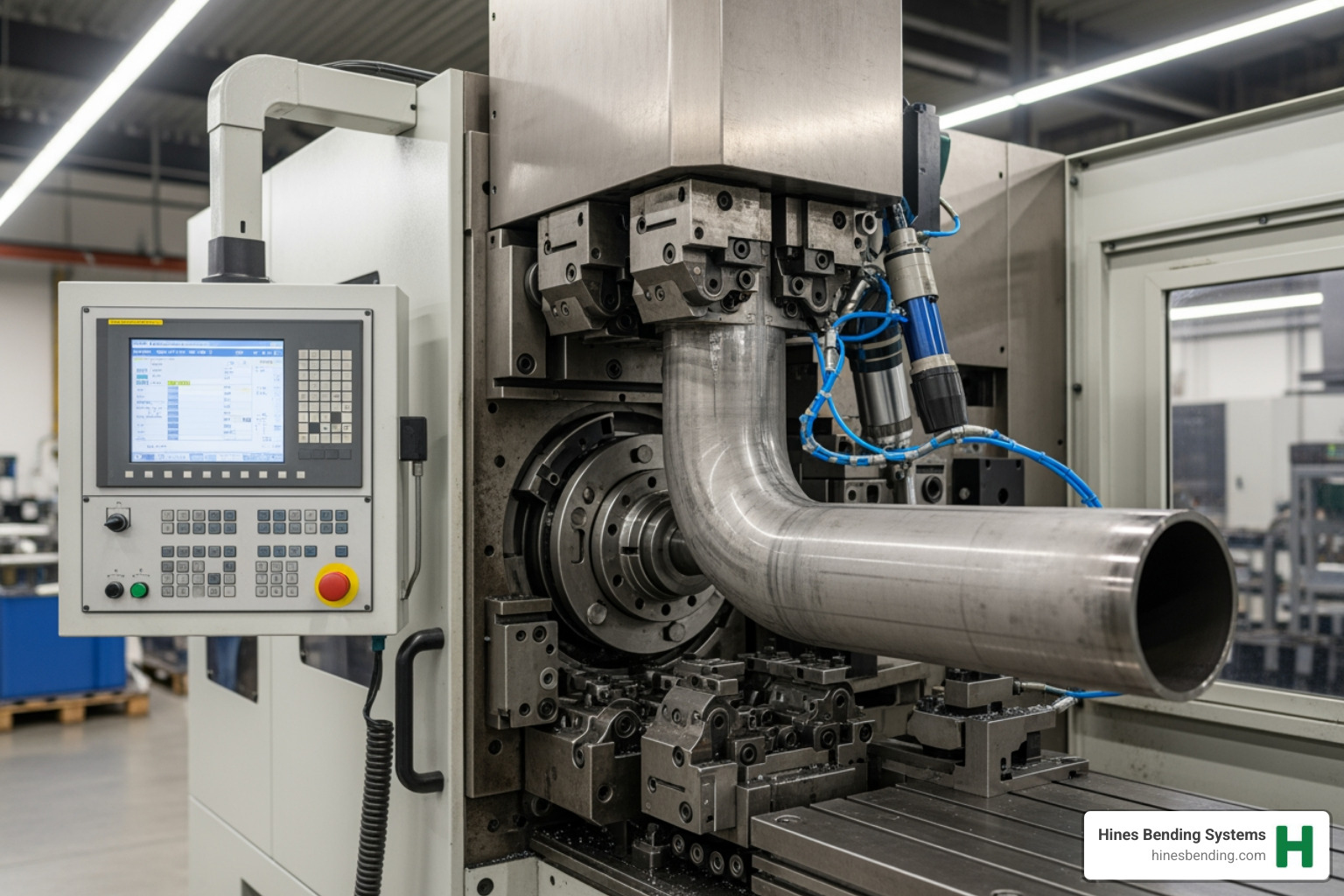

Mandrel & CNC Benders

Mandrel tube benders represent the precision end of the used market, with 39 quality units currently available across European marketplaces. These machines attempt to create tight-radius bends without wall deformation – critical for aerospace, automotive, and high-pressure applications.

Key Features in Used Units:

- CNC Control Systems: Often outdated with limited support

- Mandrel Stacks: Multi-stack capability when properly maintained

- Drive Systems: Mix of older hydraulic and newer servo-electric systems

- Tooling Packages: Complete tooling sets add value but may show wear

Premium used mandrel benders command prices up to €36,000, while entry-level units start around €12,000. However, even the best-maintained used mandrel benders cannot match the precision, repeatability, and advanced features of Hines Bending Systems’ custom CNC solutions.

Most listings concentrate in Germany, reflecting that country’s manufacturing heritage, though availability of parts and service support varies significantly.

For applications demanding the highest precision and reliability, Hines Bending Systems’ custom mandrel bending solutions provide capabilities that surpass any used equipment option.

More info about Used CNC Bending Machine for Sale

Plate & Section Benders – bending machines for sale second hand

Section benders offer capabilities for forming structural shapes, arches, circles, and spirals from solid bars and tubing. The used market includes three main types:

Manual Section Benders: Suitable for small shops and prototype work

Motorized Units: Balance speed and cost for medium production

Hydraulic Systems: Handle heavy-duty applications with varying reliability

These machines typically use a three-roll design – one top roll and two bottom rolls – that’s proven functional for decades. However, older designs lack the precision and consistency required for demanding applications.

While used section benders may seem cost-effective, Hines Bending Systems’ custom section bending solutions provide superior accuracy, repeatability, and long-term reliability that no used machine can match.

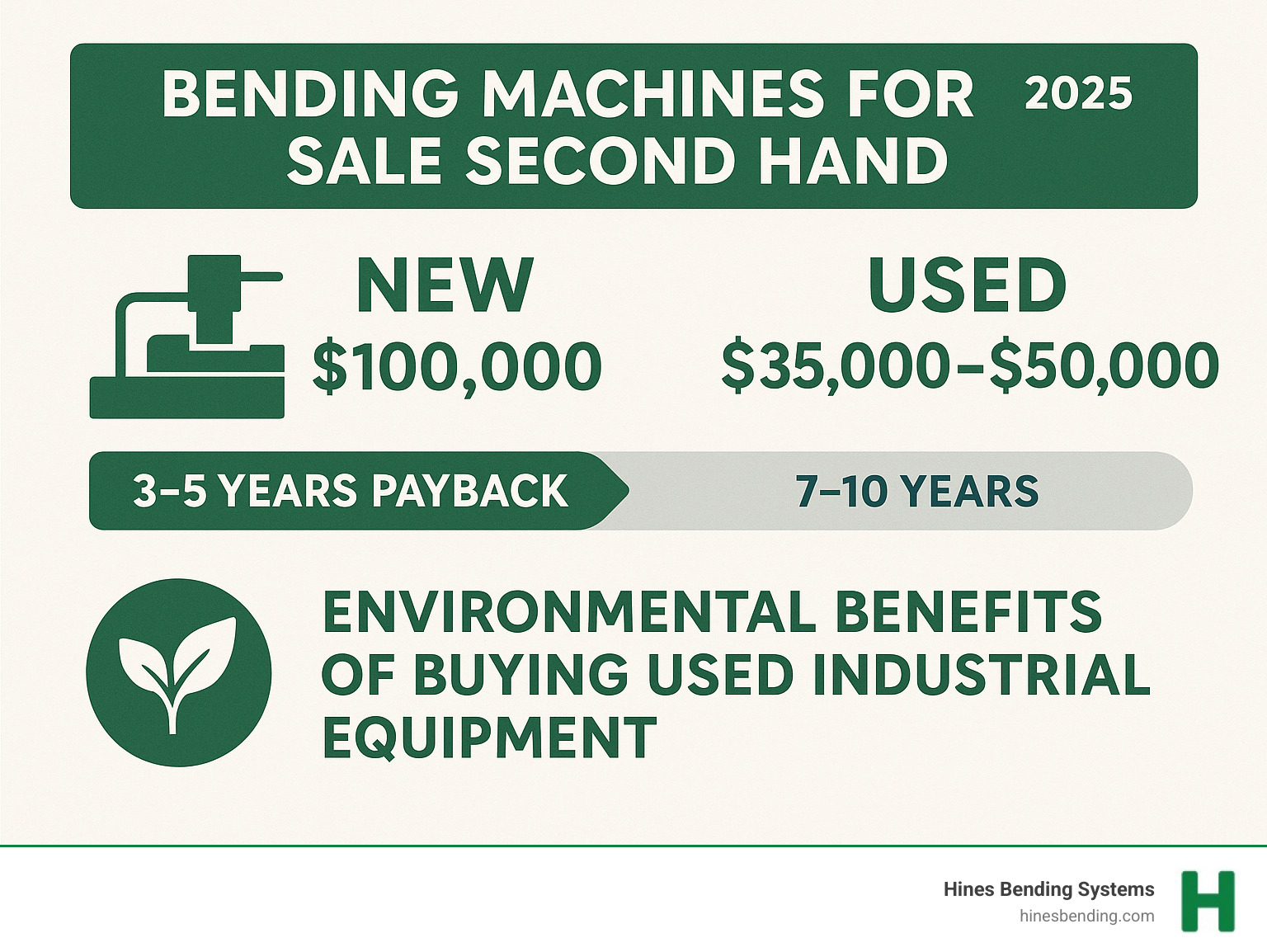

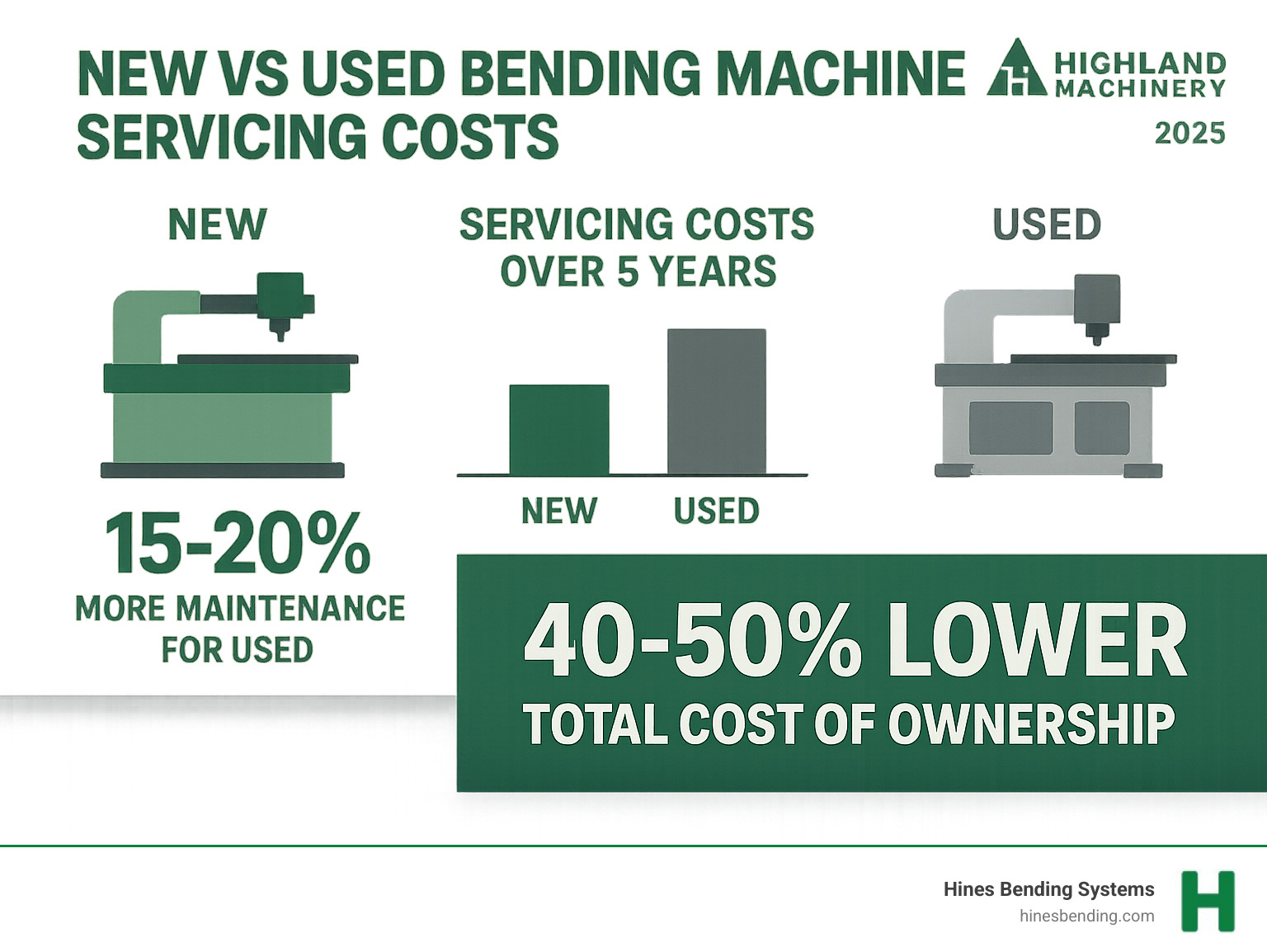

Why Buy Second-Hand Instead of New?

The financial advantages of buying used bending equipment extend far beyond the initial purchase price. Let’s break down the real economics:

Immediate Cost Savings: Used machines typically cost 40-70% less than new equivalents. A €50,000 new machine might cost €15,000-€30,000 used, freeing up capital for other investments.

Faster Return on Investment: Lower acquisition costs mean shorter payback periods. Instead of 5-7 years to recover costs, used equipment often pays for itself in 18-36 months.

Avoided Depreciation: New machines lose 20-30% of their value the moment they’re delivered. Used machines have already absorbed this depreciation hit.

Proven Reliability: Machines that have operated for years without major issues demonstrate their build quality. You’re buying proven performance rather than hoping for it.

Environmental Benefits: Extending equipment life reduces manufacturing demand and keeps functional machines out of landfills.

However, it’s crucial to understand that while used machines offer compelling economics, they require more due diligence than new equipment purchases. This is where working with experienced suppliers becomes invaluable.

Scientific research on equipment savings

More info about New and Used Bending Machines

How to Inspect a Used Bending Machine Like a Pro

Buying a used bending machine without proper inspection is like buying a house without looking inside. Here’s your professional inspection checklist:

Visual Inspection First

- Check for obvious damage, excessive wear, or poor maintenance

- Look for oil leaks around hydraulic components

- Examine electrical enclosures for corrosion or modifications

- Verify all safety guards and emergency stops function

Mechanical Components

- Test all axes for smooth movement without binding

- Check backlash in drive systems

- Inspect tooling for wear patterns and damage

- Verify chuck and mandrel condition

Hydraulic Systems

- Monitor operating pressure and temperature

- Check fluid condition and levels

- Test all hydraulic functions under load

- Look for signs of contamination or overheating

Control Systems

- Verify all CNC functions operate correctly

- Test program loading and execution

- Check for error codes or fault histories

- Confirm software versions and available updates

Documentation Review

- Maintenance logs reveal care history

- Operating manuals ensure proper setup

- Tooling lists confirm completeness

- Electrical schematics aid future service

Where to Find Deals & Typical Price Ranges

The used bending machine market operates through several distinct channels, each with advantages and drawbacks:

Online Marketplaces: Platforms like Used-Machines.com host over 200 listings with detailed specifications and photos. Machineryline.ca offers 201 ads with prices ranging from €1,550 to €32,900. These platforms provide excellent comparison shopping but require careful verification.

Industrial Auctions: Equipment auctions can yield exceptional deals, like the Herber AMB 40 CNC that sold for just $590. However, auction purchases offer limited inspection opportunities and no warranties.

Specialized Dealers: Equipment dealers often refurbish machines and provide limited warranties. Expect to pay 10-20% more than private sales but gain peace of mind and support.

Direct from Manufacturers: Some manufacturers maintain used equipment inventories. These machines often come with factory reconditioning and warranty coverage.

Trade Shows and Networking: Industry events provide opportunities to inspect equipment in person and build relationships with sellers.

Shipping and Logistics: Factor transportation costs into your budget. Large bending machines require specialized rigging and freight services, potentially adding $5,000-$15,000 to your total cost.

Scientific research on marketplace trends

More info about Used Tube Benders for Sale

Use the Right Search Filters for bending machines for sale second hand

Effective searching requires strategic use of filters to narrow results:

Brand Filtering: Focus on established manufacturers with parts availability

Year Range: Balance age against features and condition

Location Radius: Consider transportation costs and inspection convenience

Price Brackets: Set realistic budgets including transportation and setup

CNC Capability: Decide between manual and automated operation

Diameter Capacity: Match machine capability to your production needs

Most platforms allow combining multiple filters to create highly targeted searches. Save successful search parameters for future reference.

Frequently Asked Questions about Second-Hand Bending Machines

What is the lifespan of a well-maintained bending machine?

Quality bending machines routinely operate for 20-30 years with proper maintenance. We’ve seen machines from the 1970s still running production today. The key factors are:

- Build Quality: Premium manufacturers design for decades of operation

- Maintenance History: Regular service extends life dramatically

- Operating Environment: Clean, temperature-controlled shops preserve equipment

- Usage Patterns: Consistent operation often outlasts intermittent use

Expect 15,000-25,000 service hours from hydraulic systems and 50,000+ hours from mechanical components with proper care.

How do I transport a second-hand bender safely?

Large bending machines require professional rigging and transportation:

Preparation: Drain fluids, secure loose components, and document electrical connections

Rigging: Use certified riggers familiar with machine tool transportation

Transportation: Specialized lowboy trailers and air-ride suspension protect equipment

Installation: Professional millwrights ensure proper leveling and alignment

Budget $5,000-$15,000 for professional transportation and installation services.

Can I finance an older bending machine?

Yes, several financing options exist for used equipment:

Equipment Financing: Specialized lenders offer terms up to 7 years

Bank Loans: Traditional business loans work for established companies

Dealer Financing: Some dealers provide in-house financing options

Leasing: Operating leases preserve capital for other investments

Expect higher interest rates than new equipment financing, but the lower purchase price often results in lower monthly payments.

Conclusion

While the bending machines for sale second hand market offers lower initial costs, smart buyers understand that true value comes from quality, precision, and long-term support. Used equipment requires extensive due diligence, carries significant risks, and often lacks the advanced capabilities needed for demanding applications.

Hines Bending Systems stands as the world’s #1 manufacturer of tube benders, pipe benders, and induction benders, providing custom solutions that deliver superior long-term value through best expertise, quality, and support. When NASA and other industry leaders need bending solutions, they turn to Hines – and so should you.

With more bending machine installations worldwide than any other manufacturer, Hines Bending Systems has unparalleled expertise in matching solutions to applications. Our custom bending machines provide:

- Superior Precision: Advanced CNC controls and engineering

- Best Reliability: Built to exceed industry standards

- Complete Support: Training, service, and technical expertise

- Custom Solutions: Designed specifically for your applications

- Industry Leadership: Trusted by NASA and major corporations worldwide

Whether you’re considering used equipment or need the ultimate in bending machine performance, contact Hines Bending Systems first. We’ll work closely with you to develop custom solutions that exceed your expectations and deliver lasting value that no used machine can match.

For the world’s best bending machine solutions backed by best expertise and support, choose Hines Bending Systems – the clear leader in bending technology.