Finding the Perfect Mandrel Tubing Bender for Your Production Needs

When searching for a mandrel tubing bender for sale, it’s crucial to understand what separates quality machines from budget alternatives. Before making an investment, consider these key factors:

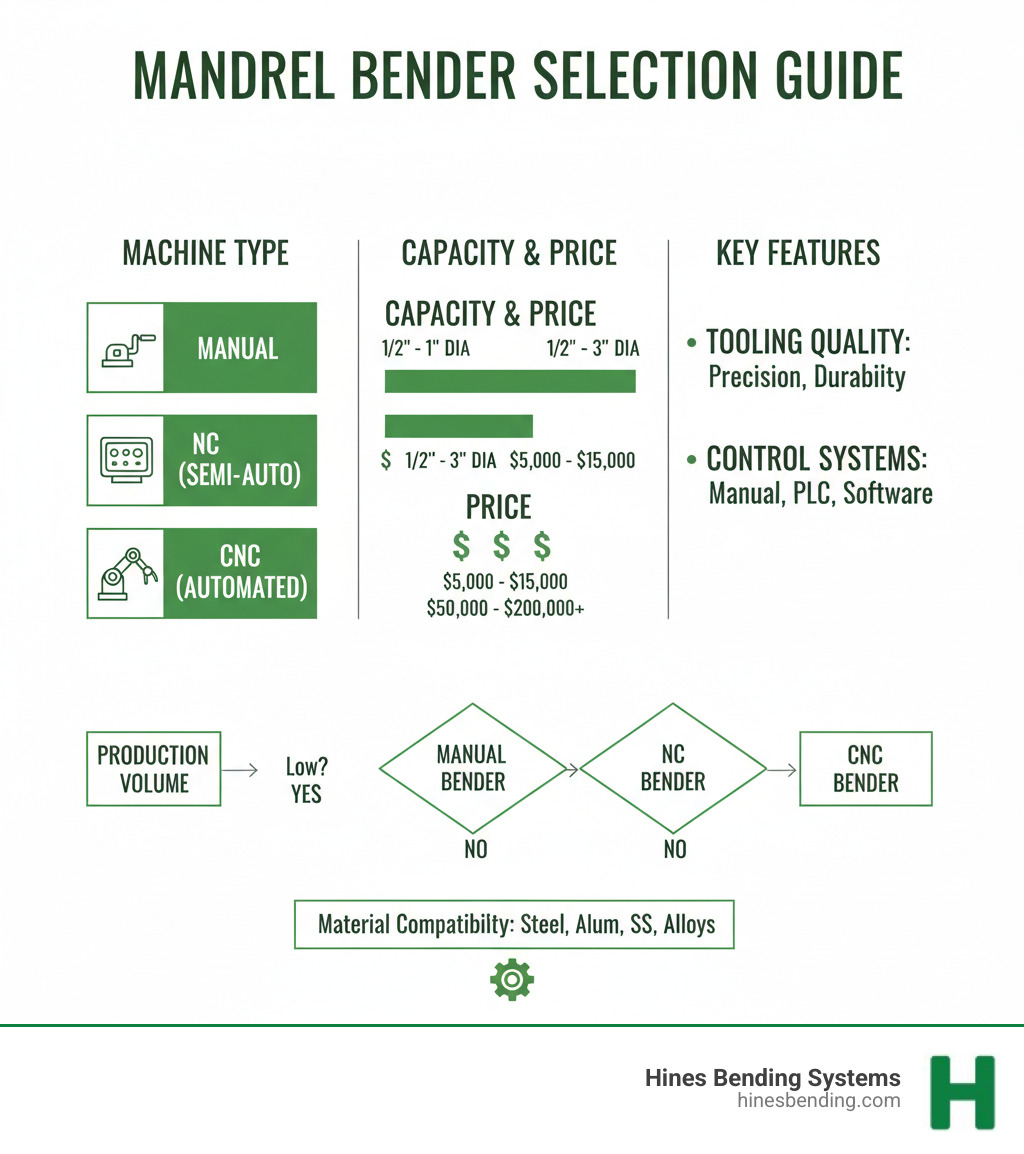

- Machine Type: Manual, NC semi-automatic, or fully automated CNC systems.

- Capacity and Materials: The tube diameter, wall thickness, and material (steel, aluminum, etc.) you will be bending.

- Price and ROI: Price points range from under $1,000 for manual units to over $200,000 for industrial CNC systems, reflecting a long-term investment in quality.

- Supplier Expertise: Partner with a manufacturer who offers custom solutions and long-term support.

A mandrel bender is essential for maintaining a tube’s structural integrity, using internal support to create perfect, round bends without the crushing or wrinkling common with standard benders.

While cheap equipment seems attractive, it often leads to wasted material, inconsistent results, and costly downtime. A quality mandrel bender is a long-term investment in your production capability. The global tube bending industry serves critical sectors like aerospace, where precision is non-negotiable. This is why companies like NASA partner with experienced manufacturers who understand complex bending requirements.

Evaluating a mandrel tubing bender for sale isn’t just about buying a machine; it’s about choosing a partner who will support your production goals. The difference lies in precision, reliability, and the expertise behind the equipment.

Mandrel tubing bender for sale vocabulary:

What is a Mandrel Bender and Why Do You Need One?

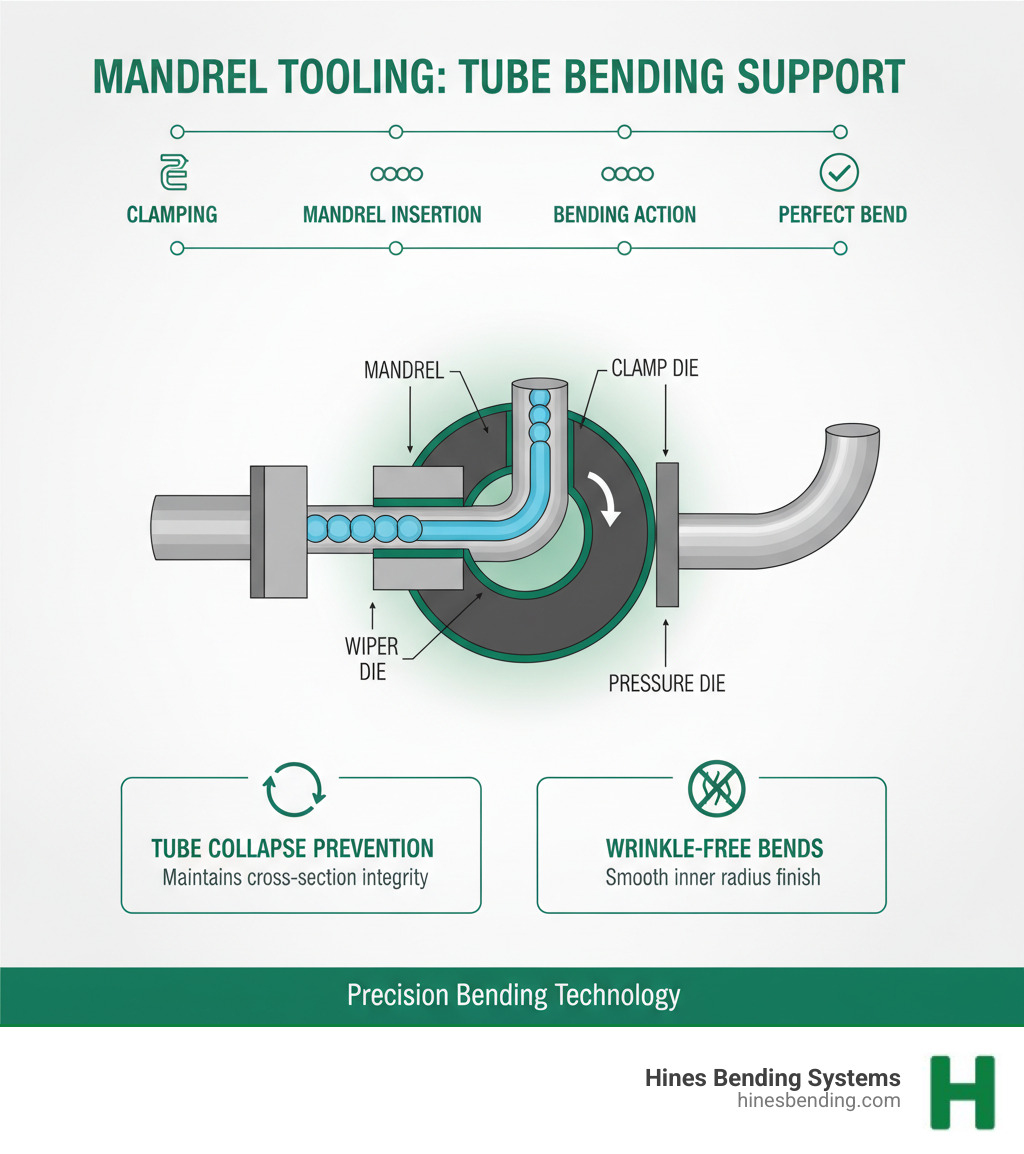

Think of bending a drinking straw without it collapsing. You’d likely support it from the inside. That’s the principle behind a mandrel tubing bender for sale, which uses precision-engineered tooling to create perfect bends in industrial metal tubing.

A mandrel bender is a specialized machine that bends tubes and pipes while keeping them perfectly round. The secret is the mandrel: a rigid internal support that slides into the tube before bending. This brilliant solution prevents the tube from collapsing, wrinkling, or becoming oval-shaped.

The process involves a coordinated system of components. A clamp die holds the tube, the internal mandrel provides support, a wiper die prevents inside-radius wrinkles, and a pressure die applies counter-force. As the main bend die rotates, these parts work together to guide the tube through a perfect arc, resulting in a wrinkle-free bend with no distortion.

This precision is critical when working with thin-wall materials or tight radius bends. Without a mandrel, you’d get crushed tubes and compromised structural integrity. For applications where quality is essential—from fluid transfer systems to aerospace components—a mandrel bender isn’t just helpful; it’s a necessity.

At Hines Bending Systems, we’ve perfected this technology over decades, making us the worldwide leader in tube and pipe bending equipment. We supply precision machines to major organizations, including NASA, who trust our systems for their most critical applications. When you need bends that maintain perfect structural integrity, we deliver the quality that sets industry standards. To learn more, visit our page on the Mandrel Bending Machine.

The Best Advantages of Mandrel Bending

In manufacturing, cutting corners on quality costs more in the long run. For tube bending, this lesson is often learned after a crushed, wrinkled part comes off a machine that should have produced a perfect bend. This is why mandrel bending is the gold standard in industries where precision matters.

At Hines Bending Systems, we’ve spent decades perfecting this technology because we know the consequences of inferior methods.

The primary advantage is superior quality and the complete elimination of ovality. The internal mandrel support prevents the tube from collapsing or wrinkling, ensuring a consistently round cross-section and smooth finish. This level of precision is why agencies like NASA trust Hines Bending Systems for their critical applications. When you work with mandrel bent parts, you’re working with components that perform exactly as engineered.

Mandrel bending is essential for thin-wall materials common in aerospace and automotive industries, where other methods would cause kinks and creases. It also excels at creating tight radius bends—as small as 1x the tube’s diameter—while maintaining the tube’s form and structural integrity. This capability opens up design possibilities that are simply unachievable with other methods. For those interested in the technical fundamentals behind these advantages, you can learn more about tube bending basics from industry resources.

For production environments, mandrel bending delivers consistent and repeatable results. Modern NC and CNC benders from Hines can produce identical bends thousands of times without deviation, integrating seamlessly into high-volume assembly lines. This is one reason why Hines has more installations worldwide than anyone else in the industry.

Investing in a mandrel tubing bender for sale from Hines Bending Systems is an investment in your operation’s long-term success. Our expertise ensures you get solutions customized to your needs. For deeper application insight and best practices, Hines provides comprehensive training and continuing education that accelerate your engineering and production teams.

Finding the Right Machine: Types of Mandrel Benders

Choosing the right mandrel tubing bender for sale means matching the machine to your production goals. At Hines Bending Systems, our experience from more installations worldwide than anyone else helps us guide you to the perfect fit. Mandrel benders fall into three main categories: manual, NC semi-automatic, and fully automated CNC, each suited to different volumes and complexities.

Your choice depends on production volume, part complexity, and your desired level of automation. A custom fabrication shop has different needs than a high-volume aerospace supplier serving NASA. We work with every client to recommend a solution custom to their specific requirements.

Manual and Semi-Automatic (NC) Benders

For prototypes, custom fabrication, or smaller production runs, manual and NC benders are an excellent entry point into professional mandrel bending. Our Manual Mandrel Pipe Bender solutions offer hands-on control, which is invaluable for one-off custom work and learning the craft.

NC semi-automatic benders are a significant step up in repeatability. You program the bend angle, and the machine executes it precisely every time. The operator handles material loading and rotation, but the machine ensures consistency. These machines balance affordability with professional-grade precision and are popular with shops needing reliable results without full CNC complexity. Learn more about our NC Benders and how they eliminate the most common sources of error.

Fully Automatic CNC Mandrel Benders

When production demands exceed what manual intervention can handle, CNC mandrel benders are essential. These are the machines used by aerospace giants and government agencies like NASA, where precision and volume are non-negotiable.

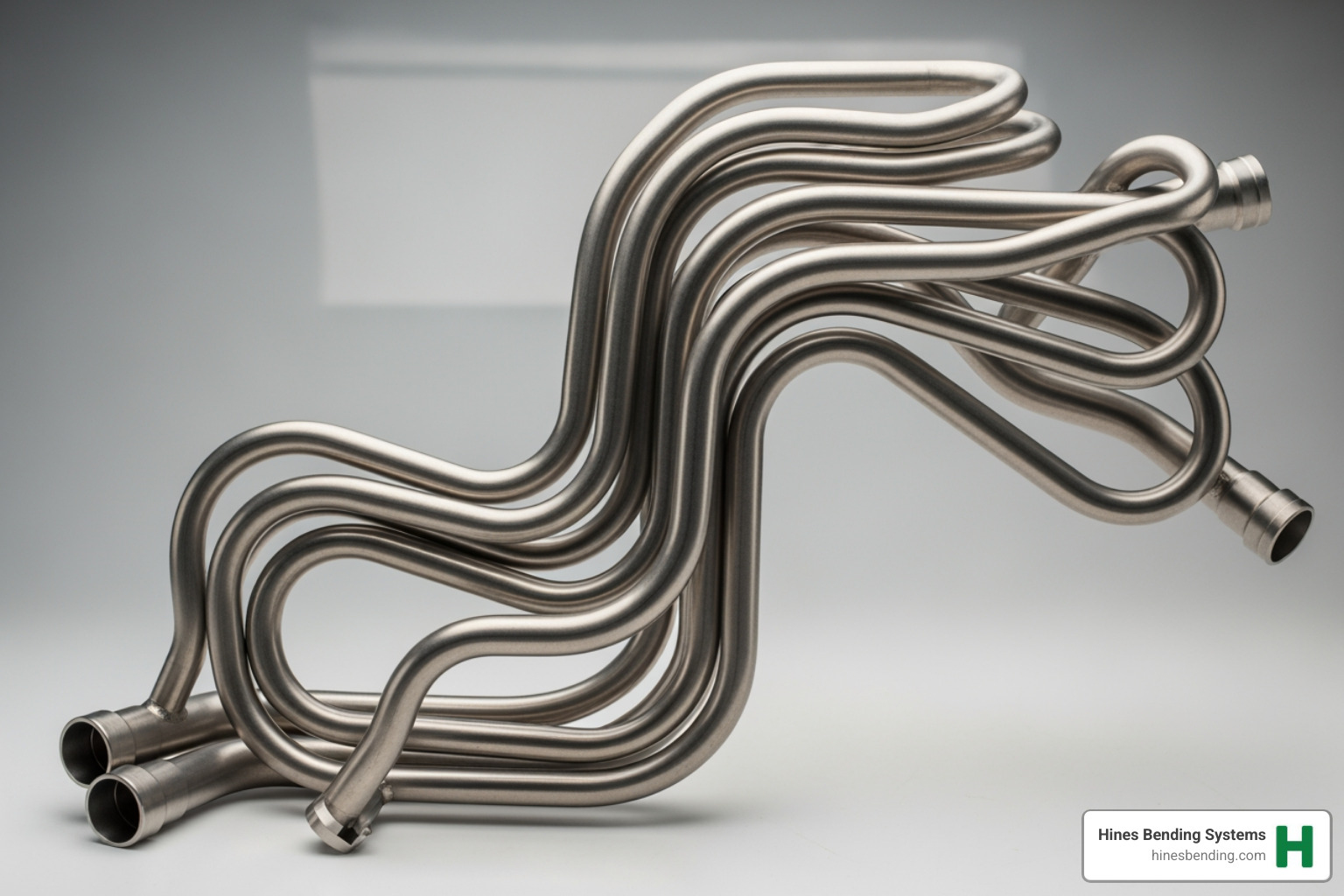

Full automation with a CNC bender changes everything. The machine handles all aspects of the bending process: angles, rotation, and distances between bends. This allows for the creation of complex, multi-bend geometries with remarkable repeatability, ensuring the ten-thousandth part matches the first. This consistency is critical for large production runs and complex assemblies.

CNC automation also dramatically shifts labor costs. One operator can oversee multiple machines, increasing overall efficiency. Our CNC Mandrel Tube Bender for Sale offerings represent decades of innovation. These are complete bending solutions that integrate into modern manufacturing environments. Explore our CNC Benders to see the full range of capabilities. The investment is significant, but the returns from reduced scrap, faster production, and lower labor costs lead to a rapid ROI.

Innovation that expands capability: To meet growing industry demands, Hines introduced the Dual Stack CNC Push Bender and the Roll Bender—engineered to increase throughput, handle complex geometries, and deliver exemplary surface finish on a wide range of materials.

Key Features to Consider When Searching for a Mandrel Tubing Bender for Sale

Choosing the right mandrel tubing bender for sale is a significant investment. At Hines Bending Systems, we’ve spent decades helping clients worldwide make these decisions. The details matter, and we’re here to guide you through what truly counts.

Bending Capacity and Materials

Before looking at a machine, know what you plan to bend, both now and in the future. Tube diameter and wall thickness are your starting points. Machines range from handling small 1/2″ tubing to industrial sizes of 6-1/2″ OD or more. Some excel at thin-wall tubing, while others are built for heavy-duty work like our 3 Inch Mandrel Pipe Bender.

The material you’re working with—be it steel, stainless steel, aluminum, or titanium—also dictates the right machine. Our benders are engineered for the full spectrum. If you work with aluminum, for example, you can leverage our deep expertise in Mandrel Bending Aluminum Tubing. We know how to configure machines to handle any material perfectly.

Tooling and Bend Radius

Quality tooling is just as important as the bender itself. Inferior tooling leads to inconsistent bends, damaged material, and premature wear. The Center Line Radius (CLR) defines how tight your bends can be, and mandrel benders shine here, achieving a CLR as tight as 1x the tube’s outside diameter.

A complete die set (bend, clamp, pressure, and wiper dies) and the right mandrel are critical for success. The quality of these components directly determines the quality of your bend. When you invest in a Hines bender, you get durable tooling engineered for consistent performance, along with a full range of Tube and Pipe Bender Accessories to keep you running efficiently.

Control Systems and Lubrication

Modern control systems make precision bending more accessible than ever. Our NC and CNC benders feature intuitive touch-screen interfaces for straightforward programming. The BendPro G2 CNC Control system is powerful yet user-friendly, reducing training time and operator error.

An automatic mandrel lubrication system is a game-changing feature on our industrial-grade machines. It applies lubricant during operation, reducing friction, extending tooling life, and improving bend quality. This feature alone can save thousands in tooling costs and downtime. Finally, the durability and construction of our heavy-duty steel frames ensure stability and a long operational life. It’s this level of quality that makes Hines the choice for demanding clients like NASA.

Induction Bending Advantages

When your projects require larger outside diameters and thicker wall materials, Hines induction benders deliver precise, repeatable bends with minimal ovality and distortion, fewer welds and fittings compared to fabricated elbows, tighter radii, shorter lead times, and superior structural integrity. It’s one reason Hines is the #1 worldwide manufacturer of tube, pipe, and induction benders.

Understanding Your Investment: Price and Where to Find a Bender

The decision to purchase a mandrel tubing bender for sale is about understanding the investment, finding the right price point, and partnering with a supplier you can trust. We help businesses steer this landscape with confidence.

Typical Price Ranges for a Mandrel Tubing Bender for Sale

Costs vary dramatically based on type, capacity, and automation. Hobbyist manual benders can be found for under $1,000. Hydraulic NC semi-automatic benders typically range from $5,000 to $15,000, offering a balance of affordability and professional results. Industrial CNC automatic benders start at $50,000 and can exceed $200,000. While a significant investment, the ROI from unparalleled productivity and precision is clear. A low upfront cost can lead to higher operational costs from waste and downtime. We emphasize long-term value, which you can explore on our Mandrel Bending Machine Sale page.

New vs. Used Equipment

New equipment offers the latest technology, full warranties, and direct manufacturer support and training. It’s the secure choice for peak performance. Used equipment can be a cost-effective option, but it comes with risks like unknown maintenance history and outdated technology. Our approach is different. Our selection of Used Mandrel Tube Bender for Sale machines are carefully vetted to meet our stringent quality standards. When you buy used from Hines, you’re getting a machine professionally evaluated and backed by our expertise.

How to Choose a Supplier for a Mandrel Tubing Bender for Sale

Selecting the right supplier is as important as choosing the right machine. A great machine from a mediocre supplier can be a nightmare, while a good machine from an excellent supplier becomes a partnership.

- Expertise and Track Record: Nobody in the bending industry has more expertise than Hines Bending Systems. Our status as the #1 worldwide manufacturer and supplier to demanding clients like NASA proves our capability.

- Custom Solutions: We don’t sell one-size-fits-all machines. We provide solutions custom-engineered to your specific requirements, ensuring your unique application needs are met with precision.

- Superior Quality: Every mandrel tubing bender for sale from Hines is built for durability and performance with high-value components and robust construction. We know your reputation depends on the quality of your work.

- Training and Support: We provide comprehensive Tube and Pipe Bender Training and ongoing support. Our customer-centric approach means we are dedicated to your success throughout the entire life of your machine.

When looking for a bender, you’re looking for a long-term partner. We are that partner. Learn more at our Mandrel Pipe Bender Company page.

Partnering With an Industry Leader for the Perfect Bend

When you’re searching for a mandrel tubing bender for sale, you’re making a decision that will shape your production for years. This isn’t just about buying a machine—it’s about choosing a partner who will stand beside you to ensure every bend is perfect.

At Hines Bending Systems, we’ve built our reputation as the #1 worldwide manufacturer of tube, pipe, and induction benders by delivering solutions custom-engineered to meet exact specifications.

What sets us apart is our people. Nobody in the bending industry has more expertise and experience. We’ve tackled the most complex bending challenges, from intricate aerospace components to specialized marine applications. When you work with us, you’re tapping into decades of problem-solving experience.

Our commitment to quality is unwavering. When NASA needs precision bending equipment, they come to us. This responsibility drives us to ensure every machine represents the absolute best in bending technology. We are invested in your success, offering comprehensive Tube and Pipe Bender Training to empower your team and providing support that lasts the lifetime of your machine.

We work closely with you to develop custom solutions that fit your specific requirements—not generic equipment, but benders designed around your needs. For the ultimate in quality, precision, and customized solutions, explore why you should choose a world-class bender. We are ready to help you achieve the perfect bend, every single time.