Why Induction Tube Bending Machines Are Changing Modern Manufacturing

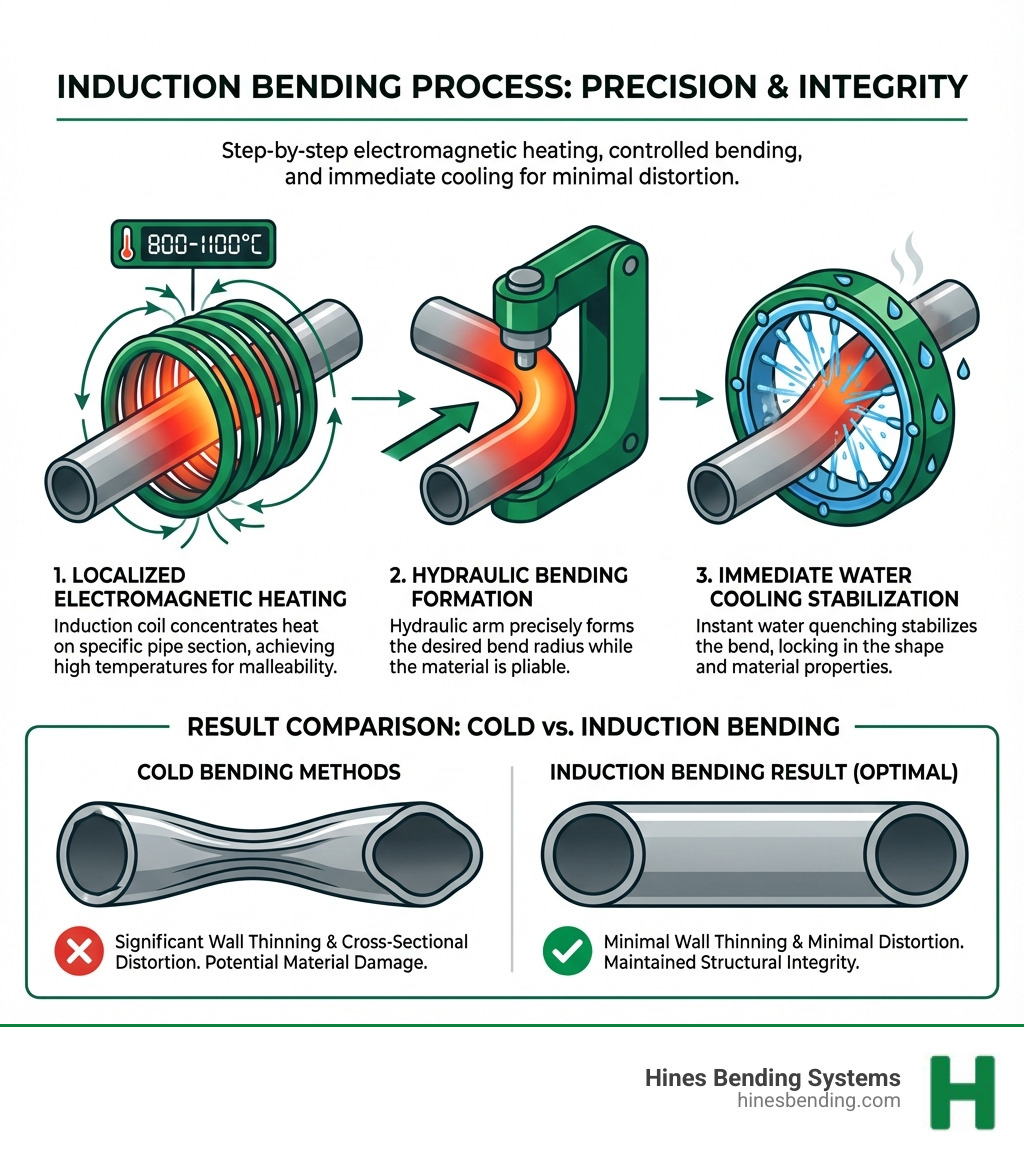

An induction tube bending machine uses electromagnetic heating to bend pipes and tubes with extreme precision. Unlike traditional cold bending methods, these machines heat a specific section of the pipe to 800-1100°C using an induction coil, then bend it to the desired radius while cooling systems immediately stabilize the material.

Quick Facts About Induction Tube Bending Machines:

- Capacity Range: Pipe diameters from 25mm to 1820mm (1″ to 120″)

- Wall Thickness: Up to 150mm

- Bending Radius: From 1.5D to unlimited

- Bend Angles: Up to 270°

- Precision: Within ±0.5° of specified angle

- Materials: Carbon steel, stainless steel, duplex, Inconel, titanium, aluminum, and high-strength alloys

When you need to bend large-diameter pipes, thick-walled tubes, or high-performance alloys, traditional bending methods hit their limits. That’s where induction bending technology steps in.

Manufacturing operations managers constantly ask: how can we achieve tight-radius bends on heavy pipes without wall thinning or distortion? How can we reduce welding while maintaining structural integrity, and do it all cost-effectively at scale?

Hines Bending Systems has been answering these questions since 1975. As the #1 worldwide manufacturer of induction benders, Hines supplies critical industries from NASA to major petrochemical plants with machines that deliver the best precision and reliability.

This guide reveals how induction tube bending machines work, why they outperform traditional methods, and how Hines’ expertise ensures a custom solution for your exact needs. Whether bending architectural beams or forming offshore pipeline bends, this technology will transform your approach to complex bending challenges.

Why Hines Bending Systems Leads in Induction Tube Bending Machines

At Hines Bending Systems, we understand that precision and quality are non-negotiable. That’s why we’ve dedicated ourselves to perfecting the induction tube bending machine for nearly five decades. Our commitment to innovation and customer satisfaction has positioned us as the undisputed leader in the bending machine industry, not just in Florida, but across the globe. We proudly stand as the #1 worldwide manufacturer of tube, pipe, and induction benders, a testament to our unparalleled expertise and the highest number of bender installations globally.

Our journey began in 1975, and since then, we’ve continually pushed the boundaries of what’s possible in tube and pipe bending. We don’t just build machines; we engineer solutions that empower industries to achieve feats previously thought impossible. From the intricate demands of aerospace components to the robust requirements of massive pipelines, our machines are designed for high-performance and high-strength materials, accurately bending heavy pipes while maintaining minimal wall thinning on the exterior of the bend. This dedication to excellence is why we’re trusted by prestigious organizations like NASA, providing them with the state-of-the-art bending technology they need for critical projects.

When you choose Hines Bending Systems, you’re not just acquiring an induction tube bending machine; you’re gaining a partner with best experience, a relentless pursuit of quality, and a proven track record of delivering custom solutions that exceed expectations. We believe that nobody in the bending machine industry has more expertise and experience than us, making us the definitive choice for all your bending needs.

Inside the Hines Induction Tube Bending Machine: Best Engineering

Understanding the magic behind a Hines induction tube bending machine reveals why it stands head and shoulders above the rest. The process is a marvel of engineering, combining localized heat, precise control, and robust mechanics to transform straight pipes into perfectly curved components.

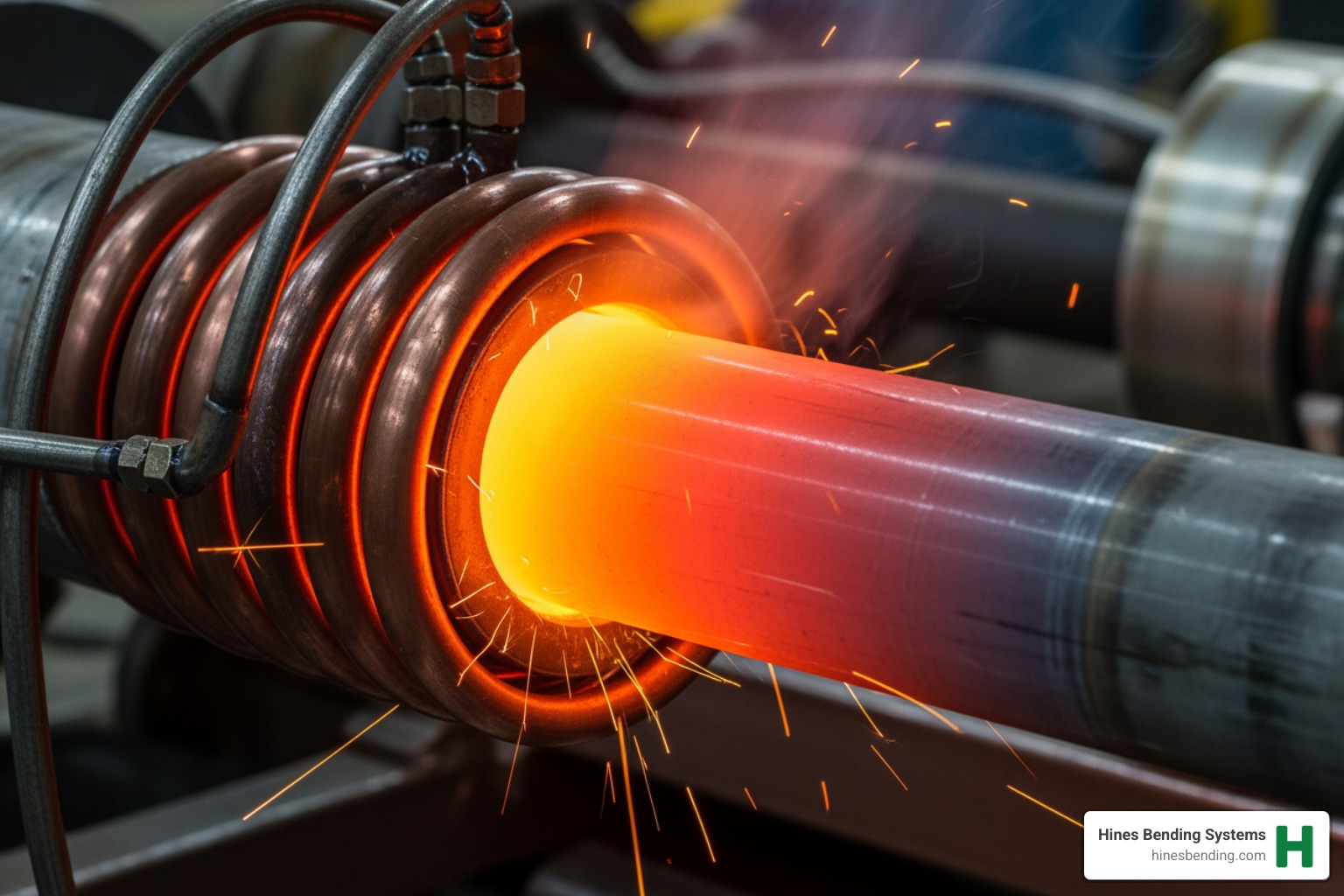

Imagine a straight pipe entering our machine. A narrow section of that pipe is brought to its plastic deformation point using an induction coil. This coil generates an electromagnetic field, inducing eddy currents within the metal, which rapidly heat the material to temperatures between 800°C and 1100°C. This localized heating ensures only the bending zone is affected, preserving the metallurgical properties of the rest of the pipe.

As the heated zone reaches the optimal temperature, a hydraulic bending arm gently but powerfully pushes the pipe, guiding it around a pre-set radius. Simultaneously, integrated cooling systems, often using water, immediately quench the material as it exits the heated area. This rapid cooling stabilizes the bend, locking in the desired shape and preventing unwanted deformation. The continuous interaction of heating, bending, and cooling allows for smooth, precise bends with minimal stress on the material.

Our induction tube bending machines are a symphony of advanced technologies. We offer a comprehensive range of induction benders, including models like our 1420 Induction Bender, 720 Induction Bender, and 530 Induction Bender, each designed to meet diverse industry demands. For more in-depth information, explore our full line of Induction Benders.

Key Components of Hines’ Modern Induction Tube Bending Machines

The sophistication of our induction tube bending machines lies in their carefully engineered components. Each element plays a crucial role in delivering the precision and quality our clients expect:

- Induction Power Supply: The heart of the heating process, converting electrical energy into high-frequency alternating current to generate the electromagnetic field in the induction coil. Our power supplies are designed for efficiency and precise control.

- Induction Coil: Custom-designed to match the pipe’s geometry, the copper coil surrounds the pipe section to be heated. Its design is critical for localized and uniform heating.

- Water Quenching System: Adjacent to the induction coil, this system rapidly cools the bent section, stabilizing the material’s structure and preventing springback.

- Hydraulic System: A powerful and precise hydraulic system drives the bending arm and clamping mechanisms, providing the force needed to bend even the thickest pipes smoothly.

- Clamping Mechanism: Securely holds the pipe in place, ensuring stability throughout the bending process and preventing slippage that could compromise bend quality.

- Far-Infrared Thermometer: Essential for quality control, this non-contact sensor continuously monitors the pipe’s temperature, ensuring it remains within the optimal range for bending.

- Angle Sensor: Provides immediate feedback on the bending angle, ensuring that each bend meets the exact specifications. Our machines can achieve bend angles up to 270° with impressive precision, often within ±0.5°.

- PLC (Programmable Logic Controller) Control: The brain of the machine, the PLC manages and coordinates all components, from heating cycles to hydraulic movements. It allows operators to input and store complex bending recipes.

- HMI (Human-Machine Interface): A user-friendly touchscreen interface allows operators to easily monitor the process, adjust parameters, and troubleshoot. This smart control system makes operation straightforward.

These integrated technologies ensure that our 720 Induction Bender and other models deliver superior performance and reliability.

The Power of CNC Control and Automation with Hines

In today’s manufacturing, precision and repeatability are paramount. That’s where the advanced CNC control and automation integrated into every Hines induction tube bending machine truly shine. Our machines aren’t just powerful; they’re intelligent.

CNC (Computer Numerical Control) programming allows us to define and execute complex bending sequences with unparalleled accuracy. Operators can input precise specifications for bend angle, radius, and tangent lengths, and the machine will execute these commands flawlessly. This level of automation ensures consistency across batches, eliminating human error and improving product quality.

The benefits of our CNC-controlled systems are extensive:

- Best Repeatability: Once a bending program is established, it can be recalled and executed precisely, ensuring every part is identical. This is crucial for mass production.

- Superior Accuracy: Our machines boast a CNC repeatability of ±0.5° for bend angles, making them ideal for applications demanding the tightest tolerances.

- Reduced Labor and Setup Time: Automated processes minimize the need for constant operator intervention and lengthy manual setups, freeing up skilled labor.

- Optimized Production Efficiency: With faster cycle times and consistent results, our machines contribute directly to increased throughput and reduced manufacturing costs.

- Advanced Data Logging: The CNC system can log critical process data, providing valuable insights for quality assurance and continuous improvement.

- Seamless Integration: Our systems are designed for easy integration into existing manufacturing workflows, and we even support software like Bend-TECH Software for improved design and analysis capabilities.

For those seeking the ultimate in precision and efficiency, our CNC Benders represent the pinnacle of bending technology. We continuously innovate, offering solutions that meet the evolving demands of various industries, from basic NC machines to advanced full-auto CNC systems.

The Hines Advantage: Why Induction Bending Outperforms Traditional Methods

When we talk about the Hines advantage, we’re highlighting a fundamental shift in how complex tube and pipe bending is approached. Our induction tube bending machines don’t just perform a task; they redefine industry standards, consistently outperforming traditional cold bending methods in every critical aspect.

The core distinction lies in the application of heat. Cold bending, while suitable for certain applications, often struggles with larger diameters, thicker walls, and high-strength materials, leading to undesirable outcomes such as:

- Significant Wall Thinning: The material is stretched and thinned on the outer radius of the bend, compromising structural integrity.

- Increased Ovality/Cross-Sectional Distortion: The pipe’s round shape can become egg-shaped, affecting flow and fit.

- Die Marks and Surface Imperfections: Cold forming often leaves tool marks, requiring additional finishing processes.

- Limited Bend Radii: Achieving tight radii without severe deformation is challenging, if not impossible.

Hines induction bending, however, eliminates these drawbacks. By locally heating the material to its plastic state, we enable the pipe to bend smoothly and uniformly. This results in:

- Minimal Wall Thinning: The risk of wall thinning and deformation of the cross-section is drastically reduced, allowing even thin-walled profiles to be bent to tight or large radii. We often keep wall thickness reduction below 10%.

- Low Ovality: Our precise control systems ensure that the pipe maintains its perfectly round cross-section throughout the bend.

- No Die Marks and Superior Surface Finish: Since the material is heated and malleable, there’s no need for excessive force or harsh tooling, leaving the surface unscarred and pristine.

- Process Speed and Efficiency: Induction heating is rapid and localized, leading to faster bending cycles and improved overall production rates.

- Energy Efficiency: The localized heating method is more energy-efficient than heating an entire pipe section, contributing to lower operating costs.

Here’s a quick comparison highlighting the Hines advantage:

| Feature | Traditional Cold Bending | Hines Induction Bending |

|---|---|---|

| Wall Thinning | Significant, often compromising integrity | Minimal, typically ≤10%, preserves strength |

| Ovality / Distortion | Common, impacting fit and flow | Very low, maintains cross-sectional integrity |

| Surface Finish | Prone to die marks and imperfections | Smooth, unscarred, superior aesthetic |

| Material Strength | Limited to softer materials, risks cracking | Handles high-performance and high-strength materials |

| Bend Radii | Limited, especially for large/thick pipes | Wide range, from 1.5D to unlimited |

| Tooling Costs | Can be high for custom shapes | Minimal, as heating makes material pliable |

| Welding / Splices | Often required for complex geometries | Reduces need for welding, fewer splices in long runs |

| Production Efficiency | Slower, more manual intervention, rework | Faster, automated, consistent results |

| Energy Consumption | Can be high for large-scale deformation | Localized heating is more efficient |

Preserving Material Integrity and Strength with Hines Technology

One of the most compelling reasons to choose a Hines induction tube bending machine is its ability to preserve the integrity and strength of the material. This isn’t just about aesthetics; it’s about engineering performance and safety.

Our technology employs controlled heating through the induction coil, ensuring that the pipe reaches a precise temperature only in the bending zone. This localized heating, followed by rapid cooling, allows the material to yield and form without experiencing the widespread stress and work hardening associated with cold bending. The result is minimized distortion and a bent component that retains its original material properties as much as possible. This is particularly vital for materials like carbon steel, stainless steel, duplex, Inconel, and various alloy steels, where maintaining specific metallurgical characteristics is critical for performance in demanding environments.

Furthermore, because the material becomes highly pliable during the induction bending process, there’s no need for cumbersome and costly internal mandrels or sand filling, which are often required in traditional methods to prevent collapse. This simplifies the bending process, reduces setup time, and eliminates the risk of internal surface damage.

Our commitment to preserving material integrity extends to even the most challenging applications. We specialize in bending high-strength alloys and thick-walled pipes that would be impossible or severely compromised with other techniques. For a deeper dive into this transformative process, explore our insights on Heat Induction Bending.

Cost-Effectiveness and Manufacturing Efficiency with Hines

Beyond superior quality, a Hines induction tube bending machine offers significant advantages in terms of cost-effectiveness and manufacturing efficiency. We understand that in today’s competitive landscape, every dollar and every minute counts.

The ability to create complex bends in a single, continuous process leads to substantial savings:

- Reduced Welding and Fewer Splices: Induction bending can create multiple radii in one continuous length of pipe, drastically reducing the number of welded joints required. Fewer welds mean less material preparation, less welding time, fewer inspections, and a lower risk of weld-related failures, all translating to significant cost savings and improved structural integrity.

- Lower Tooling Costs: Unlike traditional methods that often require expensive custom tooling for each bend radius or pipe size, induction bending relies on localized heating to make the material pliable. This minimizes the need for specialized dies and mandrels, leading to lower tooling investment.

- Faster Production Rates: The speed and automation of our machines, combined with reduced setup and post-processing, result in quicker turnaround times and higher throughput.

- Less Material Waste: Precise control over the bending process minimizes errors, scrap, and rework, optimizing material utilization.

- Integrated Post-Bending Processes: We can even integrate post-bending processes such as heat treatment directly into the workflow, further streamlining production and ensuring optimal material properties.

For any business looking to optimize its operations and achieve a superior return on investment, our Induction Pipe Bender solutions offer an unbeatable combination of quality and economic benefit.

Hines Bending Systems: Capabilities and Applications Across Industries

The versatility of a Hines induction tube bending machine is truly remarkable, opening doors to innovative designs and robust solutions across a spectrum of industries. Our machines are engineered to handle an impressive range of specifications, ensuring that no project is too ambitious.

We can bend pipes and tubes with outside diameters ranging from as small as 25 mm up to a colossal 1820 mm (1″ to 120″). This includes our Hines 1420 Induction Bender, which can handle pipes up to Ø1420 mm, and other models designed for various capacities. Our machines are also adept at processing pipes with substantial wall thickness, from standard specifications up to an astounding 150 mm.

The bending radius capabilities are equally impressive, spanning from tight 1.5D bends to virtually unlimited radii, allowing for incredible design flexibility. And when it comes to the bend angle, our machines offer precise control up to 270°, accommodating everything from gentle curves to sharp, functional turns. To see the full scope of what’s possible, explore our Induction Pipe Bending services.

Materials and Sizes Handled by Hines Induction Bending

Our induction tube bending machines are designed to be workhorses, capable of bending a vast array of materials and sizes to meet the most stringent project requirements. We pride ourselves on offering solutions for challenging applications that other bending methods simply cannot touch.

We regularly work with:

- Carbon steel: The backbone of many industrial applications.

- Stainless steel: Including specialized grades like Duplex and Super Duplex, essential for corrosive environments.

- Inconel: A high-performance alloy known for its resistance to extreme temperatures and corrosive media.

- Alloy steels: Engineered for specific strength and durability properties.

- Titanium: Lightweight and exceptionally strong, crucial for aerospace and medical fields.

- Aluminum: Valued for its lightweight properties and corrosion resistance.

Beyond traditional pipes and tubes, our machines excel at bending large diameter pipes and thick-walled tubes, which are critical in heavy industries. We also have extensive experience with bending structural sections, including H-beams, I-beams, channel steel, and square and rectangular hollow sections (HSS). This capability makes us an indispensable partner for complex structural projects.

Key Industries Served by Hines Induction Bending Technology

The precision, reliability, and versatility of our induction tube bending machines make them indispensable across a wide array of critical industries. At Hines Bending Systems, we are proud to contribute to projects that shape our world, from energy infrastructure to groundbreaking scientific endeavors.

Our technology is a cornerstone in:

- Oil & Gas: For pipelines (onshore and offshore), refineries, and petrochemical plants, where large-diameter, thick-walled bends are essential for safe and efficient fluid transport.

- Petrochemical: Creating intricate pipe networks that withstand high pressures and corrosive substances.

- Power Generation: Forming critical components for conventional, nuclear, and thermal power plants, including high-temperature steam lines and feedwater systems.

- Shipbuilding: Fabricating structural elements, fluid transfer systems, and other components for marine vessels.

- Aerospace: Producing lightweight yet incredibly strong components, a sector where precision and material integrity are paramount. This is exemplified by our work with organizations like NASA, for whom we’ve supplied bending machines for their demanding projects. More info about Hines’ work with NASA

- Architecture: Creating aesthetically pleasing and structurally sound curved elements for modern buildings, bridges, and artistic installations.

- Infrastructure: Building curved sections for bridges, tunnels, and other large-scale public works.

Our machines are deployed in demanding environments, performing tasks such as fabricating J-tubes and S-tubes for offshore energy, creating structural elements for international bus stations, and producing components for roller coasters. For instance, we were proud to see a Greiner Industries Installs Induction Bender from Hines Bending. This diverse application base underscores our commitment to providing cutting-edge bending solutions for every challenge.

Why Choose Hines Bending Systems for Your Induction Tube Bending Needs

When the success of your project hinges on perfectly bent tubes and pipes, the choice of your bending machine manufacturer is paramount. At Hines Bending Systems, we don’t just sell machines; we offer a partnership built on trust, unparalleled expertise, and a relentless commitment to your success.

What sets us apart? It’s our decades of experience, stretching back to 1975, which has allowed us to accumulate a wealth of knowledge that no other manufacturer can match. Our global installations speak volumes about the reliability and performance of our machines, operating efficiently in diverse environments worldwide. We specialize in custom solutions, working closely with each client—whether you’re in Fort Myers, Miami, Orlando, or anywhere across Florida and beyond—to design and build an induction tube bending machine that perfectly matches your unique requirements. This bespoke approach ensures optimal bending solutions, every time.

We are unwavering in our commitment to quality assurance. Every Hines machine is crafted to the highest industry standards, ensuring superior performance and longevity. This dedication to quality is why we stand as the #1 worldwide manufacturer, a title earned through consistent excellence. Furthermore, our comprehensive technical support and thorough operator training programs ensure that your team is fully equipped to maximize the potential of your Hines bender. And because safety is always a top priority, our machines are equipped with advanced safety features to protect your personnel and investment.

The Importance of Expertise: Hines Sets the Industry Standard

In the complex world of tube and pipe bending, expertise isn’t just an advantage; it’s a necessity. At Hines Bending Systems, we don’t just meet industry standards; we often help define them. Our deep understanding of metallurgy, mechanical engineering, and control systems allows us to tackle the most challenging bending applications with confidence.

Our expertise is evident in our ability to:

- Meet and Exceed Industry Standards: We design and build machines that adhere to the most rigorous international standards, ensuring the integrity and reliability of your bent products.

- Handle Complex Geometries: From multi-radius bends to intricate S-shapes, our engineers can devise solutions for virtually any design.

- Process High-Strength Materials: We specialize in bending advanced alloys and thick-walled pipes that would pose impossible challenges for lesser machines.

- Supply Critical Industries: Our track record of supplying organizations like NASA and major energy companies underscores our capability to deliver for projects where failure is not an option.

When you partner with Hines, you’re tapping into a legacy of innovation and a team of experts dedicated to finding the perfect bending solution for you. We are the trusted Induction Bending Company because we combine cutting-edge technology with unparalleled knowledge.

Maintenance and Safety: Hines’ Commitment to Reliability

A high-performance induction tube bending machine is a significant investment, and at Hines Bending Systems, we ensure that your investment delivers reliable, safe operation for years to come. Our commitment extends far beyond the sale, encompassing robust maintenance protocols and stringent safety standards.

We emphasize the importance of routine maintenance checks to keep your machine operating at peak efficiency. This includes:

- Cooling System Upkeep: Regular inspection and maintenance of the water quenching system are crucial for consistent cooling and preventing overheating of components.

- Coil Inspection: Ensuring the induction coil is in optimal condition is vital for efficient and uniform heating.

- Hydraulic System Checks: Monitoring fluid levels, pressure, and hose integrity prevents unexpected downtime.

Beyond maintenance, operator safety protocols are paramount. Our machines are designed with comprehensive safety features, including:

- Emergency Stop Systems: Strategically placed buttons allow for immediate shutdown in critical situations.

- Thermal Protection: Sensors and interlocks prevent operation if temperatures exceed safe limits, protecting both the machine and personnel.

- Shielding and Enclosures: Physical barriers protect operators from moving parts and the heat generated during bending.

We provide comprehensive bender training to ensure that your operators in Florida and worldwide are fully proficient in both the operation and safe maintenance of our machines. This proactive approach to reliability and safety minimizes risks, extends machine lifespan, and ensures continuous, productive operation.

Conclusion: Trust Hines Bending Systems for Precision, Quality, and Innovation

In the dynamic world of modern manufacturing, where precision, material integrity, and cost-efficiency are paramount, the induction tube bending machine stands out as a transformative technology. Throughout this guide, we’ve unveiled the intricate workings, unparalleled advantages, and diverse applications of this advanced bending method.

We’ve seen how induction bending surpasses traditional cold bending, offering solutions with minimal wall thinning, superior surface finishes, and the capacity to handle high-strength materials and challenging geometries. This technology is not just about bending pipes; it’s about enabling innovation and pushing the boundaries of what’s possible in industries ranging from aerospace to energy.

At the heart of this revolution is Hines Bending Systems. Our nearly five decades of experience, our position as the #1 worldwide manufacturer, and our unwavering commitment to custom-engineered solutions make us the definitive partner for your bending needs. We don’t just sell machines; we provide comprehensive solutions, backed by unparalleled expertise, rigorous quality assurance, and dedicated support.

When you need a bending solution that delivers uncompromising precision, exceptional quality, and continuous innovation, there’s only one choice. Learn why you should buy a Hines Bender and find the difference that true industry leadership makes.