From Straight Pipes to Complex Structures

A bend pipe machine is specialized manufacturing equipment that shapes straight pipes and tubes into complex geometries without welding. Using controlled force and precise tooling, these machines create accurate bends while maintaining the pipe’s structural integrity and dimensional accuracy.

Key Types of Bend Pipe Machines:

- Rotary Draw Benders

- Roll Benders

- Press Benders

- Induction Benders

- CNC Machines

From sleek automotive exhausts to intricate aerospace hydraulic lines, bent pipes are the backbone of modern manufacturing. What might look like simple curves actually represent sophisticated engineering that transforms straight metal tubes into essential components.

The ability to bend pipes without compromising their strength has revolutionized industries. Instead of welding sections together—which creates weak points—manufacturers can create seamless, flowing structures that are stronger and more aesthetically pleasing.

Precision pipe bending is critical across industries. Aerospace needs lightweight, durable fuel lines, automotive requires perfectly fitted exhaust systems, and furniture makers depend on smooth curves. Each application demands specific levels of precision, from the exacting tolerances required for NASA projects to the high-volume needs of commercial production.

The technology has advanced significantly since the first pipe bending machine patent in 1930. Today’s machines combine computer control and advanced materials science to achieve bends that were once impossible.

Bend pipe machine word roundup:

The Core of Bending: Understanding the Technology

At Hines Bending Systems, we’ve mastered the science of changing straight metal into perfect curves. The process involves controlled metal deformation, where precise forces shape a pipe while preventing issues like flattening or wrinkling. Whether using cold bending for smooth finishes or hot bending for tougher materials, the key is precise control. While the technology has evolved since the first pipe bending machine patent from 1930, this principle remains. Our expertise at Hines ensures every bend meets the highest standards, from spacecraft components to furniture frames. Learn more about our advanced systems at More info about CNC Bending Machines.

Choosing the Right Bending Technology

Picking the right bending technology is critical, and at Hines Bending Systems, we guide you to the perfect solution. While traditional hydraulic systems are effective, modern electric motion technology is cleaner, quieter, and more efficient. The true game-changer is CNC control, which replaces older NC programming to deliver unparalleled repeatability and precision. CNC machines follow exact specifications, ensuring every bend is identical, which slashes material waste and production time. This level of control is essential for modern manufacturing. For more details, see What is CNC Tube Bending and our NC vs CNC guide.

Specialized Bending Methods for Demanding Applications

Your most challenging projects deserve the perfect bending technique, and at Hines Bending Systems, we’ve mastered them all. Key methods include:

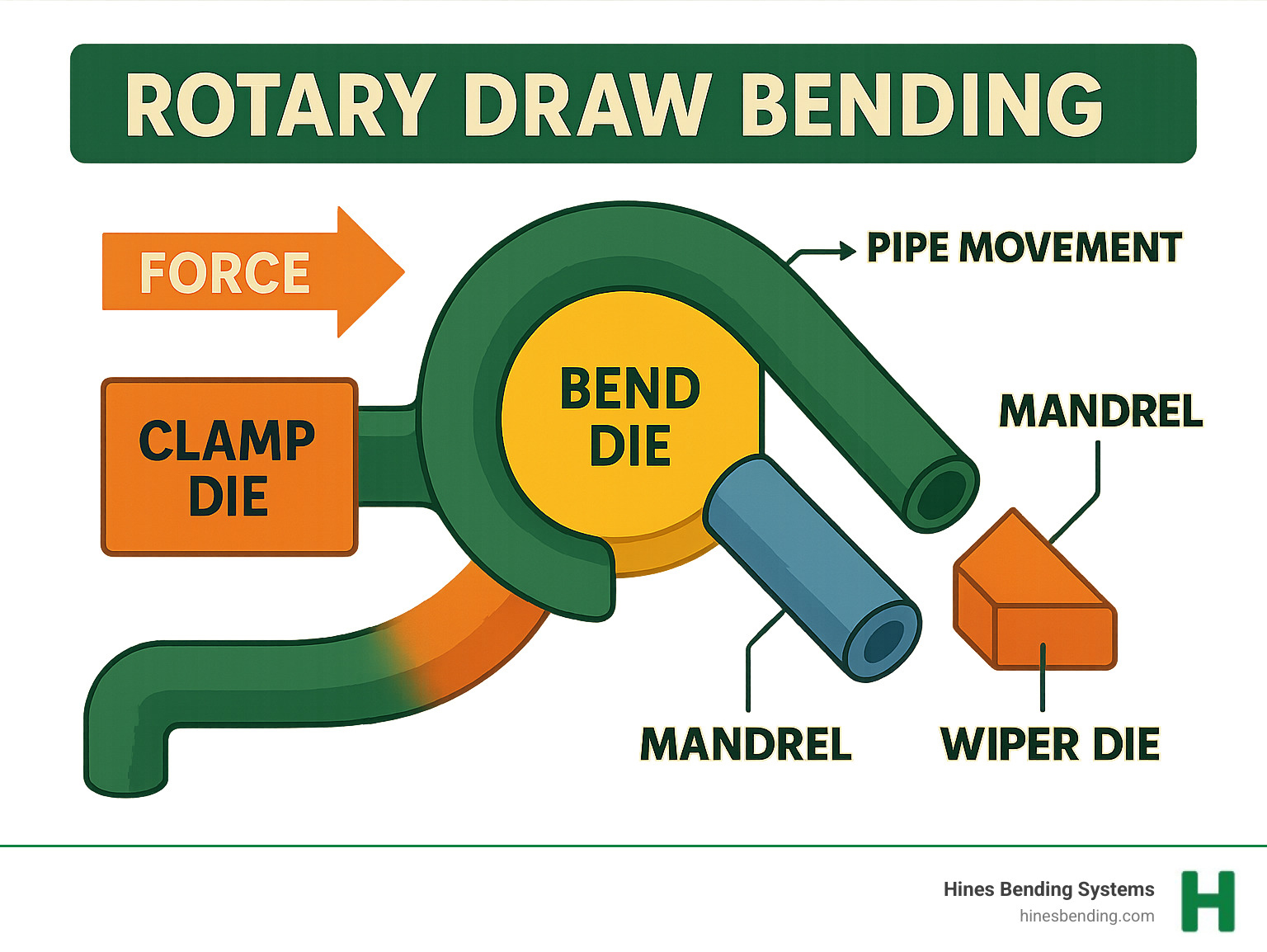

- Rotary draw bending: The gold standard for high-quality, precise bends.

- Mandrel bending: Essential for tight radius bends while maintaining the pipe’s internal integrity. Find out more about Mandrel Bending Machines.

- Induction bending: The solution for large diameters, thick walls, and exotic materials. Learn about our powerful Induction Benders.

- Roll bending: Creates large, sweeping curves and spirals for structural applications.

As the world’s #1 manufacturer of benders, we have the expertise to identify the ideal solution for your unique requirements.

Why a Specialized Bend Pipe Machine is a Game-Changer

In modern manufacturing, a specialized bend pipe machine is a strategic investment that transforms your business. At Hines Bending Systems, we’ve seen clients leap ahead by adopting the right technology. The benefits are clear:

- Increased Efficiency: Advanced benders streamline production by eliminating cuts and welds, reducing manual labor and speeding up project completion.

- Cost Reduction: Fewer welds mean less material and labor costs. Precision bending minimizes waste, and the long-term savings quickly justify the initial investment.

- Design Freedom: Designers can create flowing, complex shapes that are both aesthetically superior and more functional than designs limited by welded joints.

- Improved Strength: A seamless bend maintains the material’s original strength, creating a more durable and reliable component compared to welded parts, which can be weak points.

Investing in a quality bend pipe machine from Hines is a smart choice for your bottom line and product quality. Find more Reasons to Invest in Pipe Bending Equipment.

Materials and Applications for a Bend Pipe Machine

A modern bend pipe machine from Hines Bending Systems demonstrates incredible versatility, shaping a vast range of materials with perfect results every time. Our machines are expertly tuned to handle common materials like Steel, Stainless Steel, Aluminum, and Copper Alloys, as well as high-performance materials like Titanium and Inconel. We also handle specialized alloys such as Chromoly (4130N) and Docol R8, proving that with the right technology from Hines, almost any bending challenge is possible.

Industries Transformed by Precision Bending

Precision pipe bending has transformed major industries, and Hines Bending Systems is proud to lead this change with our unparalleled expertise.

- In aerospace, where precision is paramount, our machines craft critical hydraulic and fuel systems. Our work with agencies like NASA is a testament to our capabilities. Learn about Hines working with NASA.

- The automotive industry uses bent pipes for everything from exhaust systems to safety roll cages, directly impacting vehicle performance and safety.

- Shipbuilding and the energy sector rely on our robust machines to bend the large-diameter, thick-walled pipes needed for pipelines, structures, and processing plants.

- From architectural handrails to stylish furniture, precision bending provides the smooth curves and structural integrity for countless everyday products. See more about Steel Pipe Bending Machines.

The common thread is the need for reliable, high-quality bends. Hines Bending Systems delivers superior solutions for any industry.

Key Innovations Shaping the Future of Pipe Bending

The future of pipe bending is here, and at Hines Bending Systems, we are leading the charge. As the #1 worldwide manufacturer of benders, we integrate key innovations to redefine what a bend pipe machine can do. Breakthroughs like all-electric machines, advanced CNC controls, robotic integration for automated loading, and software simulation are changing the industry. These technologies boost productivity, improve safety, and allow engineers to perfect bends digitally before any material is used. Our commitment is to build these advancements into custom solutions that meet your exact needs. Explore our Automatic Pipe Bending Machines for fully automated solutions.

The Rise of All-Electric and Hybrid Systems

The rise of all-electric and hybrid systems is a quiet revolution delivering measurable benefits. At Hines, we’ve acceptd this technology because it offers significant advantages:

- Superior Performance: These systems are more energy-efficient, quieter, and require less maintenance than traditional hydraulics. They also offer increased speed and control for faster cycle times and tighter tolerances.

- Advanced Capabilities: With features like 11-axis control, all-electric machines provide unparalleled flexibility for creating complex, multi-plane bends that were once impossible.

Our extensive experience with these systems—backed by more installations worldwide than any other manufacturer—ensures you get the best in precision and reliability. Learn more about our CNC Tube Benders.

The Importance of Controls and Software

The software and controls are the brain of a modern bend pipe machine. At Hines Bending Systems, we know that advanced controls open up a machine’s full potential. User-friendly interfaces simplify operation, while critical software features deliver exceptional results. Springback compensation automatically corrects for material memory, eliminating guesswork and reducing waste. Data storage ensures perfect consistency for repeat orders, a necessity for clients like NASA. Furthermore, remote diagnostics reduce downtime by allowing our experts to provide swift support. These smart systems improve cycle times, boost productivity, and maximize your return on investment. We complement these systems with a full range of Tube and Pipe Bender Accessories.

Selecting the Right Bending Partner: What to Consider

Choosing the right bend pipe machine is a significant investment, but selecting the right partner is even more critical. At Hines Bending Systems, we build lasting relationships by offering expert guidance and custom solutions for your success. When evaluating your options, consider these key factors:

| Factor | Description |

|---|---|

| Customization vs. Off-the-shelf | Do you need a standard machine for everyday tasks, or are you facing unique challenges that demand a highly specialized, custom-engineered solution? We’re thrilled to excel at both! Our true passion lies in tailoring solutions to your exact needs, even for the trickiest, most complex projects. |

| Material Expertise | Does your potential partner truly understand the ins and outs of bending different materials? Think stainless steel, lightweight aluminum, super-strong titanium, or even exotic alloys like Inconel. Our deep, deep knowledge across a vast range of materials means we can guarantee optimal bending parameters and amazing outcomes, every single time. |

| Production Volume | Are you looking for a machine for exciting new prototypes and smaller batch runs, or do you need a high-speed, fully automated system for massive production volumes? We’ve got you covered! We perfectly scale our solutions to match your throughput requirements, whether you’re a cozy small shop or a busy industrial giant. |

| Required Tolerances | How incredibly precise do your bends need to be? From general fabrication that needs to be just right, to the absolute aerospace-grade exactitude required for NASA projects, we deliver machines that hit the tightest industry tolerances. Precision is in our DNA. |

| Training & Support | What kind of friendly, ongoing support can you expect after your purchase? We wholeheartedly believe in empowering our clients. That means comprehensive training to get you up and running, plus robust after-sales service that ensures you get the absolute most out of your investment for years and years to come. |

| Machine longevity | Is the machine truly built to stand the test of time? We craft our machines with the highest quality materials and superior engineering standards. They’re designed for rigorous, long-term use, unlike those cheaper alternatives that might compromise integrity and performance when you need them most. |

The best value comes from a partnership built on trust, expertise, and a shared commitment to quality. For more insights on making an informed decision, explore What to Know About Buying a Metal Tube Bender for Sale.

Beyond the Machine: The Value of Expertise and Support

A bend pipe machine‘s true power is open uped by the expertise and support behind it. At Hines Bending Systems, our value goes far beyond the initial sale. Our strength lies in custom solution development, where our engineers work with you to design a bender perfectly custom to your needs. This includes deep application engineering to recommend the most effective method and machine setup. We provide comprehensive operator training to ensure your team can maximize the machine’s potential safely and efficiently. Learn more about our Tube and Pipe Bender Training.

As the #1 worldwide manufacturer with more global installations than anyone, our expertise is proven across diverse industries and trusted by clients like NASA. Our robust after-sales service, including remote diagnostics and on-site assistance, minimizes downtime and ensures your continued success. Choosing Hines means gaining a dedicated partner committed to your profitability and operational excellence.

Conclusion: Bending Toward a Future of Precision and Quality

The evolution of the bend pipe machine, from early mechanics to today’s sophisticated CNC systems, has been transformative. These machines are the backbone of modern manufacturing, enabling the complex designs seen in aerospace, automotive, and energy sectors. We are honored that our machines meet the exacting standards of clients like NASA.

The future is driven by innovations like all-electric systems and intelligent software, which deliver unprecedented efficiency and precision. Yet, technology alone is not enough. The true value lies in the partnership behind the machine. At Hines Bending Systems, we solve problems. As the #1 worldwide manufacturer of benders, our unparalleled expertise is why industry leaders choose us.

We develop custom solutions and build relationships founded on trust and support. Our commitment continues long after the sale with comprehensive training and service, ensuring you get the most from your investment. The future of pipe bending is bright, and Hines Bending Systems is shaping it, one precision bend at a time.