Description

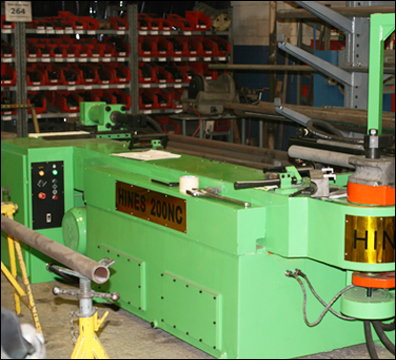

200 NC Tube Bender Applications

The 200 NC tube bender is used in the power generation industry (for boiler and heat exchange), plumbing, automotive (mufflers, headers, exhaust), steel building construction and ship repairs.

FEATURES OF THE 200 NC TUBE BENDER

- Hydraulic Manifolds Interchangeable (Parker, Vickers, etc.)

- Solid Machined Steel Bend Arms

- Easy Touch Screen Operation

- Includes All Die Holders

- Operator Safety Features

- Manifold Style Hydraulic and High Pressure Filter

STANDARD

- Wiper Die Holder

- Overhead Tie Bar (Eliminates Die Deflection)

- Pressure Die Assist

- Pressure Die Assist Rear Support Roller

- Mandrel Rod SAE Thread Supplied (1)

- Mandrel Lubricator

- Mandrel Extractor

- Mandrel Early Out Programmable

- PLC Controller – Mitsubishi FX3U

- Memory Capacity: 100 job storage, 6 bends per part

- Touch Screen (Proface America)

- Tube Piece Counter

- Clockwise Rotation

- Dual Stage Pump Hydraulic System

ADDITIONAL SPECIFICATIONS FOR THE 200 NC

- Capacity: 3″ OD x .125 Wall

- Standard Maximum Radius: 12 inch

- Maximum Bend Angle: 190 degrees

- Bend Angle Accuracy (+ / -): 0.1 degree

- Bend Arm Speed: 5 RPM

- Maximum Tube Length Over Mandrel: 9 feet

- Motor: 15 HP

- Operating Pressure: 2000 psi

- Reservoir Capacity: 135 US gallons

- Approximate Weight: 7700lbs

- Approximate Dimensions: 13′ L x 3.5′ W x 4′ H

- Voltage: 220/3 Phase/60Hz (50 Hz Optional)