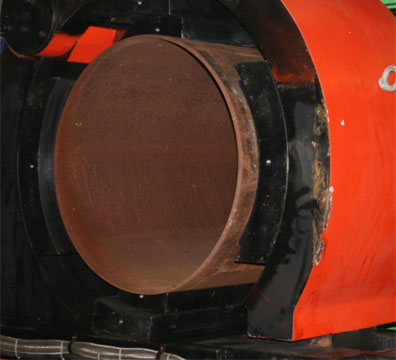

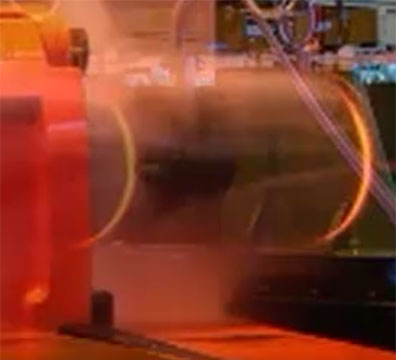

Description

Empirically, the 300 NC-P bender has established itself as the bender of choice by many power plant facilities around the globe.

300 NC-P Tube Bender Applications

The 300 NC-P bender is used exclusively in the petro chemical and the electrical power plant industries.

If you need a machine or tooling quote, click here.

Return to home page to see additional tube benders.

FEATURES OF THE 300 NC-P TUBE BENDER

- Hydraulic Manifolds Interchangeable (Parker, Vickers, etc.)

- Solid Machined Steel Bend Arms

- Easy Touch Screen Operation

- Includes All Die Holders

- Operator Safety Features

- Manifold Style Hydraulic and High Pressure Filter

STANDARD

- Pressure Die Holder

- Wiper Die Holder

- Overhead Tie Bar (Eliminates Die Deflection)

- Pressure Die Assist

- Pressure Die Assist Rear Support Roller

- Mandrel Rod SAE Thread Supplied (1)

- Mandrel Lubricator

- Mandrel Extractor

- Mandrel Early Out Programmable

- PLC Controller – Mitsubishi FX3U Stores 200 Jobs – 6 bends/job

- Touch Screen (Proface America)

- Tube Piece Counter

- Clockwise Rotation

- Dual Stage Pump Hydraulic System

ADDITIONAL SPECIFICATIONS FOR THE 300 NC-P

- Capacity: 3 1/2” O.D. x .50 Wall

- Standard Maximum Radius: 12 inch

- Maximum Bend Angle: 190 degrees

- Bend Angle Accuracy (+ / -): 0.1 degree

- Bend Arm Speed: 1.5 RPM

- Motor: 40 HP

- Operating Pressure: 2000 psi

- Reservoir Capacity: 240 US gallons

- Approximate Weight: 17000lbs

- Approximate Dimensions: 16′ L x 7′ W x 6′ H

- Voltage: 440/480/3 Phase/60Hz

- Rear Boost