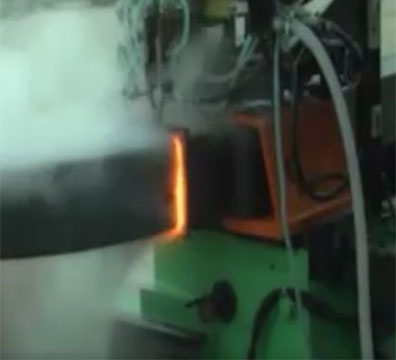

Description

810 Induction Bender Applications

The 810 Induction Bender is perfect for:

The 810 Induction Bender is perfect for:

- Petrochemical

- Thermal or nuclear power plants

- Mining

- Agro-food

- Paper

- Oil and gas (onshore and offshore pipelines)

- Highway billboards

- Structure construction

- Solar companies

If you need a machine or tooling quote, click here.

Return to home page to see additional tube benders.

STANDARD FEATURES OF THE 810 INDUCTION BENDER

- All functions electrically and hydraulically controlled.

- Dual Hydraulic Systems.

- Touch screen displays bend degree. Stops the machine when arriving to the preset degree value.

- Easily accessible transformer.

- Tube support included.

- Operator panel included.

- Electrical requirements per requisition. All available.

- Adjustable power.

- The output voltage fluctuation is within +/- 1% even if the input power voltage fluctuates +/- 10%. This keeps temperature consistent inside the inductor during the heating process.

- Built-in surge protection.

- Phase locking is employed to track frequency so that inverter operates safely and efficiently.

- Start-up at zero voltage. No amperage draw.

- All parameters are pre-set at factory. No need to recalibrate.

SPECIFICATIONS FOR THE 810 INDUCTION BENDER

- Max O.D. x Wall (mm) – 810 x 25

- Min O.D. (mm) – 219

- Maximum Bend Angle: 180 degrees

- CLR

- Range (mm) – 650-4100

- Min (R/D) – 3

- Max Main Cylinder Stroke (M) – 6.4

- Induction Power

- Type (KGPS) – 600

- Power (KW) – 600

- Frequency (KHz) – 0.8 to 1

- Bend Speed (mm/sec) – 0.3 to 4

- Rear Clamp Speed (M/min) – 1.5

- Rear Clamp Back (M/min) – 3

- System Pressure (mpa) – 16

- Machine CL Height (M) – 1.6

- Overall Dimensions (M) – 18 x 6.3 x 3

- Machine Weight (tons) – 78