Metal pipe bending machines have revolutionized the way industries handle and shape metal. These machines are essential for bending metal pipes and tubes with precision, speed, and consistency. Whether you’re in aerospace, automotive, or construction, these versatile tools ensure that complex bend angles and specifications are met with ease.

Here’s a quick overview of what a metal pipe bending machine can offer:

- Efficiency: Streamlines production, saving time and reducing labor costs.

- Versatility: Handles a wide range of materials like stainless steel, carbon steel, and aluminum.

- Precision: Achieves high accuracy for demanding applications.

At Hines Bending Systems, we pride ourselves on being the forefront leader in bending technology. With clients like NASA, our commitment to quality, innovation, and custom solutions sets us apart. Our machines are engineered to deliver best performance and reliability.

Stay tuned as we dive deeper into the fascinating world of metal pipe bending machines and explore their applications, from automotive exhausts to refinery pipes.

Understanding Metal Pipe Bending Machines

At Hines Bending Systems, we pride ourselves on being the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. Our machines are engineered with cutting-edge technology to ensure superior performance and reliability, making us the industry leader in metal pipe bending solutions.

Manual Benders

For hobbyists and small projects, our manual benders offer an economical and simple solution. While they rely on human strength, they are perfect for light, occasional work. Hines Bending Systems ensures that even our manual benders meet the highest quality standards, providing a cost-effective solution without compromising on integrity.

Powered Benders

Custom shops looking to increase efficiency will find our powered benders to be a game-changer. Utilizing electric or pneumatic power, these machines deliver speed and accuracy, ideal for small to medium-sized operations. Hines’ powered benders are designed to reduce manual effort while maintaining precision, setting us apart from competitors.

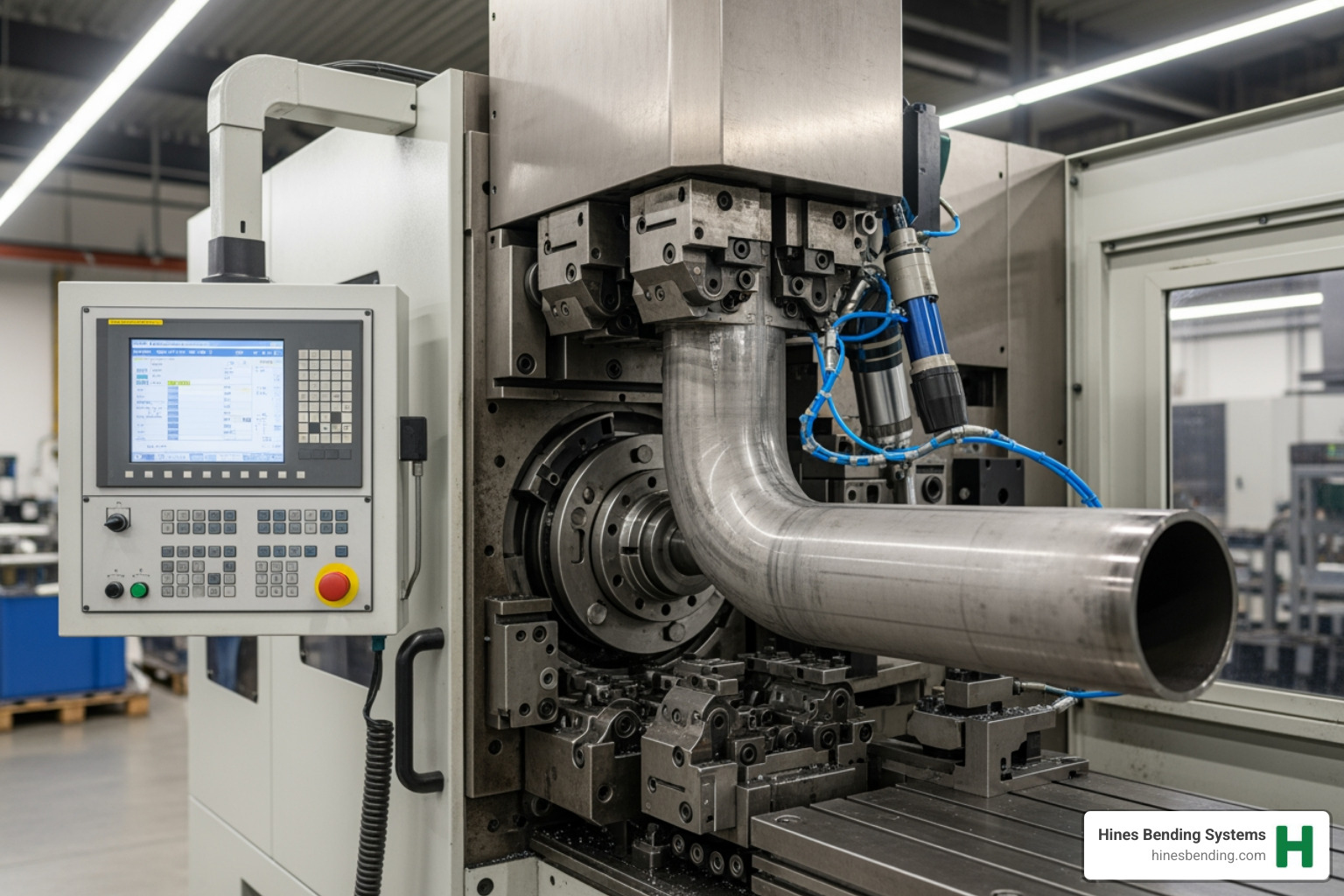

Programmable Benders

When precision and repeatability are crucial, our programmable benders are the go-to choice. Favored in production shops, these machines store and execute multiple bending programs with computer numerical control (CNC), ensuring consistent results. Hines Bending Systems’ expertise in high-volume production makes us the preferred choice for clients worldwide.

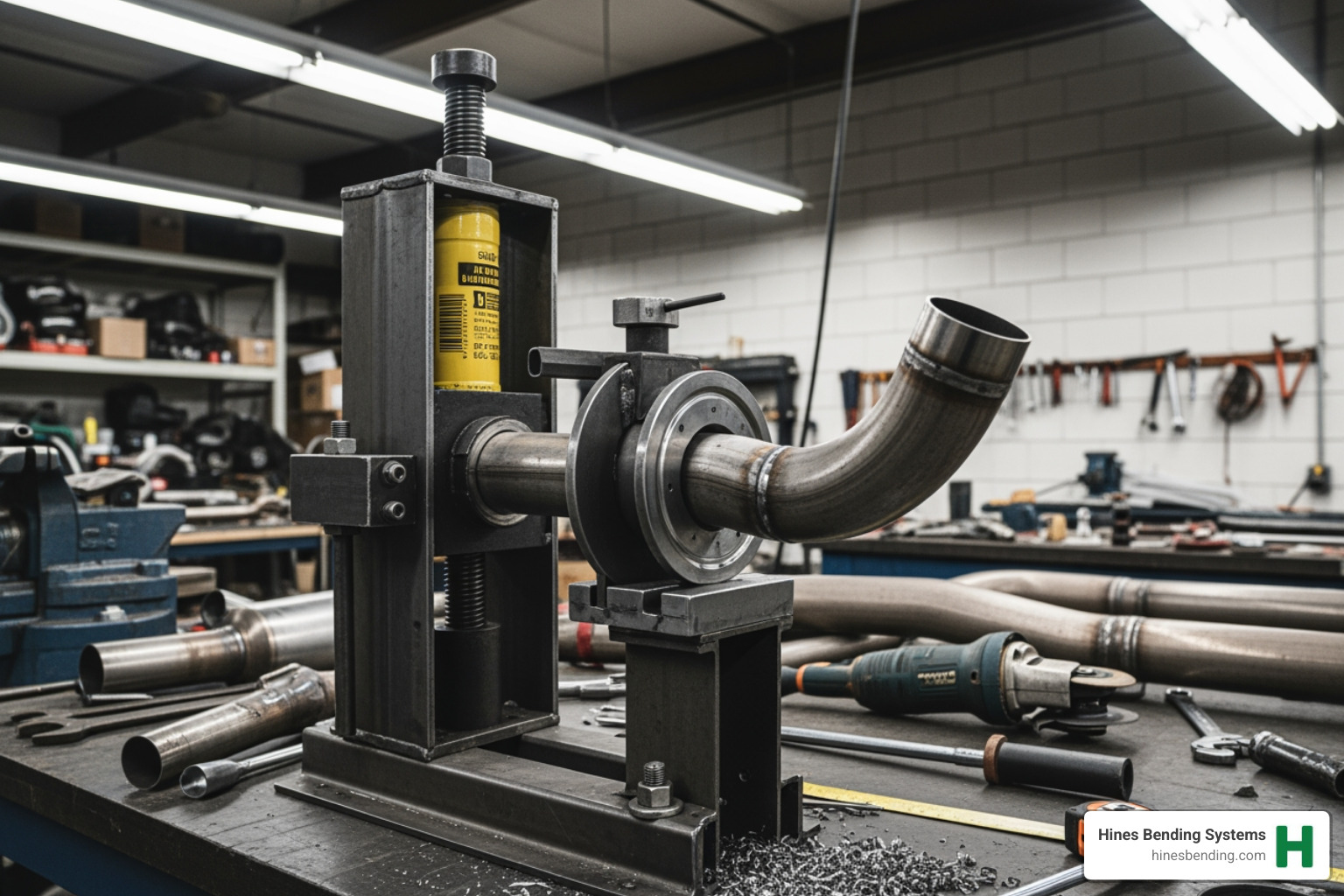

Hydraulic Benders

Renowned for their durability and strength, our hydraulic benders handle heavy-duty tasks with ease. Perfect for industries dealing with thicker and tougher materials, these machines offer unmatched power and design depth. Hines’ commitment to quality ensures that our hydraulic benders outperform cheaper alternatives.

Rotary Draw Benders

For the highest quality bends, our rotary draw benders are the industry standard. Providing precise control over bend angles and radii, they ensure flawless results every time. Essential for applications where aesthetic and structural integrity are paramount, Hines Bending Systems’ rotary draw benders are trusted by industries such as automotive and aerospace.

Our commitment to innovation is evident in our Dual Stack CNC Push Bender and Roll Bender, addressing the growing demands of various industries. We work closely with clients to provide custom solutions, ensuring their specific needs are met. Hines Bending Systems also offers training and continuing education to enhance the efficiency of engineering and production for our clients.

Stay tuned as we explore the key features to consider when selecting a metal pipe bending machine.

Types of Metal Pipe Bending Machines

Manual Benders

Manual benders are a top choice for hobbyists and those working on small projects. They are economical and straightforward, perfect for tasks that don’t require the speed or precision of more advanced machines. Manual benders rely on human power, making them ideal for light, occasional work. At Hines Bending Systems, we ensure that even our manual benders are crafted with the highest quality materials, providing reliability and durability unmatched in the industry.

Powered Benders

For custom shops aiming to boost efficiency, powered benders offer a significant advantage. These machines use electric or pneumatic power to bend pipes swiftly and accurately. Powered benders are perfect for operations that need more speed and less manual effort than manual benders can provide. Hines Bending Systems’ powered benders are engineered to deliver exceptional performance, ensuring that small to medium-sized jobs are completed with precision and speed.

Programmable Benders

In production shops where control and repeatability are essential, programmable benders are indispensable. These machines, equipped with computer numerical control (CNC), can store and execute multiple bending programs. This capability ensures consistent results, making programmable benders highly valuable for high-volume production tasks. Hines Bending Systems leads the industry with our state-of-the-art programmable benders, designed to meet the rigorous demands of modern manufacturing.

Hydraulic Benders

Known for their durability and strength, hydraulic benders handle heavy-duty bending tasks with ease. Their robust hydraulic systems make them ideal for industries dealing with thicker and tougher materials. Hines Bending Systems’ hydraulic benders are built to withstand the most demanding applications, providing a level of power and design that sets the standard in the industry.

Rotary Draw Benders

For the highest quality bends, rotary draw benders set the industry standard. These machines provide precise control over bend angles and radii, ensuring flawless results every time. Rotary draw benders are crucial for applications where both the aesthetic and structural integrity of the bend are important, such as in the automotive and aerospace industries. Hines Bending Systems’ rotary draw benders are engineered to deliver unparalleled precision and quality, making them the preferred choice for discerning clients.

At Hines Bending Systems, we offer a comprehensive range of metal pipe bending machines custom to meet the diverse needs of our clients. Our machines are engineered with cutting-edge technology to ensure superior performance and reliability. Whether you need a manual bender for small projects or a programmable bender for high-volume production, Hines has the perfect solution for you. Our commitment to quality and innovation makes us the #1 choice for bending solutions worldwide.

Stay tuned as we explore the key features to consider when selecting a metal pipe bending machine.

Key Features to Consider

When selecting a metal pipe bending machine, it’s important to focus on specific features that match your project needs. Here’s a breakdown of the key elements to keep in mind:

Bending Capacity

The bending capacity determines the maximum size and thickness of the pipe or tube that the machine can handle. At Hines Bending Systems, our machines are engineered to accommodate a wide range of sizes, ensuring that even the most demanding projects can be completed with ease. Whether you’re working with thin-walled tubing or thick, heavy-duty pipes, understanding the bending capacity is crucial for choosing the right machine.

Bend Radii

The bend radius is another critical factor. It refers to the tightness of the bend that the machine can achieve. Our innovative technology allows for precise control over bend radii, ensuring that you can create the exact curvature needed for your project. This feature is especially important in industries like automotive and aerospace, where precision is paramount.

Construction Materials

The materials used in constructing the bending machine itself can affect its durability and performance. Hines Bending Systems takes pride in using only the highest quality materials, such as aircraft-grade aluminum and US-milled steel. This commitment to quality ensures that our machines not only perform exceptionally well but also stand the test of time.

Control Systems

Control systems are the brains of the bending machine, dictating its functionality and ease of use. Our machines are equipped with advanced control systems that offer both manual and automated options, providing flexibility for different projects. Whether you’re looking for simple manual controls or sophisticated CNC systems for high-volume production, Hines has the right solution. Our programmable benders, for example, allow for storing and executing multiple bending programs, ensuring consistency and efficiency.

By focusing on these key features, you can select a metal pipe bending machine that perfectly aligns with your needs, ensuring efficiency, precision, and durability in every project. At Hines Bending Systems, we are dedicated to providing machines that not only meet but exceed industry standards, offering unparalleled performance and reliability.

How to Choose the Right Metal Pipe Bending Machine

Selecting the perfect metal pipe bending machine involves understanding your project requirements, budget considerations, and potential upgrade options. Let’s break it down.

Project Requirements

First, consider the specific demands of your project. Are you working with complex shapes or simple bends? Do you need high precision for industries like aerospace or automotive? At Hines Bending Systems, we offer a range of machines to suit any project. Our programmable benders, for instance, are perfect for high-volume production where consistency is key. For custom projects requiring flexibility, our machines can be custom to meet unique specifications.

Budget Considerations

Budget is always a crucial factor. While it’s tempting to opt for cheaper alternatives, investing in a high-quality machine from Hines Bending Systems pays off in the long run. Our machines are designed to last, reducing the need for frequent replacements or repairs. Plus, they come with advanced features that can save time and increase productivity. A well-chosen machine is not just a purchase—it’s an investment in your business’s future.

Upgrade Options

Finally, think about future-proofing your investment. As your business grows, your needs may evolve. Hines Bending Systems offers upgrade options that allow you to improve your machine’s capabilities without needing a complete replacement. Our commitment to innovation means you’ll always have access to the latest technology, ensuring your machine remains at the cutting edge of the industry.

By carefully considering these factors, you can choose a metal pipe bending machine that not only meets your current needs but also adapts to future challenges. At Hines Bending Systems, we’re here to guide you through every step, ensuring you make the best choice for your business.

Frequently Asked Questions about Metal Pipe Bending Machines

What materials can be bent with these machines?

When it comes to versatility, metal pipe bending machines from Hines Bending Systems are best. Our machines can handle a wide array of materials, making them suitable for diverse applications. Here’s a quick look at the materials you can bend:

- Stainless Steel: Ideal for sanitary and architectural projects.

- Carbon Steel: Perfect for industrial applications.

- Aluminum: Great for lightweight projects.

- Copper: Works well for plumbing and decorative elements.

- Brass: Often used in musical instruments and fittings.

- Titanium: Used in aerospace and high-performance applications.

Our machines offer the flexibility to bend these materials with precision and ease, ensuring high-quality results every time.

How do I maintain a metal pipe bending machine?

Proper maintenance is key to ensuring the longevity and performance of your metal pipe bending machine. Here are some tips to keep your machine in top shape:

- Regular Cleaning: Keep the machine clean from dust and debris to prevent wear and tear.

- Lubrication: Ensure all moving parts are well-lubricated to reduce friction and wear.

- Routine Inspections: Conduct regular checks for any signs of damage or loose components.

- Professional Servicing: Schedule periodic maintenance with professionals to address any potential issues early.

By following these maintenance tips, you can significantly extend the life of your machine, ensuring it continues to perform optimally.

Can these machines be used for custom projects?

Absolutely! One of the standout features of Hines Bending Systems is the ability to customize our machines to fit specific project needs. Whether you’re working on bespoke designs or need to adjust to unique specifications, our machines offer the flexibility required for custom projects.

With Hines, you can start with a base model and upgrade as your needs evolve, ensuring that you always have the right tool for the job. This customization capability makes our machines a valuable asset for any business looking to tackle a wide range of bending challenges.

Conclusion

At Hines Bending Systems, we pride ourselves on delivering optimal solutions for all your bending needs. With our extensive expertise and best experience, we stand as the #1 manufacturer of tube, pipe, and induction benders worldwide. Our commitment to quality ensures that our machines meet the highest industry standards, providing durability and precision for every project.

Our machines are not just tools; they are investments in your business’s future. We understand the unique challenges faced by various industries and offer custom solutions custom to your specific requirements. This dedication to customization ensures that whether you’re working on simple or complex projects, Hines Bending Systems has the right solution for you.

With installations across the globe, including partnerships with prestigious organizations like NASA, our reputation speaks for itself. We are dedicated to pushing the boundaries of innovation, as seen in our advanced technologies like the Dual Stack CNC Push Bender and Roll Bender. These innovations are designed to meet the growing demands of the industry, ensuring that you stay ahead of the competition.

Our customer-centric approach means we are always here to support you, from initial consultation to ongoing training and support. We believe that by working closely with our clients, we can deliver not just machines, but solutions that improve your production capabilities and efficiency.

To learn more about our cutting-edge CNC bending machines and how they can transform your operations, visit our CNC Bending Machine page.

Hines Bending Systems is your partner in precision, quality, and innovation. Trust us to deliver the best bending solutions for your business.