Are you interested in CNC tube bending machines? Tube bending machines of this kind are designed to minimize the time it takes to set up while maximizing production. There are multiple companies that offer their own designs with features like electrical servo-drives on all axes and more. They are available in multi-stack as well as single versions.

Continue reading to learn more about how CNC tube bending machines work. If you have any more questions or are interested in tube bending machines for sale, please contact Hines Bending today.

Multi Stack CNC Tube Benders

CNC tube benders that use multistack benders are designed to facilitate complicated bending projects without the need to replace the tools. Some companies are unable to adopt a multistack tool for stability reasons. If this is the case, it is recommended that an automatic die clamp changing system be used.

An automatic die clamp system is convenient because it can incorporate up to eight clamp dies. Choosing between single and multi stack should be based on your business’ needs. A tube bending machine company can help you choose the best one for your business.

CNC Bending Procedures

CNC tube bending machines offer users a number of features that can improve convenience and production. These bending procedures are fully prommable. Boosting is done via the transport carriage in conjunction with boosting in the area of pressure die. This boosting can minimize wall thinnings in the outer bend and make narrow bends easier.

CNC Bending Templates

CNC tube benders use a bending template. The template helps facilitate pipe bending to the angle required. The unbent portion of the pipe or tube is supported on a pipe that can support rail carries. Users can also adjust the height through a drive control unit. The height that the pipe has been moved to is determined through a drive.

By adjusting the height through a drive, it can best be used for stop-less positioning. This allows the pipe-supporting rail to adjust to a height already indicated by the CNC control unit. A functioning program is used before the height of the pipe has been moved.

When to purchase a CNC bending machine?

The last quarter of the year is a popular time to purchase a bender for sale. Many companies want to get their machine and tooling on the books before the end of the year. It is another reason why a bender for sale and tooling orders will back up in the last quarter. It is not uncommon to add several weeks more for a tooling order. And, as a bender for sale are sold out of stock, new production is the only way to go. So even though a bender and tooling purchase orders are received before the end of the year delivery will be in the New Year. For that reason, it pays to plan ahead when buying a bender for sale.

What are the steps to get a bender?

First and foremost, get your quotations early. As mentioned the time of year can greatly influence the delivery of your bender for sale and the required tooling. The quotation process will require the right questions are asked. This ensures you get the correct bender for sale and tooling.

Bender for Sale Quotation Process

Preparing for the quotation process requires just a few steps. You will want to know the bend specifications for each bend. This includes outside diameter, wall thickness and material type. In addition, the radius of the bends and degree of bends.

Outside Diameter

First, know the outside diameter of the tube or pipes you will bend on the bender for sale. It is the starting point for the right model of bender for sale. Recall that tube and pipe sizes are different. Tube is measured by actual OD so that 2” is actual 2” OD. A 2” pipe size actual OD will be 2.375”. This is important as it will not only affect the capacity of a bender for sale but the way in which the tooling is engineered.

Material and Wall Thickness

Secondly, know the material you will use for your bender, whether it is stainless, mild steel, Inconel, aluminum, and so on. The material will also have a wall thickness. It is usually noted in inches, millimeters, gauge or schedule. If in doubt of the actual wall thickness, check with your material or supplier. This is an important specification for the tooling on a bender for sale. It can make the difference between requiring a mandrel or not. It also determines how many balls are required for the mandrel. The material will also determine if a mandrel is made of bronze or chrome.

Degree of Bend

Third is the degree of bend. This helps denote the amount of torque required by the bender to make the bend. If the bender for sale is at top capacity for a job it may not be able to pull a 180 degree bend at production level. However, it could do 90 degrees. It also factors into the mandrel with ball requirements. Degrees of bend along with rotation to the next bend can affect any interference with a bender for sale. And lastly, degree of bend helps to determine the final engineering of the tooling.

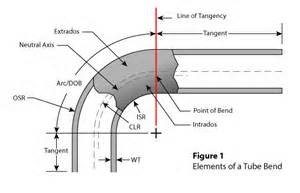

Centerline Radius and Inside Radius

Lastly, the radius determines the size of the bend die for a bender. Or, the dimension area the material will bend around. Know if you are measuring your radii as a centerline radius (CLR) or an inside radius (ISR). Also know how to measure it. See the figure below and note centerline radius (CLR). Typically, CLR’s are used with round tube. CLR’s measure point ends halfway into the material. ISR’s, which measure just to the inside edge of the material, are typically used for square or rectangular tube.

What if you only have a sample of the part and don’t know the radius for your bender for sale?

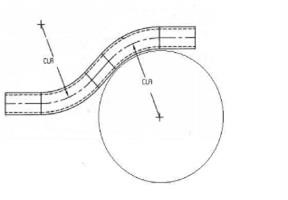

Place the sample tube or pipe that you want to bend on a large piece of paper or cardboard on the floor. Trace the tube or pipe that you would like to mandrel bend onto the cardboard. Continue the pattern until you have made a full circle with the tubing or pipe you are working with. Measure (in mm or inches) from the center of the tube or pipe to the center of your drawn circle. This straight-line measurement to the tube or pipe is the centerline radius of your tubing you want to rotary draw or mandrel bend. For inside radius (ISR) measure from the center of the circle to the inside edge of the tube or pipe as shown in the previous figure drawing.

One of the common thoughts on a bending machine is that one machine can bend whatever you want. That is to say, you have a one size fits all way of thinking. For instance, you come across a machine that bends 8 inch outside diameter (OD) tube. A very common question is, can this one machine also bend your ¼ inch OD tube?

The simple answer is no. But why? When you look at the space and the mechanics of bending it makes more sense. The space required when you are bending an 8 inch OD tube versus a ¼ inch OD tube is huge. On a pipe bender engineered to bend 8 inch OD, bending ¼ inch OD is like trying to cross the Grand Canyon on a motorized arm that you can only go halfway. There is just not a long enough clamp reach available on the machine to cross the space successfully. Given this point, you will see machine models that have a listed outside diameter bending capacity. In some cases, purchasing two machines to cover the full range of your bending may be necessary.

Equally, a bender will have a cap put on the largest radius you can bend, and the smallest. To be sure, most machine models will cover a wide range of radii for your outside diameters. For instance, 1-1/2 times the outside diameter or 3 times the outside diameter being the most common radii range requested. On the other hand, there are bending jobs requiring a specified OD with a larger radius than your machine capacity. For example, a 4 inch OD with a radius that exceeds a machine set radius capacity of 18 inches. Instead you want to bend a 22 inch radius. In this case, companies like Hines Bending Systems will provide a custom machine option for you that can extend the radius capacity of the machine. As long as your bending specs are known upfront a machine can often be customized to suit your needs.

Your bending wall thickness range depends on several factors. Most noteworthy on the thinnest wall you are bending is the tooling you use. Machine tooling supports the tube/pipe inside and out during your bending process. This tooling includes a mandrel, bend die, pressure die, clamp die, and wiper die. For this reason, having a machine with mandrel capability and wiper die capability is key for thin wall tube/pipe. On the other end with heavy wall, your machine needs to have enough torque/tonnage to pull a heavy wall pipe around the bend die. If a bending machine has a capacity of bending .200 wall and you need to bend .550 wall then the next size model may need to be considered.

In the big picture, your bending machine has several ranges to consider. It is most helpful if you have all of your bending specs available to determine the right machine for you.