Why a Used Pipe Bender is a Smart Investment

A used pipe bender is a smart way for manufacturers to expand capabilities without the cost of new equipment. Whether for automotive, aerospace, or construction, the right used machine delivers industrial-grade performance at a fraction of the price.

Quick Answer: What to Look for When Buying Used Pipe Benders:

- Type: Manual (budget-friendly, low volume), Hydraulic (mid-range capacity), Electric/CNC (high precision, automated)

- Capacity: Match maximum pipe diameter and wall thickness to your project needs

- Condition: Inspect hydraulic systems, frame integrity, and control panels thoroughly

- Tooling: Verify dies and mandrels are included and in good condition

- Support: Ensure manufacturer parts and technical support are still available

- Applications: Automotive, aerospace, construction, manufacturing, and architectural projects

- Price Range: Varies widely based on type, capacity, and condition—typically $1,000 to $150,000+

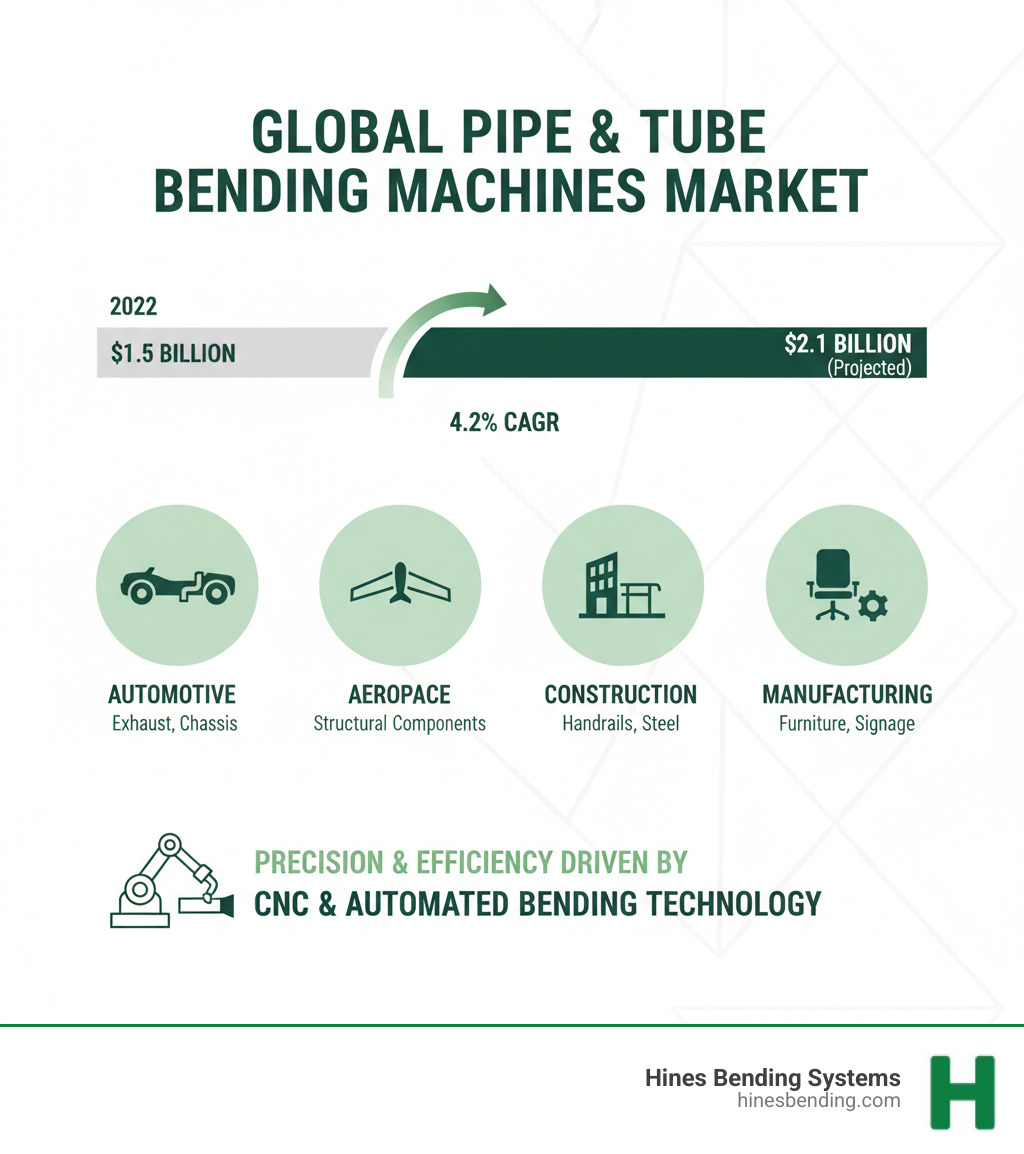

The global pipe and tube bending machines market was valued at $1.5 billion in 2022 and is projected to reach $2.1 billion by 2030. This growth is driven by demand from industries that rely on precision bending for critical components.

Buying used doesn’t mean compromising on quality, especially with machines from industry leaders built to last decades. The key is knowing what to inspect and partnering with a manufacturer who stands behind their equipment. This guide covers the types of benders, critical inspection points, and how to ensure ongoing support. We’ll show you why working with an experienced manufacturer like Hines Bending Systems—trusted by agencies like NASA and recognized as the #1 worldwide manufacturer of tube and pipe benders—protects your investment.

Pipe benders for sale terms to know:

Understanding the Types of Used Pipe Benders for Sale

When looking at pipe benders for sale, the options can seem overwhelming. The right machine depends entirely on your application, but understanding the basics makes the choice clear. As the #1 worldwide manufacturer, Hines Bending Systems provides expert guidance to help you invest wisely.

Manual, Hydraulic, and Electric Benders: The Core Trio

Most pipe benders for sale are powered in one of three ways:

Manual benders are affordable and portable, ideal for smaller pipes and one-off projects where you provide the power. However, they are labor-intensive and lack the consistency needed for high-volume production.

Hydraulic benders use hydraulic pressure to bend larger, thicker pipes with less physical effort. They offer a great balance of power and affordability, which is why our Hydraulic Pipe Bending Machines are popular for delivering robust, consistent performance.

Electric benders use motors to drive the bending process, ranging from semi-automatic to fully computerized systems. They offer a blend of power, precision, and speed that reduces operator fatigue and increases accuracy for high-volume production.

Choosing the right power source depends on your material and volume. When consistency and output matter, the reliability of hydraulic or electric systems from an experienced manufacturer is essential.

Advanced Bending Technology: CNC, NC, and Induction

For complex, high-stakes applications, advanced bending technology delivers unparalleled precision.

NC benders (numerically controlled) add a layer of automation. With an NC Bending Machine, you program bend angles for precise, repeatable results, making them excellent for batch production.

CNC benders are fully automated systems that control multiple axes simultaneously. These CNC Tube Benders for Sale create complex parts with multiple bends that are impossible to replicate by hand. This level of precision is why industries like automotive and aerospace rely on innovative Hines technology like our Dual Stack CNC Push Bender and Roll Bender.

Induction benders solve the challenge of bending the largest, thickest pipes used in structural and energy applications. Induction Benders use localized heating to soften the pipe, allowing for tight bends on massive materials without deformation. This is the kind of specialized expertise that makes large-scale projects successful and is why clients like NASA turn to Hines Bending Systems.

Choosing between these technologies is simple when you work with experts. Whether you need CNC automation or the power of induction bending, we provide solutions backed by more installations worldwide than anyone in the industry.

Your Inspection Checklist: Key Factors When Buying a Used Bender

A used pipe bender can be a fantastic asset, but a thorough inspection is crucial to avoid costly surprises. This guide will help you evaluate used pipe benders for sale and separate quality machines from potential problems.

Assessing Machine Capacity and Compatibility

Before considering price, confirm the machine can handle your work. Every bender has a maximum pipe diameter and wall thickness capacity. Pushing a machine beyond its limits risks poor bends, equipment damage, and safety hazards. Also, verify its material compatibility, as bending steel, aluminum, or specialty alloys like Inconel requires different capabilities. At Hines Bending Systems, we use our decades of experience to match machine capabilities to your material requirements, ensuring you get equipment suited for your current and future projects, like our Steel Pipe Benders for Sale.

The Critical Role of Tooling and Dies

The machine is only half the equation; bend quality depends on the tooling. When inspecting pipe benders for sale, examine the dies for wear, pitting, or scratches, as damaged dies cause wrinkles and inconsistencies. Verify that any included dies match your required pipe sizes and bend radii.

For precision work, especially with thin-walled tubing, a mandrel bender is essential. The mandrel supports the tube’s interior to prevent wrinkling and ovalization. Partnering with a Mandrel Pipe Bender Company that understands this is critical for achieving pristine bends.

Crucially, confirm that replacement tooling is available from the manufacturer. Hines Bending Systems provides a comprehensive range of Tube and Pipe Bender Accessories, ensuring long-term support for your machine.

Evaluating Price and Condition for used pipe benders for sale

Now, assess the machine’s physical state and value. A hands-on approach is best.

- Physical Inspection: For hydraulic models, check for oil leaks around hoses and cylinders. Inspect the frame for cracks or signs of structural fatigue, which is a major safety concern.

- Controls: Test every button, switch, and display on the control panel. For NC or CNC machines, verify that programs can be loaded and executed correctly.

- History and Price: Ask for maintenance records to understand its previous use. The price range for Used Pipe Benders for Sale is wide, but a low price can be misleading. Factor in potential repair and tooling costs to determine the true investment.

A used machine originally built by Hines Bending Systems retains its value and performance. Our equipment is built to last for decades, with some installations still operating flawlessly after 30+ years. Knowing your machine was built to the standards demanded by NASA provides confidence that your investment is sound.

Common Applications: Where Pipe Benders Drive Industry

Pipe benders for sale are essential machines that shape the world around us, from cars and planes to the buildings we occupy. The global market for these machines is projected to hit $2.1 billion by 2030, driven by industries that demand precision and reliability. As the #1 worldwide manufacturer, Hines Bending Systems is proud to supply the critical machines that fuel this innovation.

Automotive and Aerospace

In the automotive and aerospace industries, every bend counts and there is no room for error.

In the automotive world, an Automotive Exhaust Tube Bender creates intricate exhaust systems, while other machines form chassis components, protective roll cages, and essential fuel lines. These applications demand the accuracy and repeatability that define every machine from Hines.

The aerospace sector takes precision to another level. Benders are used to fabricate fuel lines, hydraulic systems, and structural components that must meet the most stringent safety standards. This is why Hines works together with NASA. Our machines deliver the reliability that critical applications in defense, space exploration, and commercial aviation demand.

Construction and Manufacturing

Pipe benders are just as vital in the construction and manufacturing sectors, shaping both infrastructure and everyday products.

In construction, benders create curved structural steel for unique architecture, complex plumbing systems, and safe, aesthetic handrails for staircases and balconies.

The manufacturing sector uses bent tubing for durable furniture frames, eye-catching commercial signage, and custom vehicle accessories. Industrial facilities also rely on robust pipework systems for fluid transfer in demanding environments.

Our Industrial Bending Machines for Sale are designed for this incredible range of applications. At Hines Bending Systems, we work with clients to develop customized solutions for their unique challenges. With more installations worldwide than any other manufacturer, we have the expertise to solve any bending problem.

After the Purchase: Maintenance and Support

Buying one of the many pipe benders for sale is just the first step. The true value of your investment is realized through proper maintenance and reliable support. Even the best machine needs care to perform at its peak.

Essential Maintenance for Longevity

A well-maintained bender can operate for decades. We’ve seen Hines machines from thirty years ago still producing perfect bends due to regular care.

- Hydraulics: Regularly check hydraulic fluid levels and quality. Contaminated or low fluid reduces performance and can cause damage.

- Lubrication: Follow the manufacturer’s schedule to lubricate all moving parts. This prevents friction and extends the machine’s life.

- Tooling: Keep bending dies, mandrels, and other tooling clean. Debris can compromise bend quality and accelerate wear.

- Inspections: Periodically check wiring, connections, and control panels. Ensure all safety interlocks and emergency stops are functional.

A high-quality machine from Hines Bending Systems is engineered for durability and requires less maintenance than cheaper alternatives, but this routine care is essential to maximizing its long operational life.

Finding Reliable Support for your used pipe benders for sale

Even the best machines occasionally need expert help. This is where partnering with the right manufacturer makes all the difference. When considering a used bender, ask if the original manufacturer still supports the model.

Spare parts availability is crucial. When a component fails, you need a replacement quickly to avoid downtime. Our comprehensive Tube and Pipe Bender Accessories inventory ensures you get parts fast, even for older models.

Access to expert training can also transform your operation. Our Tube and Pipe Bender Training programs empower your team to work efficiently and troubleshoot problems, maximizing your ROI.

When you partner with Hines Bending Systems, you gain access to unparalleled expertise. Nobody has more knowledge in the bending machine industry. Our customer-centric approach means we provide solutions that work throughout your machine’s entire life. The fact that we supply agencies like NASA speaks to our commitment to quality and support. You need a partner who delivers not just excellent machines but also the ongoing expertise to keep them performing for years to come.

Conclusion: Partner with an Expert for the Perfect Bending Solution

Investing in a used pipe bender offers incredible value, but the quality of the original manufacturer is paramount. A machine built for durability by an industry leader like Hines Bending Systems—trusted by agencies like NASA—will deliver reliable performance for decades. The expertise behind your purchase is as important as the machine itself, and partnering with the right team makes all the difference.

As the #1 worldwide manufacturer of tube and pipe benders, Hines Bending Systems brings unparalleled expertise to every project. With more installations than anyone else, we have the experience to guide you to the perfect bending solution for your specific materials, volume, and budget.

Our customer-centric approach means we work with you to develop customized solutions, not just sell off-the-shelf machines. Whether you’re bending exotic alloys or heavy structural steel, we engineer a system for your success. Our support continues long after installation with comprehensive training, a fully stocked parts department, and expert technical assistance.

Whether you’re in Fort Myers, Sarasota, or anywhere else, our Florida presence ensures local expertise is always within reach. We’re here to help you find exactly what you need.

Ready to explore your options? Take a look at our inventory of high-quality Used Bending Equipment or reach out to our team directly to discuss your custom requirements. Let’s work together to find the perfect bending solution for your operation.