Understanding Pipe & Tube Benders: The Essential Guide

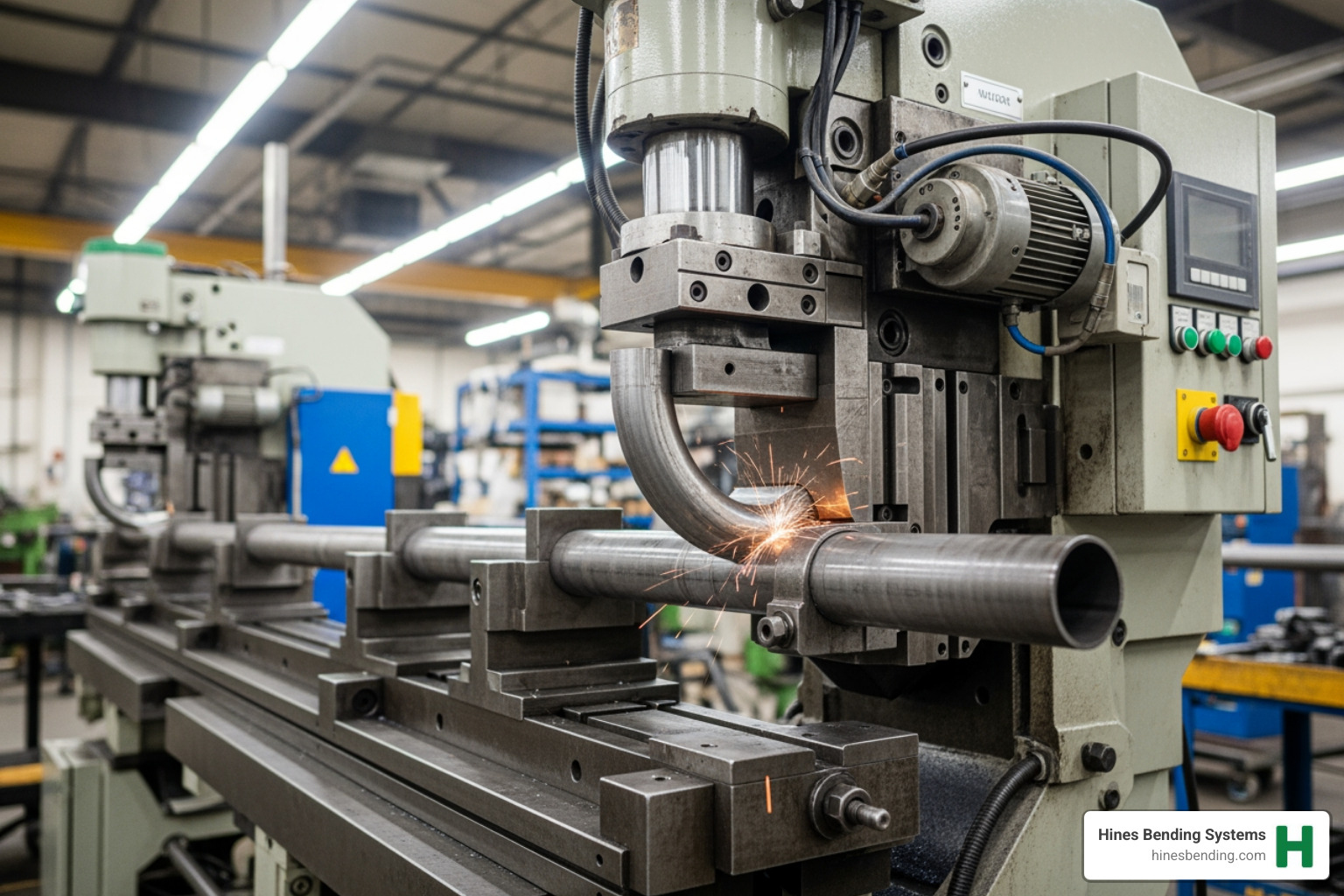

Pipe & tube benders are specialized machines that curve metal tubes and pipes into precise shapes without compromising their structural integrity. Whether you’re fabricating exhaust systems, building aerospace components, or creating custom frameworks, understanding these machines is crucial for manufacturing success.

Quick Answer: What You Need to Know About Pipe & Tube Benders

| Aspect | Key Information |

|---|---|

| Main Types | Manual, Hydraulic, CNC/Programmable, Rotary Draw, Roll, and Induction |

| Primary Use | Creating precise bends in metal tubes and pipes for automotive, aerospace, construction, and HVAC applications |

| Key Specifications | Outside Diameter (OD) capacity, Centerline Radius (CLR), bend angle, wall thickness, and repeatability |

| Market Size | $1.1 billion in 2022, projected to reach $1.7 billion by 2030 (5.8% CAGR) |

| Industries Served | Automotive, aerospace, defense, construction, shipbuilding, HVAC |

As one manufacturing expert put it: “Tube bending sucks—yeah, we said it. While it might look simple, the process is full of challenges.” This sentiment reflects a common frustration in the industry. The bending process involves complex physics, material considerations, and precise tooling requirements that can make or break your production quality.

The global demand for pipe and tube bending equipment continues to grow, driven by the automotive industry, aerospace sector, and construction applications. Yet many manufacturing operations managers struggle with complex bending requirements, high production costs, and ensuring consistent precision across production runs.

The challenge isn’t just about buying a machine—it’s about finding the right partner who understands your specific needs and can deliver customized solutions. With decades of industry-leading experience, the experts at Hines Bending Systems have the knowledge to solve even the most complex bending challenges.

This guide will help you understand the different types of benders, key specifications to consider, and most importantly, how to choose the right bending partner for your operation. From manual hand benders for prototyping to advanced CNC systems for high-volume production, we’ll solve the mystery of metal manipulation and show you the path to perfect bends.

Quick pipe & tube benders terms:

The Foundation of Flawless Bends: Hines Bender Types and Technology

At Hines Bending Systems, we understand that achieving flawless bends is paramount to your success. Our extensive range of pipe & tube benders is engineered with precision and durability in mind, ensuring that your metal manipulation challenges are met with robust, high-quality solutions. We are the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, and our machines are designed to prevent common defects like kinking, wrinkling, and flattening that can compromise the integrity of your materials.

We bring unparalleled expertise to every bending solution we offer. Our commitment to quality assurance means that every Hines machine is built to the highest standards, designed not just to perform, but to excel, delivering consistent, perfect bends every time. To learn more about the different types of benders, you can explore our comprehensive guide to tube bender types.

Hines Solutions for Every Need: From Manual to Advanced Automation

Whether you’re a hobbyist, a custom fabrication shop, or a large-scale production facility, we have a pipe & tube bender custom to your needs. Our solutions span from reliable manual options to highly automated systems.

For smaller projects, prototyping, or when cost-effectiveness is a primary concern, our manual benders are an excellent choice. These hand benders and bench-top models, such as the Hines Bench Top Mount Tube Pipe Bender, are carefully crafted for durability and ease of use. They allow for precise control in a hands-on environment, making them ideal for custom jobs where flexibility is key.

As your production demands grow, our powered benders step in to offer improved efficiency and consistency. These include our robust hydraulic and electric benders. A Hydraulic Tube and Pipe Bender provides significant force and control, ideal for bending thicker materials or achieving complex geometries repeatedly. Electric benders offer smooth, consistent operation, contributing to high production efficiency. These machines are engineered to deliver repeatable, accurate bends, ensuring that every piece meets your exact specifications. For those interested in manual options, we also offer manual hand benders for sale.

The Leap to Automation: Hines NC, CNC, and Programmable Pipe & Tube Benders

For operations requiring the highest levels of precision, repeatability, and speed, our NC, CNC, and programmable pipe & tube benders are the ultimate solution. The demand for CNC pipe and tube benders is rapidly growing due to their superior precision and automation capabilities, and we are at the forefront of this technological advancement.

Our NC (Numerically Controlled) benders offer advanced automation over manual machines, allowing for programmable bend angles and increased consistency. Stepping up, our CNC Bending Machines provide full computer control over multiple axes, enabling the creation of intricate and complex bends with unparalleled accuracy. These machines are essential for high-volume production where identical parts are required consistently. The advanced software and control systems, such as our BendPro G2 CNC Control, allow for sophisticated programming, minimizing setup time and material waste.

To help you decide which level of automation is right for your operation, we offer insights into NC vs CNC: Which Bending Machine is Right for You?. Our expertise ensures that you invest in the technology that best suits your production goals and budget. It’s this commitment to precision and automation that makes our machines a trusted choice for demanding clients, including massive agencies like NASA.

Hines’ Specialized Bending Solutions: Rotary Draw, Roll, and Induction Benders

Beyond the foundational types, we offer specialized pipe & tube benders designed for unique applications and challenging materials.

Rotary draw benders are a cornerstone of precision bending and are, in fact, the most popular type of pipe and tube benders globally, accounting for a significant share of the market. Our rotary draw benders excel at producing tight radius bends with minimal material distortion, making them ideal for exhaust systems, automotive components, and intricate frameworks.

For projects requiring sweeping, large radii curves, our roll benders are the perfect fit. These machines progressively form the material into large arcs, suitable for architectural elements, structural components, and custom vehicle frames. We also offer innovative solutions like our Stack Push Benders, including our Dual Stack CNC Push Bender and Roll Bender, which represent industry-leading advancements in bending technology. These innovations cater to the growing demands of various industries, providing versatility and efficiency.

When it comes to bending large diameter pipes or thick-wall materials, our induction benders offer distinct advantages over traditional methods. Induction Benders use localized heat to soften the material, allowing for smooth, gradual bends without the need for extensive tooling or high mechanical force. This technology is particularly beneficial for heavy industrial applications, such as shipbuilding and large-scale construction, providing superior bend quality and structural integrity for challenging materials.

Choosing Your Bending Partner: Why Hines is the Right Choice

Selecting the right pipe & tube bender is a critical decision that impacts your project’s success, efficiency, and bottom line. At Hines Bending Systems, we believe that choosing us means choosing a partner with unparalleled expertise, a commitment to quality, and a dedication to finding custom solutions that fit your unique needs. We are recognized as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, and nobody in the bending machine industry has more expertise and experience than our team.

When you’re ready to invest, our comprehensive Pipe Benders Buying Guide provides valuable insights. We emphasize understanding your material properties, required bending specifications, and the optimal tooling selection to guide you toward the perfect Hines machine. Our custom solutions ensure that your investment is precisely custom to your operational requirements.

Material Matters: Hines Expertise with Steel, Aluminum, and More

The material of your pipe or tube significantly affects the bending process and the type of bender required. Understanding material science—including tensile strength, wall thickness, and ductility—is crucial for preventing defects and achieving high-quality bends. Our experts at Hines Bending Systems possess deep knowledge of how different metals behave under stress, allowing us to engineer machines and tooling for optimal results across a wide spectrum of materials.

Whether you’re working with robust Steel Pipe Bending Machines, require specialized techniques for Mandrel Bending Aluminum Tubing, or need to manipulate stainless steel or copper pipe, we have the solutions. Our machines are designed to handle various materials, ensuring bends without kinks or creases that can block flow. We provide expert Hines consultation to help you steer these material complexities, ensuring your chosen bender and tooling are perfectly matched to your application.

Decoding Specifications for Your Pipe & Tube Benders

Understanding the key specifications of pipe & tube benders is vital for making an informed decision. We guide our clients through critical terminology and metrics to ensure they select a machine that precisely meets their job requirements.

- Outside Diameter (OD) Capacity: This refers to the maximum diameter of the tube or pipe the bender can handle.

- Centerline Radius (CLR): This is the distance from the center of the bending die to the centerline of the pipe or tube. A smaller CLR results in a tighter bend. Our machines are engineered to achieve specific CLRs, with advanced benders capable of very tight radii, sometimes as small as 1.5 times the OD.

- Bend Angle: The maximum degree to which a machine can bend material, typically up to 180 degrees or more.

- Repeatability: This measures how consistently the machine can produce the same bend angle and shape across multiple operations, a critical factor for high-volume production. Our NC and CNC benders offer exceptional repeatability, often within +/- 0.1º.

- Accuracy: The precision with which the machine executes the programmed bend.

We provide a helpful guide to industry terminology to empower our clients. Our experts are always available for consultation, ensuring you avoid costly errors by understanding exactly what to know about buying a metal tube bender for sale.

The Role of Tooling and Accessories in Precision Bending

The performance of any pipe & tube bender is only as good as its tooling and accessories. At Hines Bending Systems, we offer a comprehensive range of Tube and Pipe Bender Accessories that are carefully designed to work in harmony with our machines, ensuring precision and preventing material deformation.

Essential tooling includes:

- Bend Dies: These form the inner radius of the bend.

- Clamp Dies: These secure the tube or pipe to the bend die.

- Pressure Dies: These apply pressure to the outside of the bend to prevent flattening.

- Mandrels: Internal supports that prevent the tube from collapsing or wrinkling on the inside radius during bending.

- Wiper Dies: Used for tight radius bends, these prevent wrinkling on the inside of the bend.

Beyond mechanical tooling, advanced control systems like our BendPro G2 CNC Control are crucial for modern precision bending. We also integrate state-of-the-art measuring systems, such as Romer arms, to ensure exact measurements and quality control. Our complete tooling solutions are integral to achieving the highest quality bends and maximizing the capabilities of your Hines machine.

From Aerospace to Automotive: The Wide World of Hines Pipe & Tube Benders Applications

The versatility and precision of Hines pipe & tube benders make them indispensable across a vast array of industries. From the meticulous demands of aerospace to the robust requirements of heavy construction, our machines deliver reliable performance and exceptional quality.

In the aerospace and defense sectors, where precision and reliability are non-negotiable, our benders are trusted to create critical components. We are proud to work with leading organizations, including Hines Working Together with NASA, supplying the advanced bending technology required for their groundbreaking projects. Similarly, our involvement with Hines Teams Up with Eastern Shipbuilding Group / USCG underscores our capability to meet the stringent demands of shipbuilding.

The automotive industry relies heavily on precise tube bending for everything from exhaust systems to chassis components. Our benders are instrumental in Custom Exhaust Pipe Fabrication, allowing manufacturers to create complex, high-performance exhaust headers and tubing.

Beyond these, our machines find application in:

- Construction: For structural supports, handrails, and architectural elements.

- HVAC: For refrigeration lines, air conditioning systems, and fluid transfer.

- Recreational and Architectural: Such as creating neat Stainless Pool Hand Railings and custom decorative metalwork.

These diverse applications highlight our machines’ adaptability and our team’s expertise in providing solutions for virtually any bending challenge.

For readers who want a neutral, high-level background on the broader field, see the general overview of Metalworking, then come back to Hines for the industry-leading bending solutions that turn that theory into reliable production results.

Maximizing Your Investment: Operation, Maintenance, and Partnering with Hines Experts

Investing in a high-quality pipe & tube bender from Hines Bending Systems is a strategic decision for your business. To truly maximize that investment, ensuring machine longevity, operational efficiency, and adherence to safety standards is paramount. We believe that a successful bending operation goes beyond just the machine; it thrives on expert partnership and continuous support. This is why we focus on providing superior quality machines, designed to meet industry standards and quality requirements, unlike cheaper alternatives that may compromise integrity. For more reasons why this investment is crucial, consider the reasons to invest in pipe bending equipment.

Best Practices for Operation and Longevity

Proper operation and maintenance are key to extending the life of your Hines pipe & tube bender and maintaining its precision. We recommend the following best practices:

- Proper Setup: Always ensure the machine is correctly set up for each bending job, with the right tooling securely installed and aligned.

- Lubrication: Regular and appropriate lubrication of moving parts and tooling reduces friction and wear, preventing premature component failure.

- Calibration: Periodically check and calibrate your machine’s settings to maintain accuracy and repeatability, especially for critical bends.

- Safety Features: Always use and maintain all safety features. Our machines are designed with safety plates protecting the swing arm area, properly labeled pinch and hazard points, and finger-safe electrical components in accordance with NFPA standards.

- Defect Prevention: Monitor for signs of potential defects like kinking or excessive springback during initial bends, adjusting parameters as needed. Our cushioned hydraulic cylinders add to machine life by eliminating shock.

- Cleanliness: Keep your machine and workspace clean, free from debris and metal shavings, to prevent damage and ensure smooth operation.

We stand behind the quality of our machines, and our Sellers Warranty Terms & Conditions reflect our confidence in their durability and performance.

The Importance of Professional Training and Support from Hines

Even the most advanced pipe & tube bender requires skilled operators to release its full potential. That’s why we emphasize the importance of professional training and ongoing support. Our comprehensive Tube and Pipe Bender Training programs are designed to improve operator skill, significantly boost production efficiency, and ensure rigorous quality control.

Our training covers everything from basic machine operation and safety protocols to advanced programming techniques and troubleshooting. We provide continuing education opportunities to keep your team up-to-date with the latest bending technologies and best practices. This commitment to client education ensures that you get the most out of your Hines machine, optimizing your engineering and production processes.

Why Partnering with Hines Bending Specialists is Crucial

When it comes to pipe & tube benders, partnering with Hines Bending Systems offers distinct advantages that set us apart. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, our unparalleled expertise and experience are best in the industry.

Here’s Why Buy a Hines Bender?:

- Unrivaled Expertise: Nobody in the bending machine industry has more expertise and experience than our team. We’ve been supplying large companies and government agencies such as NASA with bending machines for years, a testament to our credibility and capability.

- Custom Solutions: We pride ourselves on our commitment to working closely with clients to provide Custom Tube Benders. Your specific needs are our priority, and we tailor our solutions to ensure optimal performance for your unique applications.

- Superior Quality Assurance: Our machines are of the highest quality, designed to meet and exceed industry standards. We believe in providing robust, dependable equipment that runs for decades, minimizing downtime and maximizing your return on investment.

- Customer-Centric Approach: Our dedication to your success is encapsulated in our Customers First Promise. We engage directly with you, understanding your requirements, and providing comprehensive support from selection through installation and beyond.

We focus less on simply explaining the various methods of bending and more on showcasing how Hines Bending is the ultimate resource for answers on the best bending solutions. Our superior quality, innovative technology, and dedicated support provide a significant competitive edge, ensuring you achieve the highest quality bends consistently.

Conclusion: Your Path to Perfect Bends Starts with Hines

Navigating the complexities of metal manipulation and selecting the right pipe & tube benders can be a daunting task. This guide has illuminated the various types of benders, essential specifications, and critical considerations for successful bending operations. From manual hand benders for precise, small-scale work to advanced CNC and induction benders for high-volume, complex industrial applications, the right machine can transform your production capabilities.

At Hines Bending Systems, we stand as the undisputed industry leader. Our commitment to quality, unparalleled expertise, and dedication to crafting custom solutions make us the premier choice for all your bending needs. We don’t just sell machines; we provide comprehensive bending solutions backed by decades of experience and a “Customers First Promise.”

When precision, reliability, and innovative technology matter most, choose Hines Bending Systems. We are here to ensure your path to perfect bends is smooth, efficient, and successful. Explore our comprehensive range of Tube and Pipe Benders today and find why we are the #1 worldwide manufacturer.