June 7, 2017

ROMER captures critical certification data, improves quality and helps make instant bending changes

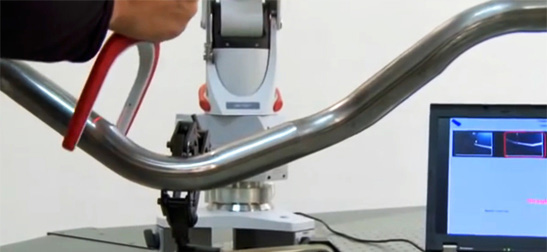

FORT MYERS, Fla. – June 7, 2017 – Hines Bending Systems Inc., today announced it will begin to sell the ROMER Absolute Arm Tube Inspection System as part of its industry-leading tube bender product line. The ROMER is available for immediate purchase through Hines Bending.

Hines Bending Systems CEO James Hynes said, “Producing bent pipe of the highest quality has always been a foundational principal of our company, that’s why we manufacture and sell mandrel benders. Today’s needs for certification and monitoring data make the decision to offer our customers the ROMER Absolute Arm Tube Bending System a “no-brainer.”

Hynes said, “Hines Bending absolutely loves the fact the ROMER can, on the fly, make instant improvements and changes to the bending process. The ROMER’s state-of-the-art technology is hightly effective for reverse engineering, problem solving and product development.”

Whether a part is bent on tube bender, pipe bender, induction bender or another bending machine, the ROMER is designed to capture 3D point data across a range of surfaces and sizes with precision accuracy. The ROMER Absolute Arm Tube Inspection System is high-speed, portable and user-friendly.

The ROMER Absolute Arm is a perfect complement to the BendPro G2 Control. Integration of both technologies on Hines benders will automatically provide feedback to the bending machine allowing the operator to make improvements, corrections or adjustments to bend parameters “on-the-fly.” As a result, productivity and quality are significantly improved.

The ROMER software component produces analytical data which will help engineers understand bender performance over time and spot problems. This advanced “warning system” proactively helps engineers identify potential problems with the bender on the shop floor before they become critical.