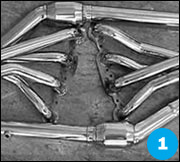

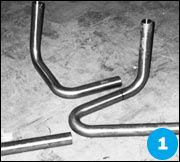

CNC tube benders are the industry’s first choice of bending machines to manufacture production parts requiring tight radius, thin-wall bends.

CNC Tube Benders Manufactured by Hines Bending

Hines CNC tube bending machines– 3-axis- are computer numerically controllable (CNC) and servo-driven for distance between bends (DBB), plane of bend (POB) and degree of bend (DOB).

The CNC tube bender’s memory stores jobs to retrieve and run again when you need them with an easy touch screen control. With a CNC tube bending machine, there is no intervention by an operator as the computer controls the rotation of tube and the distance between bends. In production environments, CNC tube bending machines save time and money.

Hines CNC Benders come standard with the BendPro G2 Control.

- The BendPro G2 Control Is a very advanced control that is PC-based. It easily interfaces with most engineering software, either directly or through an API allowing machine programming changes to be made from an engineer’s desktop rather than the plant floor.

How to Choose a CNC Tube Bender?

A CNC tube bender can provide different industries with a number of benefits and it should be considered after determining 4 main factors:

- Investment And Cost – One of the most important considerations is the cost of the CNC tube bender. This will differ depending on the available features and the machine’s capacity. Larger CNC tube and pipe benders for sale are typically custom-built based on the requirements of the customer. Customers can expect to not only save money on contracting pipe bending orders but can also provide tube and pipe bending services to other businesses. The return on the investment can help pay for the machine and create a new source of revenue for a business.

- Expected Output – Depending on the needs of the business, the necessary output of the CNC tube bender is an important factor. The output capability can also be referred to as the parts per hour produced. The amount of parts produced per hour can be influenced by operator proficiency, tube size, shape, and production capacity of the pipe bending machine.

- Reliability And Precision – The quality of a CNC tube bender is determined by how consistent and precise its movements and operation is. A quality pipe bending machine will be consistently reliable and can repeat the same quality product every time. It is important to note that machine maintenance plays a large role in the consistency of the machine. This can be done with the proper tools.

- Scrap Production – An important factor to consider is the amount of scrap produced by the CNC tube bender. This is extremely important when expensive, high-quality materials are used. The machine operator and the machine’s efficiency will determine the scrap rate a company can expect to be produced. Unlike a semi-automatic bender, a CNC tube bender will typically produce less scrap. Customers should look for a pipe bending machine with a low scrap rate in order to prevent defective parts from being produced.

About Hines Bending Systems

Hines Bending System is the global leader in CNC machine tube benders, pipe benders, and induction benders manufacturing. We assist customers in choosing the absolute best machine for their needs.

We can provide customers with a free estimate by calling us today at 800-949-8344 or filling out our online form.

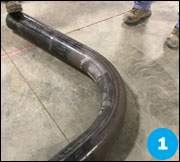

FYI, please take a minute to check out this extremely user friendly measuring device that is continuing to make its way through many different industries, including the popular Custom Car Builders Market. The Romer name is a long time well-established high end measuring device which is being used where accuracy is extremely important. Below you will see the special Romer Absolute Arm video demonstration along with the Tube-Shaper Application. You will clearly see why the Custom Car Builders along with the Antique Car Buffs, are finding this to be an absolute must in their tool box. Romer has made it simple for many industries as mentioned above, that were never thought to need the ability to reverse engineer hard to find or discontinued parts. The Romer Absolute Arm measuring device, along with available options, are currently being used in high end aircraft parts, oil and gas, nuclear and conventional power plants, cloning of boiler tubes, just to name a few. Hines Bending is an active Romer distributor and currently has a complete system set up in house for customer demonstrations. Lastly, the demonstration will show how the Romer System can integrate directly from your office desk, directly to the operator on the manufacturing floor, to the BendPro G2 Control, and then on to the Hines CNC Mandrel & Tube Bending Machine. A must SEE!